Patents

Literature

38results about How to "Suppress supercooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freeze indicators, components therefor and preparative processes

InactiveUS8128872B2Useful characteristicSuppress supercoolingThermometer detailsLiquid surface applicatorsParticulatesLiquid medium

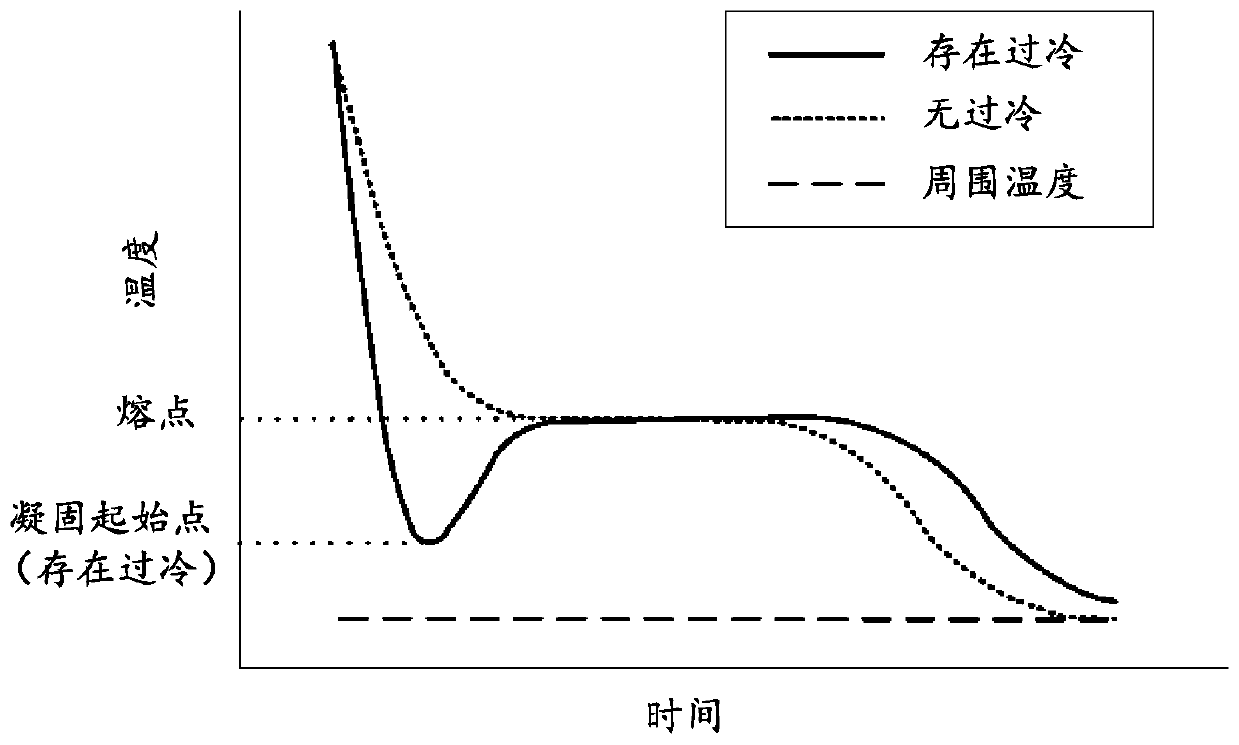

Freeze indicators can include an indicator dispersion, a liquid medium, indicator particles dispersed in the liquid medium and a particulate inorganic nucleating agent to inhibit supercooling of the liquid medium. The inorganic nucleating agent can have an ionic surface coating which can help provide a sharp end point. Optionally, freeze indicators can include indicator particles comprising an organic material and a softener to soften the indicator particles and provide the freeze indication with an enhanced visual appearance. Another option is to provide a temperature-sensitive stabilizer to inhibit coagulation of the indicator dispersion at temperatures above the liquid medium frozen state melting point while permitting coagulation of the indicator dispersion at the liquid medium frozen state melting point.

Owner:TEMPTIME CORP

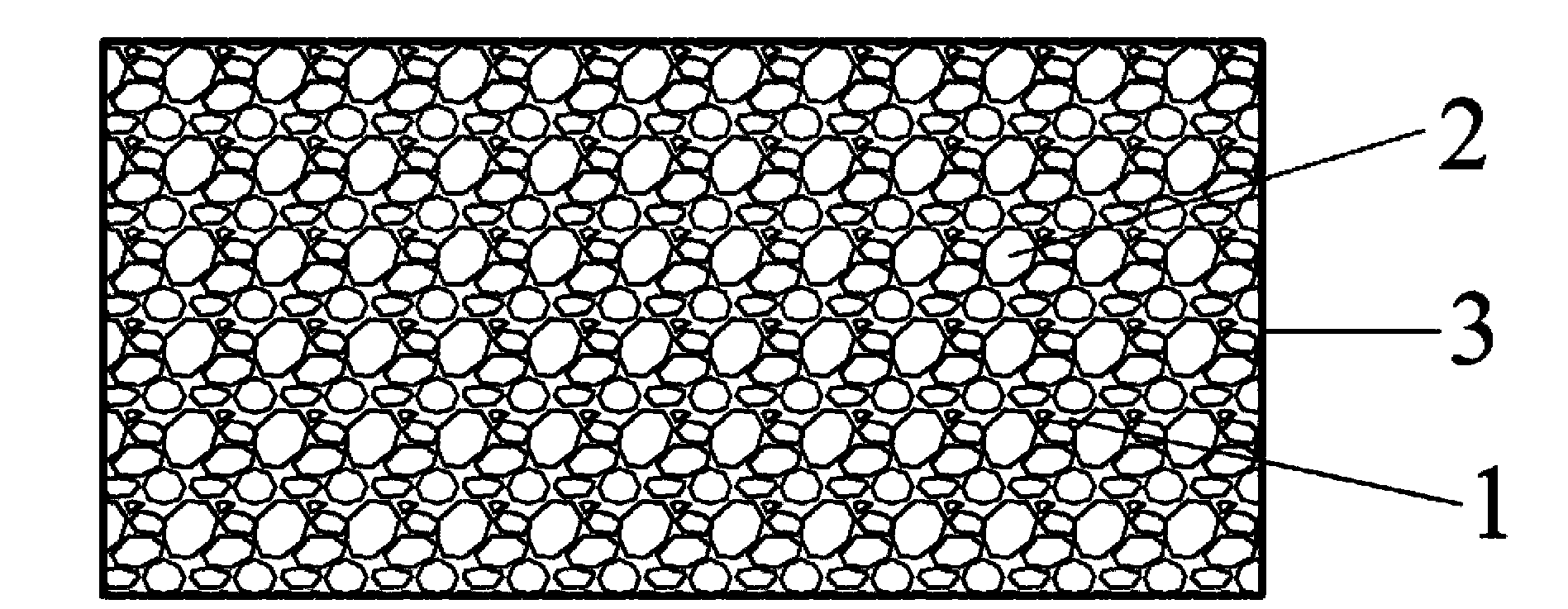

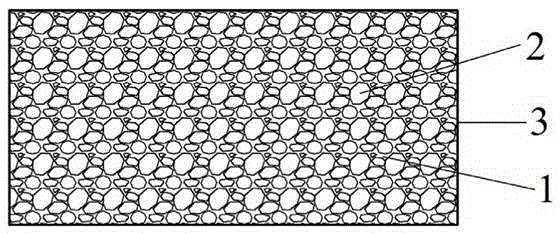

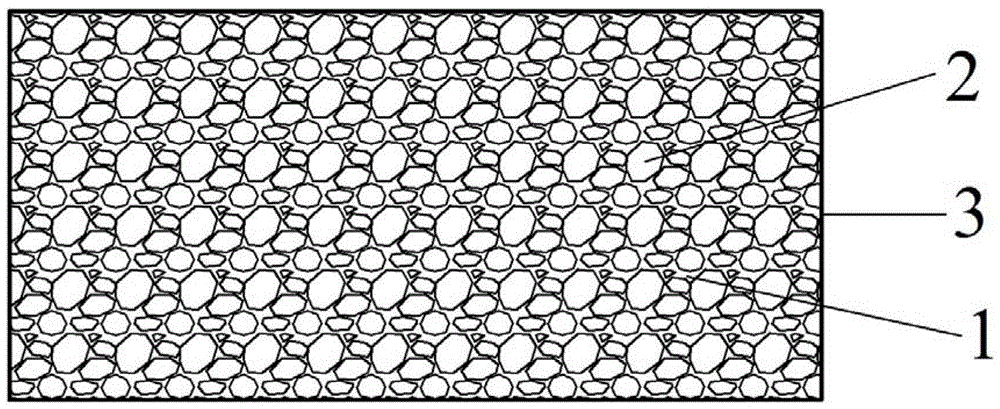

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

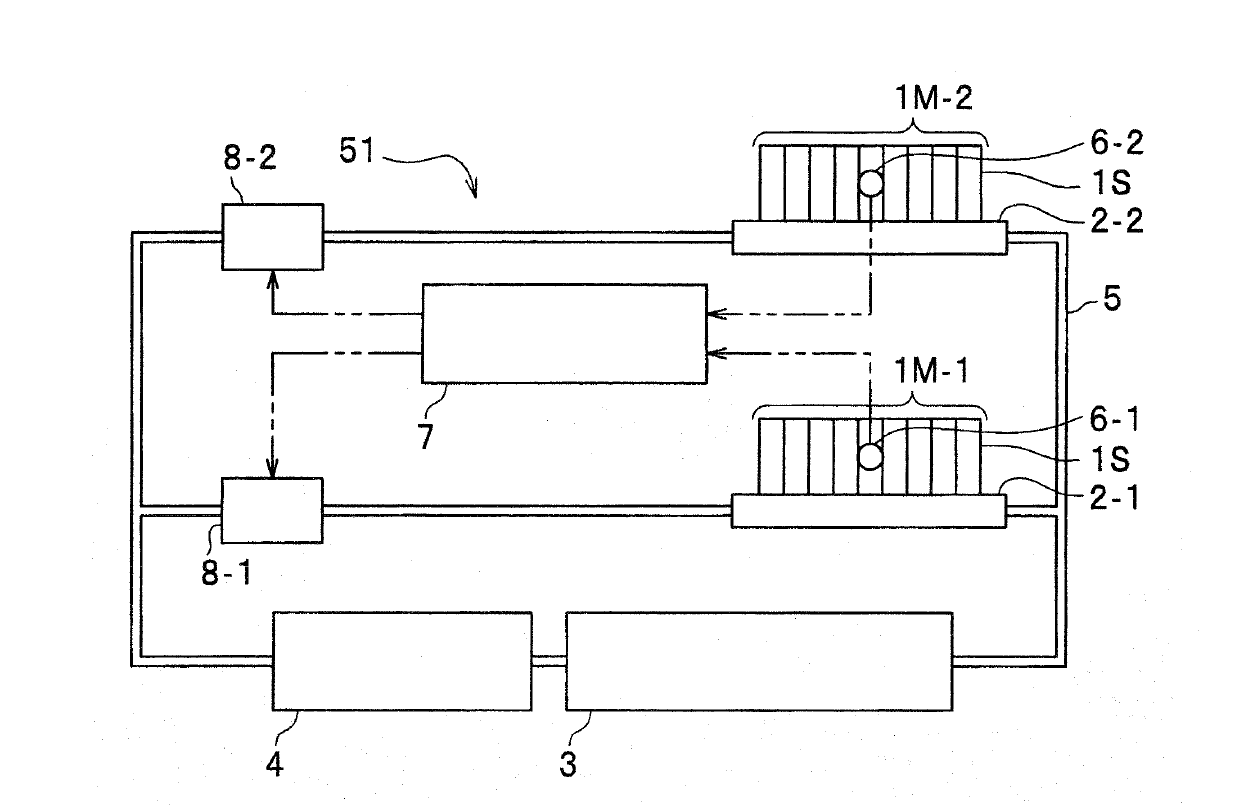

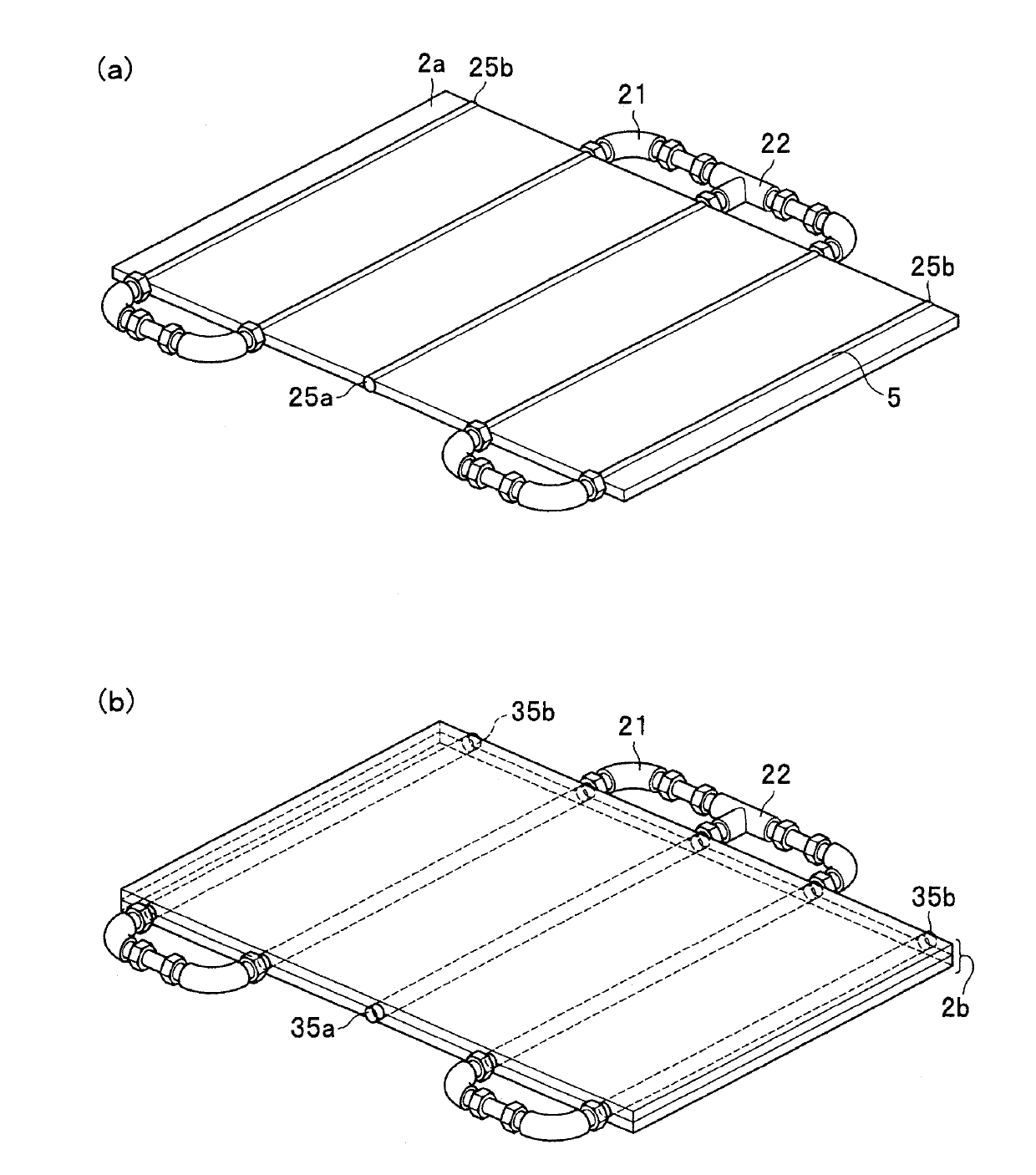

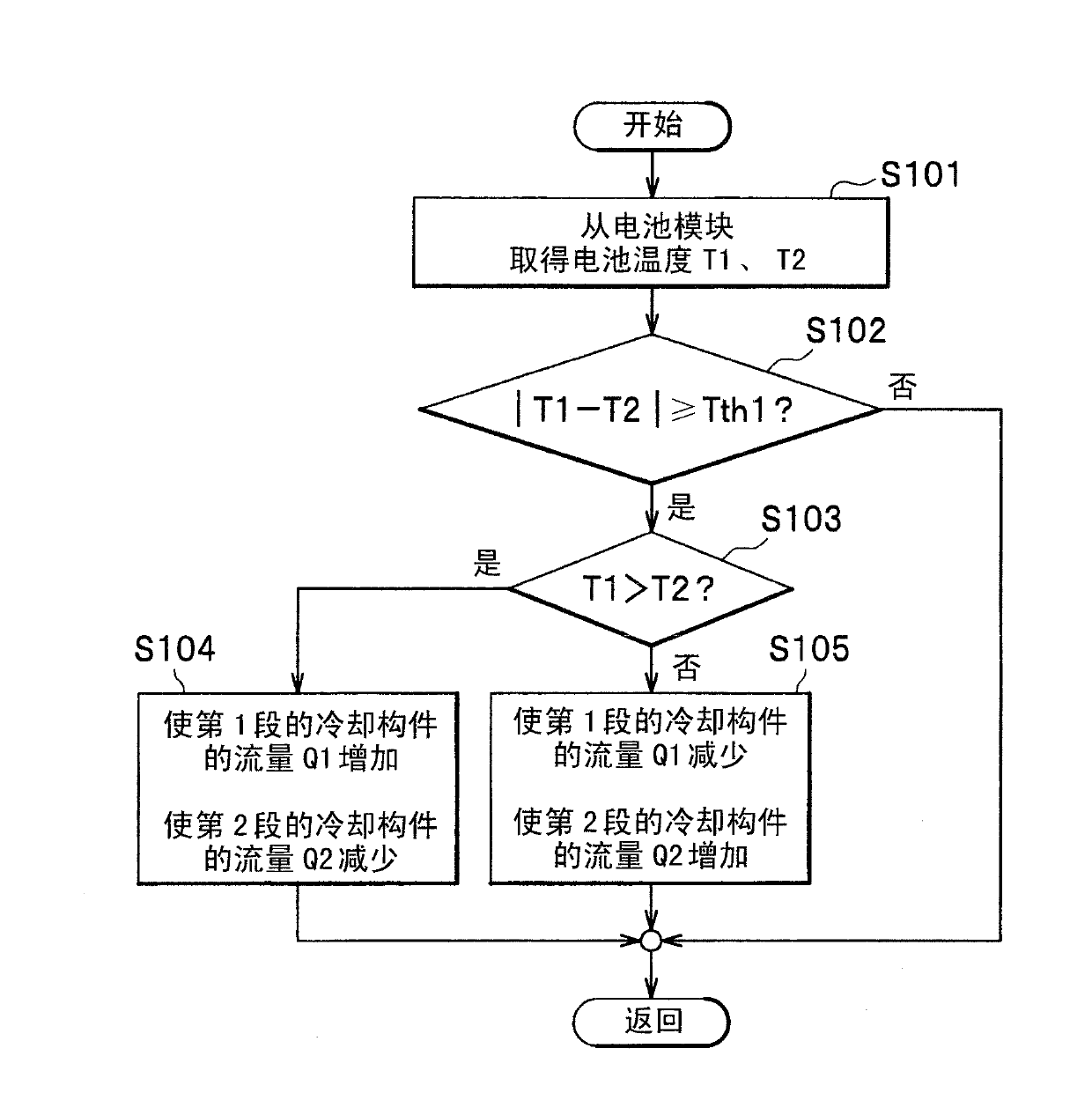

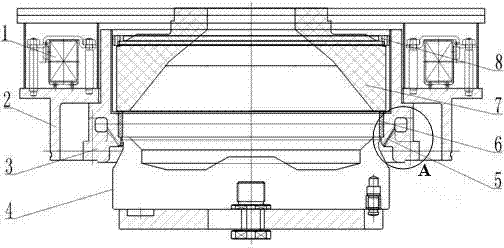

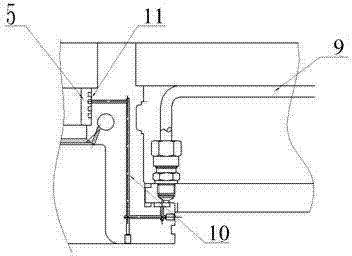

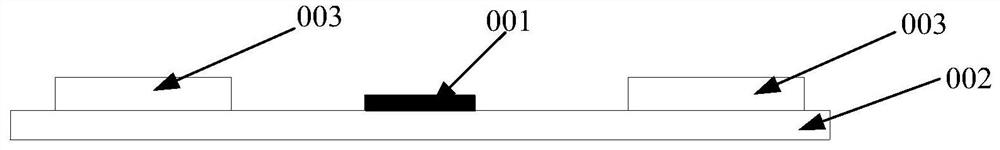

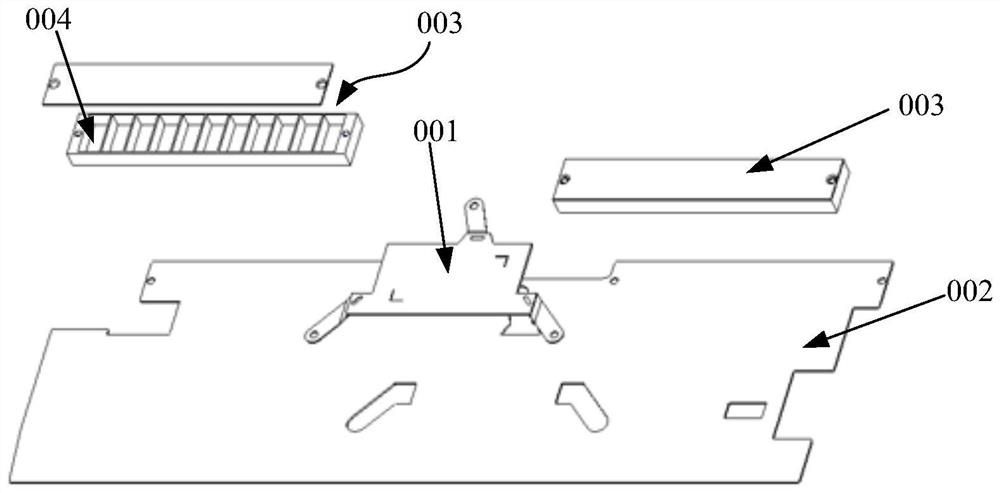

Battery system and temperature control method therefor

InactiveCN103311597ASuppress supercoolingSmall temperature deviationSecondary cellsCell component detailsTemperature controlEngineering

Provided are a battery system and temperature control method therefor capable of suppressing excessive cooling of a battery module, diminishing a temperature variance, and leveling the temperatures of plural battery modules. In the battery system including cooling units each of which is provided with a cooling plate (2-1, 2-2) which includes a flow channel through which a refrigerant flows and on which a battery module that is an object of temperature control (1M-1, 1M-2) is placed, and a flow rate adjustment device (8-1, 8-2) that adjusts the flow rate of the refrigerant that flows through the flow channel, temperature sensors (6-1, 6-2) that individually sense the temperatures of the battery modules, and a refrigerant circulation mechanism (4) that branches out the refrigerant into the flow channels accompanying the cooling units, and joins and circulates the refrigerants coming from the flow channels, a control unit (7) adjusts the refrigerant flow rates using the flow rate adjustment devices (8-1, 8-2) according to the temperatures, which are sensed by the temperature sensors (6-1, 6-2), for each of the cooling units.

