Economical 500MPa-grade steel bar and preparation method thereof

An economical and high-level technology, applied in the field of structural steel metallurgy, can solve problems such as low production efficiency, difficult smelting, and slow rolling speed, and achieve the effects of increased production efficiency, low alloy consumption, and economical comprehensive manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

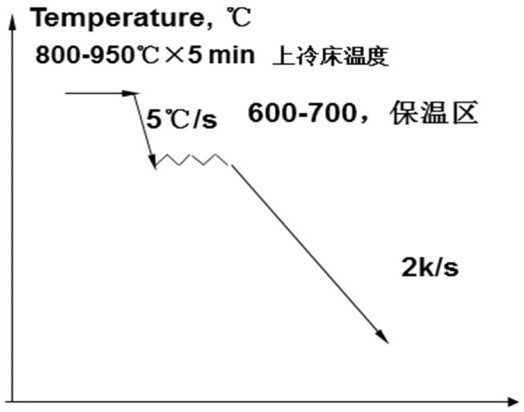

Method used

Image

Examples

Embodiment

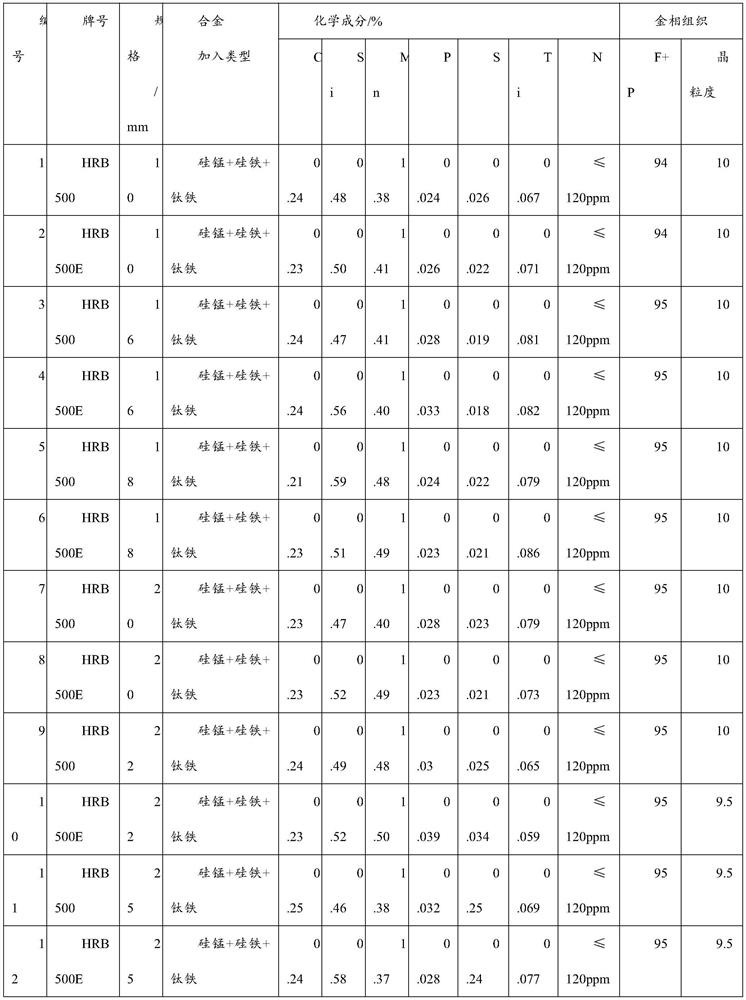

[0022] An economical 500MPa grade steel bar, the economical 500MPa grade steel bar contains components and weight percentages: C0.20~0.25wt%, Mn≤1.60wt%, Si≤0.80%, P≤0.045%, S≤0.045%, Ti≥0.05%, and the rest are iron and unavoidable impurity elements.

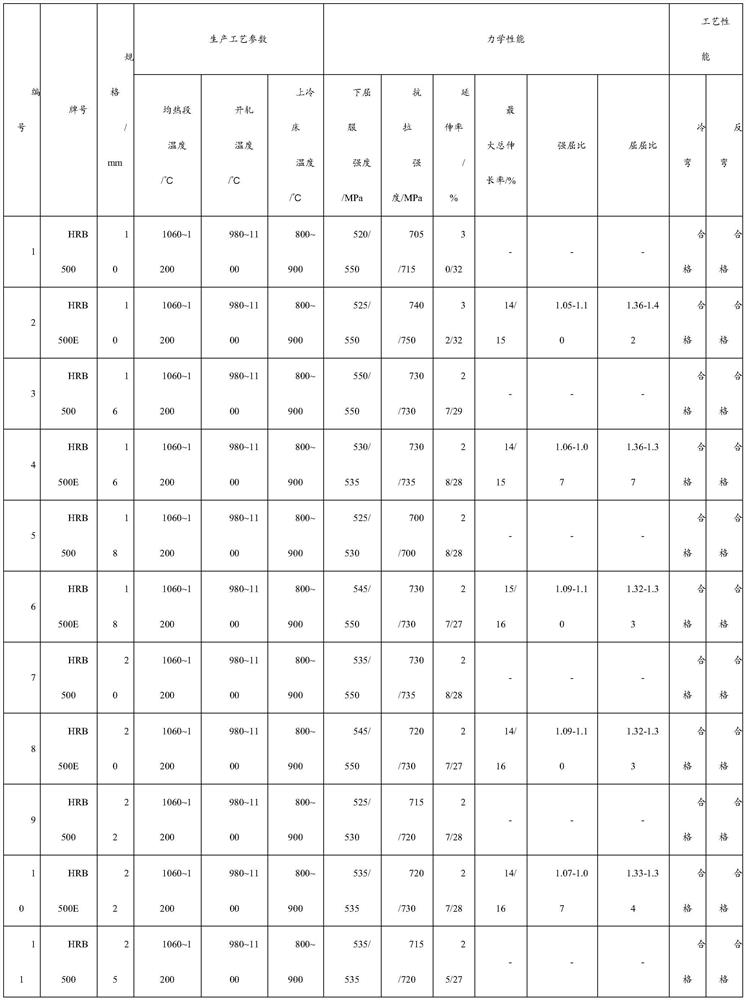

[0023] The process route for preparing economical 500MPa-grade steel bars is as follows: blast furnace molten iron is smelted by top-bottom double-blowing converter, electric furnace smelt, converter and electric furnace are tapped and alloyed, molten steel is blown at the bottom and the composition is uniform, and then the steel billet is continuously cast into billets; After heating, rolling, water cooling, and cooling bed cooling, they are cut into fixed-length smooth round steel bars or ribbed steel bars, and are stacked and shipped after inspection and bundling.

[0024]After adding steel scrap into the converter, it is mixed into molten iron in the blast furnace. The steel scrap ratio is 15-25%. Slag is added during the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com