Manufacturing method for improving low-temperature toughness of hot-rolled U75V steel rail through rare earth elements

A manufacturing method and low-temperature toughness technology, applied in the field of metallurgical materials, can solve problems such as increased cost per ton of steel, achieve good hardness, refine grains, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

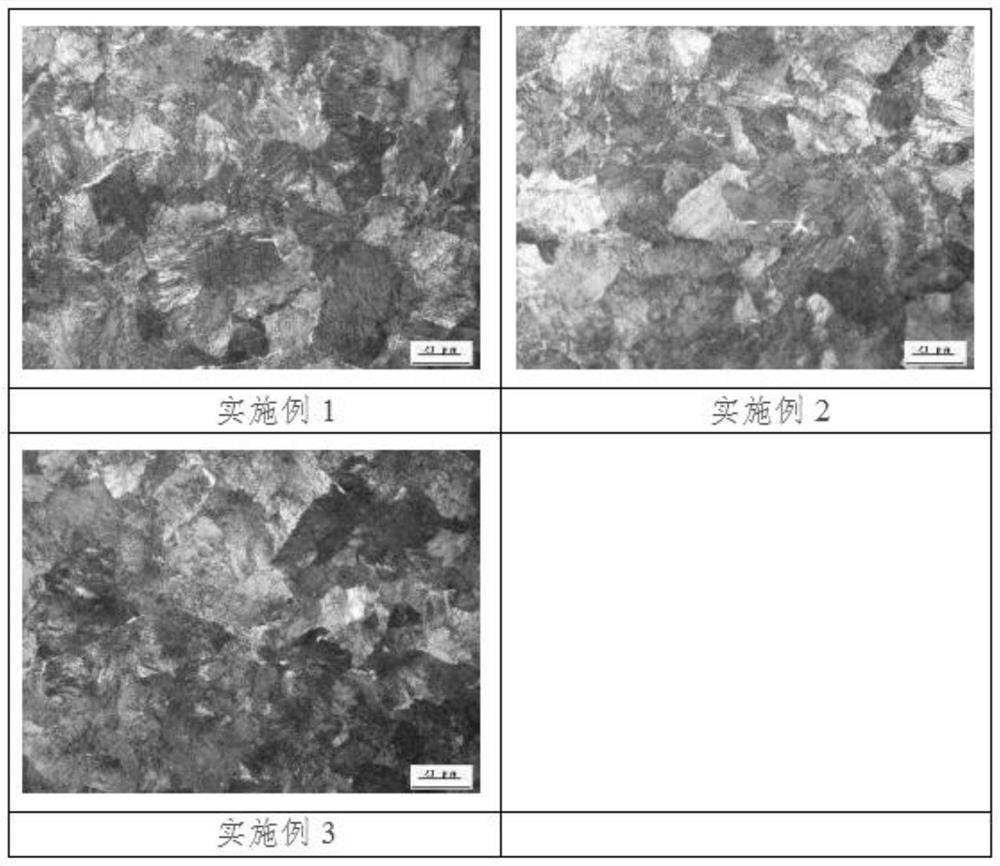

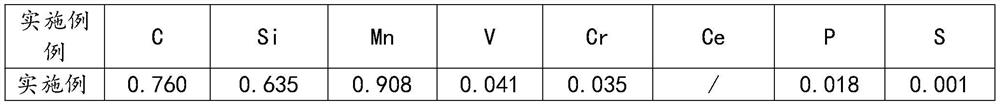

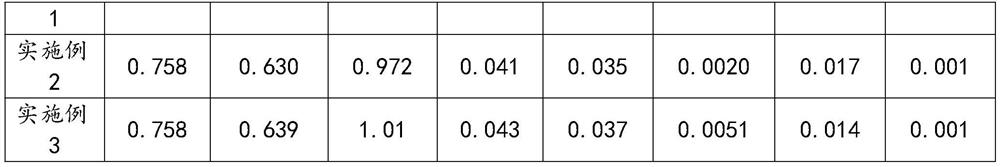

[0029] A method for manufacturing a rare earth element to improve the low-temperature toughness of a hot-rolled U75V rail. The specific components of each embodiment are shown in Table 1.

[0030] Comparison of different components in the process of the embodiment of table 1 (mass fraction) / %

[0031]

[0032]

[0033] As can be seen from Table 1, Example 1-Example 3 are all U75V rail smelting components within the standard composition range, wherein the contents of C, Si, Mn, Cr, V, P, S elements are basically the same, and the experimental steel smelting process, alloy grade, The alloy joining system is the same. Example 1 did not add rare earth Ce element, Example 2 contained 20 ppm of rare earth Ce element, and Example 3 contained 51 ppm of rare earth Ce element.

[0034] Comparison of conventional mechanical properties in the process of the embodiment of table 2

[0035]

[0036] It can be seen from Table 2 that the tensile strength of Example 1-Example 3 is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com