Owner:HITACHI LTD

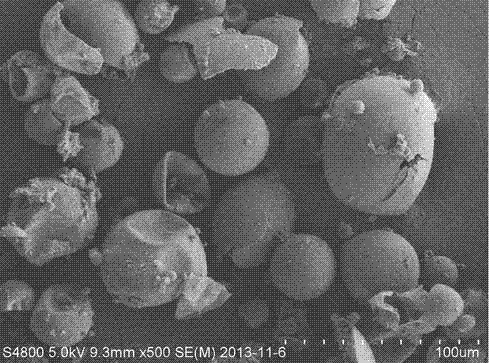

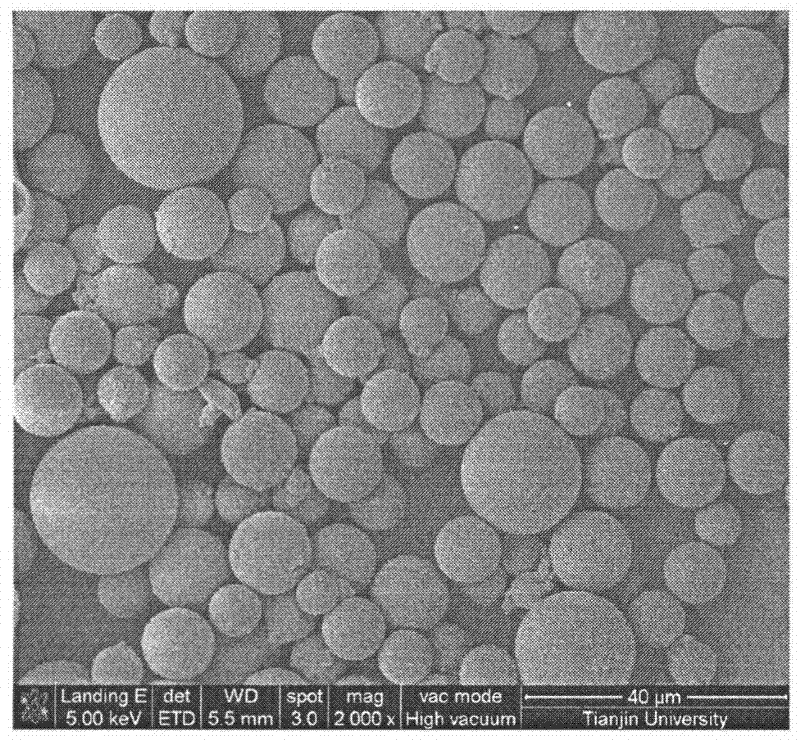

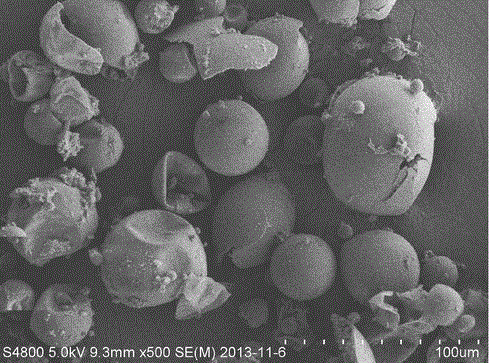

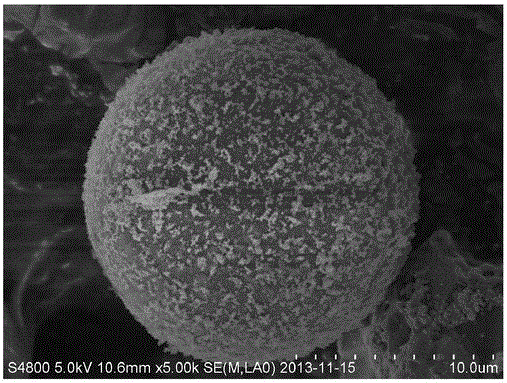

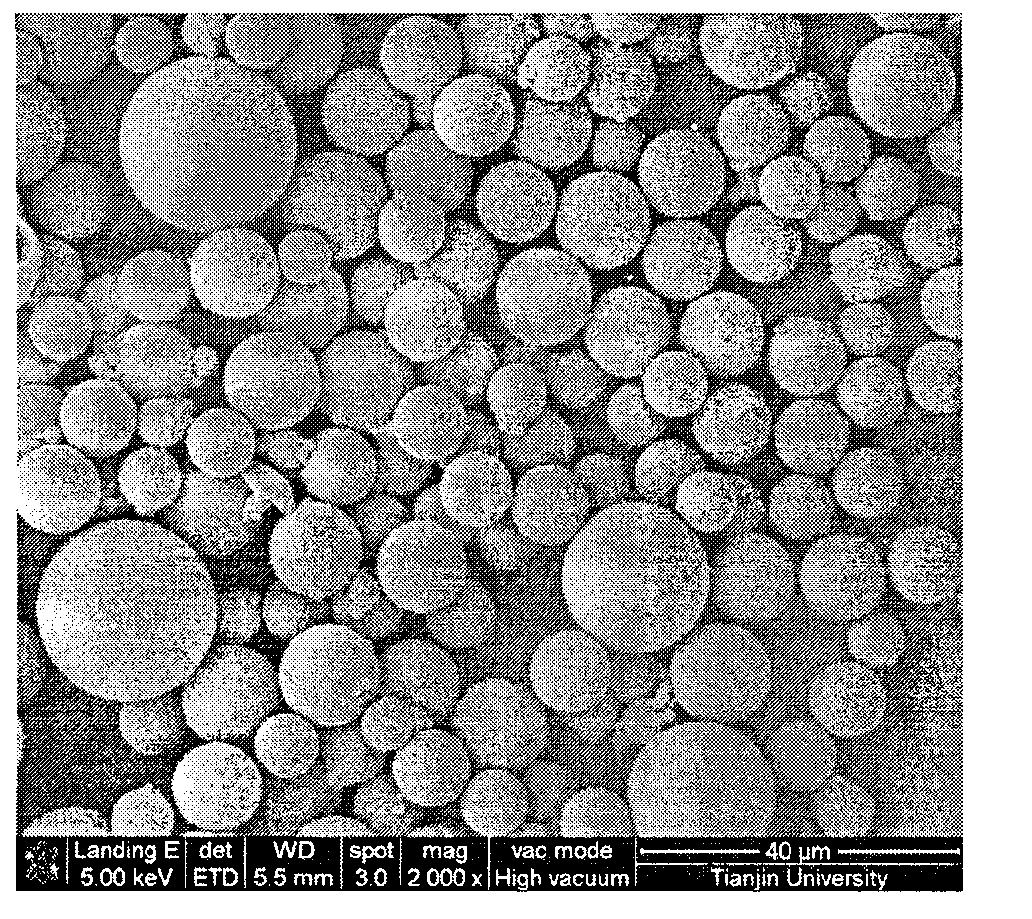

Silicon nitride-modified phase-change and energy-storage microcapsule and preparation method thereof

ActiveCN103805142AGood wear resistanceHigh thermal conductivityHeat-exchange elementsMicroballoon preparationThermal conductivitySilicon nitride

The invention discloses a silicon nitride-modified phase-change and energy-storage microcapsule, comprising a shell material and a cladded core material, wherein the shell material comprises the following raw materials in parts by weight: 50-100 parts of high-molecular polymers and 1-20 parts of silicon nitride powder which is evenly dispersed into the high-molecular polymers; the core material comprises 50-100 parts of organic phase-change and energy-storage materials and 1-20 parts of silicon nitride powder which is evenly dispersed into the organic phase-change and energy-storage materials. The invention also provides a preparation method of the phase-change energy-storage microcapsule. The thermal conductivity of the phase-change and energy-storage material is improved, overheat and overcold degrees in the phase-change process are inhibited, and meanwhile, the thermal endurance and the abrasive resistance, the thermal shock resistance, the fatigue resistance and the like also are improved. The silicon nitride-modified phase-change and energy-storage microcapsule is relatively simple in preparation technology, available in raw materials, strong in controllability, and applicable to the industrial large-scale production, an existing industrial processing technology can be fully utilized, and the performance of the phase-change and energy-storage microcapsule is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Freeze indicators, components therefor and preparative processes

InactiveUS20100162941A1Useful characteristicSuppress supercoolingThermometer detailsAnalysis using chemical indicatorsParticulatesLiquid medium

Freeze indicators can include an indicator dispersion, a liquid medium, indicator particles dispersed in the liquid medium and a particulate inorganic nucleating agent to inhibit supercooling of the liquid medium. The inorganic nucleating agent can have an ionic surface coating which can help provide a sharp end point. Optionally, freeze indicators can include indicator particles comprising an organic material and a softener to soften the indicator particles and provide the freeze indication with an enhanced visual appearance. Another option is to provide a temperature-sensitive stabilizer to inhibit coagulation of the indicator dispersion at temperatures above the liquid medium frozen state melting point while permitting coagulation of the indicator dispersion at the liquid medium frozen state melting point.

