Patents

Literature

45results about How to "Wide phase transition temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

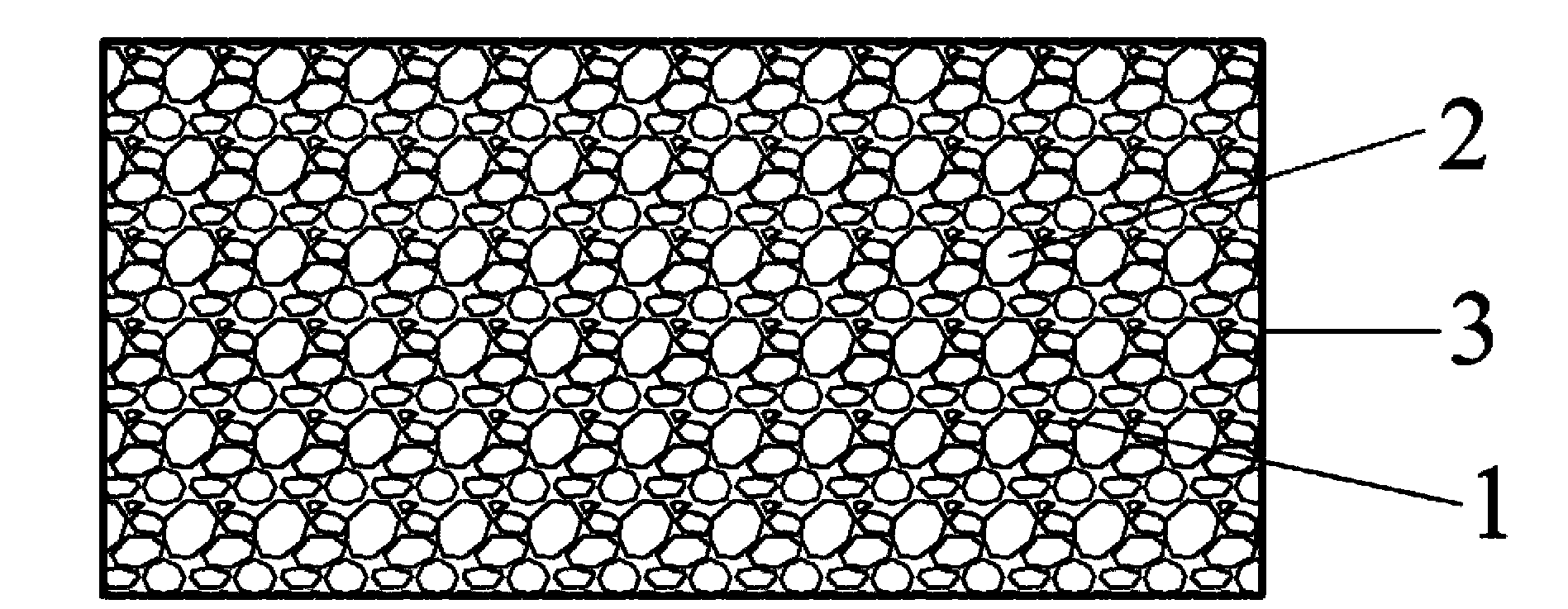

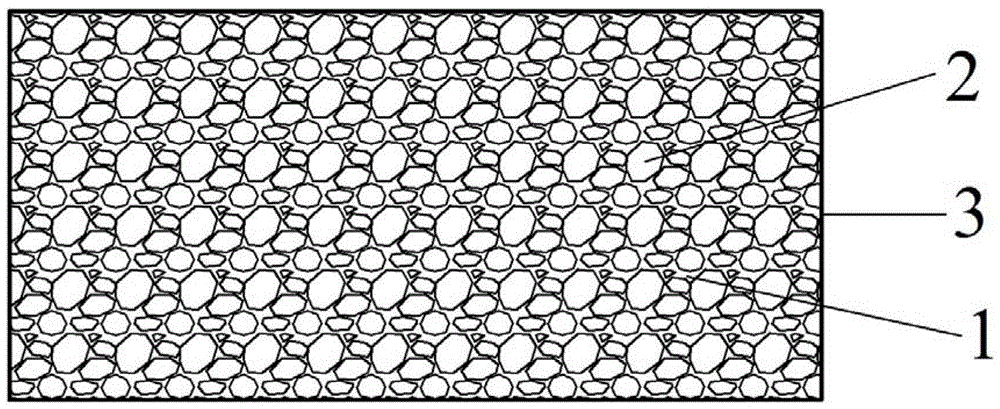

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

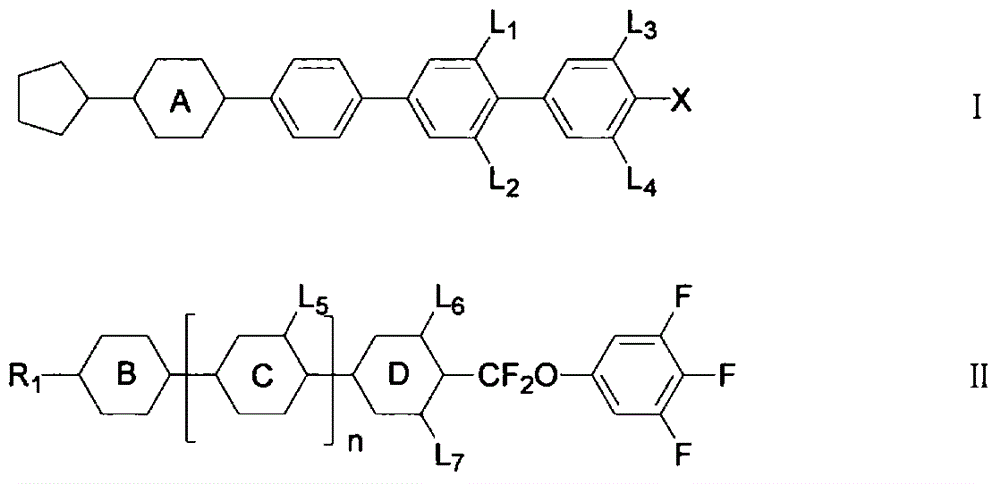

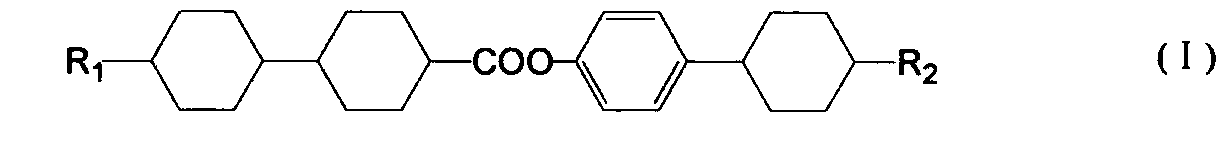

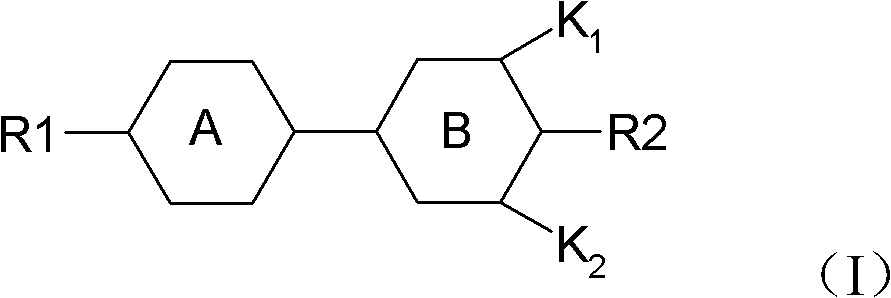

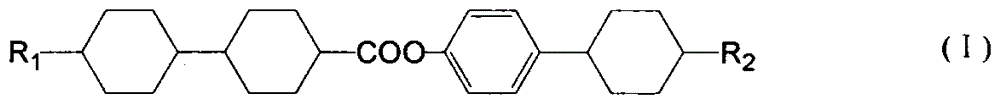

Liquid crystal composition and liquid crystal lens

ActiveCN102352260ALow Nematic Phase Onset VoltageWide phase transition temperature rangeLiquid crystal compositionsNon-linear opticsDielectric anisotropyVoltage

