Steel rail online induction heating control method

A control method and induction heating technology, applied in the field of metallurgy, can solve problems such as not involving abnormal structures, and achieve the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

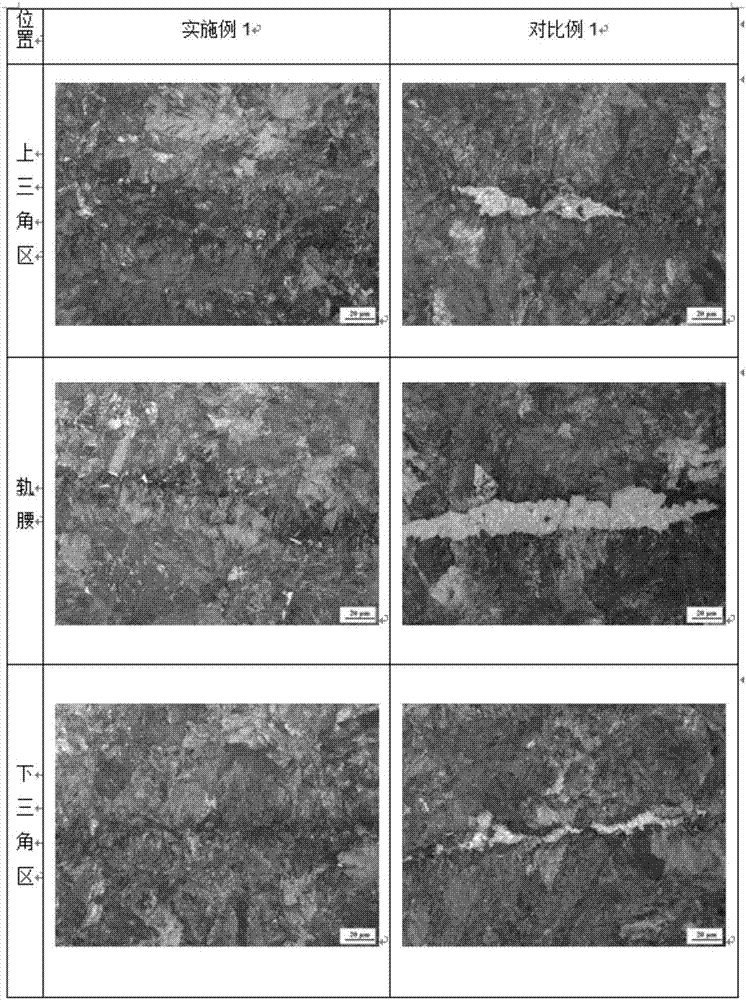

Embodiment 1

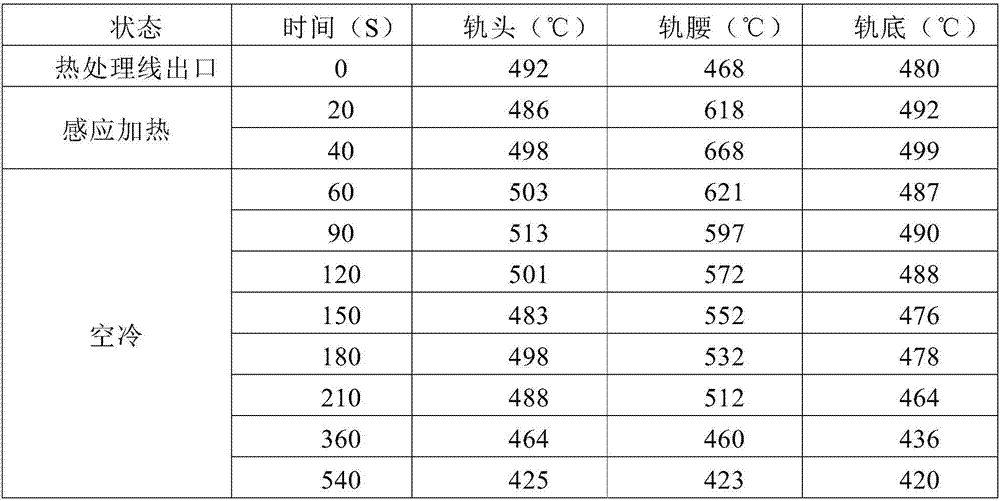

[0032] Adopting the rail on-line induction heating control method of the present invention, the main chemical components are: by weight percentage, including 0.65-1.05% C, 0.50-0.90% Si, 0.80-1.50% Mn, 0-1.00% Cr, and the rest is iron , Nb, V, Ti, RE and other micro-alloying elements and impurities on-line induction heating to produce rails.