Owner:TEMPTIME CORP

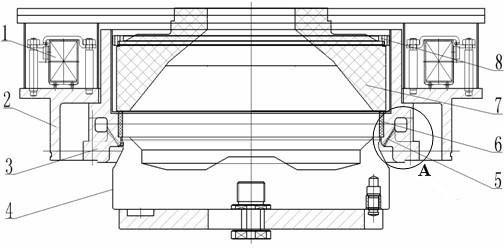

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

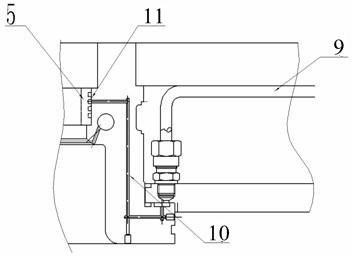

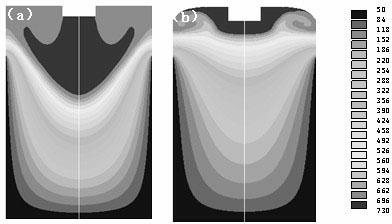

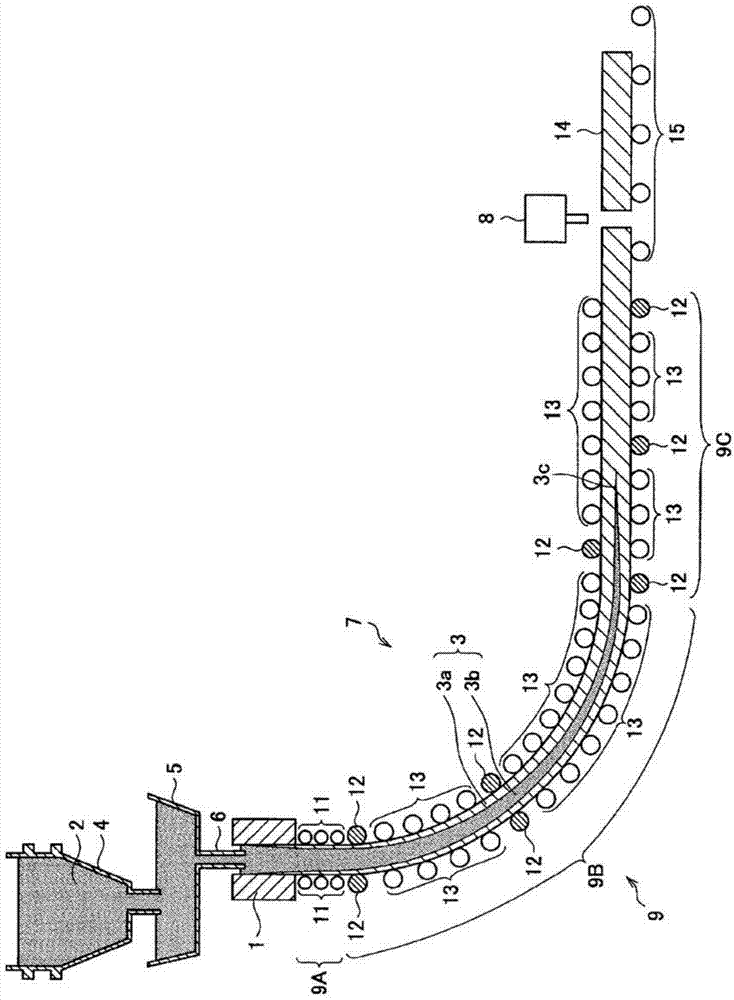

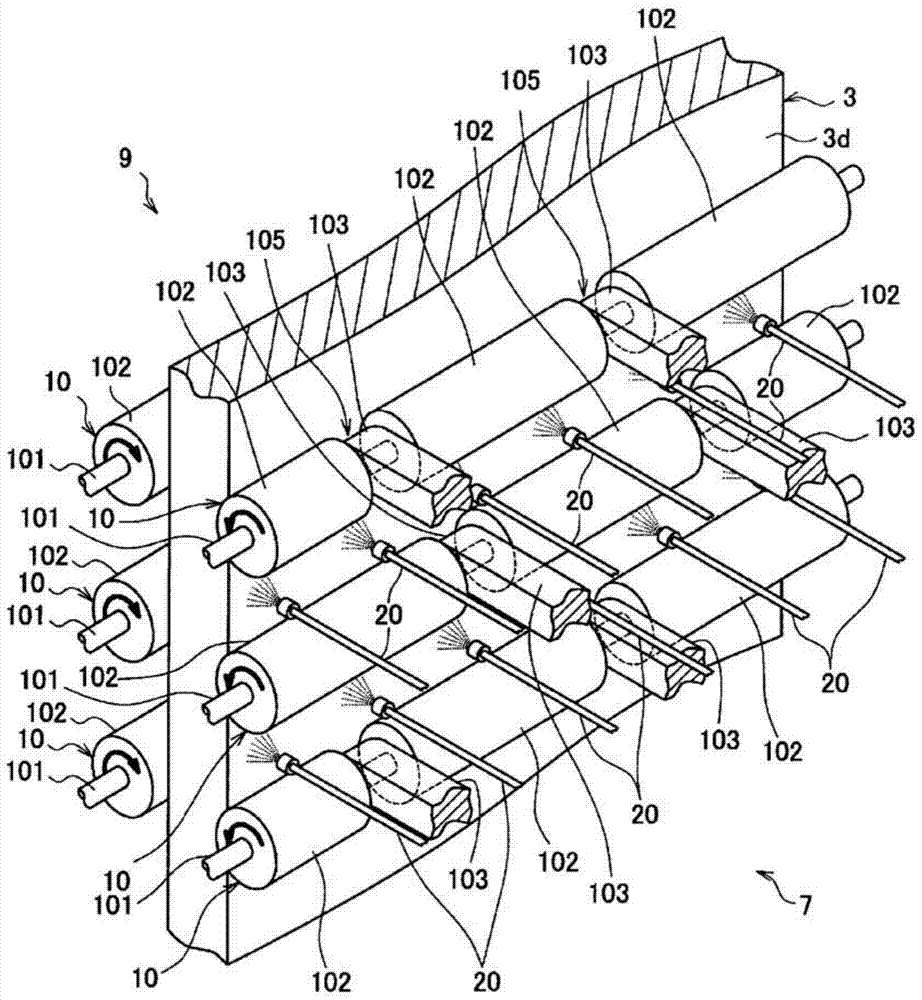

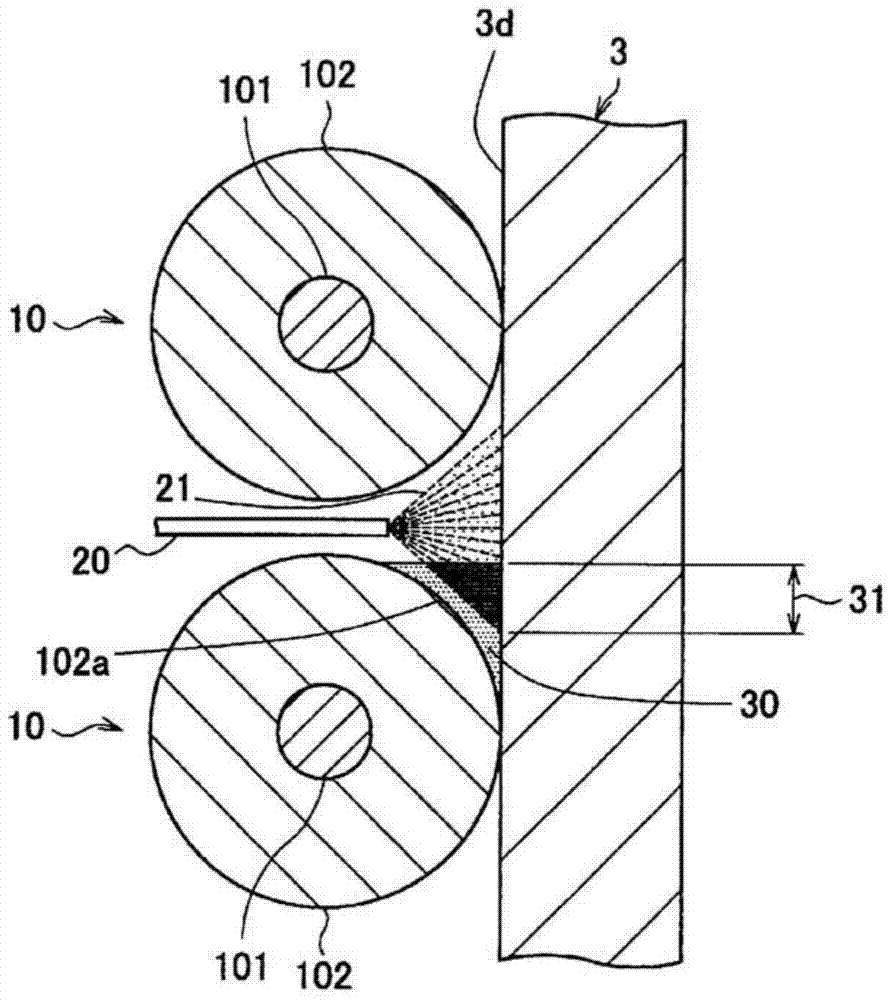

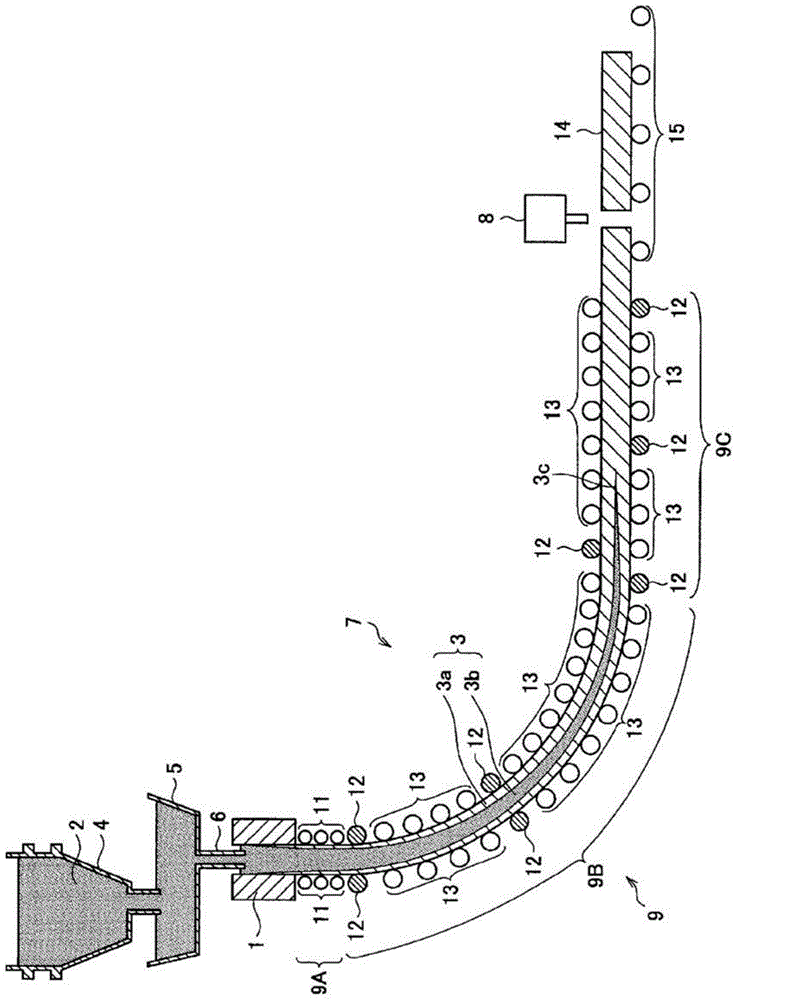

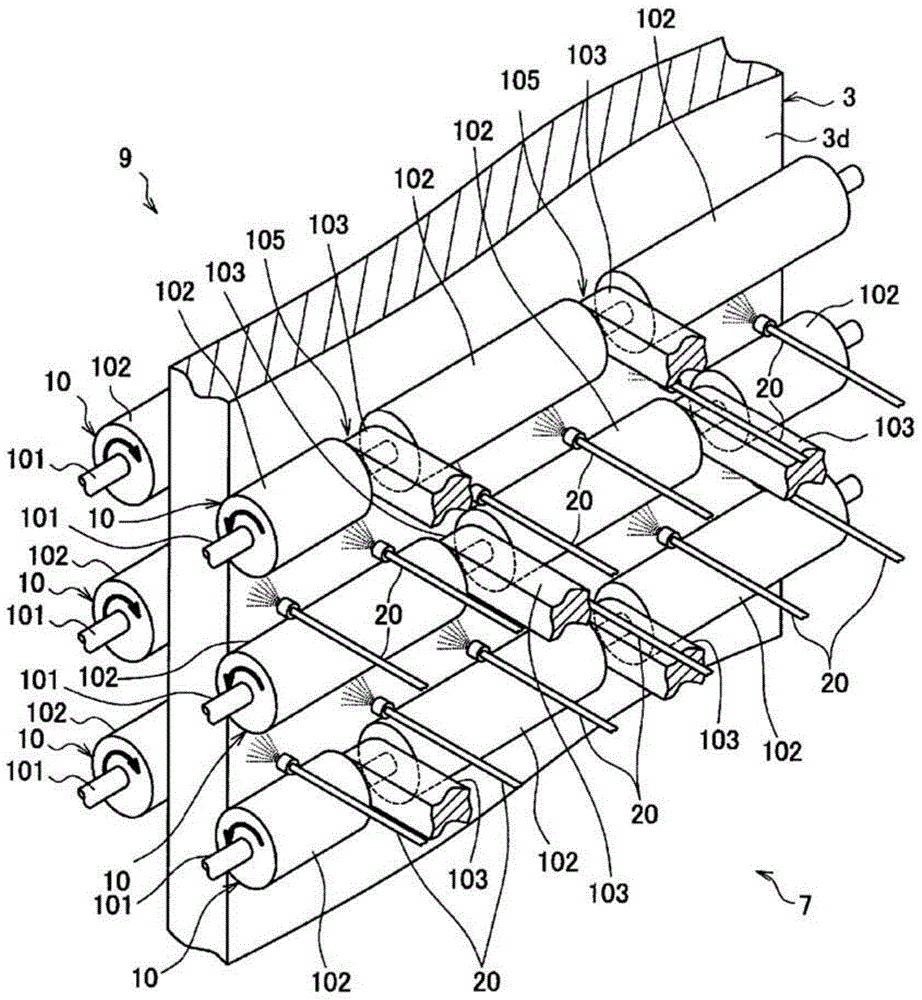

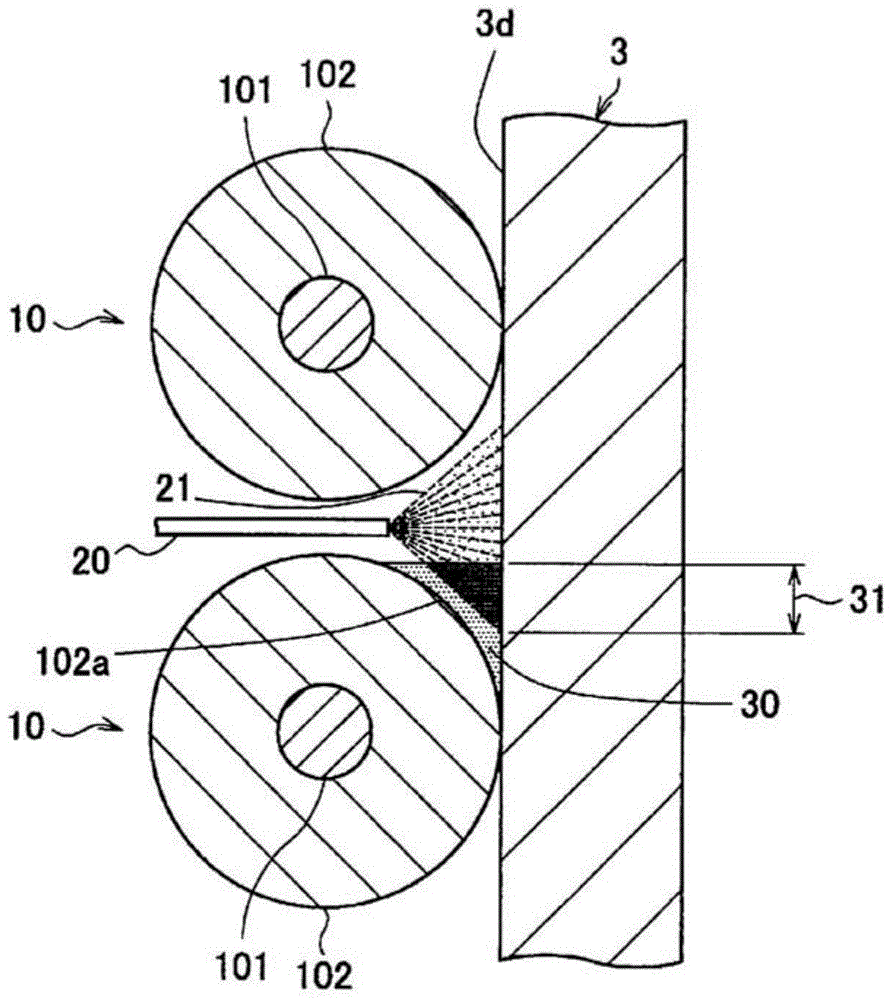

Secondary cooling method and secondary cooling device for continuous casting machine

ActiveCN103842113AImprove cooling uniformityThe heat transfer coefficient does not increaseEngineeringContinuous casting

This secondary cooling device for a continuous casting machine is provided with a plurality of pairs of support roller and a plurality of nozzles, and each support roller has: a plurality of roller sections split in the widthwise direction of a cast strand; and grooves provided between the roller sections. The grooves provided to each upstream-side support roller and downstream-side support roller adjacent in the direction of conveyance are disposed offset from each other in the widthwise direction. A first nozzle among the plurality of nozzles is disposed at a first nozzle position set between a roller section provided to an upstream-side support roller and a groove provided to a downstream-side support roller.