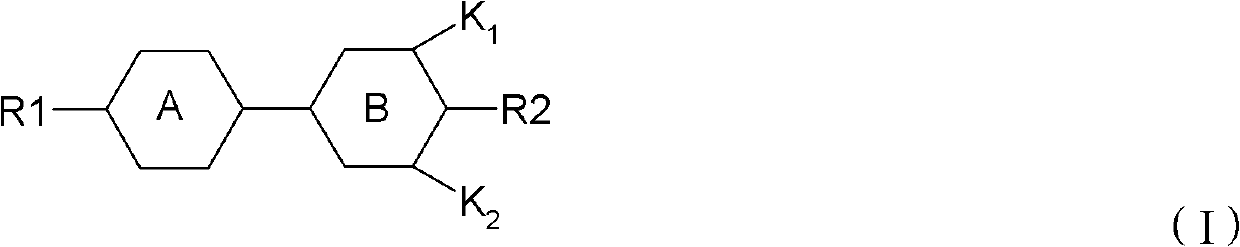

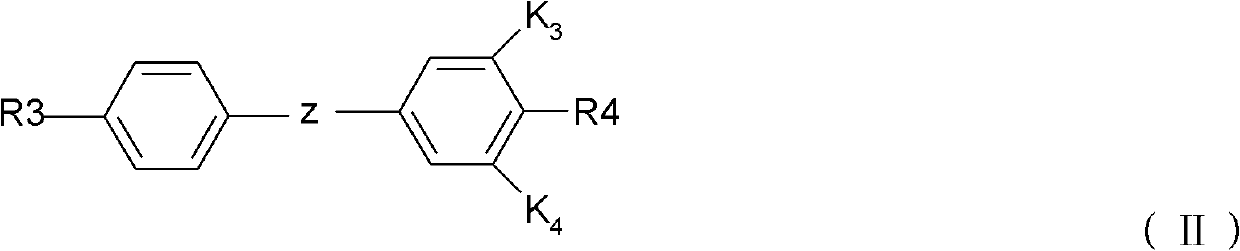

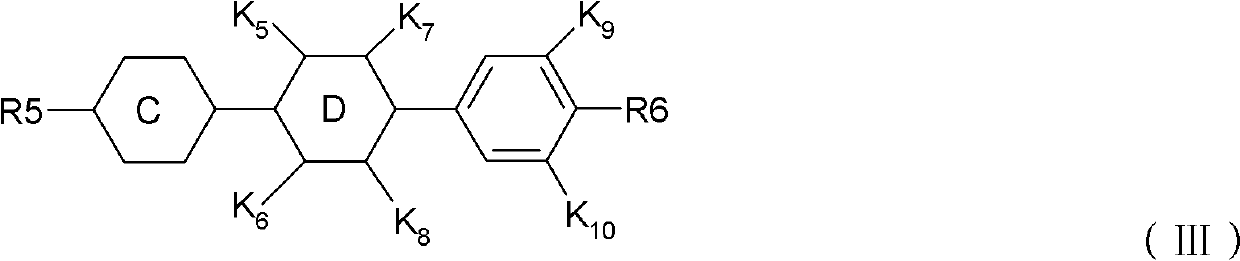

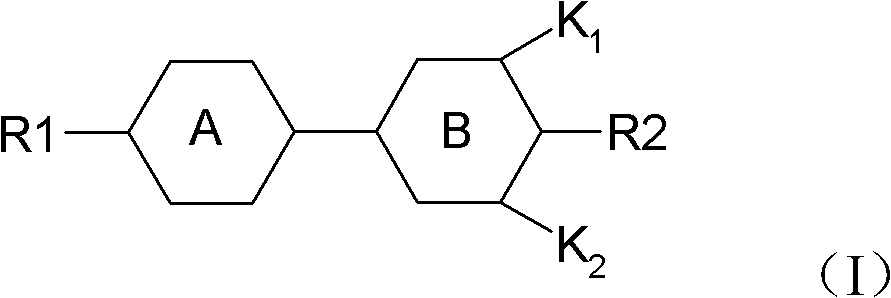

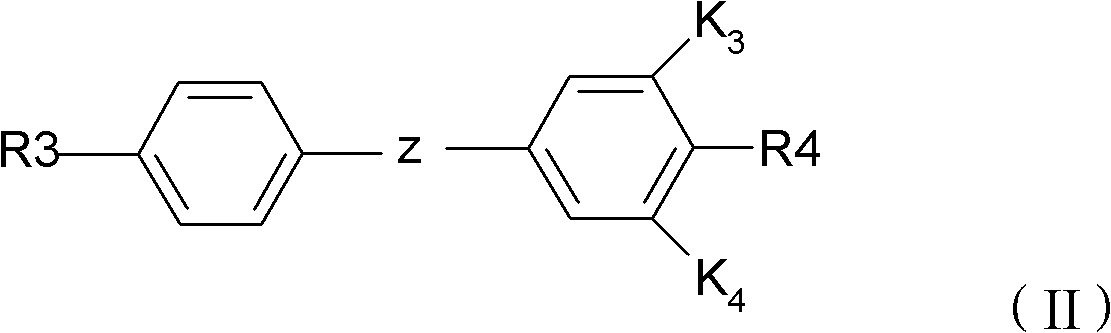

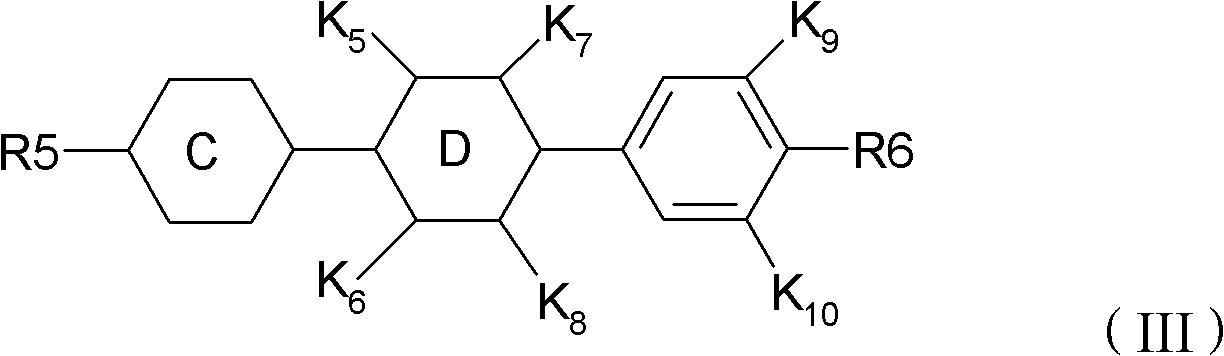

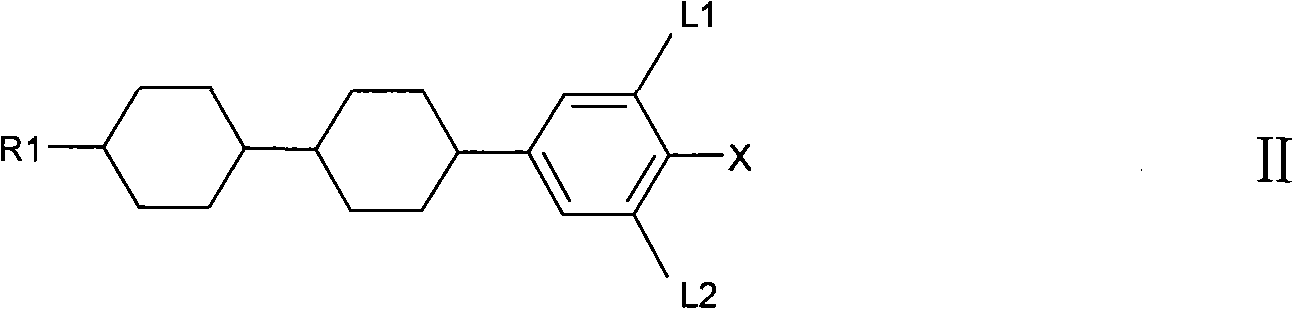

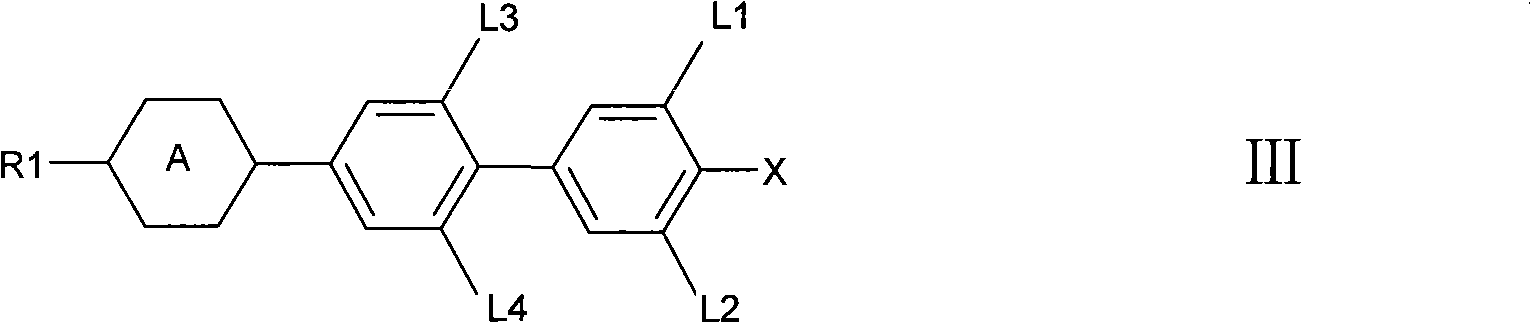

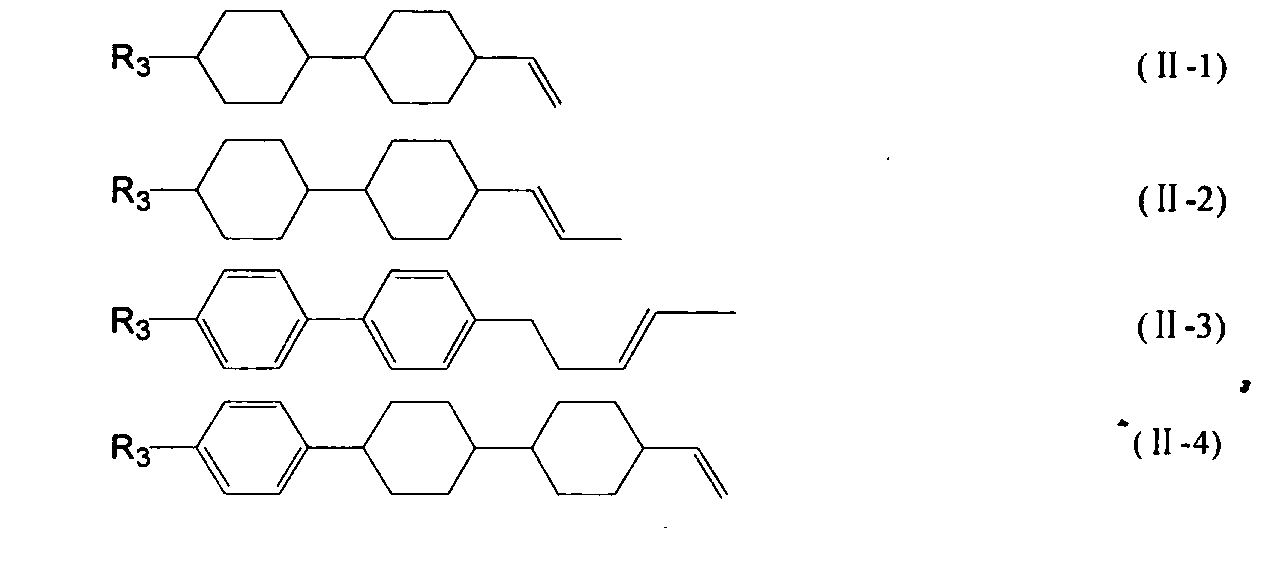

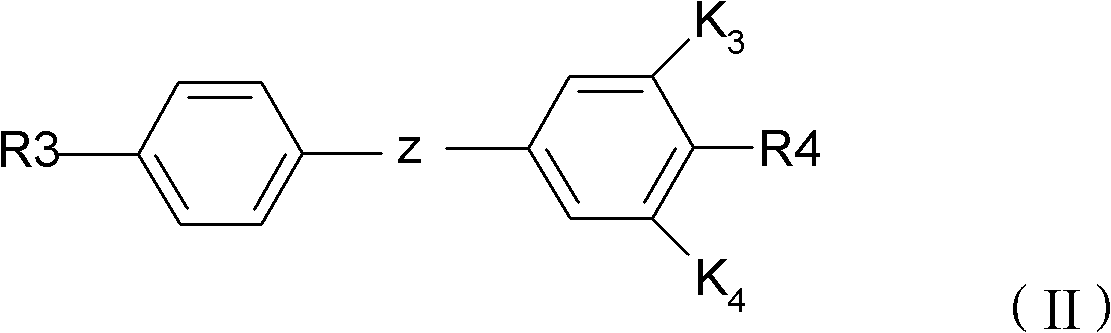

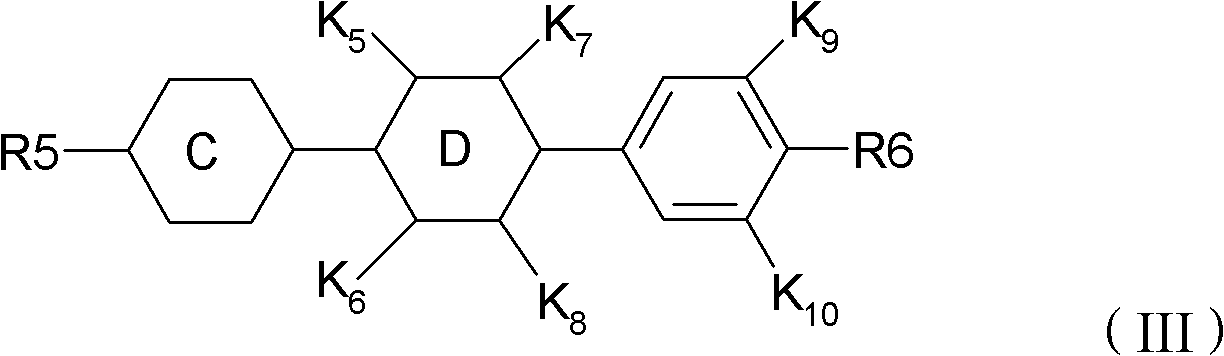

The invention discloses a liquid crystal composition, comprising a first variety of compound shown as a general formula I, a second variety of compound shown as a general formula II, a third variety of compound shown as a general formula III and a fourth variety of compound shown as a general formula IV; the invention also provides a liquid crystal lens employing the liquid crystal composition. The liquid crystal composition of the present invention has characteristics of low nematic phase initial voltage, wide phase transition temperature scope, small viscoelastic coefficient ratio gamma 1 / K11, large optical anisotropy and large dielectric anisotropy, etc., and can reduce a thickness value of a liquid crystal lens box and increase response speed of the liquid crystal lens box.

Owner:SUPERD CO LTD

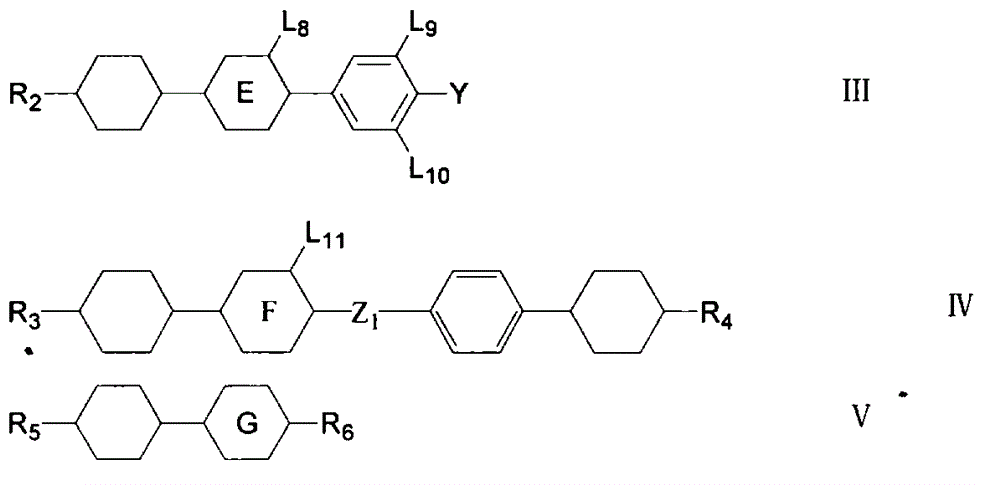

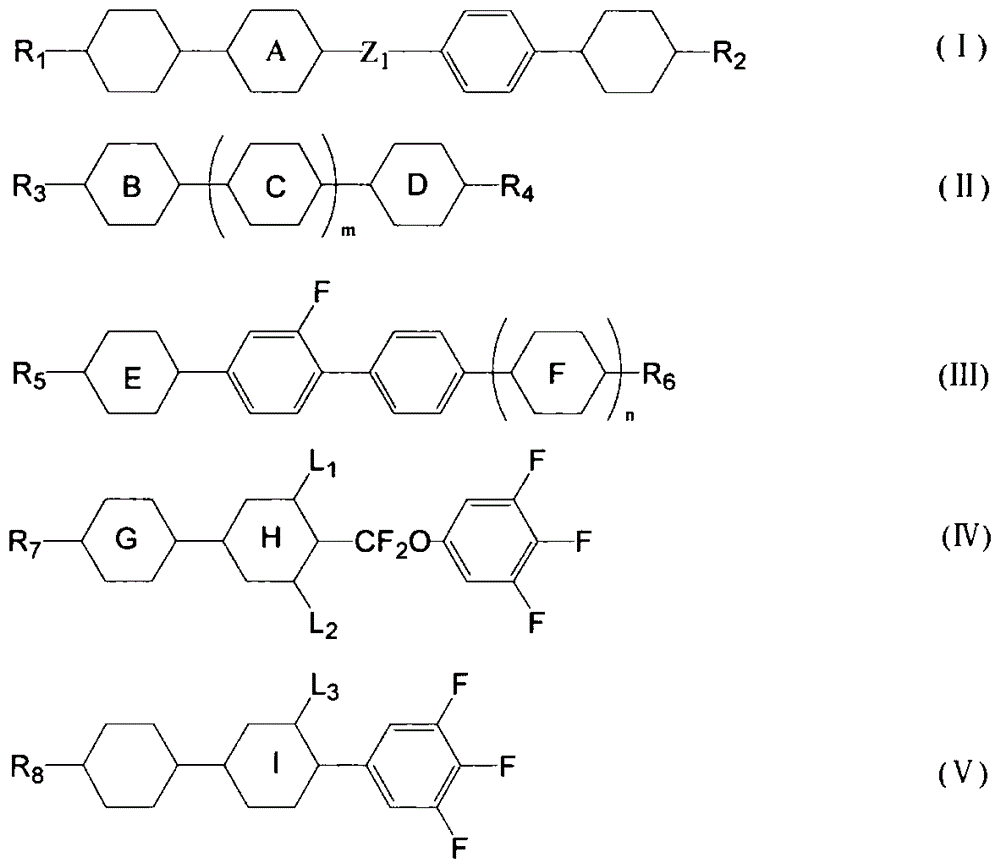

Nematic liquid crystal composition

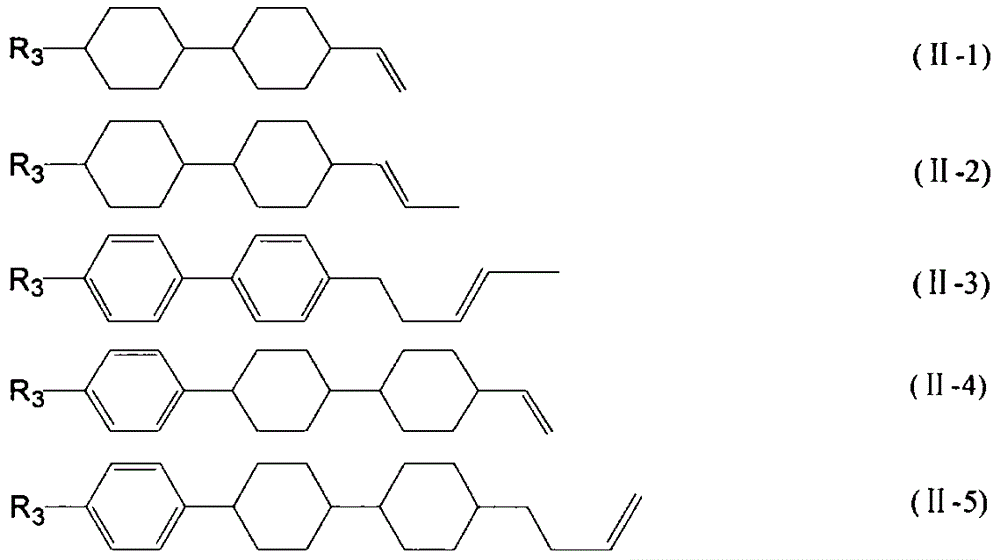

ActiveCN102433133AReduce box thicknessQuick responseLiquid crystal compositionsRefractive indexThermal stability

The invention relates to a nematic liquid crystal composition. The composition contains at least a nematic liquid crystal compound as shown in the formula (I), at least a nematic liquid crystal compound as shown in the formula (II), at least a nematic liquid crystal compound as shown in the formula (III), at least a nematic liquid crystal compound as shown in the formula (IV), at least a nematic liquid crystal compound as shown in the formula (V) and at least an optionally optically active compound. The nematic liquid crystal composition provided by the invention has high birefringence, low visco-elastic coefficient ratio gamma 1 / k11 and a wide phase transition temperature range. In addition, the liquid crystal composition has high ultraviolet ray stability and high thermal stability.

