Heat treatment process for prolonging fatigue life of GH4738 alloy

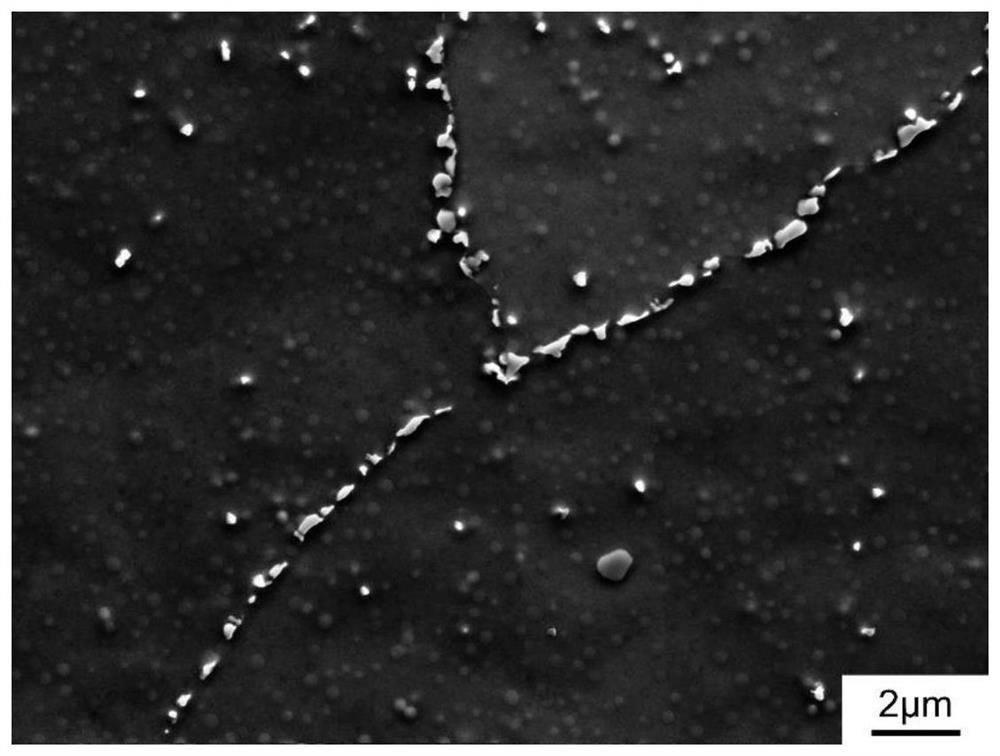

A fatigue life, nickel-based superalloy technology, applied in the field of superalloy heat treatment, can solve the problems of reducing alloy service performance, alloy crack initiation, etc., to achieve the effect of improving fatigue life, inhibiting growth, and reducing the number of carbides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

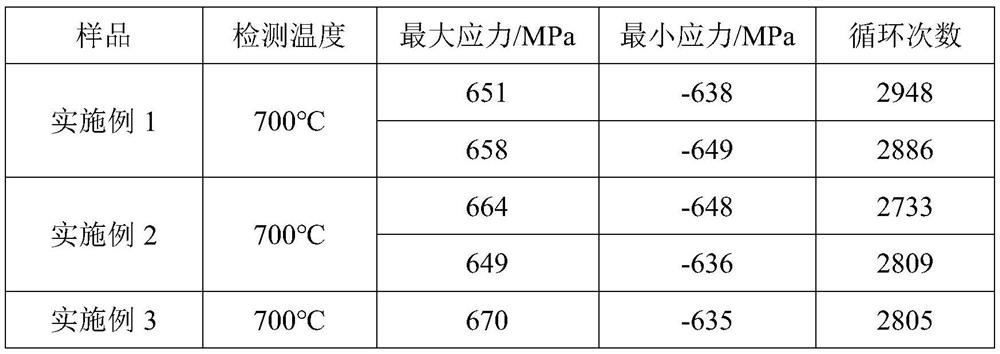

Embodiment 1

[0028] The first step, raw material preparation:

[0029] The GH4738 nickel-based superalloy with the following components is selected according to the mass fraction: carbon 0.08%, chromium 19.61%, cobalt 13.55%, molybdenum 4.23%, titanium 2.98%, aluminum 1.47%, boron 0.07%, zirconium 0.11%, and the balance is nickel. Cut the alloy into Try on sticks, wash and dry until ready to use.