Owner:NIPPON STEEL CORP

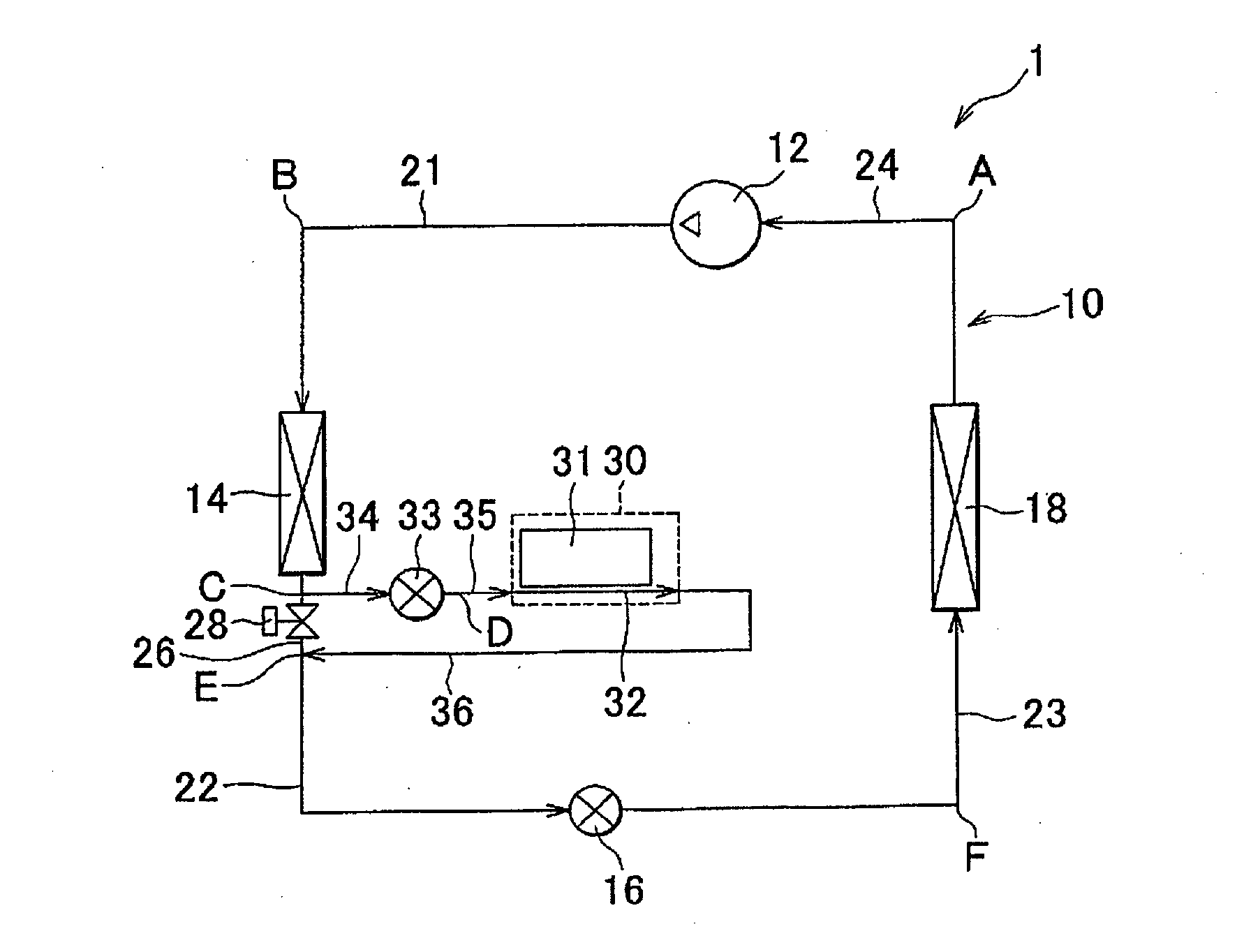

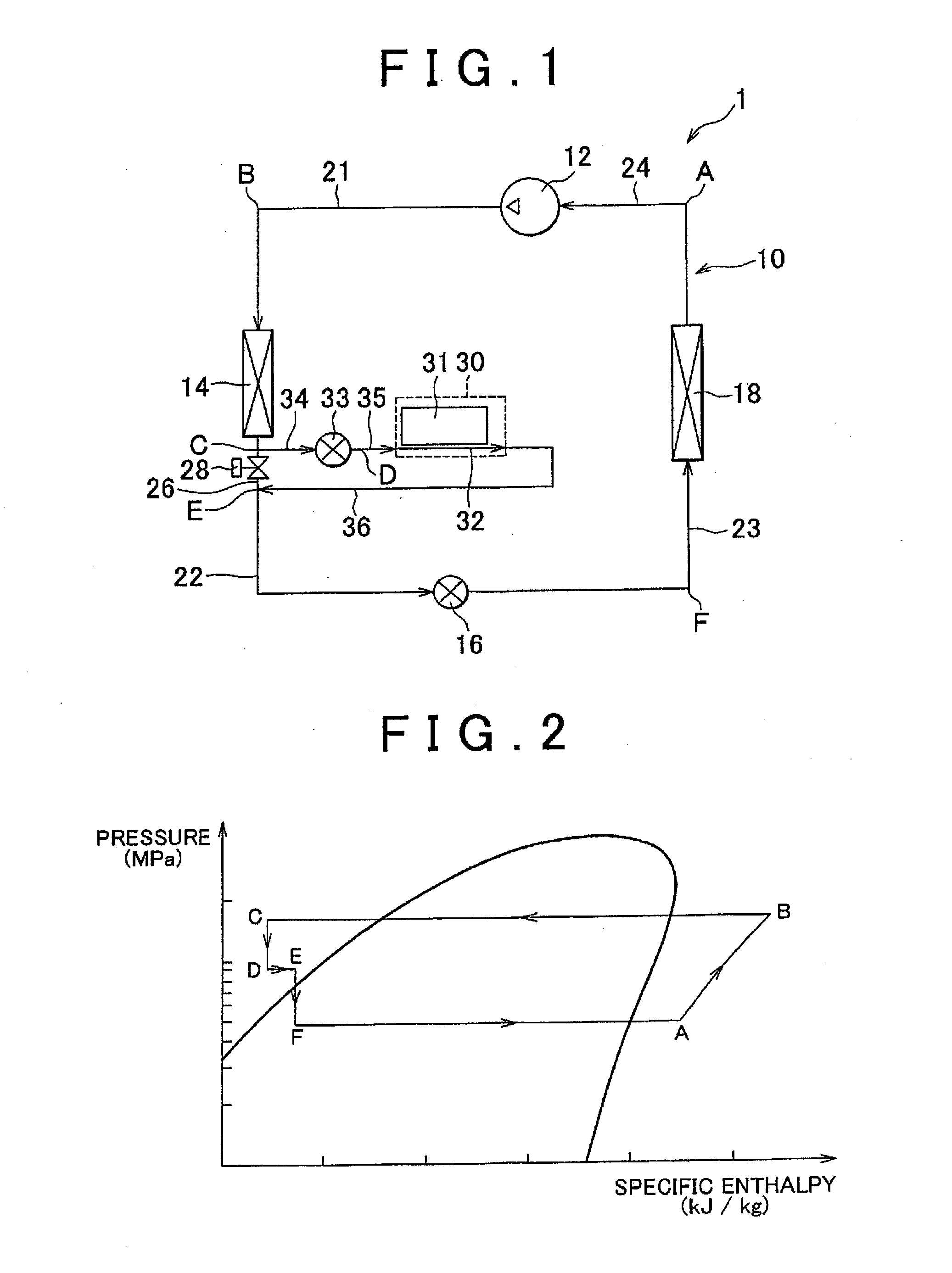

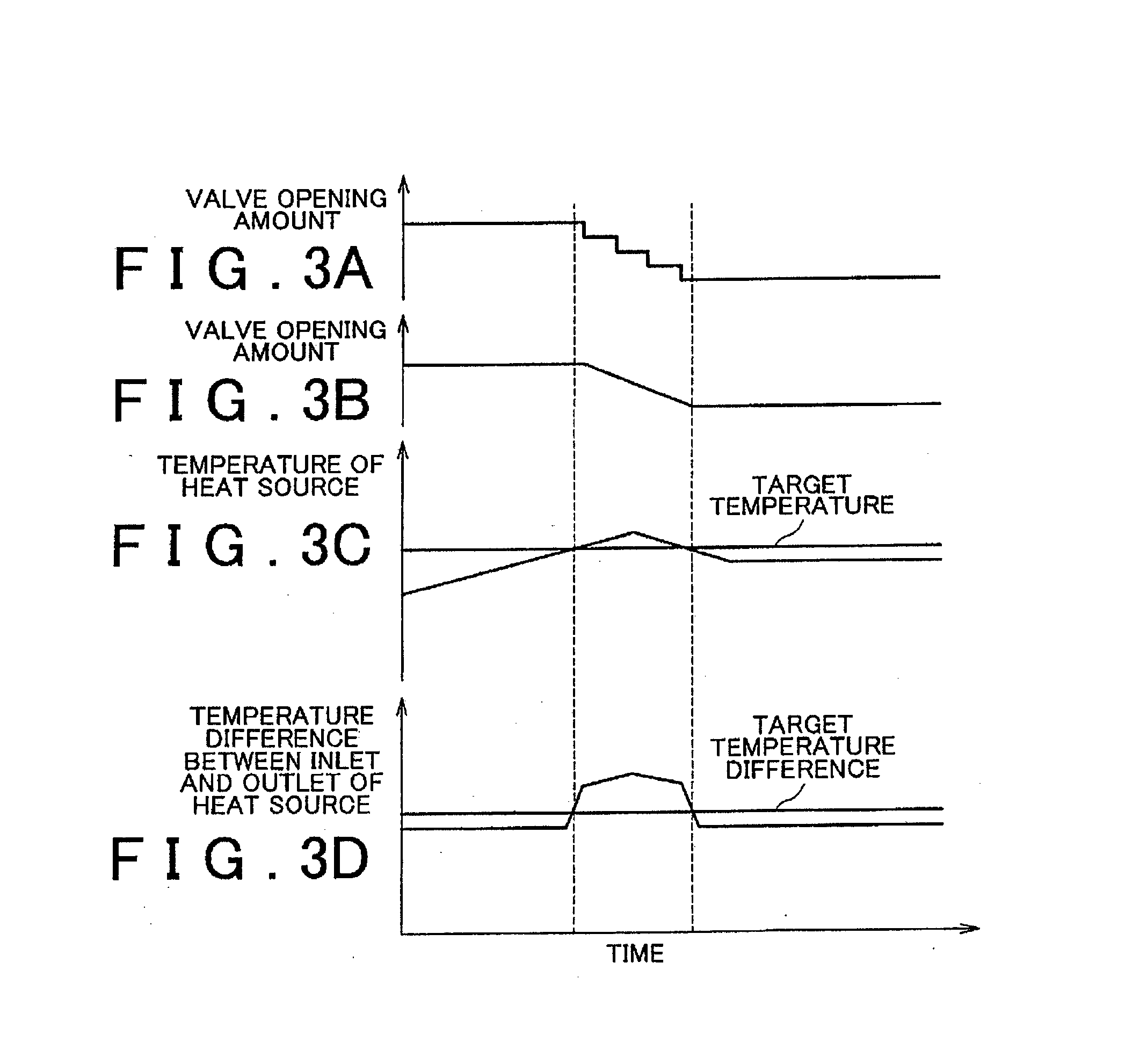

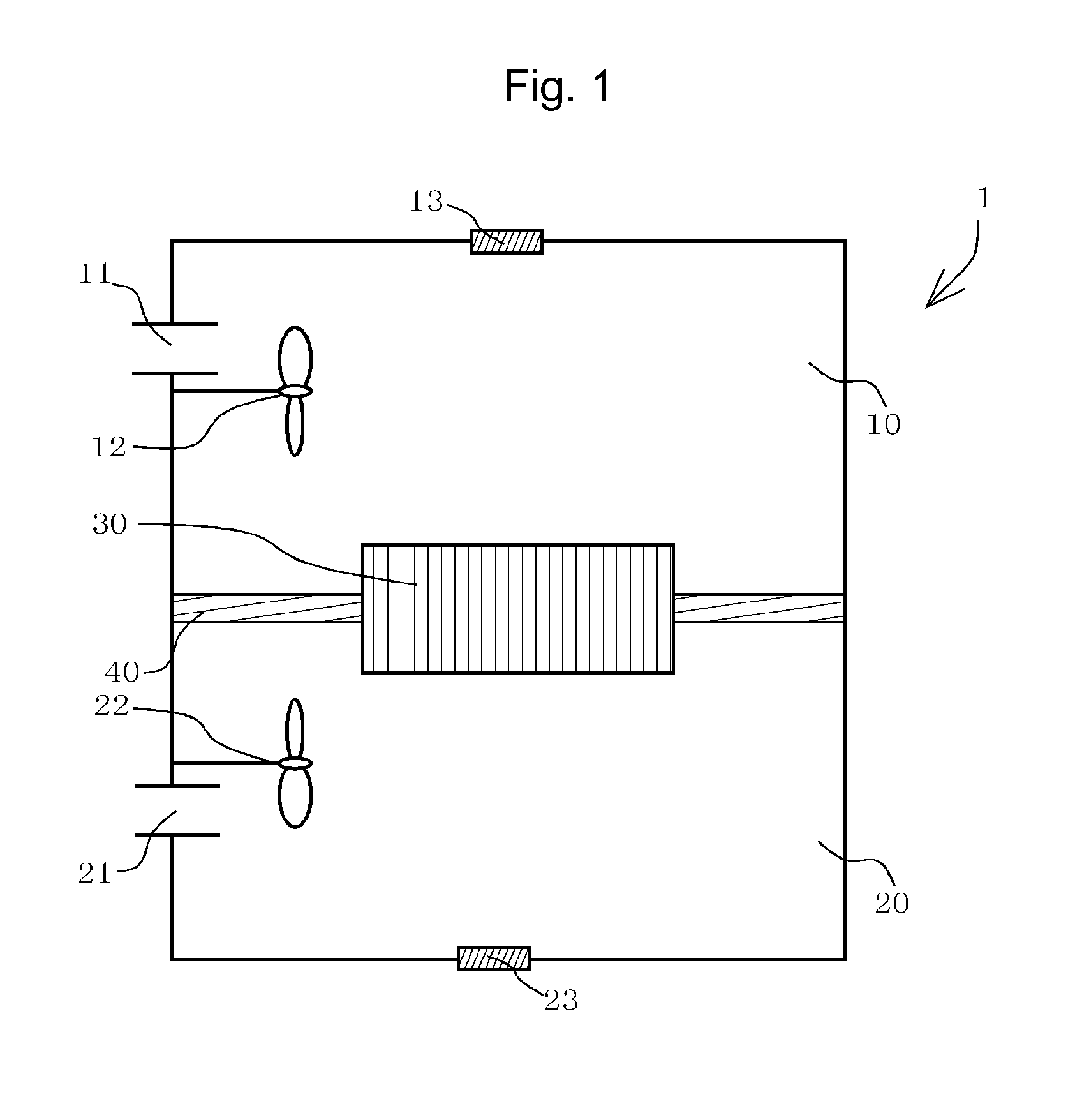

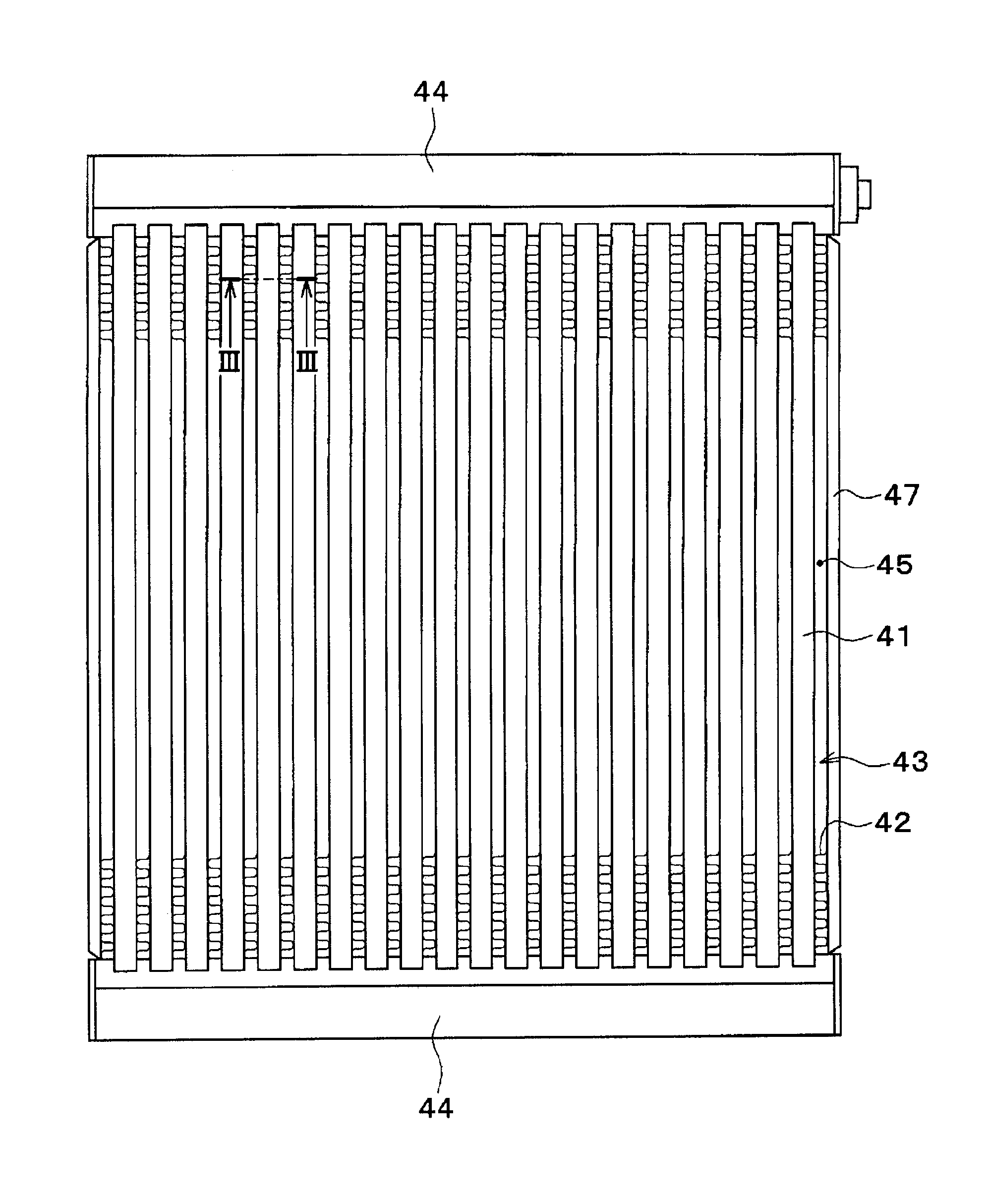

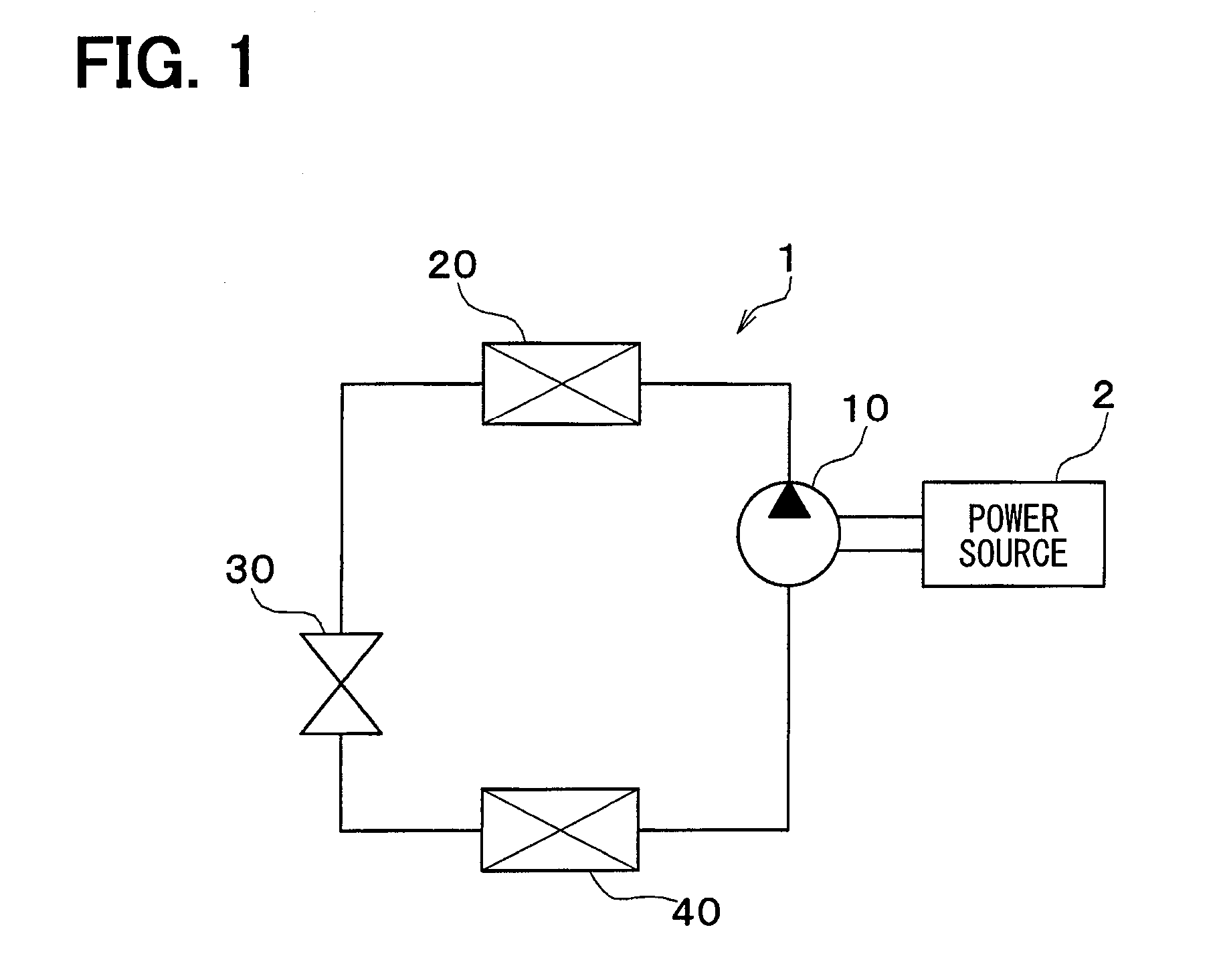

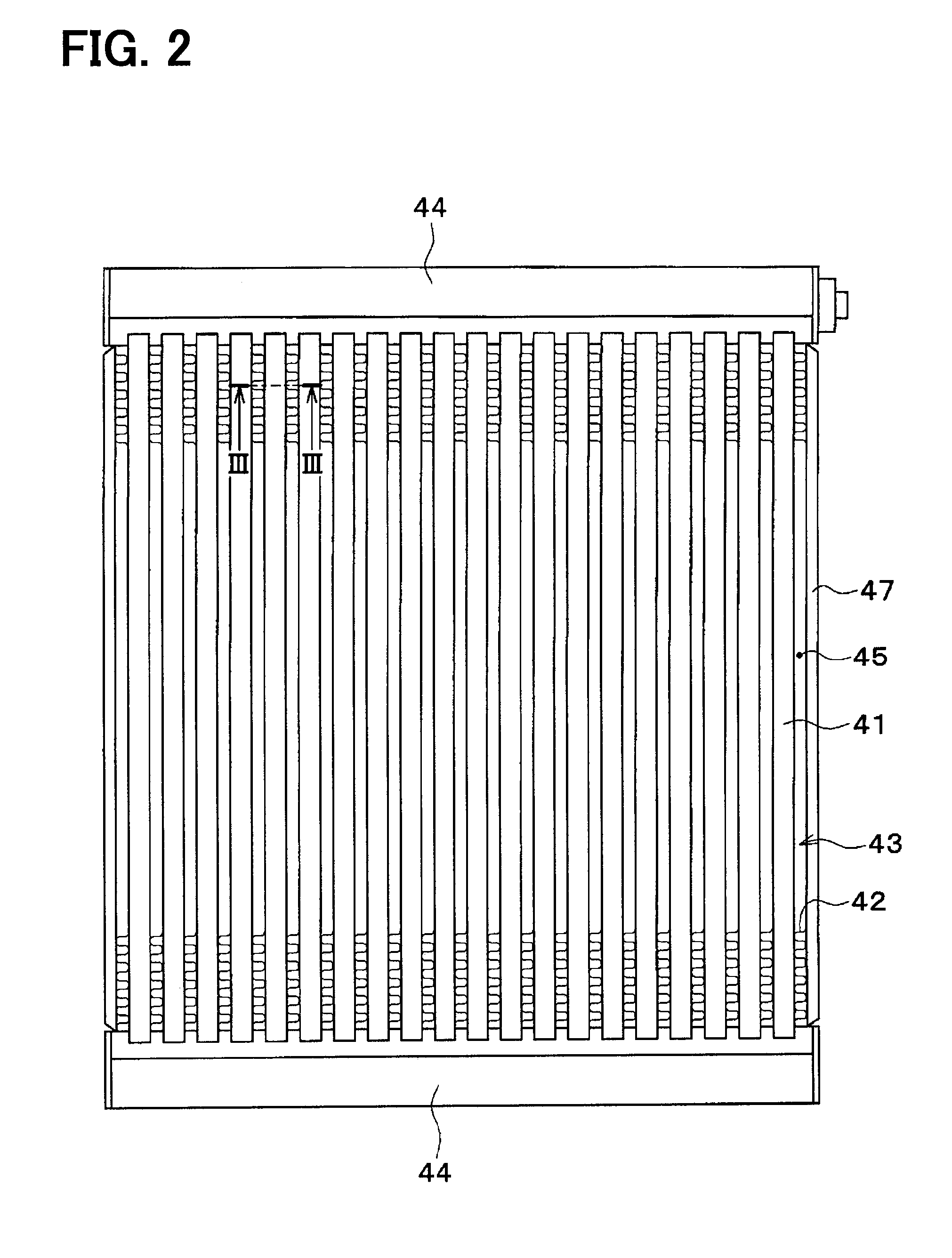

Vehicle cooling system

InactiveUS20130319038A1Great pressure lossReduce power consumptionCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

A cooling system includes a compressor that circulates refrigerant; a condenser that condenses the refrigerant; an expansion valve that reduces a pressure of the refrigerant that has been condensed by the condenser; an evaporator that vaporizes the refrigerant that has been reduced in pressure by the expansion valve; a refrigerant passage through which the refrigerant flows from an outlet of the condenser toward an inlet of the expansion valve, and that includes a passage forming portion that forms part of the refrigerant passage; a second passage that is connected in parallel with the passage forming portion; a cooling portion that is provided in the second passage and cools a heat source using the refrigerant; and an expansion valve that is arranged upstream of the cooling portion in the second passage.

Owner:TOYOTA JIDOSHA KK +1

Composite phase-transition heat-storage material and preparation method thereof

InactiveCN106753252AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsStorage efficiencyThermal conductivity

The invention provides a composite phase-transition heat-storage material and a preparation method thereof. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:CHANGDE LYRUN MATERIAL

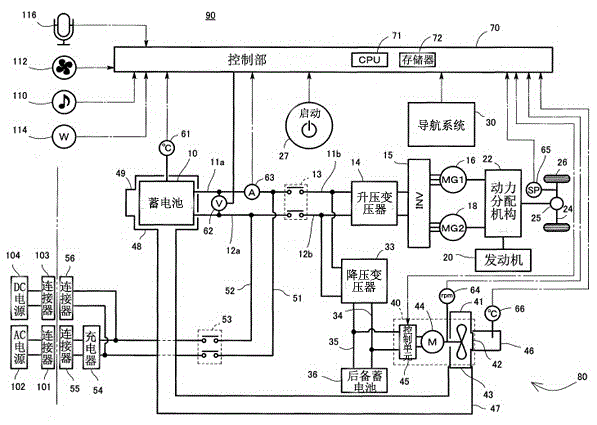

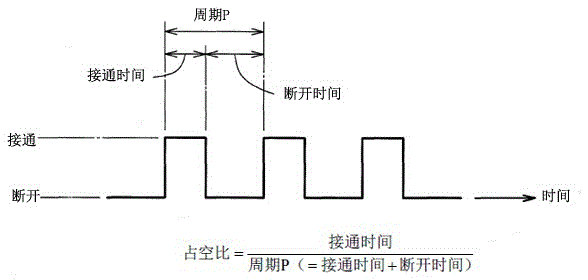

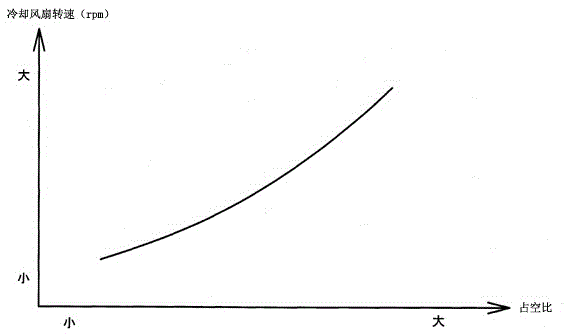

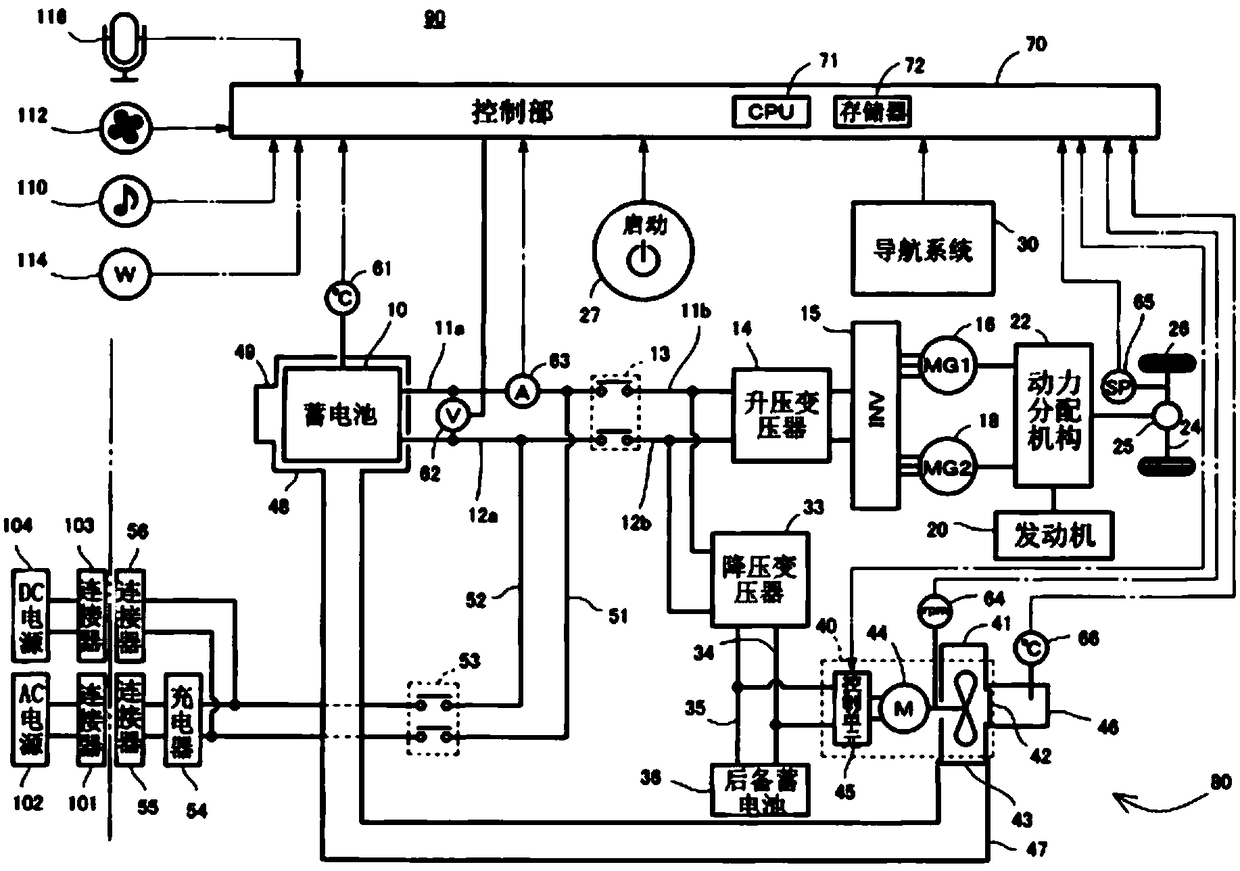

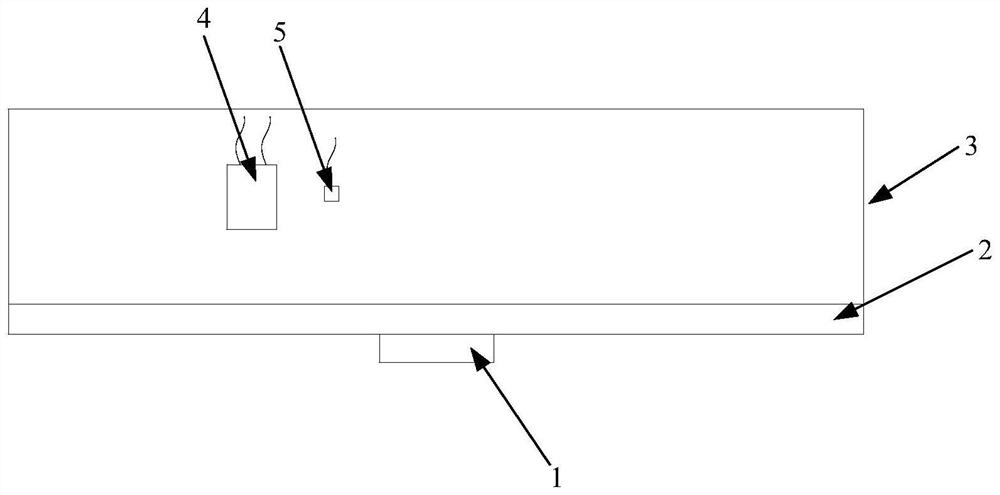

Cooling system for on-vehicle secondary battery

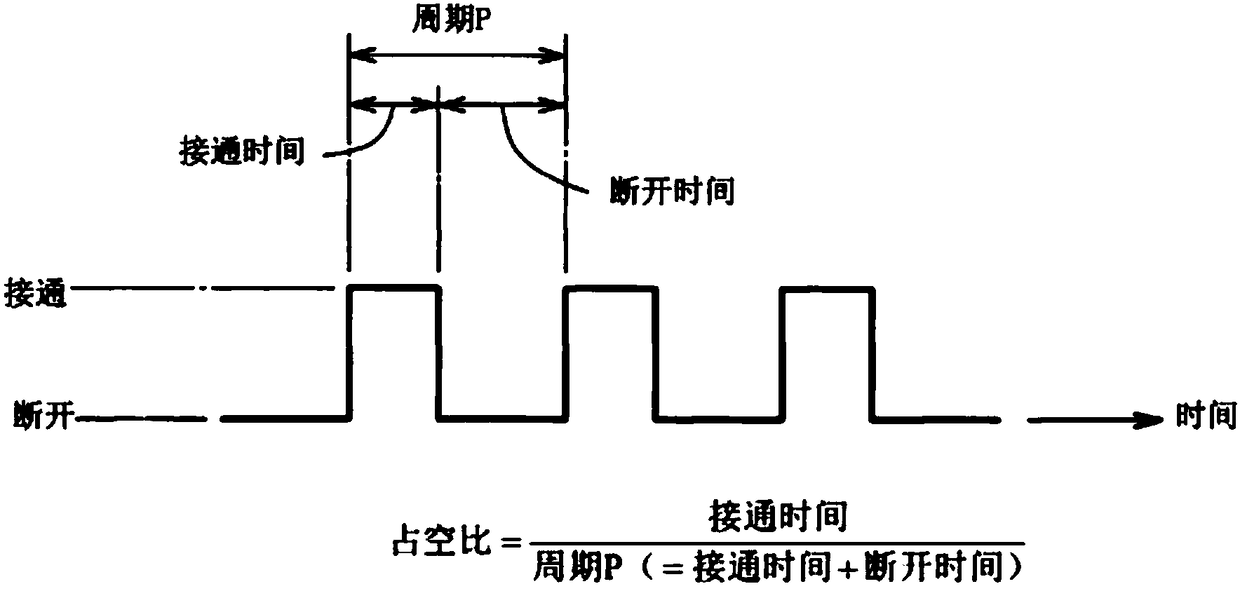

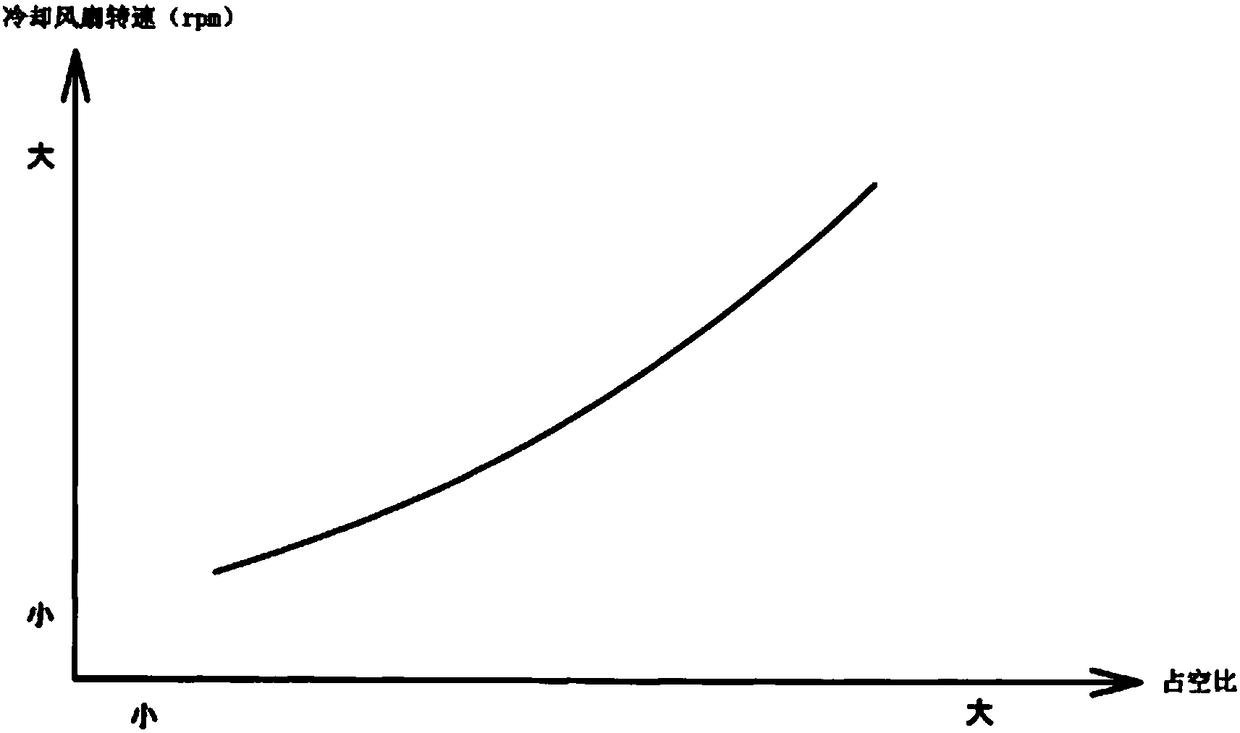

ActiveCN106042946ASuppress discomfortSuppress supercoolingPropulsion using engine-driven generatorsSecondary cellsAnomaly detectionNoise level

If the battery temperature (TB) of the main battery (10) is equal to or higher than the first temperature (T0) after a hybrid power vehicle is started, the cooling system performs first constant control for driving the cooling fan (40) with a first command value a predetermined duration and also performs the problem detection processing based on an actual rotation rate of the cooling fan (40) during the constant control. In addition, the battery temperature (TB) of the main battery (10) is equal to or higher than the first temperature (T0) during inhibition of the first constant control under a predetermined condition and a noise level within a vehicle interior is equal to or higher than a predetermined value (Lo), the cooling system performs second constant control for driving the cooling fan (40) with a second command value (D3) and performs the problem detection processing based on an actual rotation rate of the cooling fan (40) during the second constant control. And in this way, discomfort of passengers and over-temperature of a secondary battery can be suppressed, and a chance for detection of the cooling fan is fully ensured.