Owner:SUPERD CO LTD

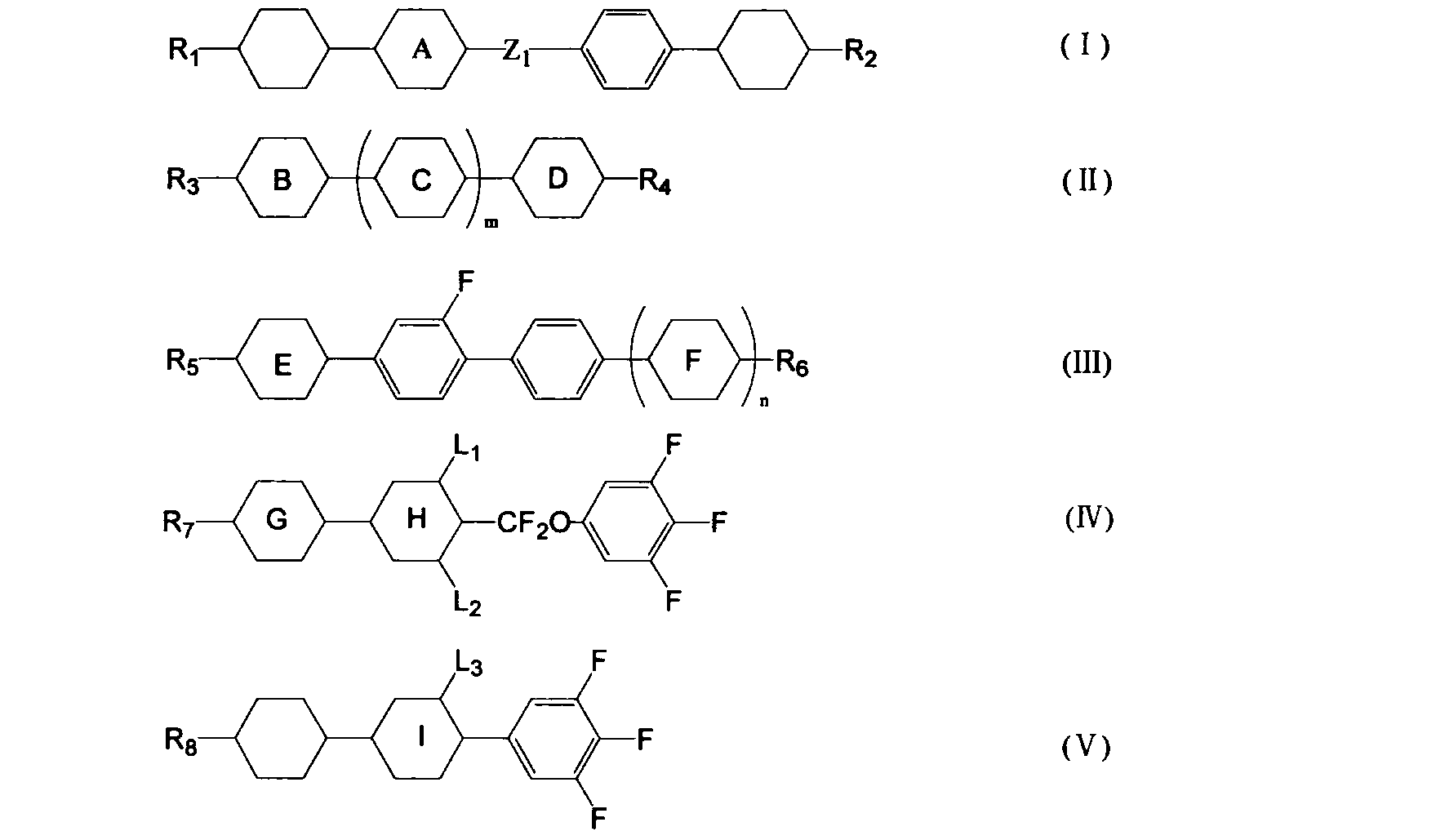

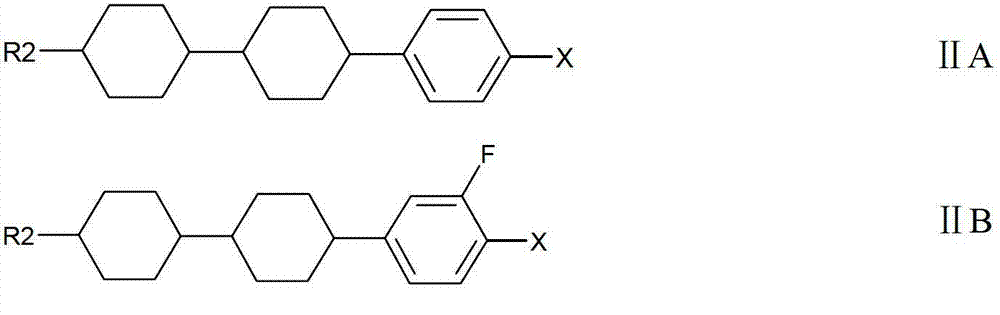

Liquid crystal composition for TFT (Thin-Film Transistor) display

ActiveCN101831307AImprove performanceLower average response timeLiquid crystal compositionsHigh resistanceLiquid-crystal display

The invention provides a liquid crystal composition for TFT (Thin-Film Transistor) display. The liquid crystal composition is prepared from the following components in percentage by weight: 1-40 percent of I-type compound, 1-70 percent of II-type compound, 1-40 percent of III-type compound, 0-45 percent of IV-type compound and 0-20 percent of V-type compound. The liquid crystal composition has excellent performance, extremely low total response time (ttot=ton+toff), lower voltage, high resistance ratio and voltage retention ratio, and can also have different threshold voltages, clearing points and delta n characteristics by adjusting the contents of the components, thereby being particularly suitable for manufacturing rapid-response TN-TFT liquid crystal displays.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

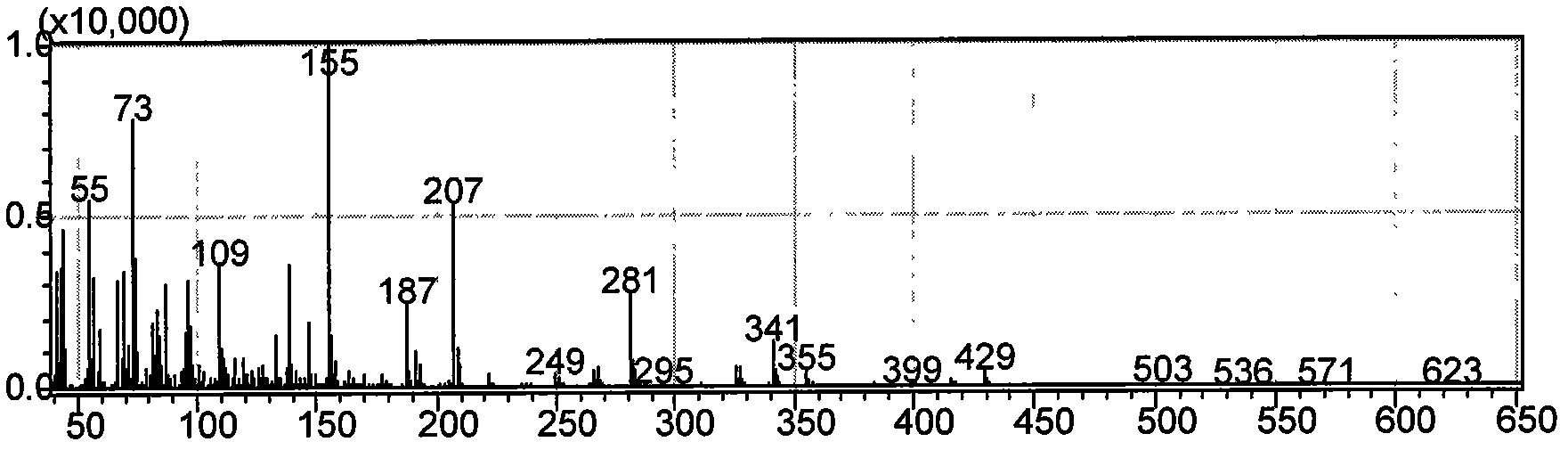

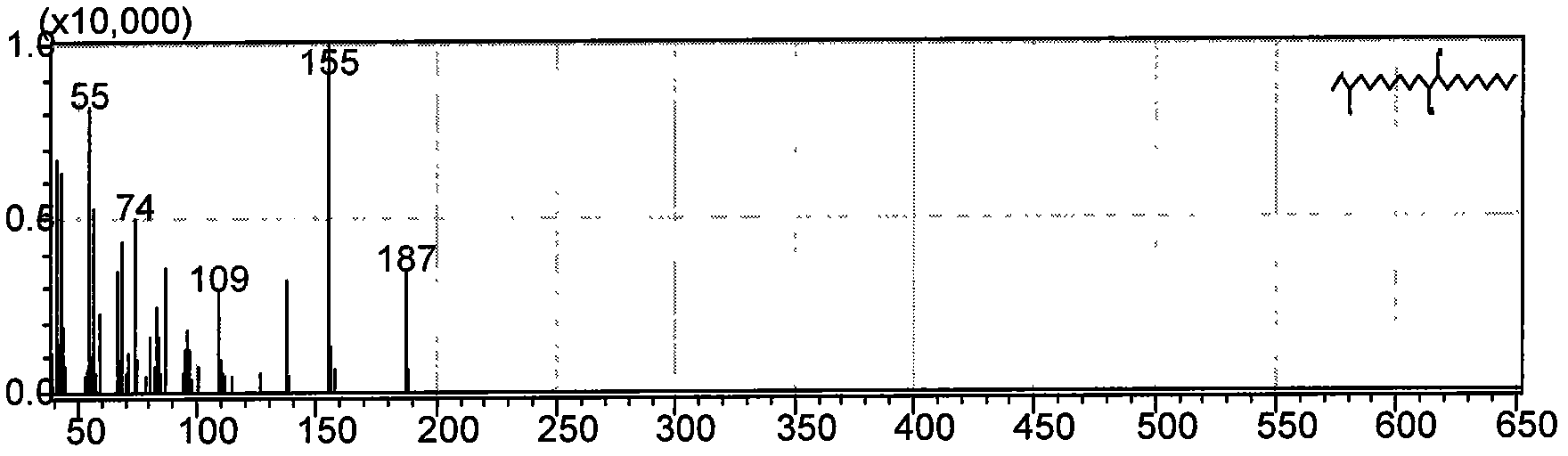

Organic phase change thermal storage material and production method thereof

InactiveCN103555280ADifficult to oozeSolve compatibility issuesHeat-exchange elementsEmulsionPhase change

The invention relates to an organic phase change thermal storage material and a production method thereof. The method comprises the following steps: preparing organic phase change material emulsion, preparing an organic phase change thermal storage material and the like. According to the method, the problems of dispersion and compatibility of the organic phase change material in ardealite are effectively solved, the prepared ardealite composite phase change energy storage material is stable in performance, the organic phase change material difficultly diffuses, and the adopted technical scheme is simple in steps and easy to implement. The technology can be widely applied to a process of compounding gypsum materials and organic phase change materials and has good application prospects.