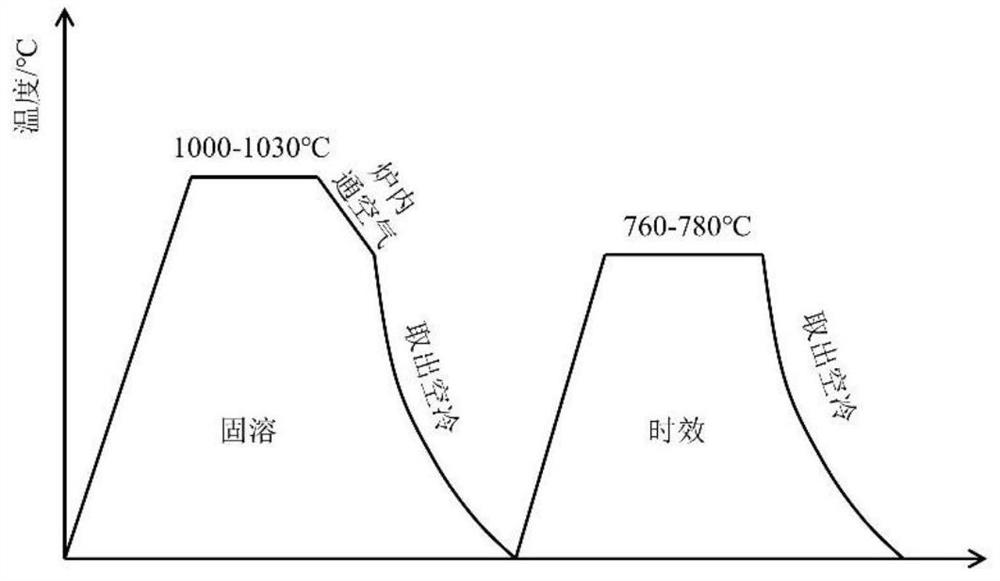

[0030] The second step, solution treatment:

[0031] The GH4738 alloy sample was heated to 1020°C for solution treatment at a heating rate of 25°C / min for 60 minutes, and then the alloy sample was cooled to 800°C by flowing air in the heat treatment furnace, and the cooling rate at this stage was 40°C / min; Remove and air cool to room temperature.

[0032] The third step, aging treatment:

[0033] The GH4738 alloy sample was heated to 770°C for 8 hours at a heating rate of 25°C / min, and then air-cooled to room temperature.

Embodiment 2

[0035] The first step, raw material preparation:

[0036] The GH4738 nickel-based superalloy with the following components is selected according to the mass fraction: carbon 0.08%, chromium 19.61%, cobalt 13.55%, molybdenum 4.23%, titanium 2.98%, aluminum 1.47%, boron 0.07%, zirconium 0.11%, and the balance is nickel. Cut the alloy into Try on sticks, wash and dry until ready to use.

[0037] The second step, solution treatment:

[0038] The GH4738 alloy sample was heated to 1025°C for solution treatment at a heating rate of 20°C / min for 70 minutes, and then the alloy sample was cooled to 800°C by flowing air in the heat treatment furnace, and the cooling rate at this stage was 45°C / min; Remove and air cool to room temperature.

[0039] The third step, aging treatment:

[0040] The GH4738 alloy sample was heated to 765°C for 9 hours at a heating rate of 20°C / min, and then air-cooled to room temperature.

Embodiment 3

[0042] The first step, raw material preparation:

[0043] The GH4738 nickel-based superalloy with the following components is selected according to the mass fraction: carbon 0.08%, chromium 19.61%, cobalt 13.55%, molybdenum 4.23%, titanium 2.98%, aluminum 1.47%, boron 0.07%, zirconium 0.11%, and the balance is nickel. Cut the alloy into Try on sticks, wash and dry until ready to use.

[0044] The second step, solution treatment:

[0045] The GH4738 alloy sample was heated to 1030°C for solution treatment at a heating rate of 25°C / min for 60 minutes, and then the alloy sample was cooled to 800°C by flowing air in the heat treatment furnace, and the cooling rate at this stage was 60°C / min; Remove and air cool to room temperature.

[0046] The third step, aging treatment:

[0047] The GH4738 alloy sample was heated to 760 °C for 10 h at a heating rate of 30 °C / min, and then air-cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com