Owner:TOYOTA JIDOSHA KK

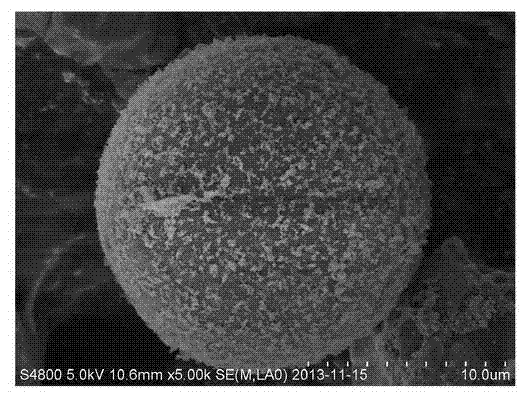

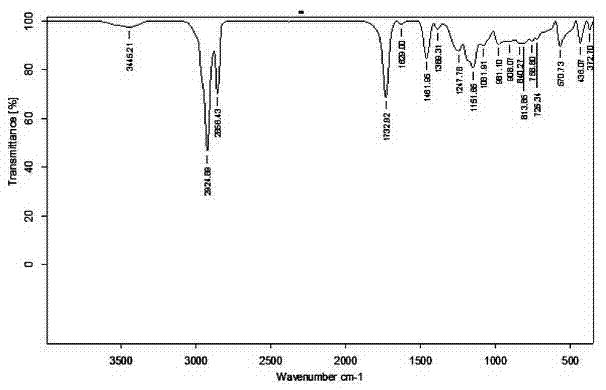

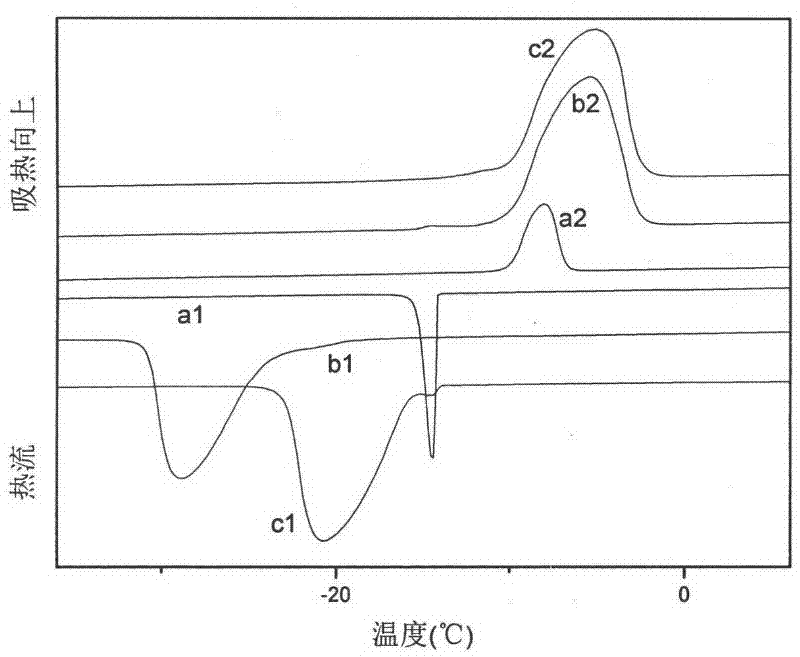

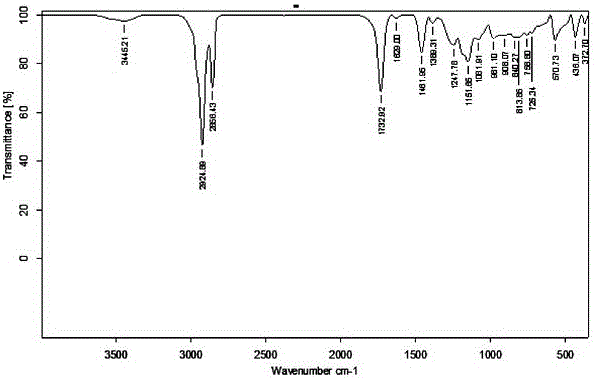

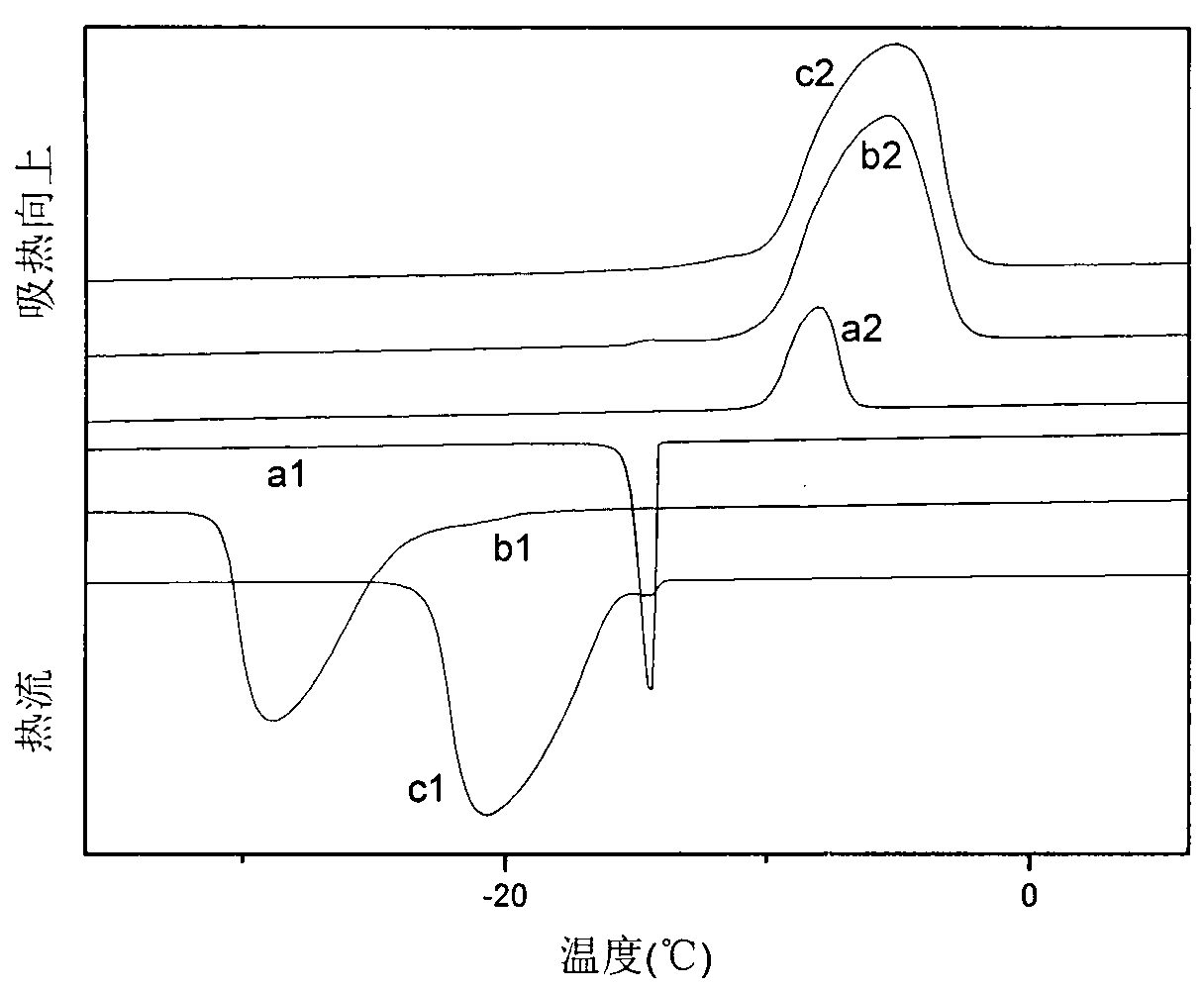

Supercooling phase change-inhibiting alkane microcapsule and preparation and application thereof

ActiveCN102391839ASuppress supercoolingNot easy to reuniteHeat-exchange elementsCoatingsAlkaneEmulsion

The invention discloses a supercooling phase change-inhibiting alkane microcapsule and preparation and application thereof. The size of the alkane microcapsule is within a range from 0.1Mu m to 100Mu m, the alkane microcapsule consists of shell materials and core materials, the shell materials are melamine resin, the core materials are n-alkane phase change agent and n-alkane nucleating agent, the carbon atom number of the n-alkane phase change agent is twelve to twenty eight, and the carbon atom number of the n-alkane nucleating agent is twenty two to forty. The preparation method for the alkane microcapsule, which is disclosed by the invention, is an in-situ polymerization method, and the preparation process includes core material emulsion preparation, shell material prepolymer preparation and alkane microcapsule preparation. For the same type of alkane microcapsule, the carbon atom number of the nucleating agent is greater than the carbon atom number of the phase change agent, and the nucleating agent and the phase change agent can be formed into gel. The invention has the advantages that: the alkane microcapsule has the characteristics of supercooling phase change inhibition, smooth surface and aggregation resistance, the preparation process for the alkane microcapsule is simple, and the application range is wide.

Owner:响水县中博纺织有限公司

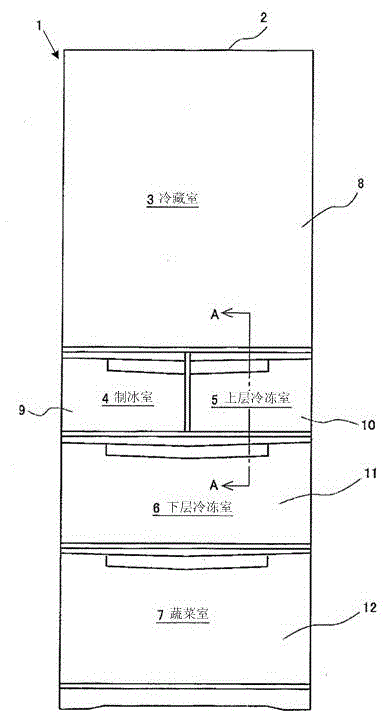

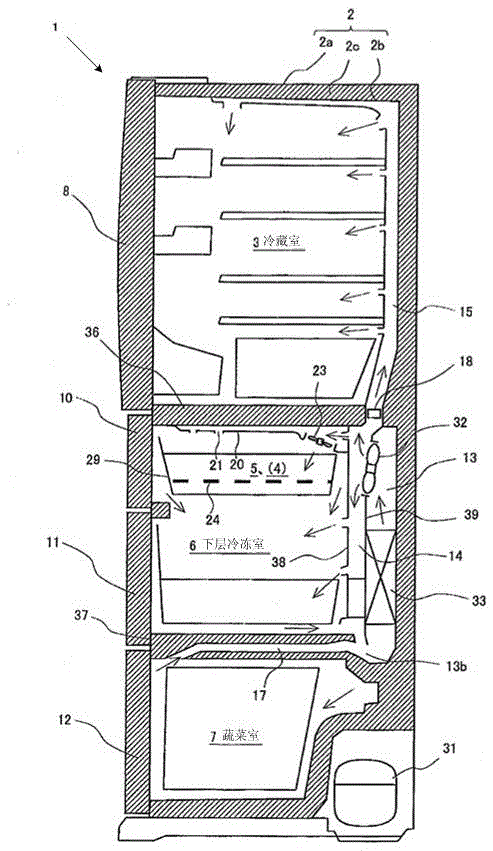

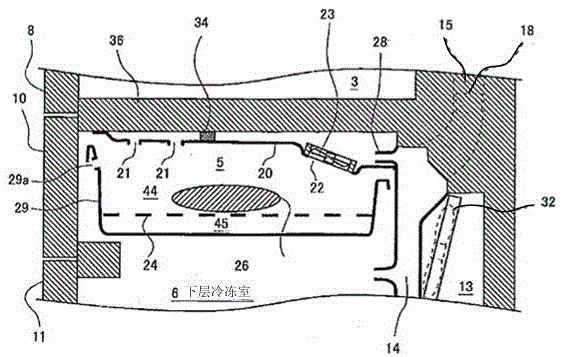

Super-cooling control method of refrigeration device

ActiveCN105806035ACurb churnSuppress supercoolingDomestic refrigeratorsSubcoolersSuper coolingEngineering

The invention provides a super-cooling control method of a refrigeration device. The refrigeration device comprises a freezing chamber used for containing frozen foods, a temperature detection mechanism used for detecting temperature of the frozen foods, an air feeder used for blowing freezing air down in the freezing chamber, and a freezing circulation loop, wherein the freezing circulation loop comprises a compressor, a radiator, an expansion valve and a cooler which are connected together. According to the refrigeration device, the foods in the freezing chamber can be efficiently frozen by super cooling; the cooling speed is kept constant as far as possible during super cooling; the temperature of the frozen foods can be measured every specified time; the operation parameters of the refrigeration device are adjusted on the basis of the measurement results; the control is updated for n1 times repeatedly under the condition that the frozen foods are thick foods; the control is updated for n2 times repeatedly under the frozen foods are thin foods; therefore, the super cooling caused by loss of thin blood can also be suppressed even if the frozen foods are thick foods.