Owner:ZHENGZHOU UNIV

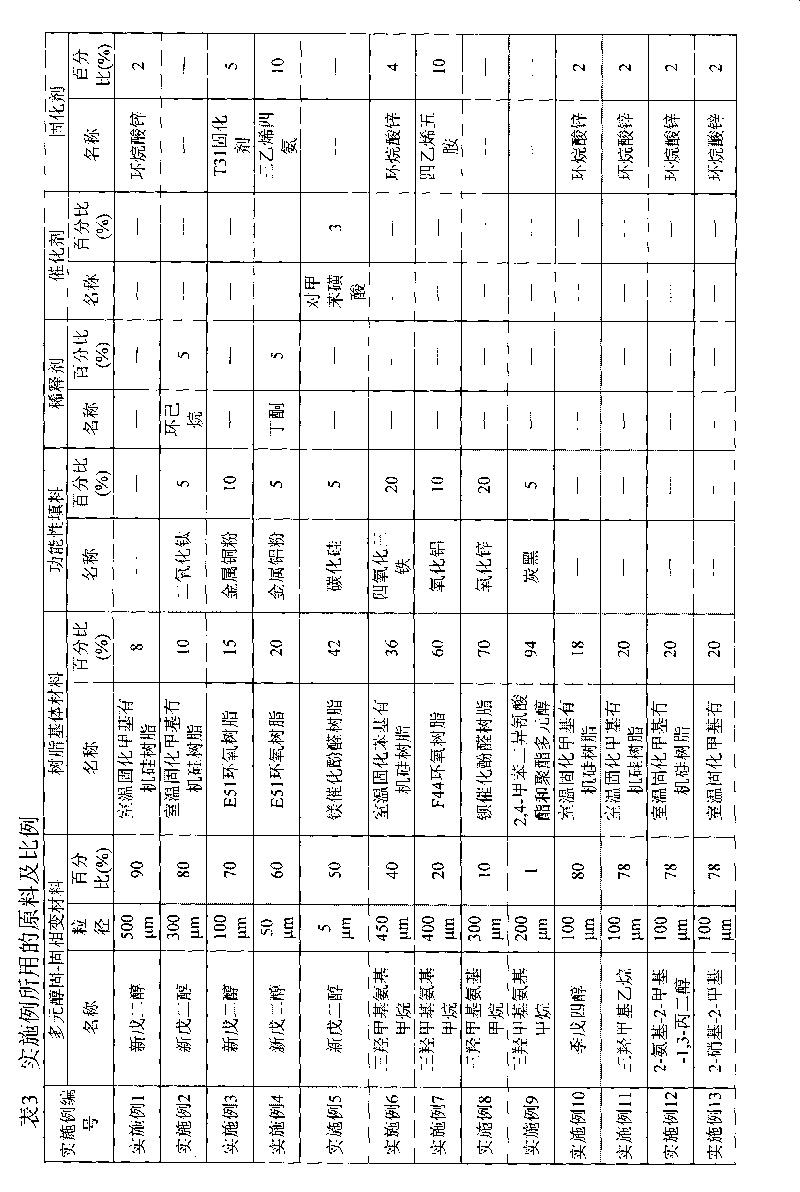

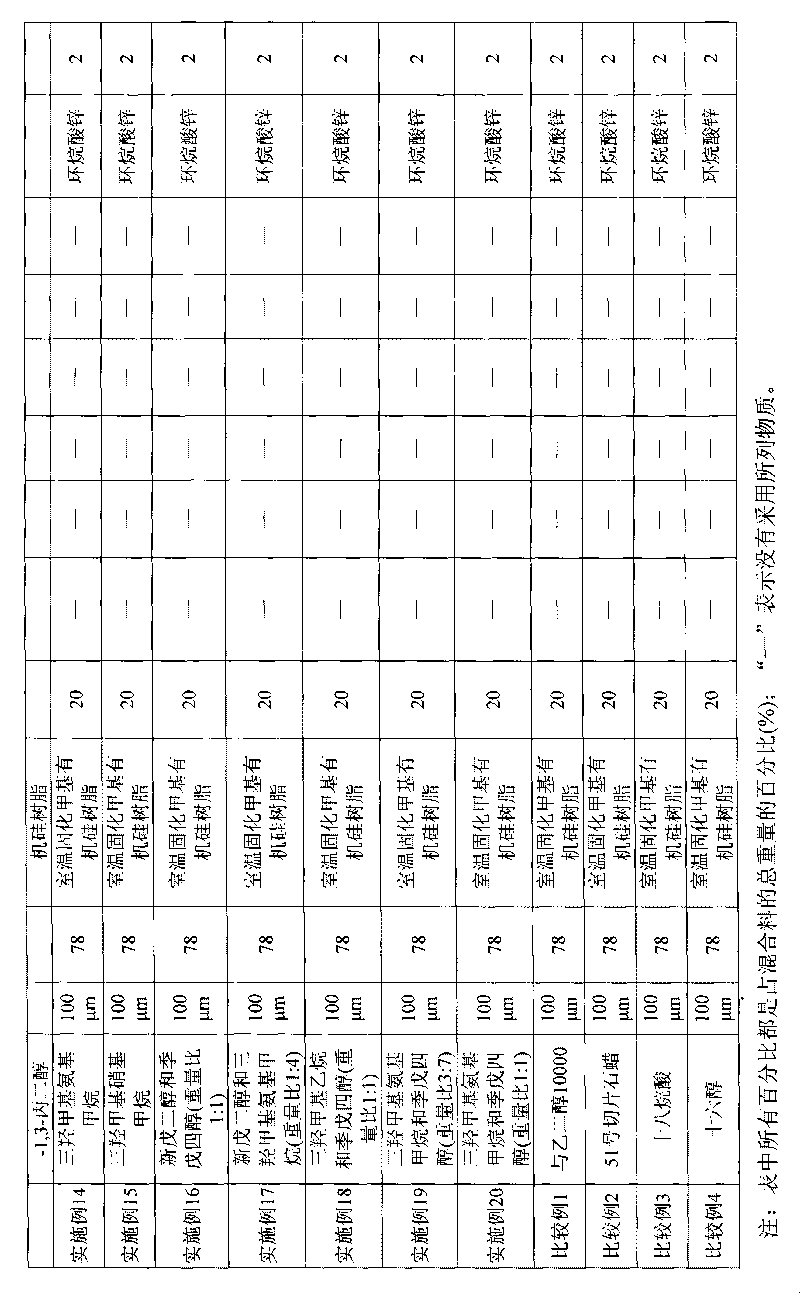

Polyalcohol solid-solid phase-change composite material and preparation method thereof

ActiveCN101701145AAvoid osmosisWide phase transition temperature rangeHeat-exchange elementsResin matrixElectric power

The invention provides a polyalcohol solid-solid phase-change composite material. The polyalcohol solid-solid phase-change composite material comprises a polyalcohol solid-solid phase-change material and a resin base material, is capable of avoiding the problems of melt flow and osmotic migration, and has wide phase-change temperature range, big phase-change latent heat, and adjustable phase-change temperature and phase-change latent heat. The invention further provides a method for preparing the polyalcohol solid-solid phase-change composite material. The method can be used for preparing the polyalcohol solid-solid phase-change composite materials with all profiles and good constancy and in all sizes. The preparation technology is simple and free from environment pollution. The polyalcohol solid-solid phase-change composite material of the invention has wide application value in the fields, such as the heat protection of aircrafts, the constant-temperature temperature control of precise instruments, meters and electronic devices, heat barrier coating, solar utilization, recovery of industrial residual heat and waste heat, the energy source of electric peak load shifting and valley filling, material, aerospace, textile, electric power, medical instrument, building and the like.

Owner:海鹰空天材料研究院(苏州)有限责任公司

PH and temperature double-sensitive intelligent nanogel and preparation method thereof

The invention provides a pH and temperature double-sensitive intelligent nanogel and a preparation method thereof. The method comprises the following steps: adding ltaconic acid into sodium hydroxide solution to obtain partially neutralized ltaconic acid water solution; adding acrylamide, N-isopropyl acrylamide and a crosslinking agent into the partially neutralized ltaconic acid water solution, and stirring to obtain a transparent single mixture solution; adding the transparent single mixture solution into a mixed solvent containing oil-soluble solvent and Span80 / Tween 80 composite surfactant, stirring, heating to 40-60DEG C, and adding an oxidant and a reducing agent, to obtain intelligent transparent or semitransparent nanogel reversed-phase microemulsion; demulsifying and precipitating the intelligent transparent or semitransparent nanogel reversed-phase microemulsion with ethanol, washing, drying and grinding to the pH and temperature double-sensitive intelligent nanogel. The invention further provides the pH and temperature double-sensitive intelligent nanogel prepared by adopting the preparation method. The pH and temperature double-sensitive intelligent nanogel has good pH and temperature double sensitivity.

Owner:PETROCHINA CO LTD

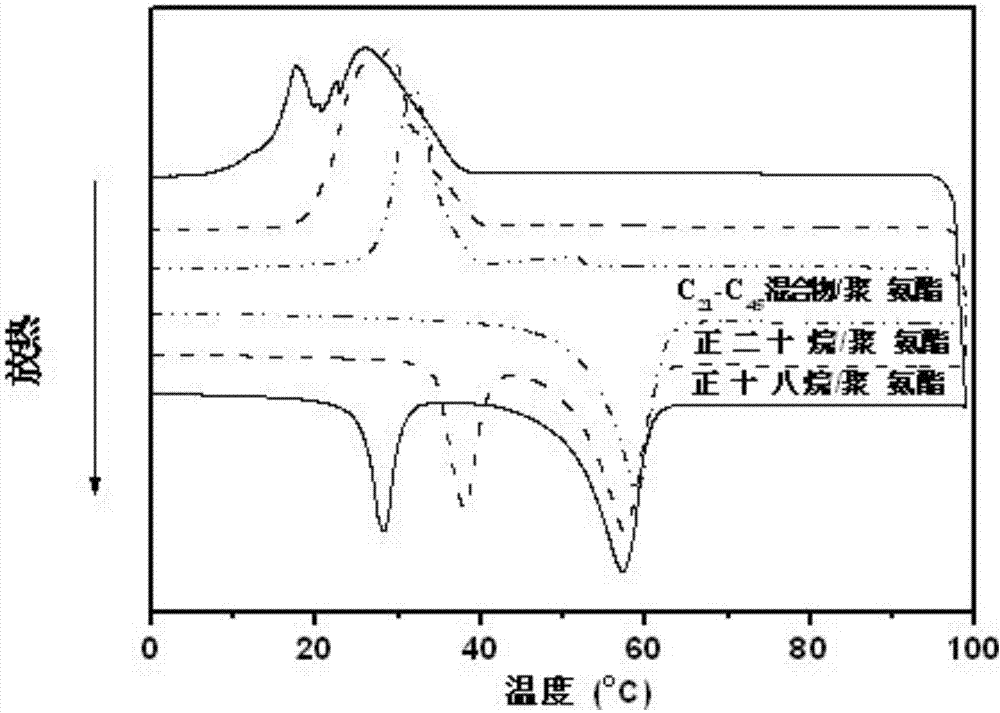

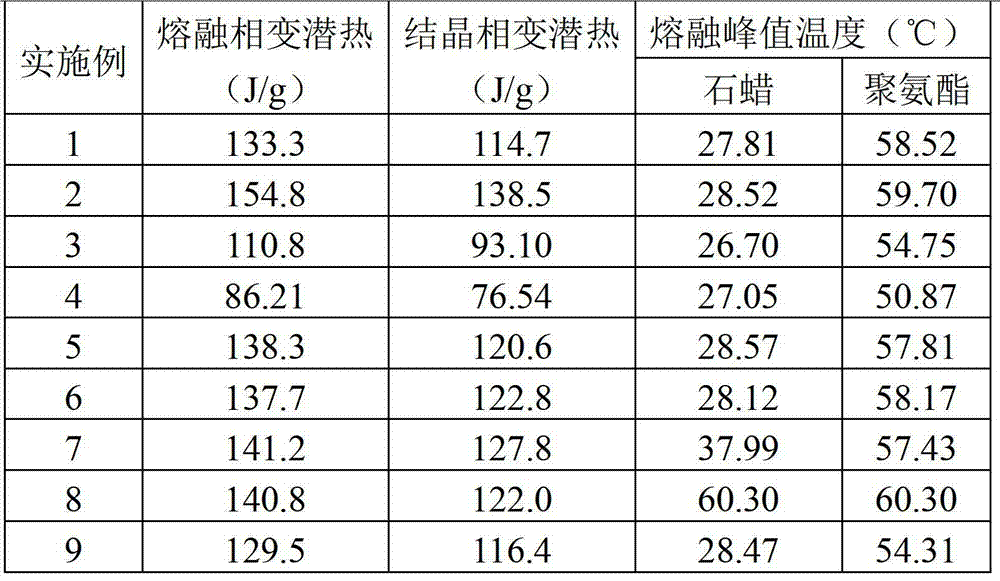

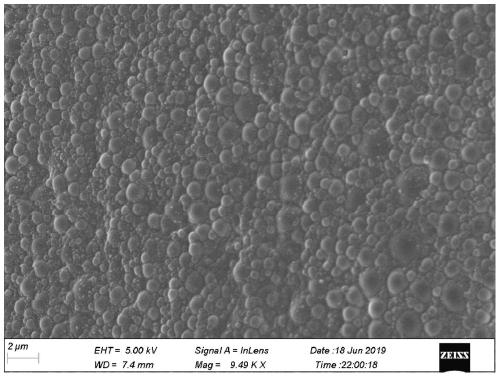

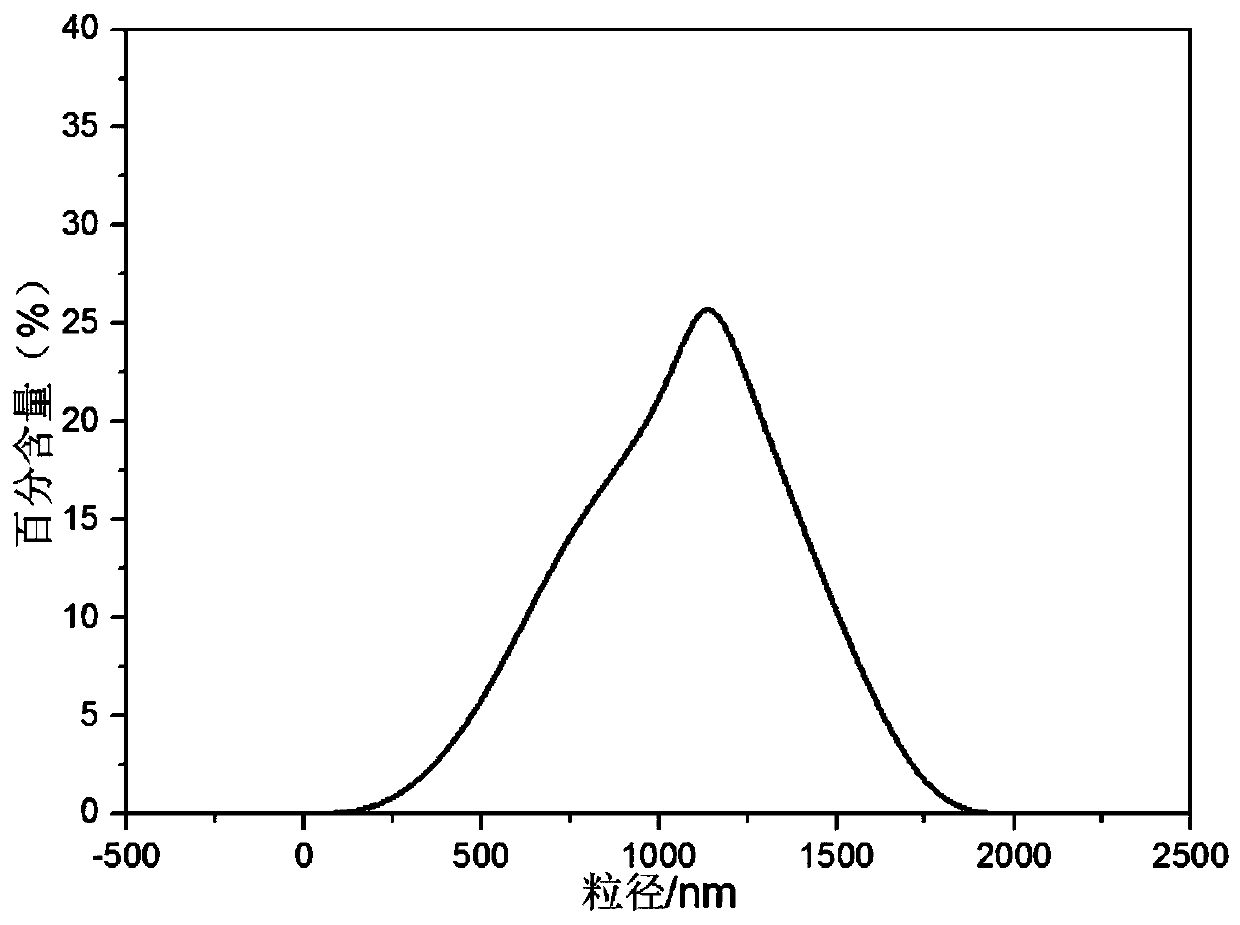

Preparation method of paraffin/polyurethane solid-solid composite double-phase change energy storage material