[0033] The specific operation is: after the rail is accelerated on-line cooling, the rail waist is continuously and rapidly heated by induction when it exits the heat treatment line. The heating temperature is 600°C, the heating time is 40 seconds, and the heating rate is 1m / s.

Embodiment 2

[0035] Using the rail on-line induction heating control method of the present invention, the main chemical components are: by weight percentage, including 0.65-1.05% C, 0.50-0.90% Si, 0.80-1.50% Mn, 0-1.00% Cr, and the rest is iron , Nb, V, Ti, RE and other micro-alloying elements and impurities on-line induction heating to produce rails.

[0036] The specific operation is: after the rail is accelerated on-line cooling, the rail waist is continuously and rapidly heated by induction when it exits the heat treatment line. The heating temperature is 680°C, the heating time is 20 seconds, and the heating rate is 0.5m / s.

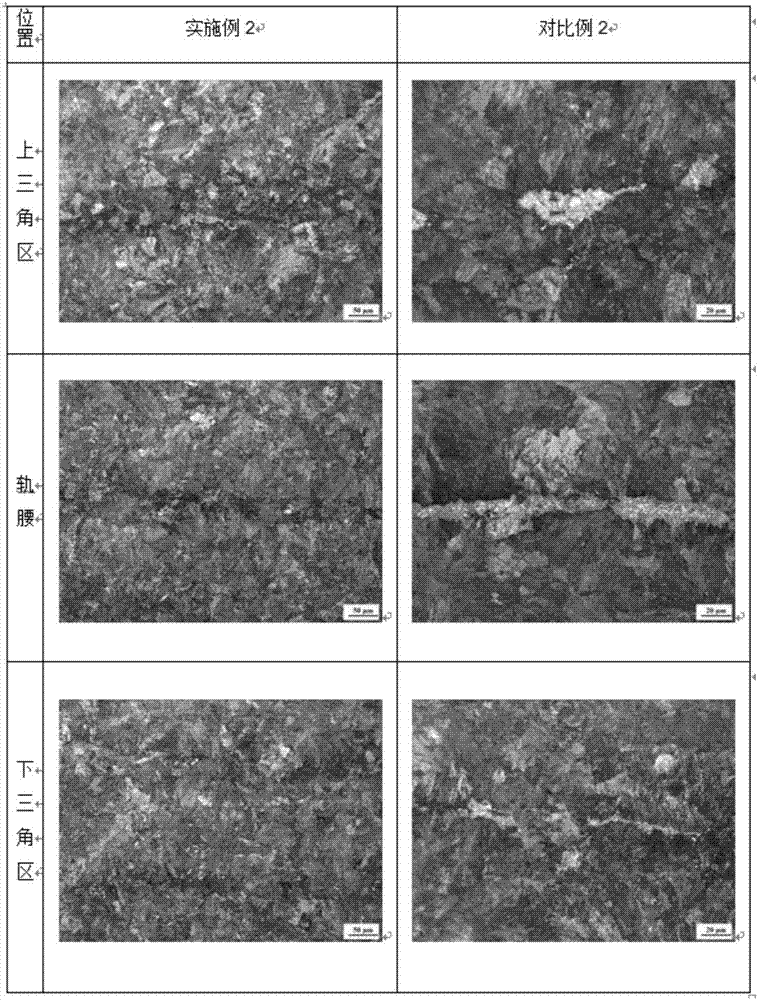

Embodiment 3

[0038] Using the rail on-line induction heating control method of the present invention, the main chemical components are: by weight percentage, including 0.65-1.05% C, 0.50-0.90% Si, 0.80-1.50% Mn, 0-1.00% Cr, and the rest is iron , Nb, V, Ti, RE and other micro-alloying elements and impurities on-line induction heating to produce rails.

[0039] The specific operation is: after the rail is accelerated on-line cooling, the rail waist is continuously and rapidly heated by induction when it exits the heat treatment line. The heating temperature is 650°C, the heating time is 25 seconds, and the heating rate is 1.2m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com