Owner:QINGDAO HAIER SPECIAL ICEBOX

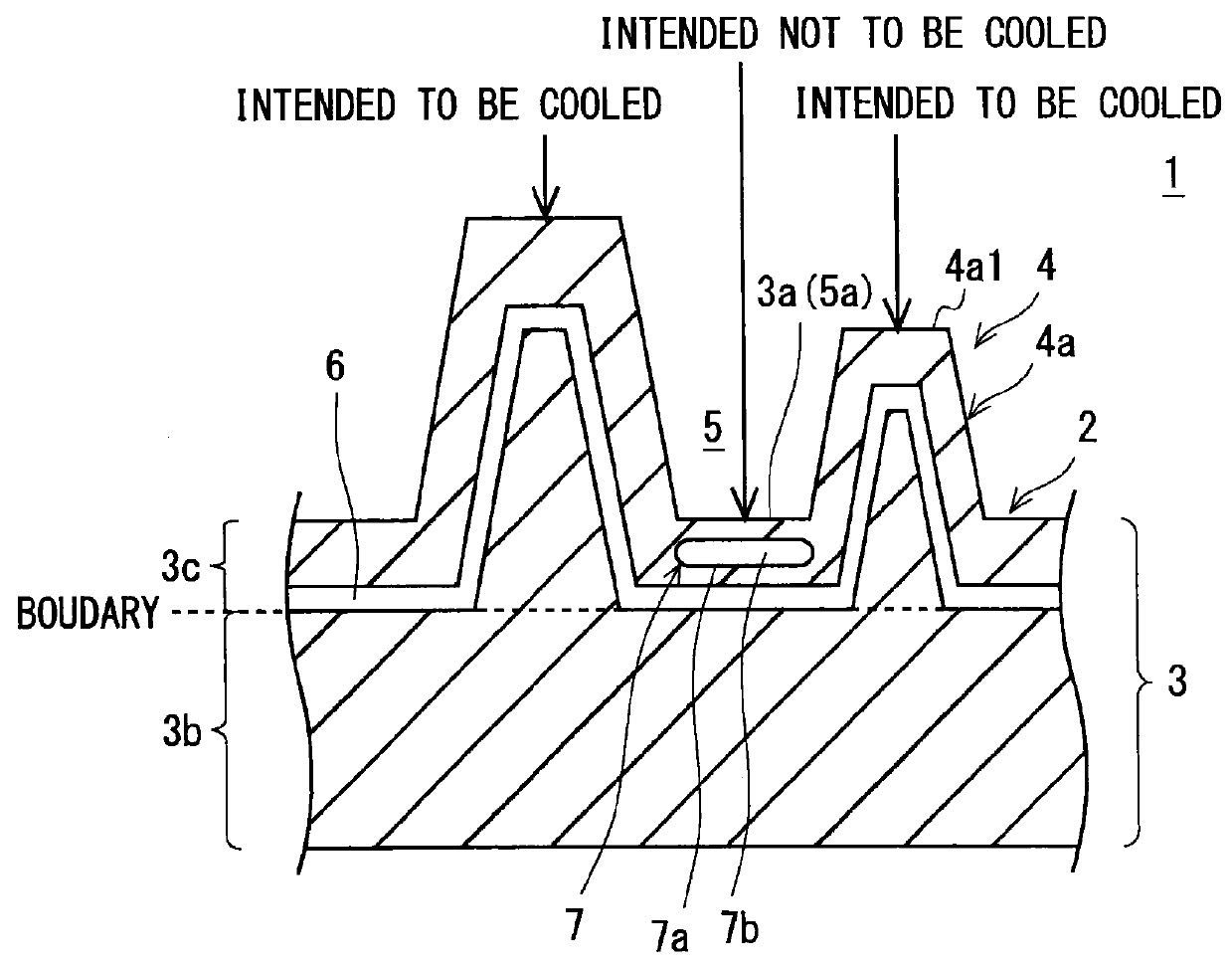

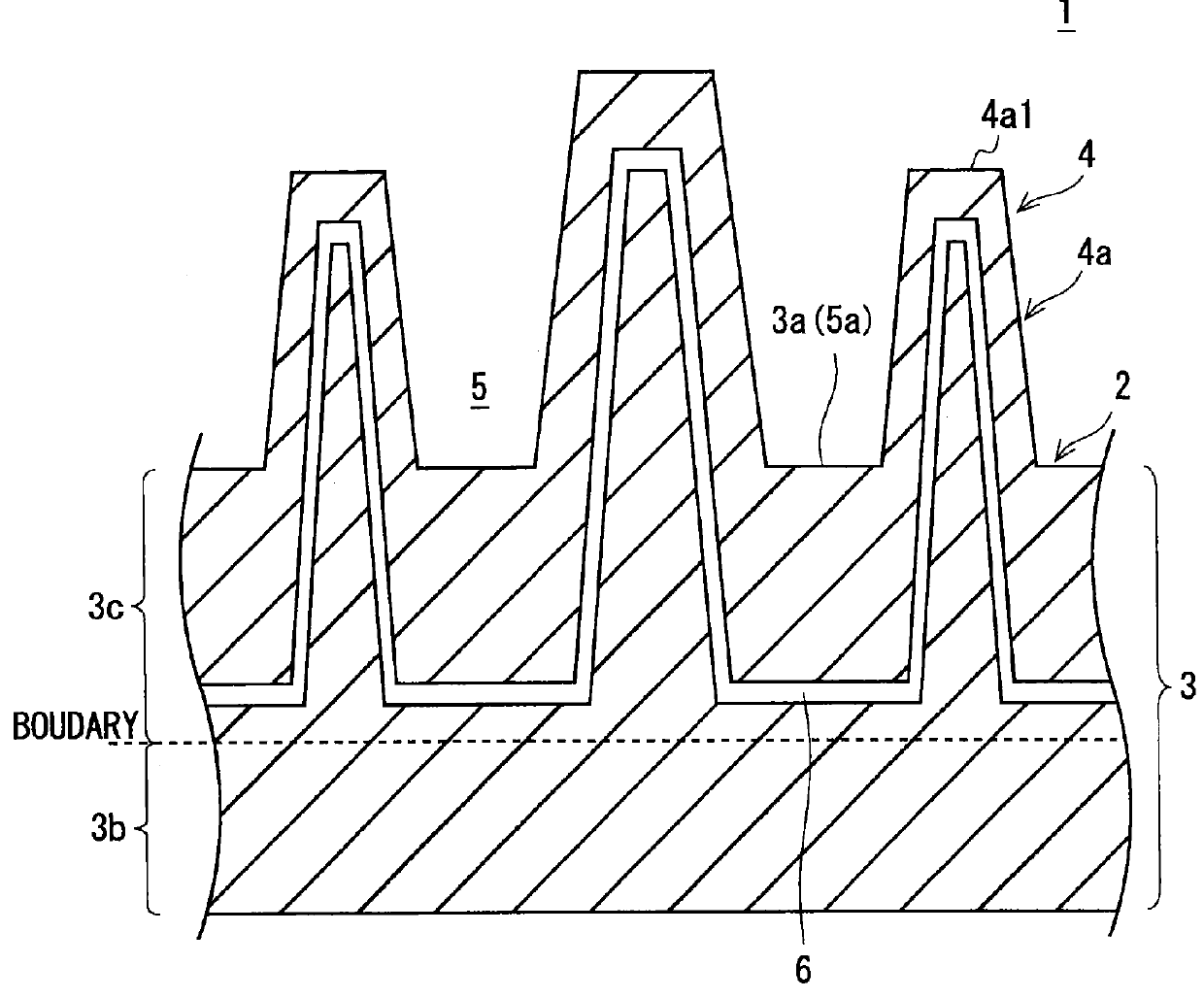

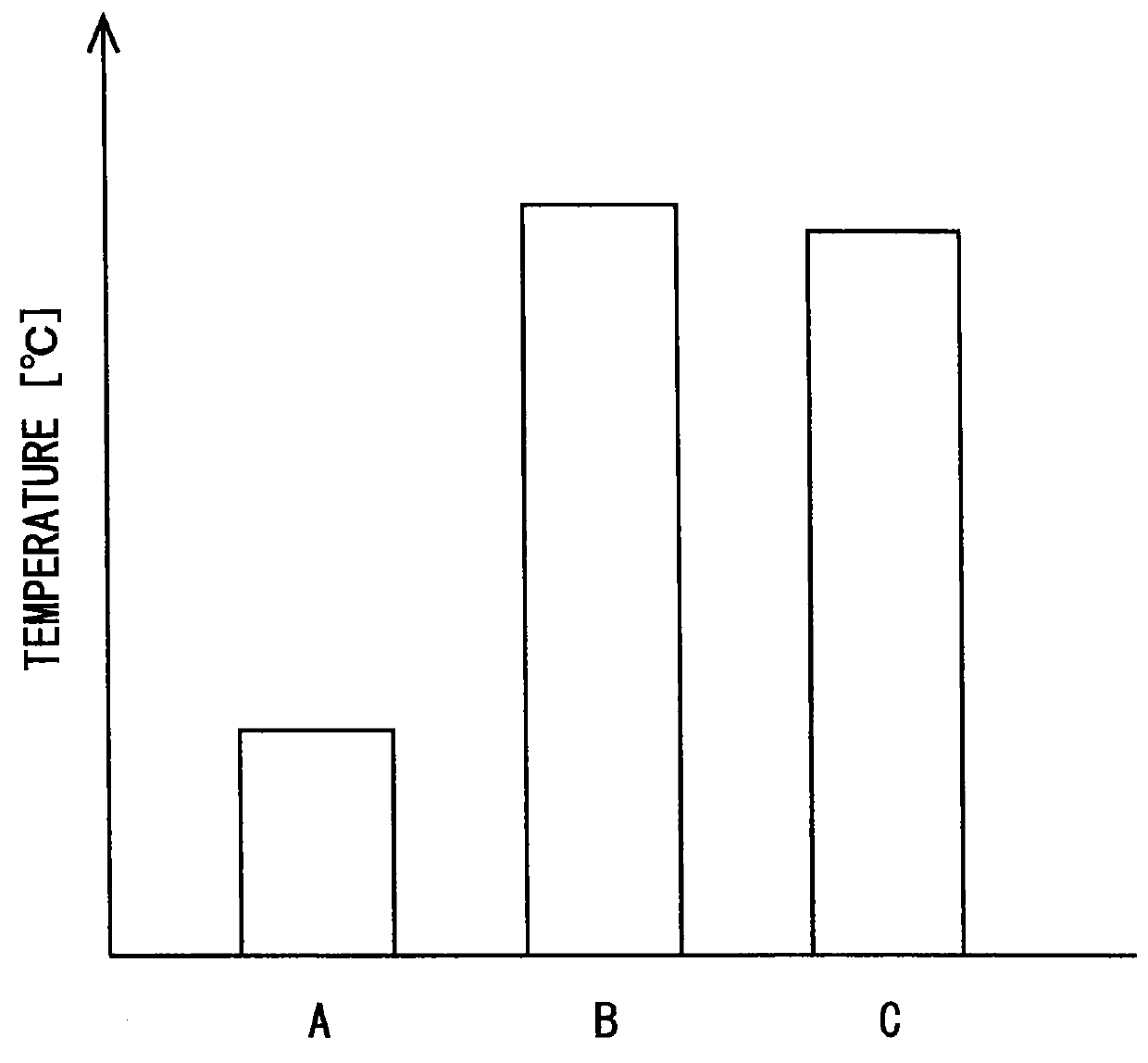

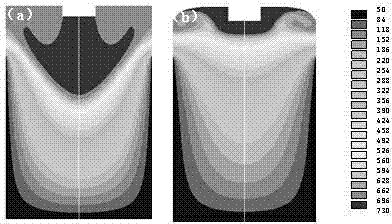

Mold

ActiveUS20160031121A1Easy to optimizeSuppress supercoolingAdditive manufacturing apparatusDomestic articlesCooling channelMaterials science

A mold capable of inhibiting supercooling is provided. A mold according to an exemplary aspect of the present invention includes a cooling channel formed therein and has a recess formed in a cavity surface. The mold includes a heat-insulating barrier formed between the cooling channel and a bottom surface of the recess formed in the cavity surface. The heat-insulating barrier includes a space formed between the cooling channel and the bottom surface of the recess formed in the cavity surface. The space is filled with a medium (for example, an air) having a thermal conductivity lower than that of other portions of the mold.

Owner:TOYOTA JIDOSHA KK

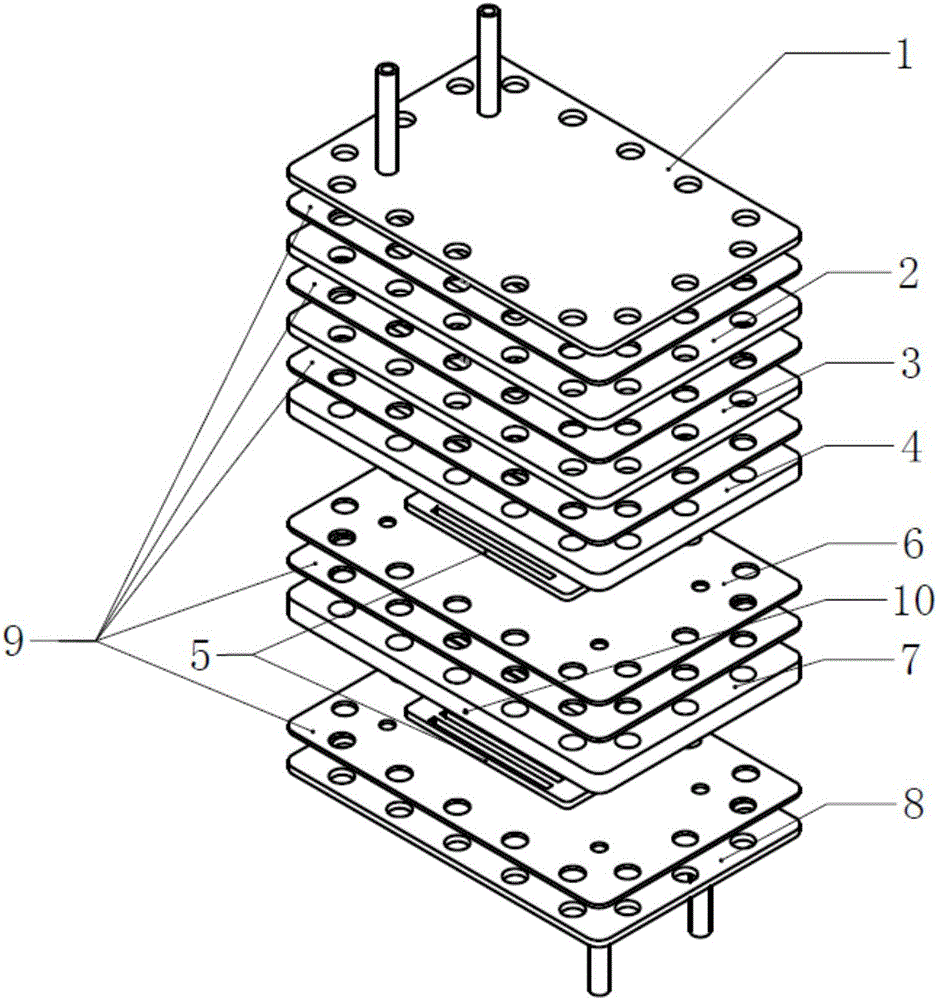

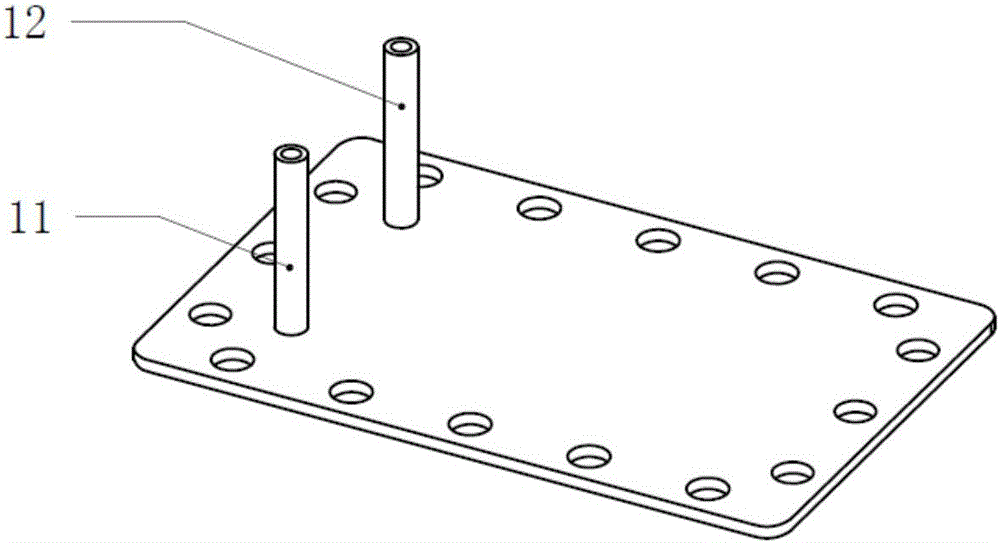

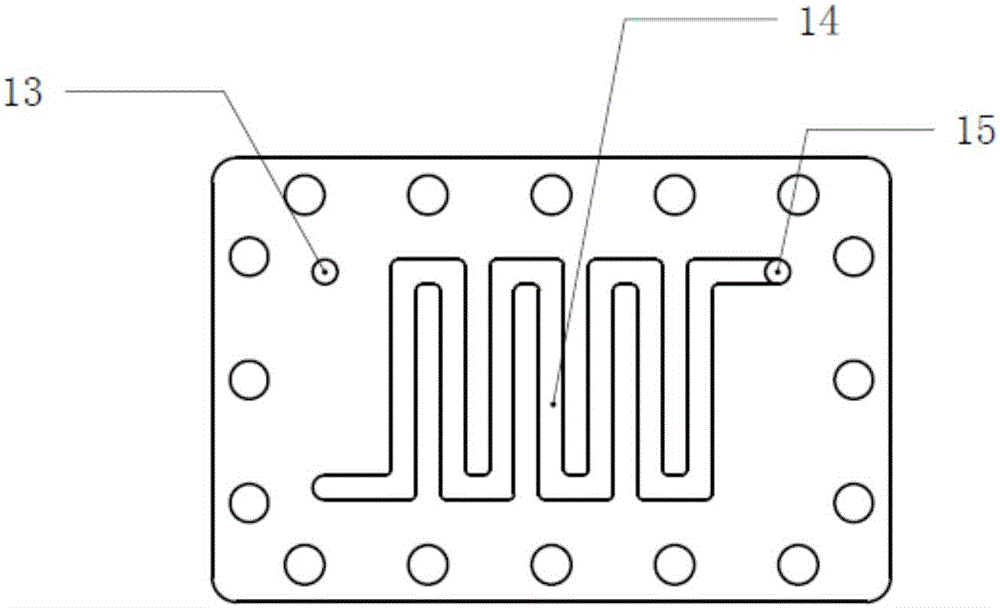

Self-heating type reactor used for hydrogen production by reforming and filled with high-temperature phase-change material

InactiveCN106629598AInhibition of excessive temperatureSuppress supercoolingHydrogenHydrogen/synthetic gas productionHeating efficiencyPhase-change material

The invention discloses a self-heating type reactor used for hydrogen production by reforming and filled with a high-temperature phase-change material. The self-heating type reactor used for hydrogen production by reforming is formed by sequentially laminating an upper cover plate provided with a methanol steam reforming reactant inlet pipe and a methanol catalytic combustion reactant inlet pipe on the upper surface, a graphite washer, an upper evaporation plate, a graphite washer, a lower evaporation plate, a graphite washer, a methanol reforming heat absorbing plate for hydrogen production filled with the high-temperature phase-change material on the lower surface, a sealing plate, a graphite washer, a methanol catalytic combustion plate filled with the high-temperature phase-change material on the lower surface, a graphite washer and a lower cover plate provided with a reformed gas outlet pipe and a combustion tail gas outlet pipe on the lower surface from top to bottom. The heat stability of a self-heating reactor is effectively improved by means of latent heat of phase change of the high-temperature phase-change material, the temperature gradient in the reactor and the temperature fluctuation of the reactor during working are reduced, catalyst activity reduction and peeling caused by overheating of the reactor are inhibited, and the heat efficiency and the methanol conversion rate of the reactor are improved.

Owner:ZHEJIANG UNIV

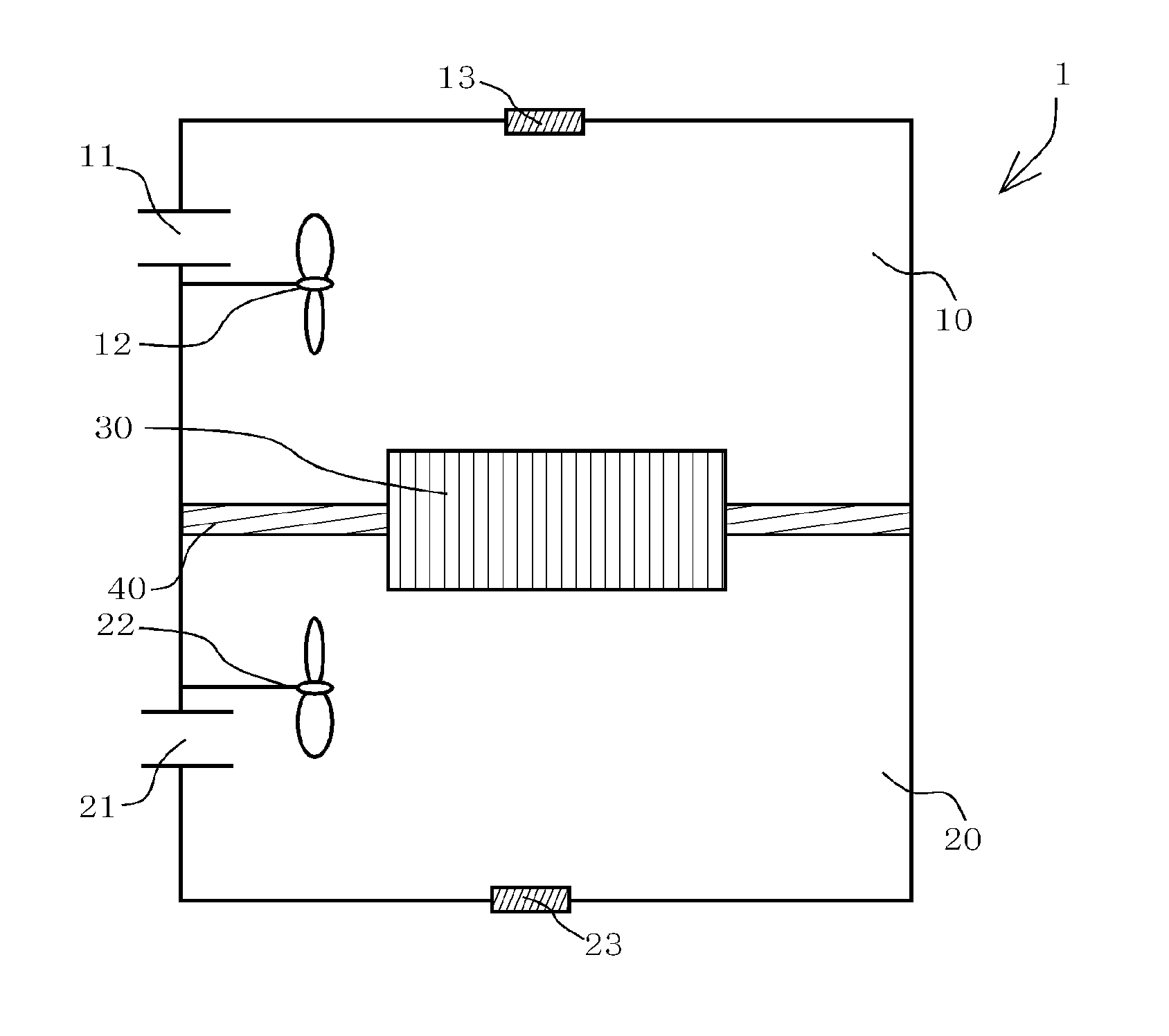

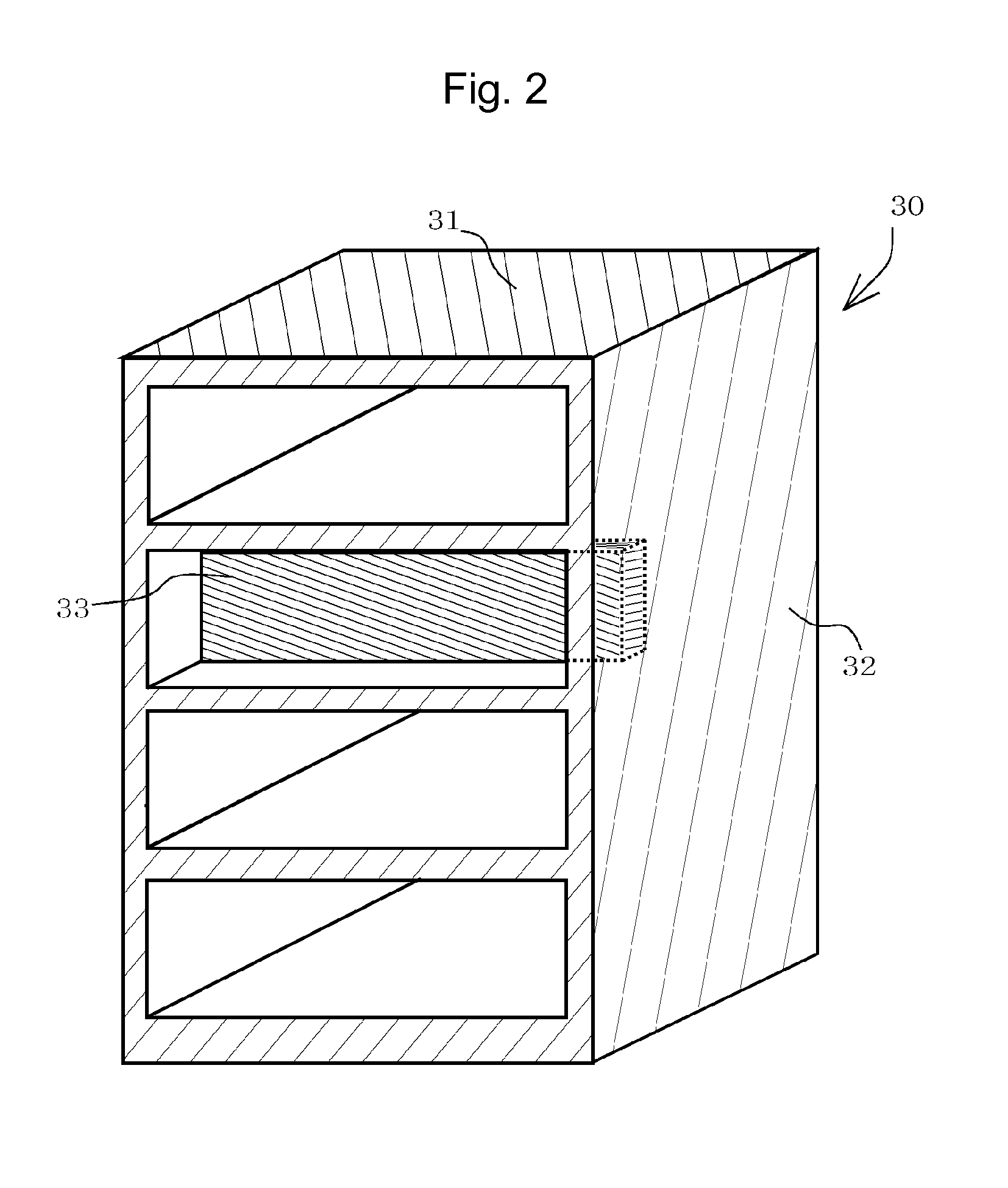

Data center and computer storing rack therefor

InactiveUS20120034860A1Reduce stepsReduce the burden onDigital data processing detailsCasings/cabinets/drawers detailsData centerComputer data storage

The problem for the present invention is to provide a data center that can allow computers such as servers or the like to be operated stably and that can greatly reduce energy consumption during operation, and a rack for storage of computers to be used therein. According to the present invention, a data center 1 is provided as a building for installation and operation of computers, and includes an intake area 10 provided with an intake device that sucks external air into the building, an exhaust area 20 provided with an exhaust device that discharges air to the exterior of the building, a dividing wall 40 that separates the intake area 10 from the exhaust area 20, a rack 30 for computer storage installed so as to pierce through a portion of the dividing wall 40, and an air flow control means that controls air flow so that air in the intake area 10 passes through the rack for computer storage 30 and flows to the exhaust area 20.