ActiveCN103224601BHigh latent heat of phase changeWide phase transition temperature rangeHeat-exchange elementsParaffin waxPtru catalyst

The invention discloses a preparation method of a paraffin / polyurethane solid-solid composite double-phase change energy storage material, comprising the following steps: selecting raw materials which comprises the following components: by weight, 40-90 parts of polyethylene glycol, 4-20 parts of isocyanate, 0-10 parts of a chain extender, 0-50 parts of paraffin, 0-5 parts of a surfactant and 0-1 part of a catalyst; melting glycol and carrying out vacuum-pumping processing, mixing the molten glycol with the surfactant and paraffin, adding isocyanate, the chain extender and the catalyst to react at a temperature of 60-90 DEG C to obtain a performed polymer, carrying out deaeration on the performed polymer, injecting the deaerated performed polymer into a mould, solidifying, cooling and demoulding. According to the composite double-phase change energy storage material provided by the invention, a paraffin hydrocarbon compound with large latent heat of phase change is used as a filling material, and a polyurethane material with a phase change function is used as a matrix. Latent heat of phase change of the prepared paraffin / polyurethane solid-solid composite double-phase change energy storage material reaches 154J / g, phase-change temperature ranges from 15 DEG C to 70 DEG C, and the material is a composite phase change material having a double-phase change character.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Biodegradable microcapsule cold storage agent and preparation method thereof

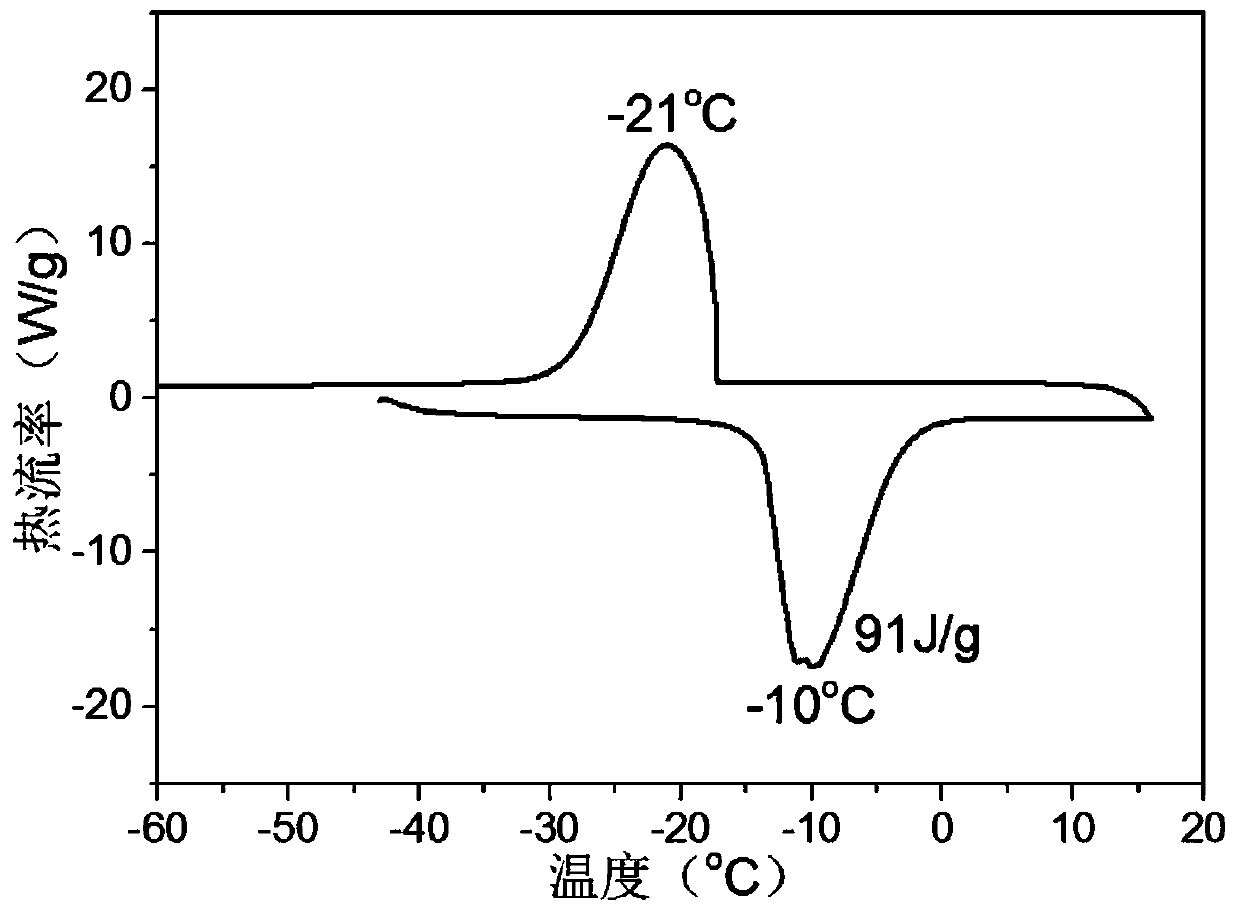

ActiveCN110205103AWide phase transition temperature rangeImprove thermal stabilityHeat-exchange elementsMicroballoon preparationInorganic saltsPolyol

The invention discloses a biodegradable microcapsule cold storage agent and a preparation method thereof. The cold storage agent comprises a novel capsule material of polylactic acid citrate and a composite phase change cold storage material as a core material formed by blending polyols and inorganic salts. In the invention, microcapsules are formed by interfacial polymerization of a polylactic acid monomer and a citric acid crosslinking agent. The adjustable phase change temperature range of the cold storage agent is -20 DEG C to 10 DEG C, the cold storage capacity is strong, the supercoolingdegree is small, the microcapsule sealing property is good, the strength is high, the core material is not easy to flow and leak, and the cold storage agent is nontoxic and harmless, biodegradable, economical and environment-friendly.

Owner:武汉中科先进材料科技有限公司

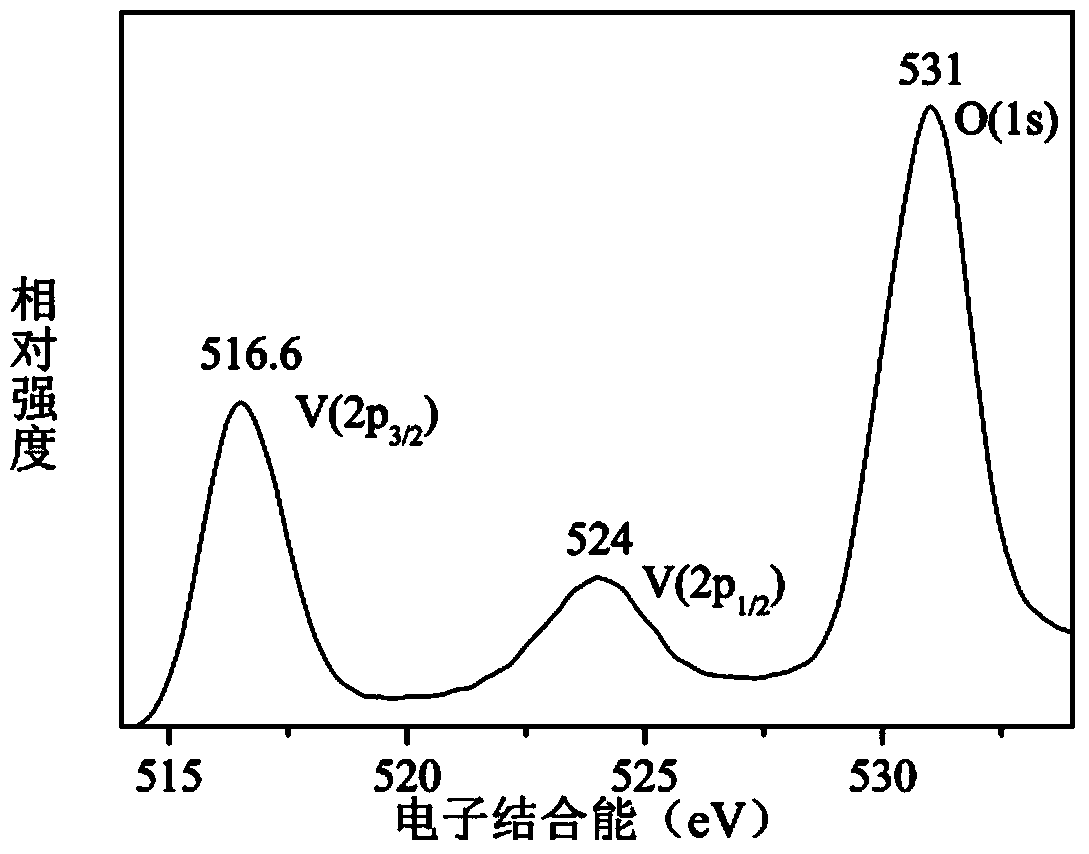

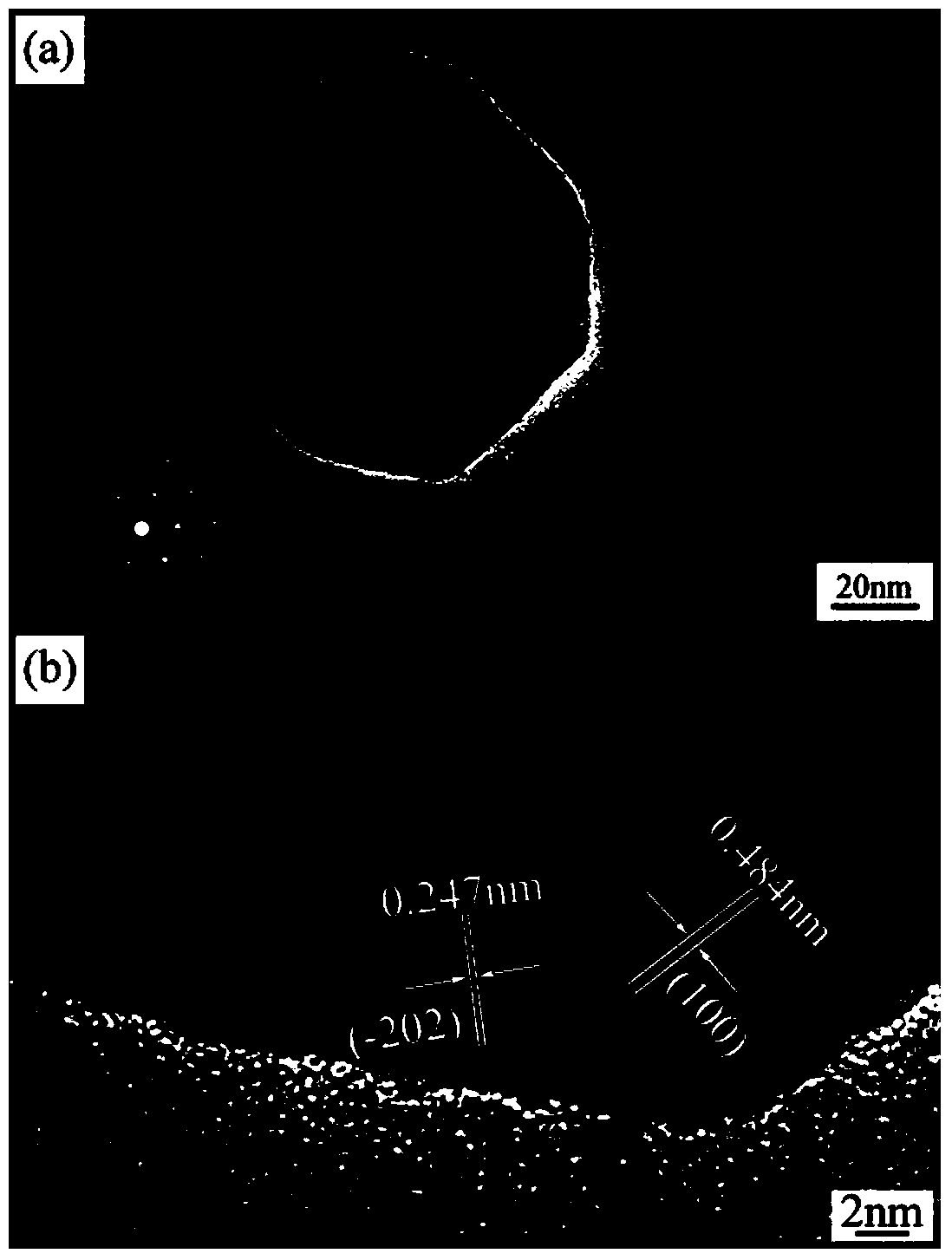

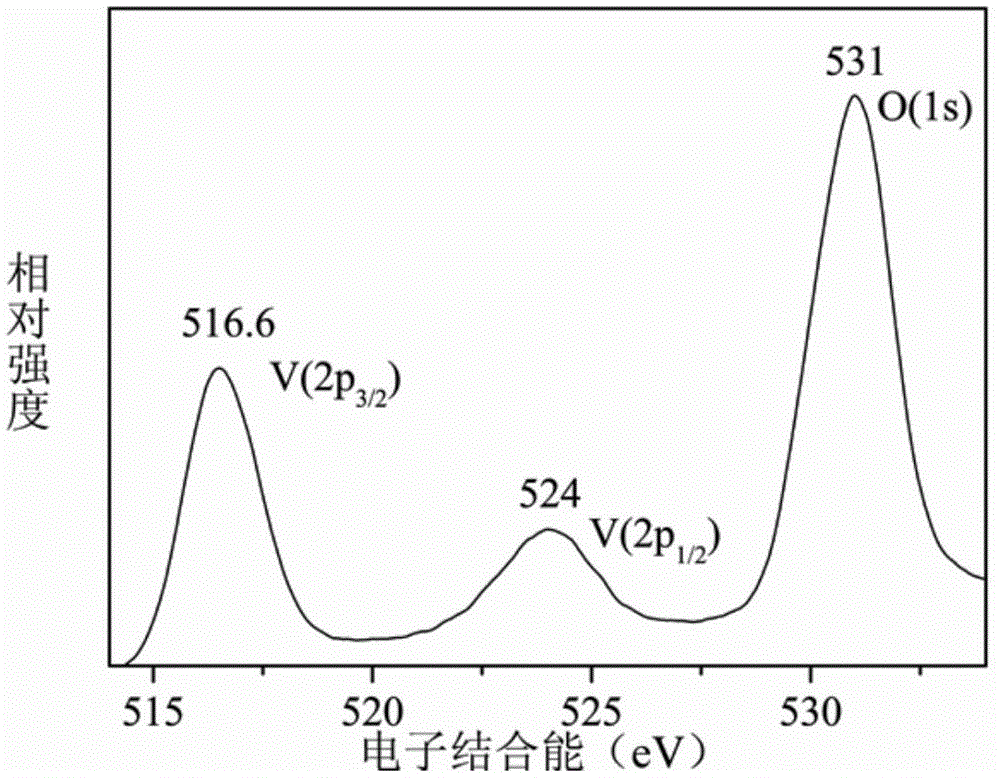

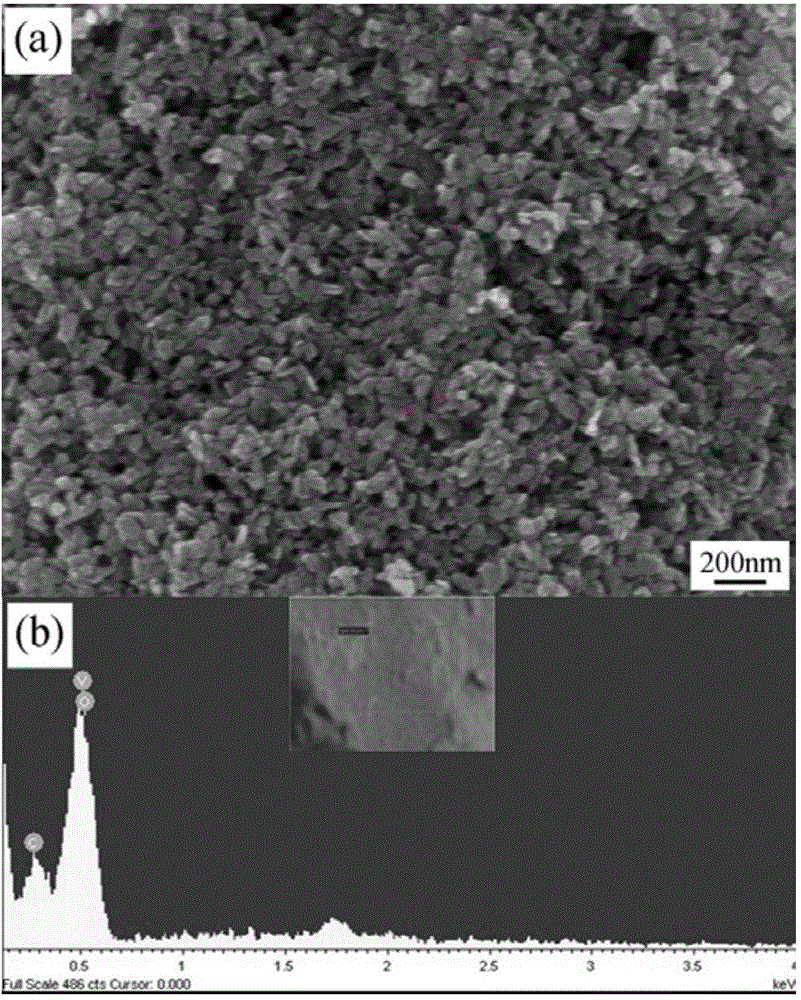

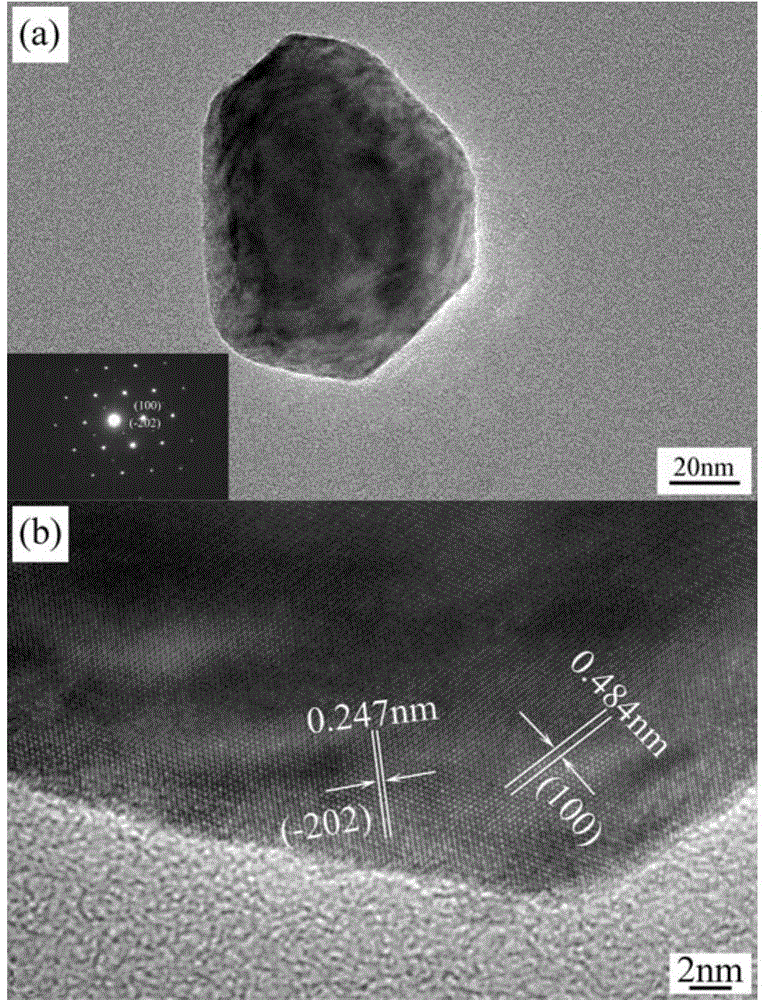

Preparation method for phase-M vanadium dioxide nanometre powder

ActiveCN103409768AEasy to prepareWide phase transition temperature rangeElectrolysis componentsChemistryVoltage

The invention discloses a preparation method for phase-M vanadium dioxide nanometre powder. The preparation method comprises the following steps: mixing polyhydric alcohol with a carbon chain length of 3 to 10 with monohydric alcohol with a carbon chain length of 1 to 5 in a volume ratio of 1: (6 to 15), so as to obtain a mixed alcohol solution; then adding quaternary ammonium salt with a carbon chain length of 1 to 16 in the mixed alcohol solution, so as to obtain electrolyte, wherein the concentration of quaternary ammonium salt in the electrolyte is 1-5 g / L; then using a vanadium metal block as an anode, using a platinum metal block or a vanadium metal block as a cathode, keeping a distance between the anode and the cathode to be 2 mm to 5 cm, placing the anode and the cathode in the electrolyte, and electrolysing for 1 to 3 hours under a voltage of 2 to 30 V, so as to obtain a reaction solution containing precipitates; then performing a solid-liquid treatment and a washing treatment on the reaction solution, so as to obtain an intermediate product; and after that, annealing the intermediate product for 1 to 3 hours at a temperature of 350 to 450 DEG C and under a pressure of 10 to 100 Pa, so as to prepare the target product with a particle size of 50 to 100 nm. The preparation method has the characteristics of being time-saving, energy-saving, environment-friendly, low in preparation cost, and easy to realize large-scale industrialized production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

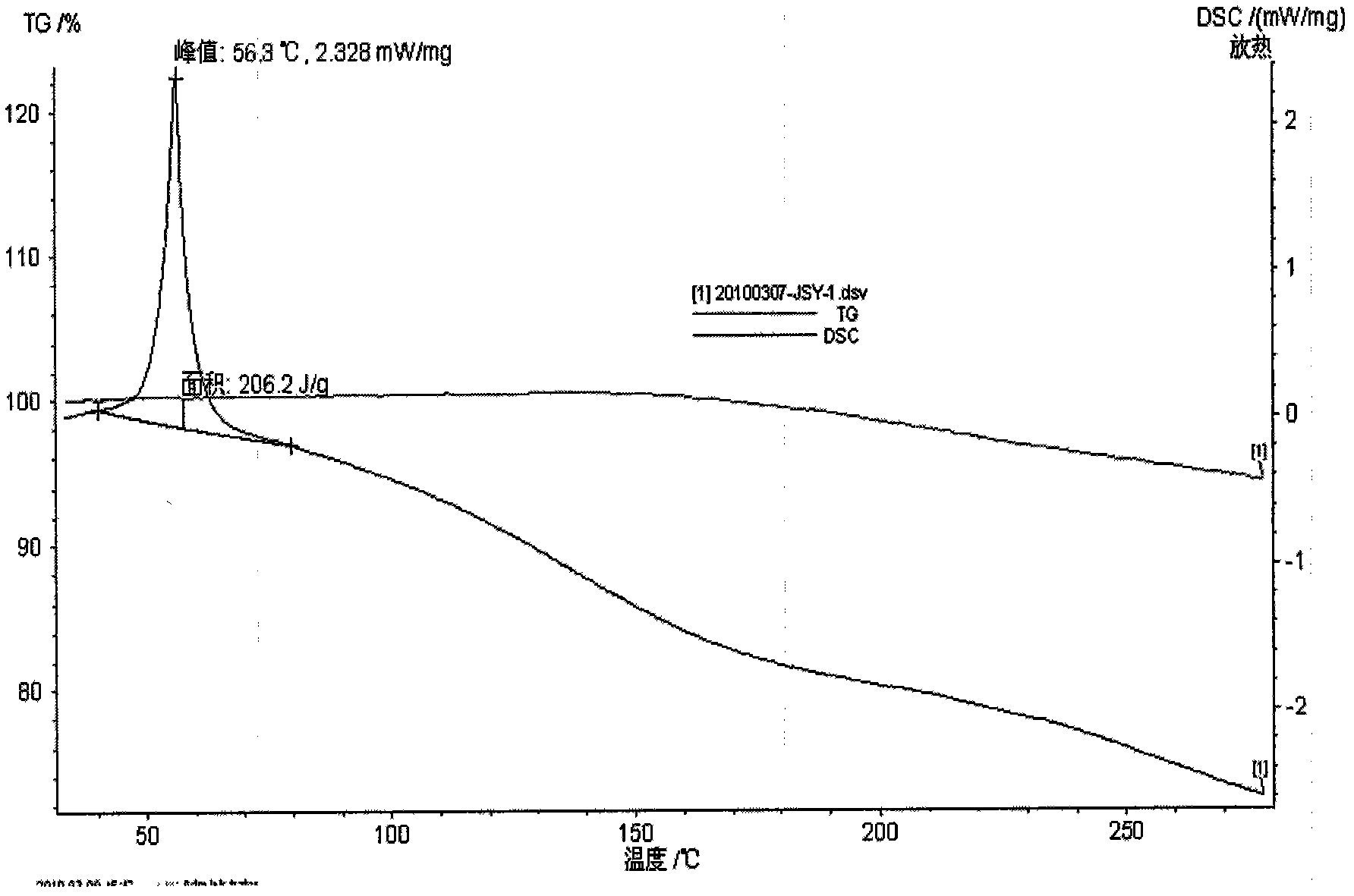

Phase change energy storage material prepared from oleic acid or esters of energy storage material and preparation method thereof

ActiveCN102010692AWide variety of sourcesLow priceOrganic compound preparationCarboxylic acid esters preparationPhase changeLatent heat

A phase change energy storage material prepared from oleic acid or esters of the energy storage material is characterized in that the general molecular formula of the material is CH3(CH2)7CHOH-CHOH(CH2)7COOR, wherein R is H, CH3 or CH2CH3. The material belongs to the compound of fatty acid derivatives and has phase change temperature between 35 DEG C and 130 DEG C and phase change latent heat of 110-206kJ / kg. The material has the advantages of controllable phase change temperature and wider range of phase change temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