Owner:OKADA RYOSUKE +1

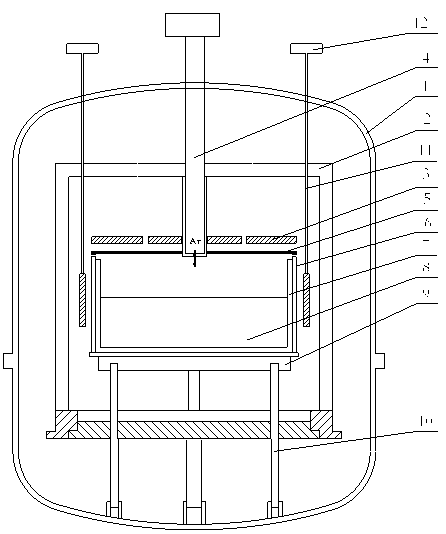

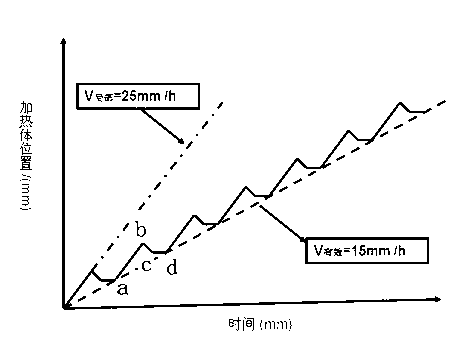

Low-carbon quasi-single crystal ingot furnace and method for adopting low-carbon quasi-single crystal ingot furnace for ingot casting

InactiveCN102703969AReduce carbon contentEliminate latencyPolycrystalline material growthFinal product manufactureMetallurgyIngot casting

The invention discloses a low-carbon quasi-single crystal ingot furnace and a method for adopting the low-carbon quasi-single crystal ingot furnace for ingot casting. The low-carbon quasi-single crystal ingot furnace comprises a furnace body (1), a heat insulation cage (2) and a heat exchange table (9), wherein a crucible (7) is placed on the heat exchange table (9), the top of the crucible (7) is provided with heaters A (3), and heaters B (8) are distributed at the circumference of the crucible (7) and are connected with traction devices (12) through heater lifting rods (11). The method comprises five steps including material charging, heating melting, crystal growth, annealing and cooling. The low-carbon quasi-single crystal ingot furnace and the method have the advantages that the ingredient supercooling phenomenon caused by carbon content enriching in a solute boundary layer can be effectively inhibited, so the influence on the growth speed of quasi-single crystals caused by impurity enriching is reduced, and meanwhile, the content of carbon in quasi-single crystal ingots can be effectively reduced; and the generation and the growth of the fine crystal regions near the crucible wall can be effectively inhibited, so the quality of the quasi-single crystal ingots can be obviously improved, and the utilization rate of the ingots is improved.

Owner:TIANWEI NEW ENERGY HLDG +1

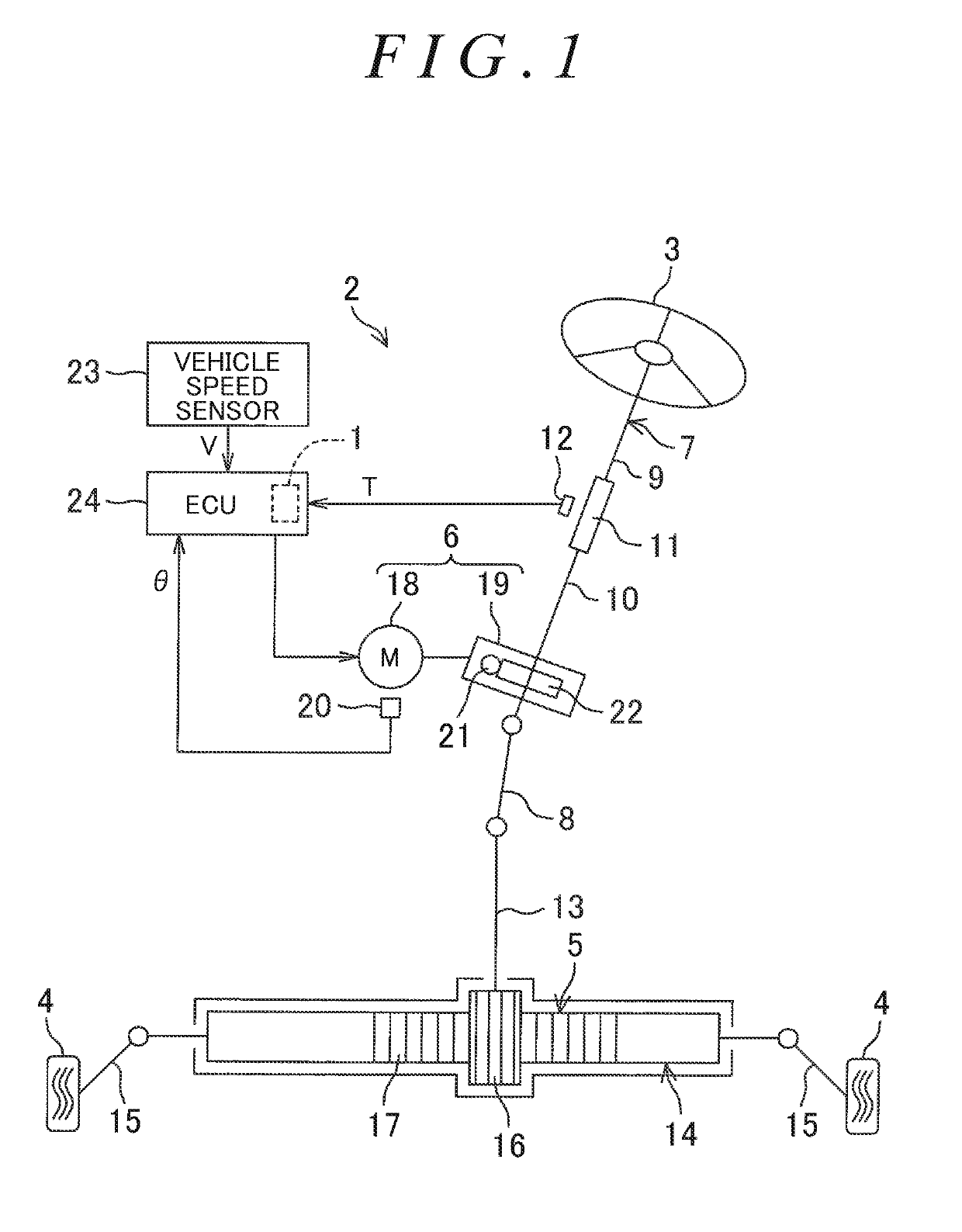

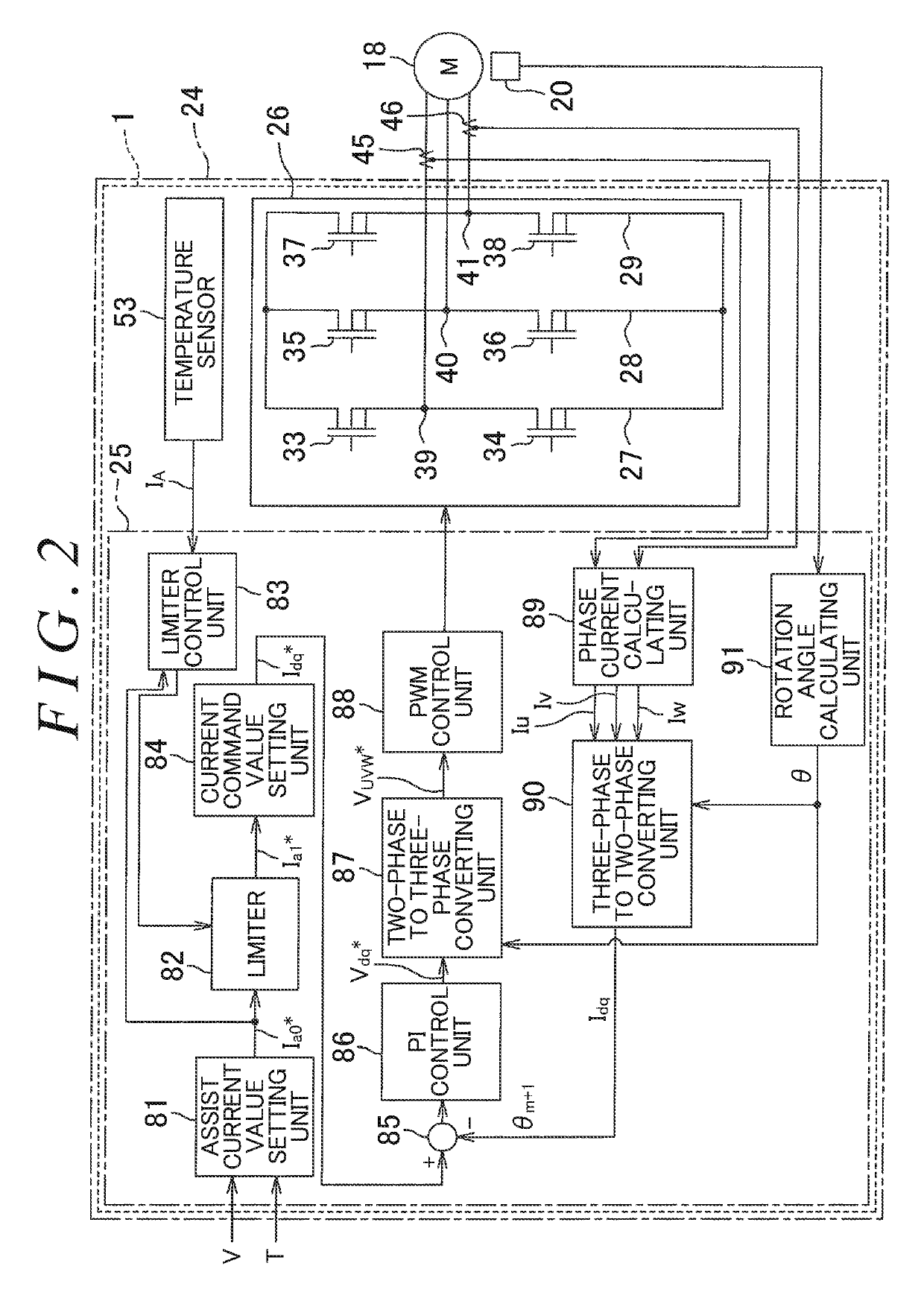

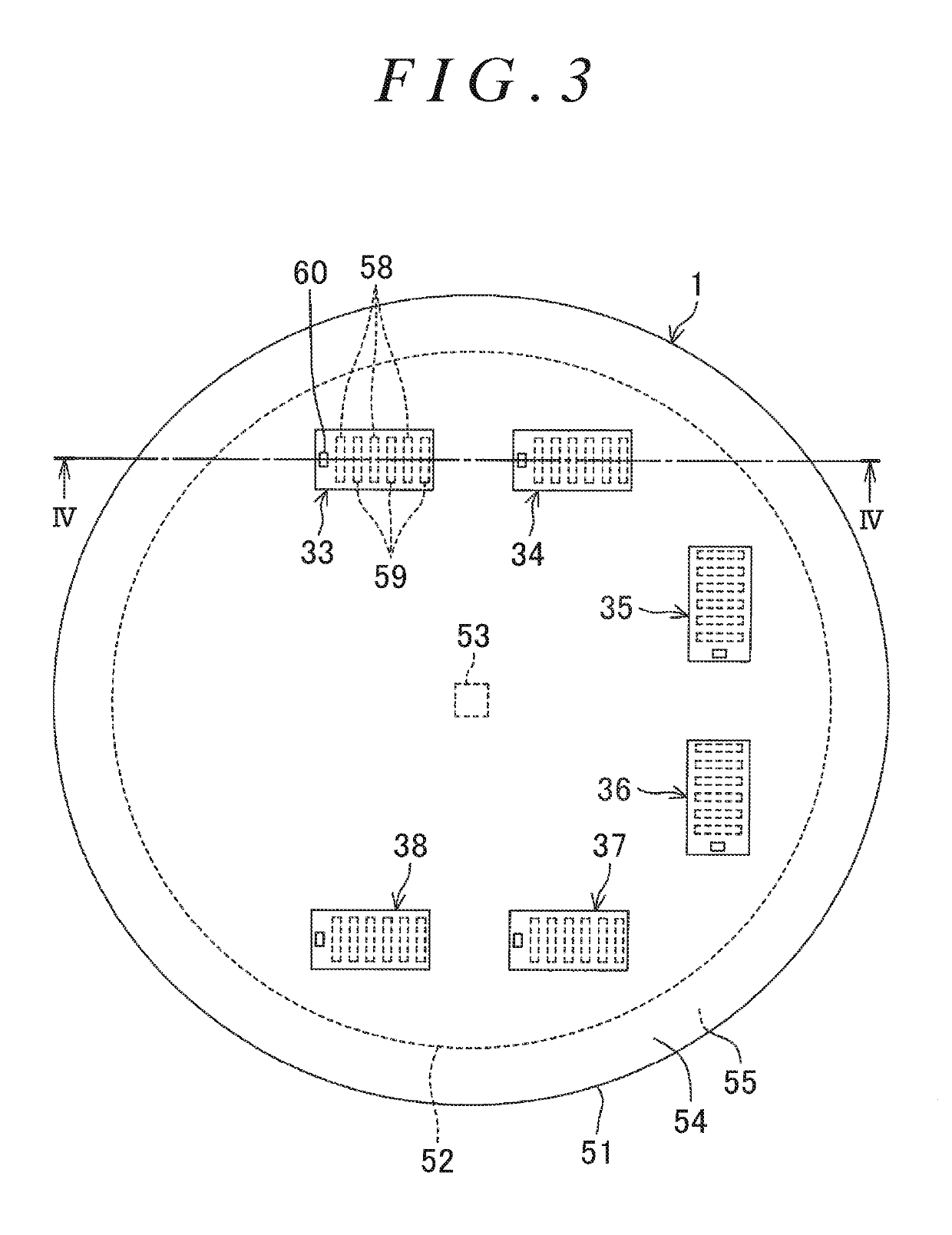

Inverter device

InactiveUS20190173406A1Suppress supercoolingAC motor controlVector control systemsMicrocomputerLatent heat storage

An inverter device includes a radiator that includes a latent heat storage material transitioning between a solid phase region, a phase transition region, and a liquid phase region, in accordance with a temperature of the latent heat storage material, and that absorbs heat generated in switching elements, a temperature sensor that detects the temperature of the latent heat storage material, and a microcomputer. The microcomputer includes a determining unit that determines whether a condition is satisfied, the condition being that the temperature of the latent heat storage material is close to a melting point of the latent heat storage material, and that the temperature of the latent heat storage material is on a rising trend, and a supercooling suppressing unit that limits a motor current when the determining unit determines that the condition is satisfied.

Owner:JTEKT CORP

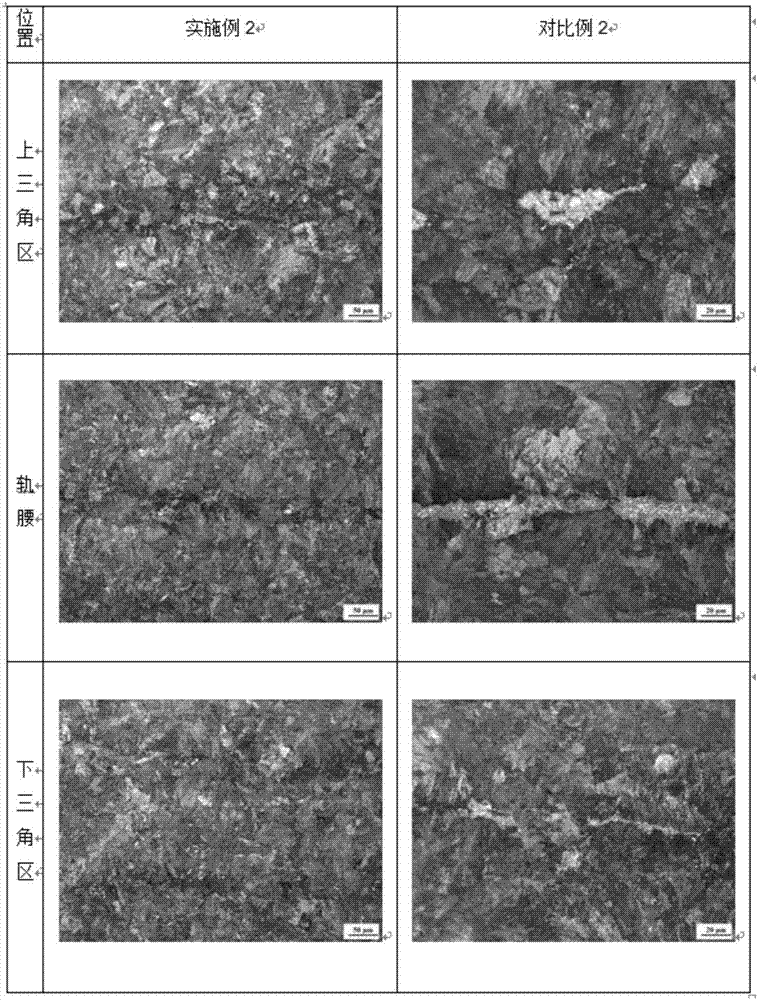

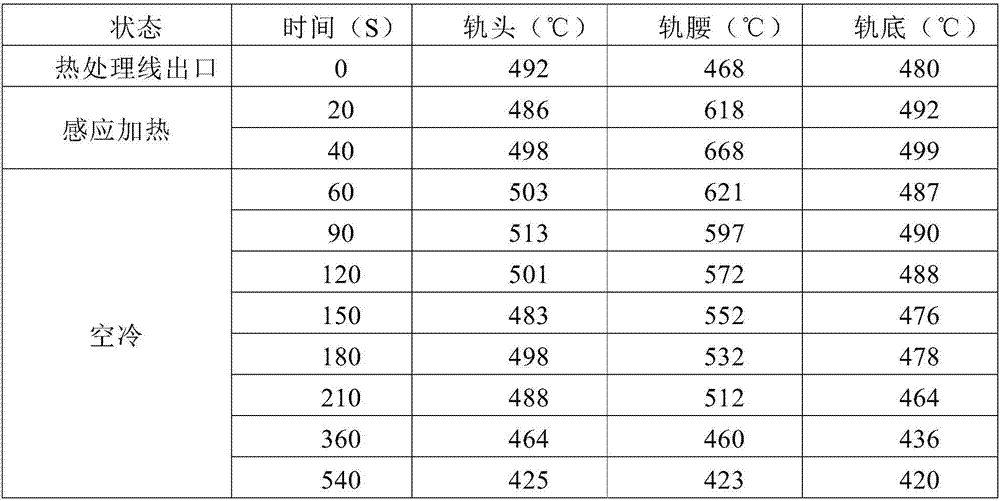

Steel rail online induction heating control method

InactiveCN107988464AElimination of abnormal tissueReduce stressFurnace typesIncreasing energy efficiencyTemperature differenceMartensite

The invention discloses a steel rail online induction heating control method. The steel rail online induction heating control method comprises the steps that induction heating is implemented to the steel rail web portion discharged out of the heat treatment line, and the heating temperature of the steel rail web portion ranges from 600 to 680 DEG C. According to the steel rail online induction heating control method, steel rail production is carried out, through the rail web compensation heating, the overcooling degree of the steel rail after online heat treatment is restrained, the staying time of the steel rail on the pearlite transition area can be prolonged, and generation of an abnormal martensite structure is avoided; through the rail web heating control, the temperature difference between the rail head and the rail bottom can be coordinated, the steel rail inner stress can be reduced, the steel rail straightening cracking risk is reduced, and the inner stress after steel rail straightening can be reduced. The method is easy and feasible and suitable for industrial production.