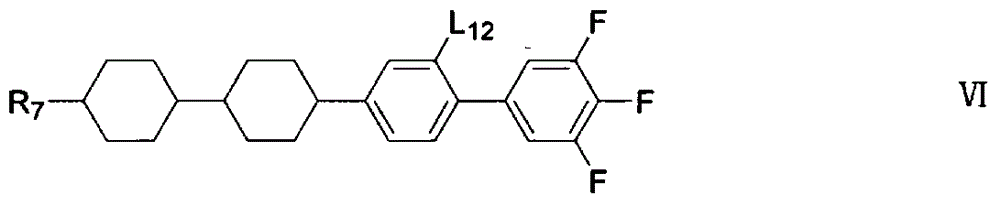

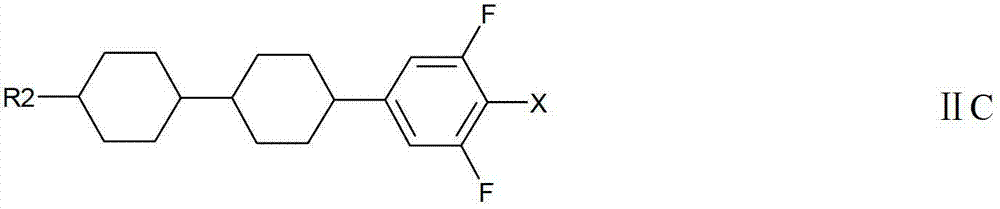

Liquid crystal composition

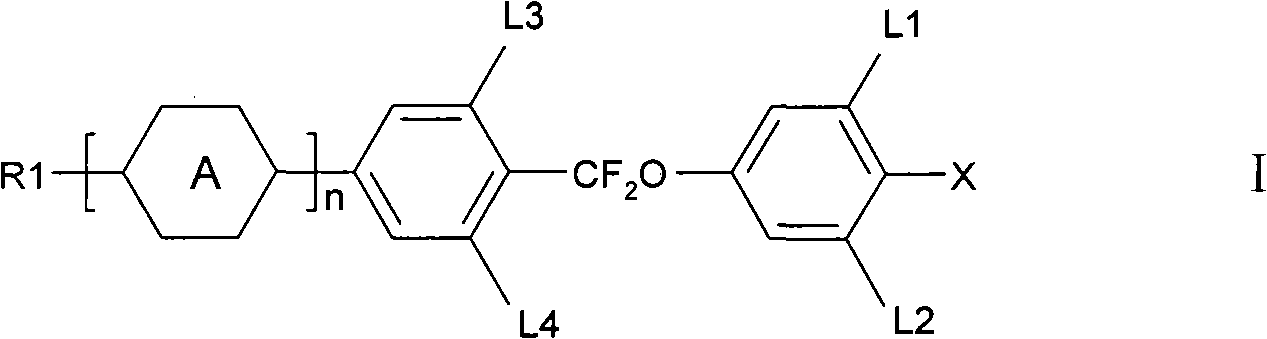

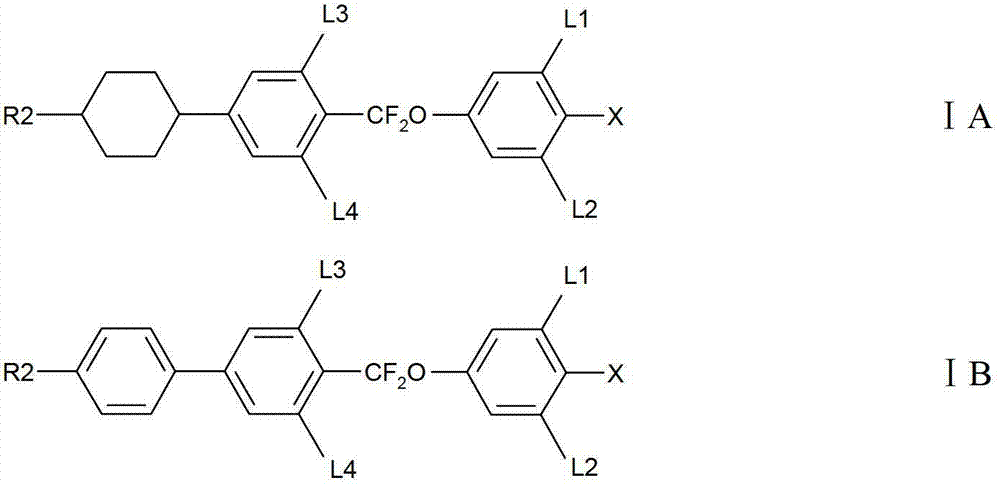

ActiveCN104610984AWide phase transition temperature rangeHigh resistivityLiquid crystal compositionsDielectric anisotropyActive matrix

The invention discloses a liquid crystal composition. The liquid crystal composition has the characteristics of high-definition light spots, high dielectric anisotropy, low driving voltage and the like, and the liquid crystal composition has higher order degree, so that the influence of disordered voltage in a panel on liquid crystal alignment is little. The leaking light between sub-pixels can be effectively reduced, so that the line width of a black matrix is reduced, the aperture opening ratio is increased, and the transmittance is improved. The liquid crystal composition is suitable for liquid crystal display elements driven by active matrix thin film transistors (AM-TFT) with positive dielectric anisotropy. The liquid crystal composition is particularly suitable for large-size liquid crystal televisions of 200-800 ppi.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Liquid crystal composition

ActiveCN104388100AWide phase transition temperature rangeHigh resistivityLiquid crystal compositionsChemistryLiquid composition

The invention discloses a liquid crystal composition. The liquid crystal composition has a wide phase transition temperature scope, high resistance, high stability, high double refraction anisotropy and rapid response and good high- and low-temperature stability, can still produce fast response at a low temperature of 0-30 DEG C and is especially suitable for industrial control instruments and vehicle-carried TNTFT-LCD. The liquid crystal composition comprises 1-20wt% of a compound I, 1-50wt% of a compound II, 1-30wt% of a compound III, 1-50wt% of a compound IV, 1-20wt% of a compound V and 0.05-0.5wt% of an optical rotation component.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

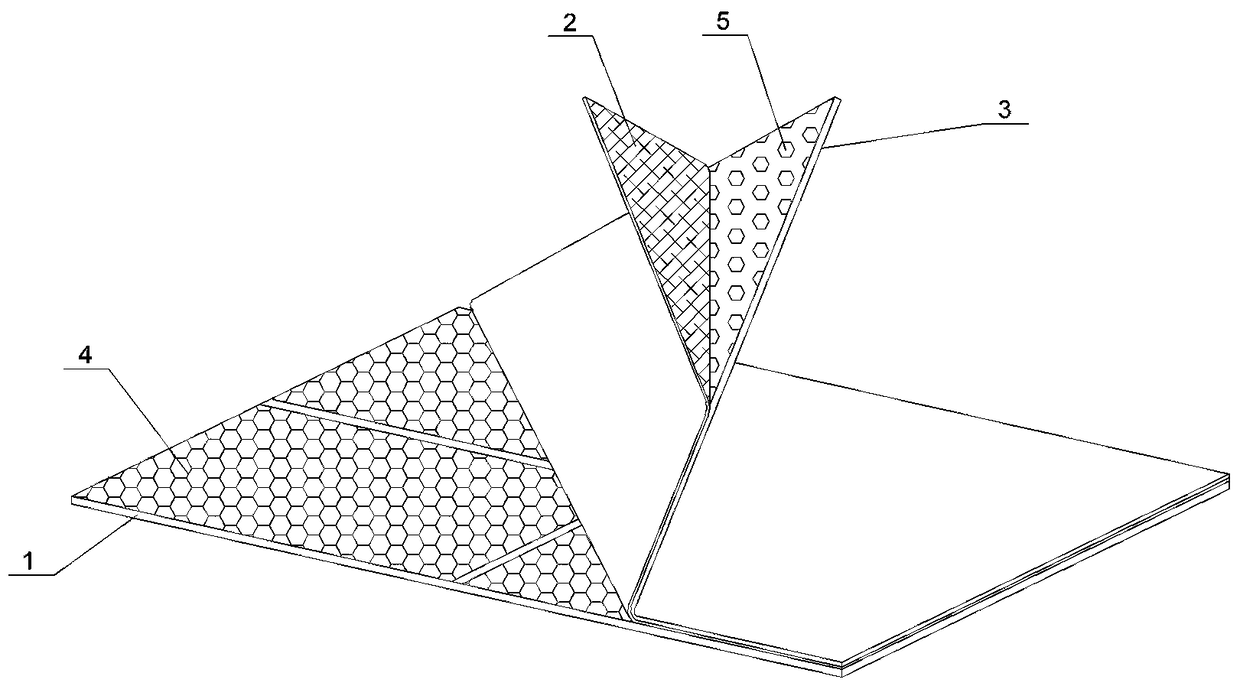

Preparation method of normal-temperature phase-change microcapsule heat storage board

InactiveCN108130051ASolve the problem of energy storageFix the leakHeat-exchange elementsMicroballoon preparationMaterials scienceFilm coating

The invention discloses a preparation method of a normal-temperature phase-change microcapsule heat storage board. Phase-change capsule core materials, namely 44# paraffin, liquid paraffin and dodecylalcohol, are firstly mixed according to a certain ratio to obtain a normal-temperature phase-change material; meanwhile, a low-temperature phase-change material is coated through high molecular polymerization by a certain technology to prepare novel normal-temperature phase-change microcapsules; and a film coating layer in a hot-melt state is compressed into a honeycomb continuous groove of a substrate through the honeycomb convex and concave surface of a surface layer, and phase-change materials can be sealed in an independent space, so that direct contact between the phase-change materialsand the external environment is prevented, and thus the effect of protecting the phase-change materials is achieved and the phase-change materials can be recycled. Through phase change of the microcapsules at normal temperature, the purposes of environment friendliness and energy saving are achieved through energy storage and energy release.

Owner:蔡兴礼

Preparation method of composite phase change coating fabric for cold-proof gloves

PendingCN110387750AAvoid heat stressMeet the need for comfortGlovesHeat-exchange elementsFiberPhase change

The invention relates to a preparation method of composite phase change coating fabric for cold-proof gloves and belongs to the technical field of functional fabric. The composite phase change coatingfabric for the cold-proof gloves is prepared by adding polyacrylate to wrap paraffin phase change microcapsules, the microcapsule technology is a technology for wrapping a solid or liquid material with a film forming material to obtain core-shell structure particles, capsule walls provide a stable enclosed environment for the phase change material, the stability of the phase change material can be enhanced, meanwhile, solid-liquid phase change can be changed into solid-solid phase change, the phase change material is composited with fiber and textile more easily, the phase change material isdispersed into small particles and thus has better thermal conductivity, the specific surface area of the phase change material can be obviously increased by the microcapsule technology, phase separation and supercooling can be eliminated, and the durability and service life can be prolonged.

Owner:杨红

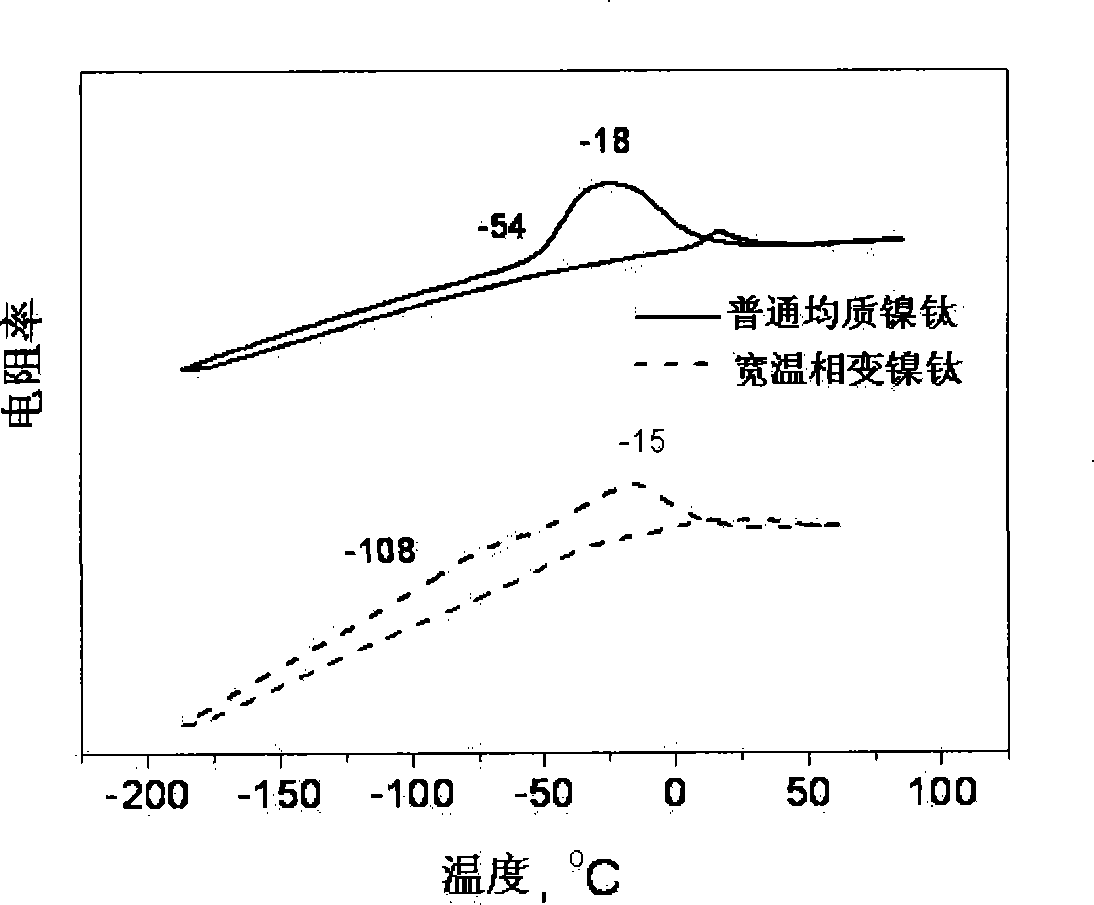

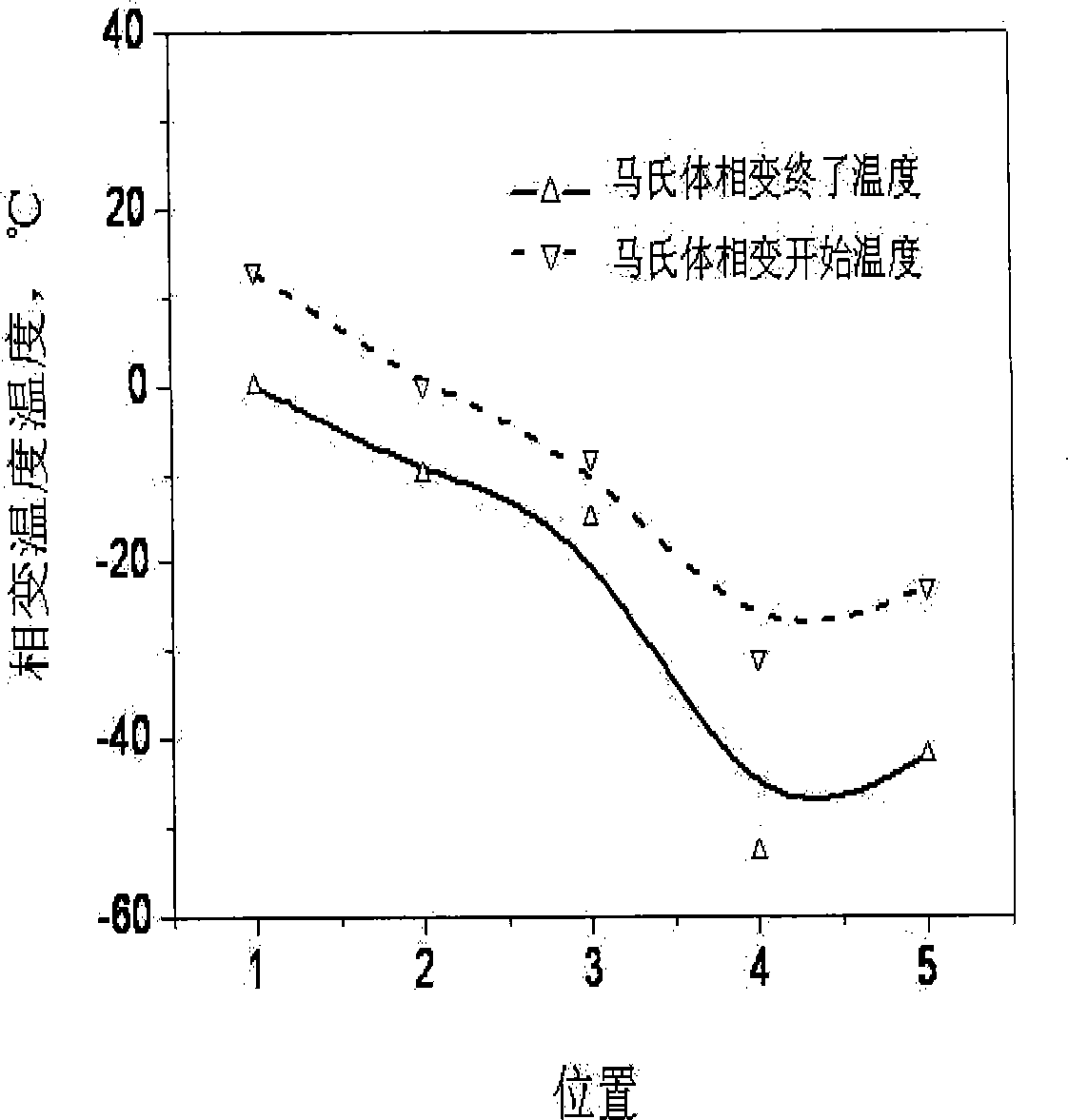

Thermodiffusion method for manufacturing wide temperature range phase transition nickel titanium alloy