Owner:BAOTOU IRON & STEEL GRP

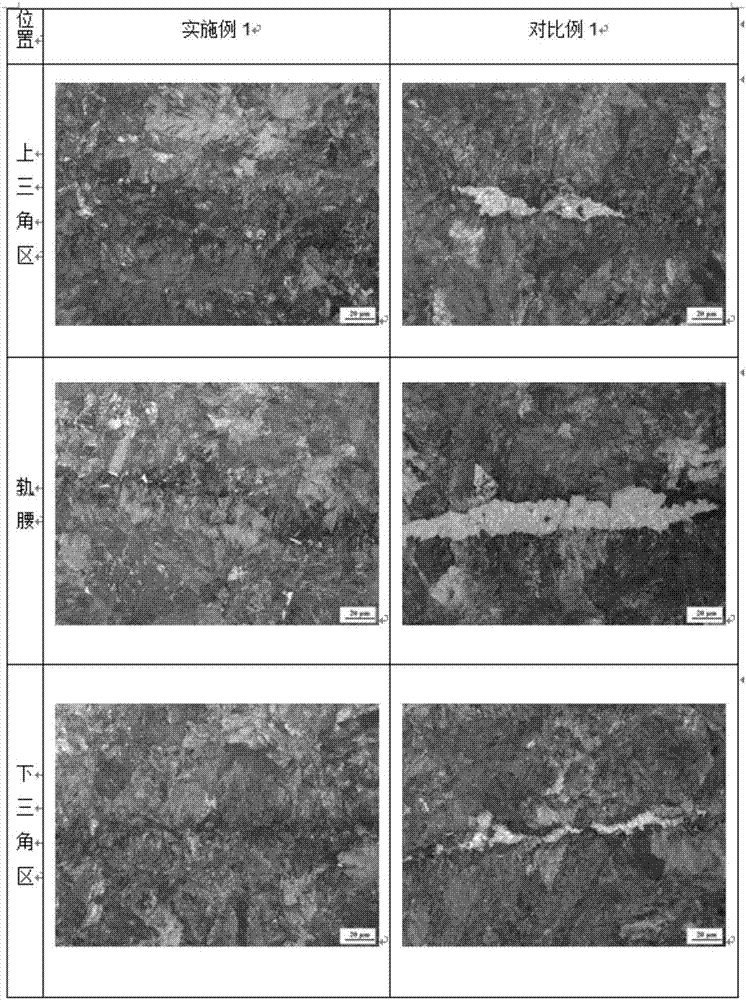

A kind of silicon nitride modified phase change energy storage microcapsule and preparation method thereof

ActiveCN103805142BFast heat conductionEasy to makeHeat-exchange elementsMicroballoon preparationPhase changeControllability

The invention discloses a silicon nitride-modified phase-change and energy-storage microcapsule, comprising a shell material and a cladded core material, wherein the shell material comprises the following raw materials in parts by weight: 50-100 parts of high-molecular polymers and 1-20 parts of silicon nitride powder which is evenly dispersed into the high-molecular polymers; the core material comprises 50-100 parts of organic phase-change and energy-storage materials and 1-20 parts of silicon nitride powder which is evenly dispersed into the organic phase-change and energy-storage materials. The invention also provides a preparation method of the phase-change energy-storage microcapsule. The thermal conductivity of the phase-change and energy-storage material is improved, overheat and overcold degrees in the phase-change process are inhibited, and meanwhile, the thermal endurance and the abrasive resistance, the thermal shock resistance, the fatigue resistance and the like also are improved. The silicon nitride-modified phase-change and energy-storage microcapsule is relatively simple in preparation technology, available in raw materials, strong in controllability, and applicable to the industrial large-scale production, an existing industrial processing technology can be fully utilized, and the performance of the phase-change and energy-storage microcapsule is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A kind of phase change material, its preparation method and use

ActiveCN107267123BImprove thermal conductivityHigh energy storage densityPhotovoltaicsHeat-exchange elementsVacuum pumpingPhotoelectric conversion

The invention belongs to the technical field of preparation of phase change energy storage materials, and concretely relates to a phase change material, and a preparation method and a use thereof. The phase change material comprises an energy storage material and a crystallized porous metal organic material. The preparation method of the phase change material comprises the following steps: mixing the energy storage material with the porous metal organic material, carrying out vacuum pumping at 80-200 DEG C until the pressure is 0-0.08 MPa, and carrying out ultrasonic treatment for 20-100 min to obtain the target phase change material. The phase change material prepared in the invention has the advantages of good stability, no supercooling phenomenon, large energy storage density and good heat conduction property, and can improve the photoelectric conversion efficiency by 20% when applied to photoelectric conversion devices.

Owner:天津启能新能源科技有限公司

Anti-ultraviolet type phase-change material nano-capsule and preparation method thereof

InactiveCN107936929ASuppress supercoolingReduce subcoolingHeat-exchange elementsTextile fiberPolymer science

The invention belongs to the technical field of a phase-change material nano-capsule, and in particular discloses an anti-ultraviolet type phase-change material nano-capsule and a preparation method thereof. In the anti-ultraviolet type phase-change material nano-capsule, a combined body of n-octadecane and nanometer stibium doped tin dioxide serves as a core material, and a copolymer of styrene and methylacrylic acid octadecyl ester or a copolymer of methyl methacrylate and methylacrylic acid octadecyl ester serves as a wall material. The anti-ultraviolet type phase-change material nano-capsule prepared by the method has the function of absorbing ultraviolet rays while realizing heat storage and temperature control and having low supercooling degree, solves the problems that the phase-change material nano-capsule encounters supercooling in actual application and is liable to age when being subjected to ultraviolet irradiation, and is widely applied in the fields of textile fiber, fabric, building coating and the like.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Heat exchanger

ActiveUS20170036507A1Reduce heat resistance requirementsContainment leakAir-treating devicesHeat storage plantsEngineeringPhase transition temperature

A heat exchanger has (i) a first passage in which a first fluid flows, (ii) a heat storage body that is thermally connected to the first passage and stores a warm heat or a cold heat, and (iii) a second passage that is thermally connected to both of the first passage and the heat storage body, the second passage in which a second fluid flows. The heat storage body changes to a first phase in a solid state when a temperature of the heat storage body is lower than or equal to a phase transition temperature, and changes to a second phase in a solid state when the temperature of the heat storage body exceeds the phase transition temperature. The heat storage body stores or dissipates heat depending on a phase transition between the first phase and the second phase.

Owner:DENSO CORP

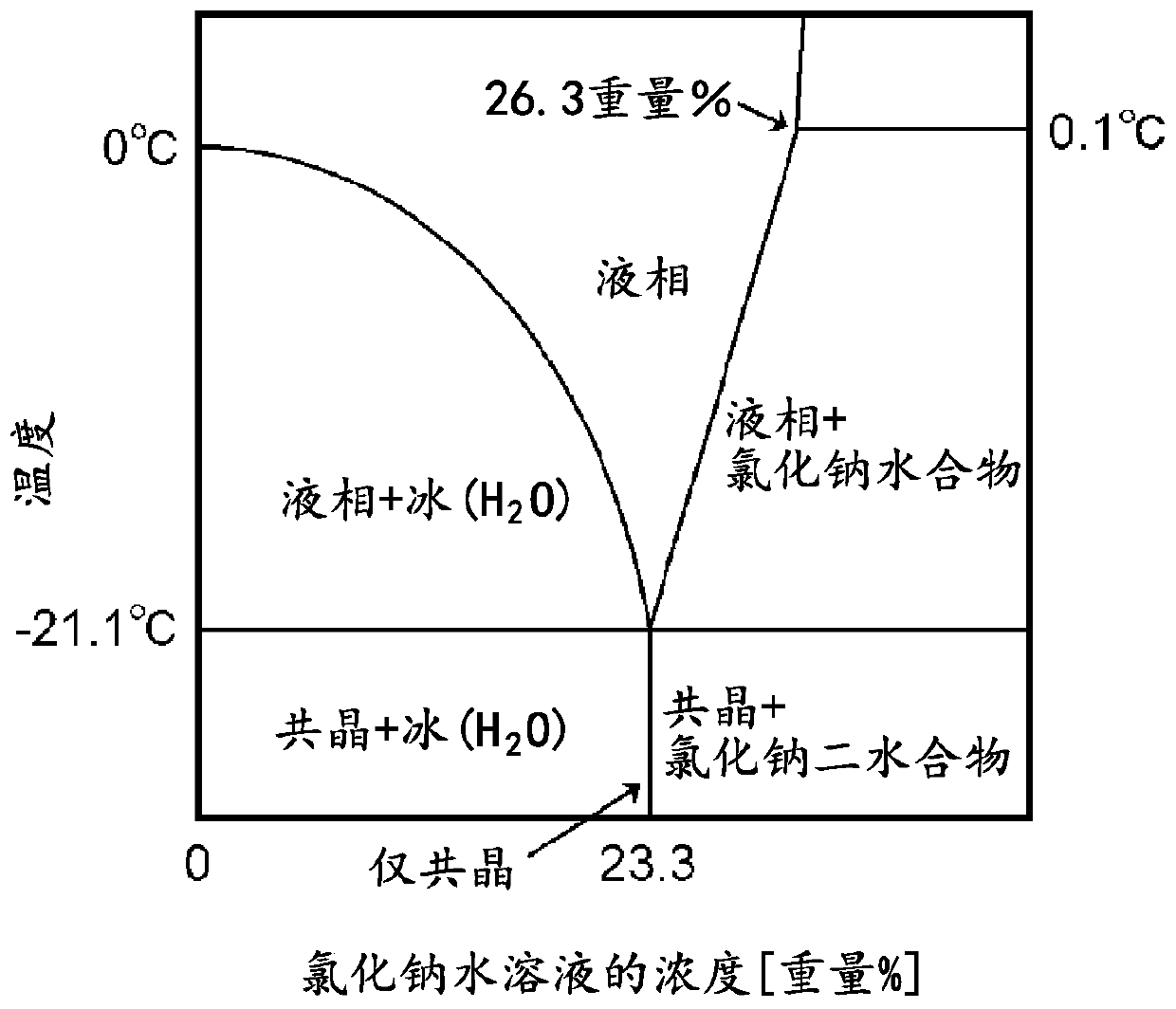

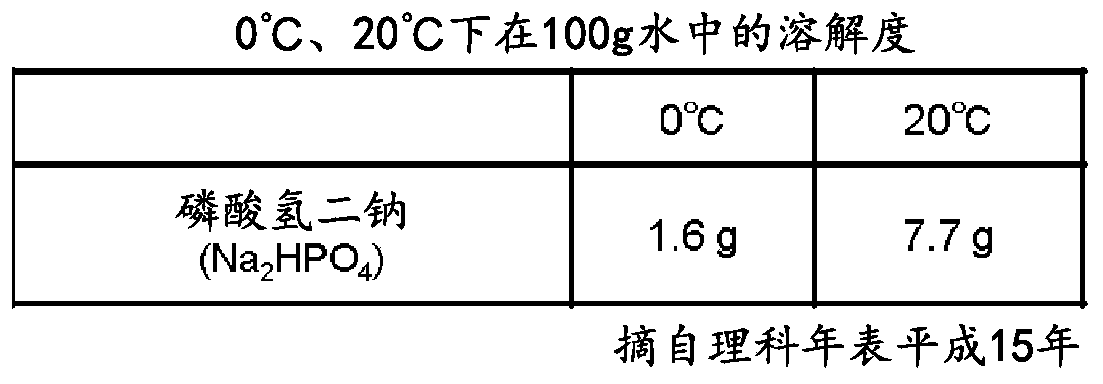

Latent-heat storage material, cooling tool, cooler box, distribution packaging container, and cooling unit

InactiveCN110945101ASuppress supercoolingLow melting pointDomestic cooling apparatusHeat storage plantsInorganic saltsThermodynamics

Provided is a latent-heat storage material containing a supercooling inhibitor which, when contained in an aqueous inorganic-salt solution containing sodium chloride, can separate out as crystals without fail upon cooling to inhibit supercooling and the inclusion of which little lowers the melting point or the quantity of latent heat. The latent-heat storage material contains an aqueous sodium chloride solution and comprises: the aqueous sodium chloride solution having a eutectic concentration; and disodium hydrogen phosphate contained in an amount not less than the saturation concentration at0 DEG C in the aqueous sodium chloride solution having the eutectic concentration. Due to this, the use of the latent-heat storage material containing the supercooling inhibitor, which can separate out as crystals without fail upon cooling to inhibit supercooling and the inclusion of which little lowers the melting point or the quantity of latent heat, makes it possible to keep cool by means of sufficient quantity of latent heat while inhibiting supercooling.

Owner:SHARP KK

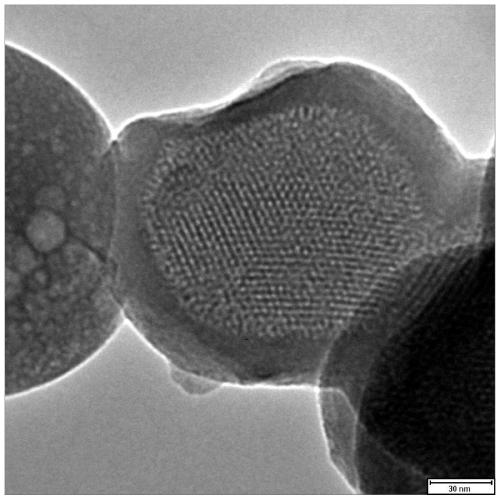

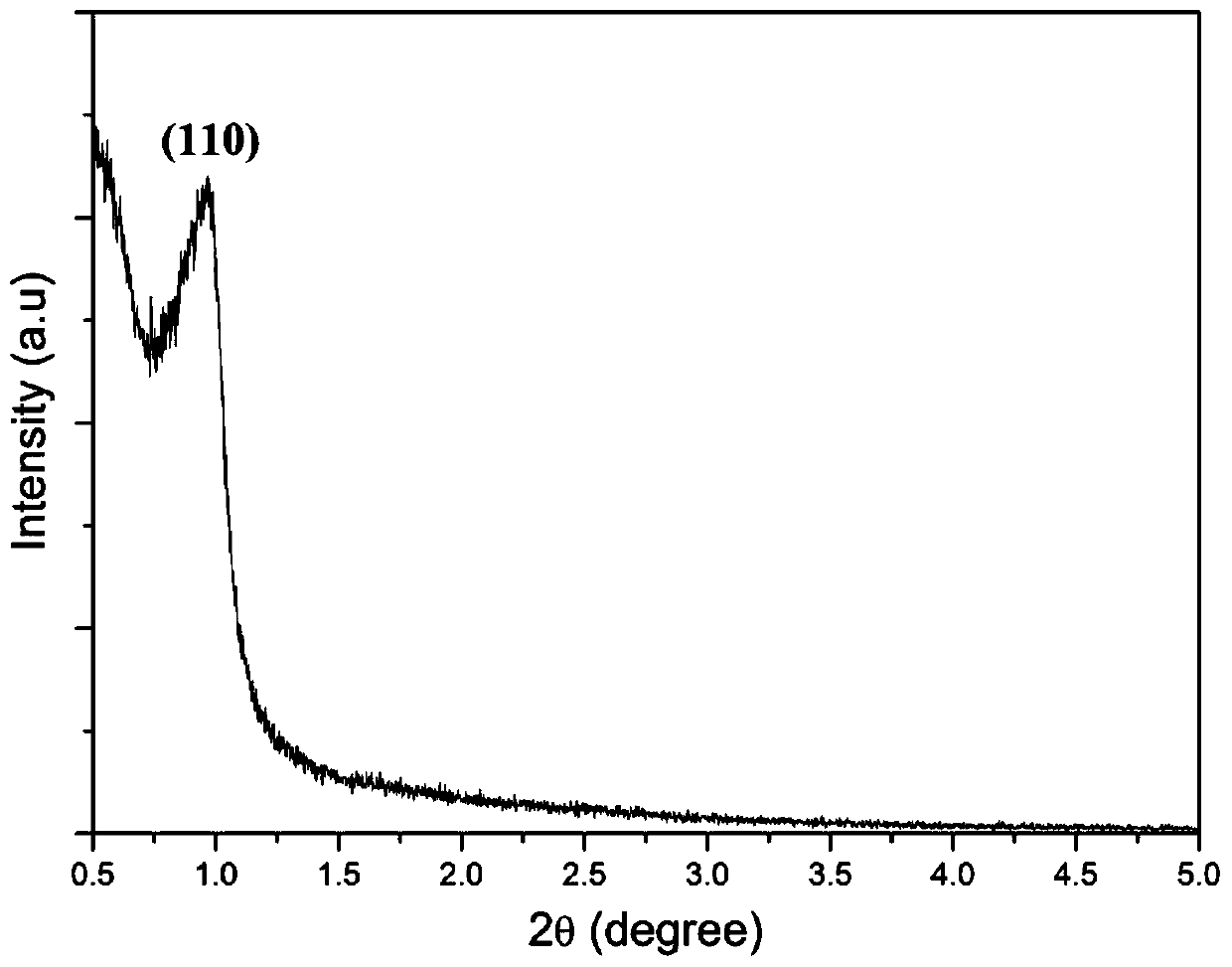

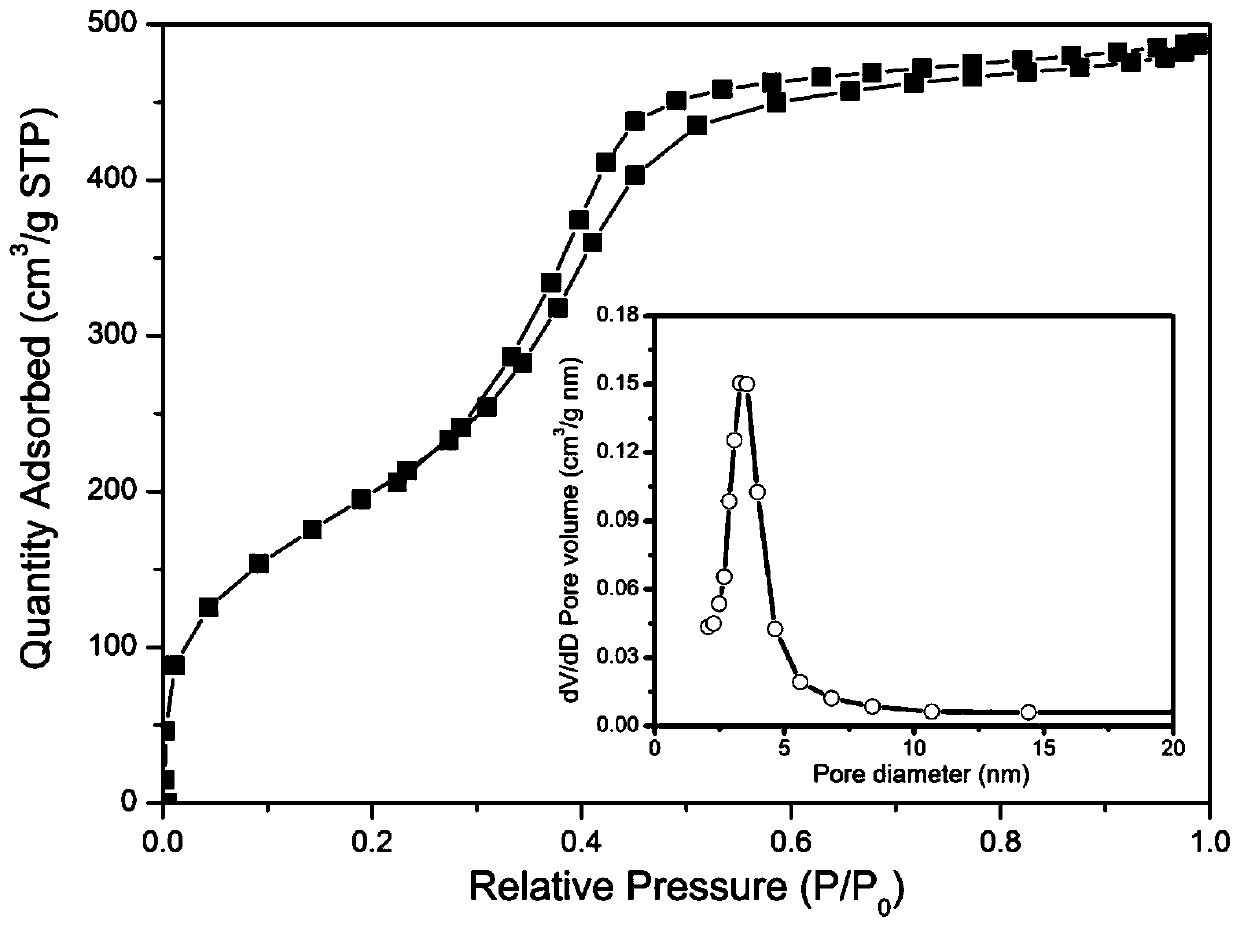

A "core-shell" mesoporous silica/organic phase change material composite nanocapsule and its preparation method

ActiveCN109468122BFast heat conductionIncrease speedMaterial nanotechnologyHeat-exchange elementsActive agentMesoporous silica

Owner:BEIJING UNIV OF CHEM TECH

A composite phase change heat storage material

ActiveCN104140786BHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Cooling system for on-board secondary battery

ActiveCN106042946BSuppress discomfortSuppress supercoolingPropulsion using engine-driven generatorsSecondary cellsElectrical batteryOn board

A cooling system for an on-vehicle secondary battery, when the battery temperature (TB) of the main battery 10 reaches a first temperature (T0) or higher after the start of the hybrid vehicle, the cooling fan is driven at a first command value for a predetermined period of time (40) The first fixed control of the fixed control, and the abnormality detection process of detecting whether the cooling fan (40) is abnormal based on the actual rotation speed of the cooling fan (40) during the fixed control, and in addition, when the battery temperature (TB) of the main battery (10) reaches When the first temperature (T0) is above and the first fixed control is prohibited due to a predetermined condition, if the noise level in the vehicle interior reaches a predetermined value (Lo) or above, the cooling fan is driven at a second command value (D3) ( 40) of the second fixed control, and abnormality detection processing is performed based on the actual rotation speed of the cooling fan (40) during the second fixed control. Thereby, it is possible to sufficiently secure a chance to detect whether or not there is an abnormality in the cooling fan while suppressing discomfort to the occupants and overheating of the secondary battery.

Owner:TOYOTA JIDOSHA KK

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

Supercooling phase change-inhibiting alkane microcapsule and preparation and application thereof

ActiveCN102391839BSuppress supercoolingNot easy to reuniteHeat-exchange elementsCoatingsAlkaneEmulsion

Owner:响水县中博纺织有限公司

A kind of cooling device and terminal electronic equipment

ActiveCN110494016BHigh energy storage densityImprove cooling effectDigital data processing detailsModifications using liquid coolingRefrigerationElectronic equipment

The embodiment of the invention provides a heat dissipation device and terminal electronic equipment, and relates to the technical field of heat dissipation; the heat dissipation device is used for dissipating heat of a heating source of the terminal electronic equipment, and the heat dissipation device comprises a hydrated salt phase change material and a refrigeration unit which is in contact with the hydrated salt phase change material and refrigerates the hydrated salt phase change material; and a heat transfer unit is included and used for conducting heat of the heating source to the hydrated salt phase change material.

Owner:HUAWEI TECH CO LTD

Secondary cooling device and secondary cooling method of continuous casting machine

ActiveCN103842113BThe heat transfer coefficient does not increaseSuppress mutual interferenceContinuous castingNozzle

This secondary cooling device for a continuous casting machine is provided with a plurality of pairs of support roller and a plurality of nozzles, and each support roller has: a plurality of roller sections split in the widthwise direction of a cast strand; and grooves provided between the roller sections. The grooves provided to each upstream-side support roller and downstream-side support roller adjacent in the direction of conveyance are disposed offset from each other in the widthwise direction. A first nozzle among the plurality of nozzles is disposed at a first nozzle position set between a roller section provided to an upstream-side support roller and a groove provided to a downstream-side support roller.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com