InactiveCN101245438AHas a fastening effectWide phase transition temperature rangeQuenchingNickel titanium

The invention relates to a thermal diffusion method for manufacturing a nitinol with wide temperature phase transition, pertaining to the filed of metallic functional materials. The invention is characterized in that the composition range of the nitinol with wide temperature phase transition is: Ni50.5-Ti to Ni52-Ti, and the manufacturing method comprises: (1) the nitinol with wide temperature phase transition is obtained by adopting a plurality of short-term heating and quenching; (2) the heating temperature for the quenching of the nitinol with wide temperature phase transition ranges from 300-900 DEG C; (3) the heating time for the quenching of the nitinol with wide temperature phase transition is 1-600s; (4) the treatment times for the quenching of the nitinol with wide temperature phase transition are 1-30. From the beginning of the phase transition to the end of the phase transition Ms-Mf, the temperature range is more than 50 DEG C. The temperature range of the martensitic phase transformation of the invention is wide, high damping temperature range is wide, good damping effect is performed under poor strain condition; the austenite phase always kept in the interior of the nitinol can ensure good hyperelasticity, thus leading an oscillating damper to have tightening effect to improve the damping effect; the thermal diffusion method requires simple equipment and is easily operated.

Owner:UNIV OF SCI & TECH BEIJING

Thin-film material with double-effect functions of heat absorption and wave absorption and preparation method thereof

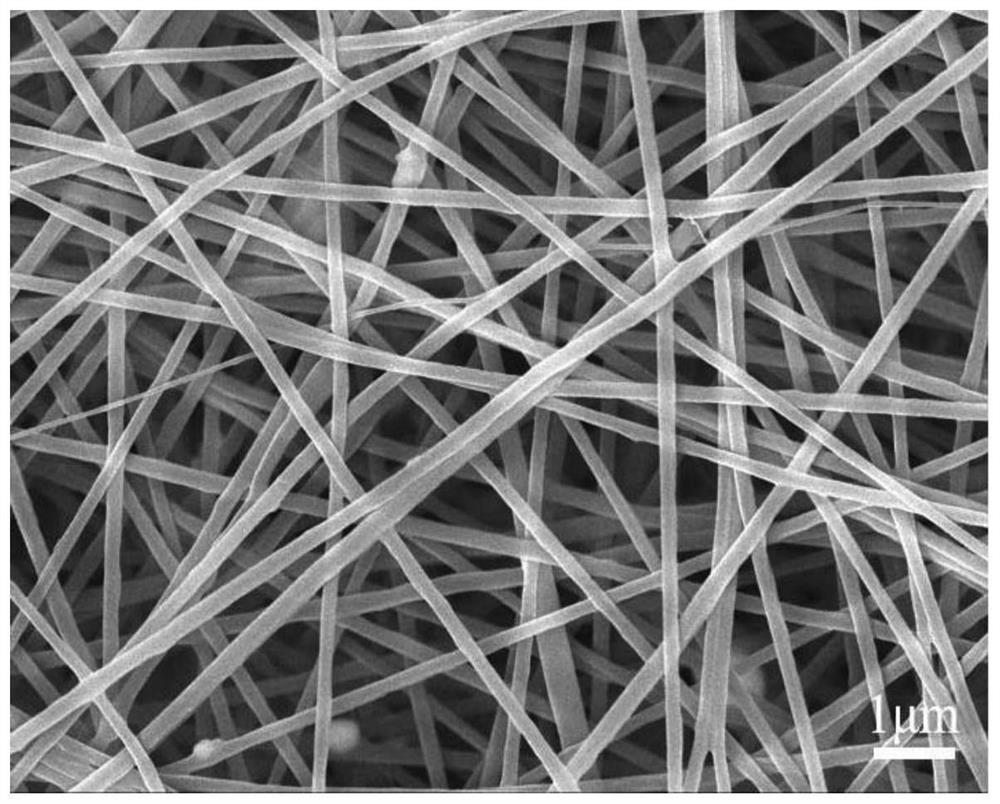

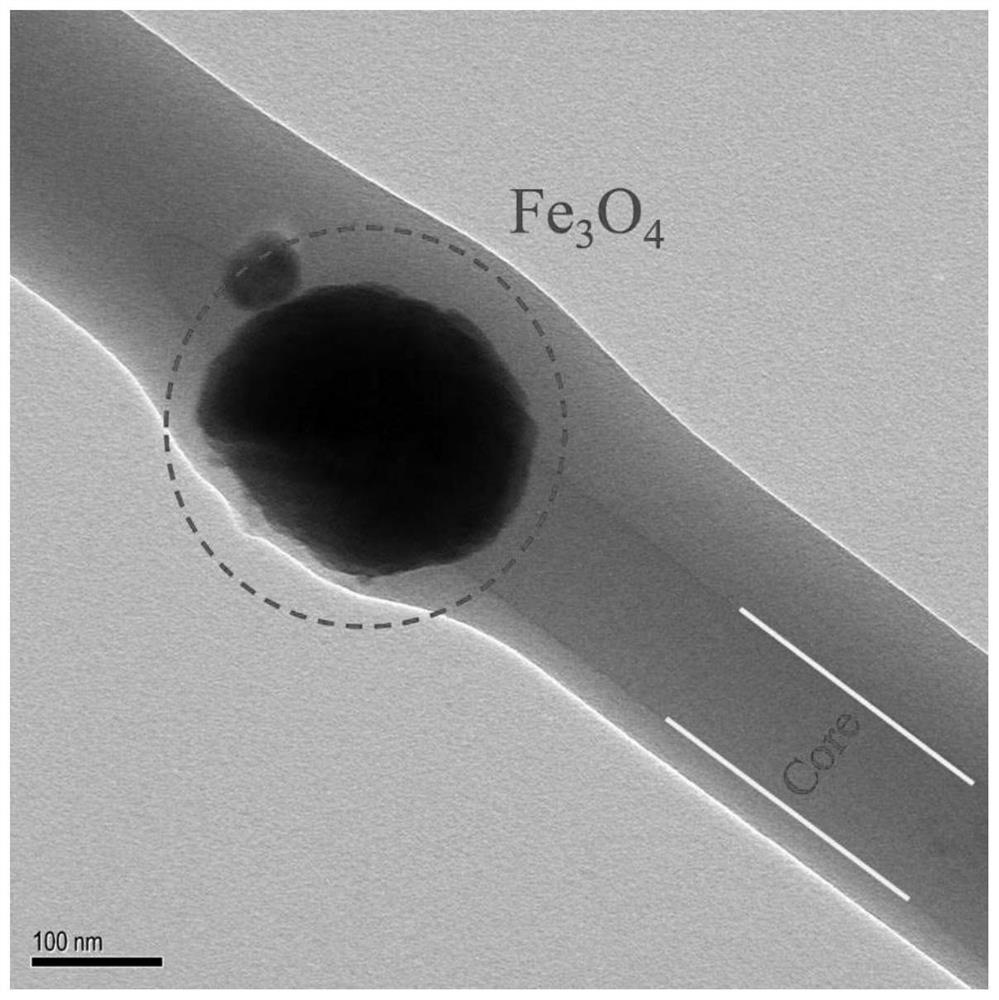

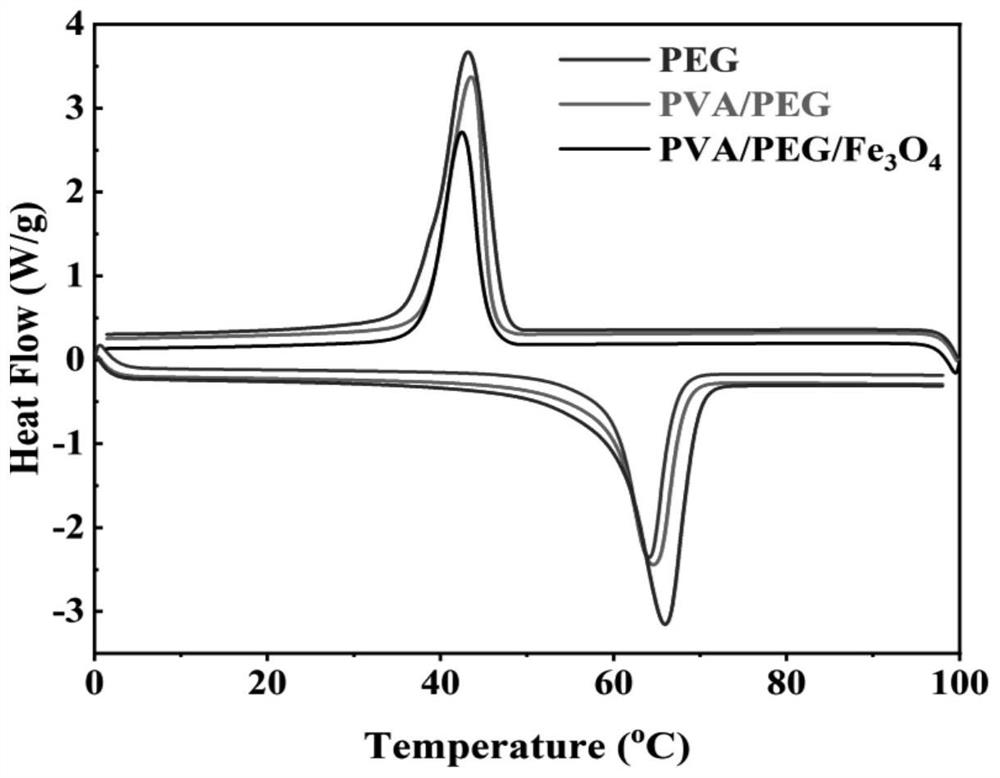

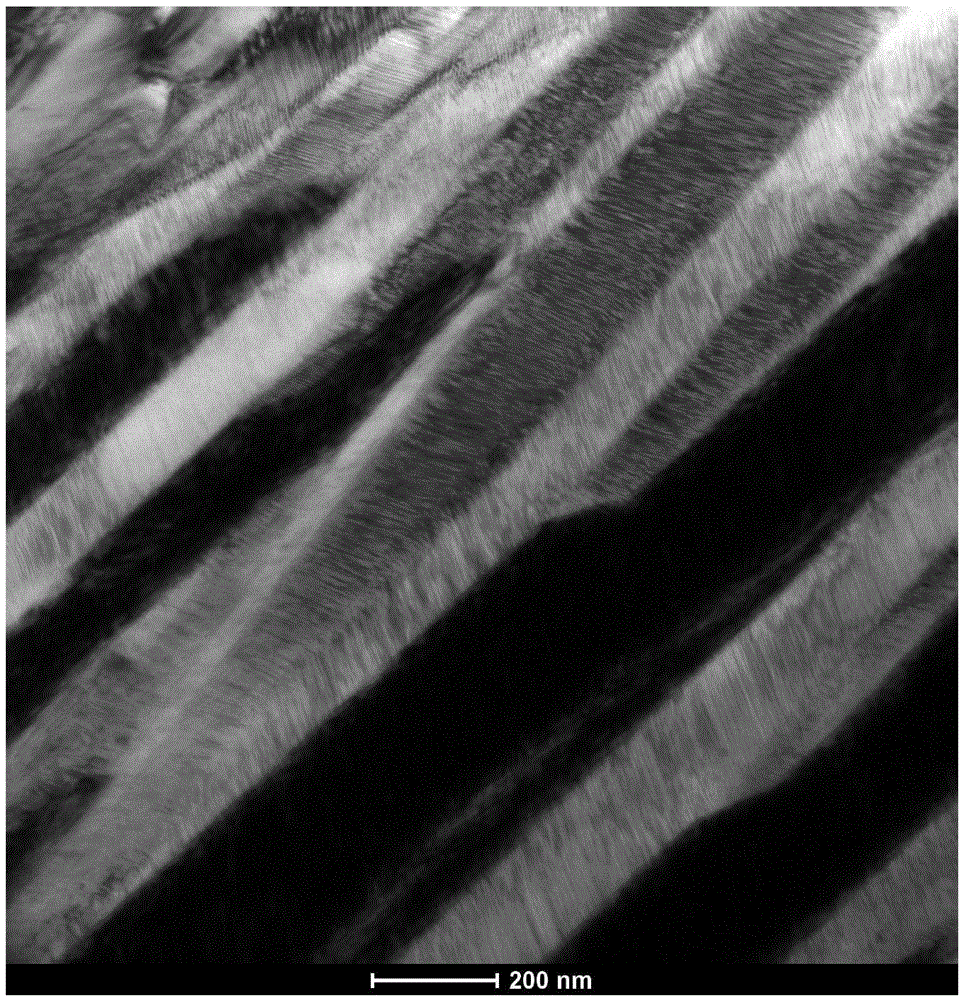

PendingCN113789609AHigh phase change enthalpyImprove cycle stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsCelluloseFiber

The invention discloses a thin-film material with double-effect functions of heat absorption and wave absorption and a preparation method thereof. The composite thin-film material takes water-soluble macromolecules such as polyvinyl alcohol (PVA), sodium cellulose and gelatin as a shell layer, takes a phase change material polyethylene glycol (PEG) as a core layer, takes magnetic nanoparticles such as metals (Fe, Co and Ni), metal alloys (FeCo) and metal oxides (Fe3O4, NiO and CoFe2O4) as wave-absorbing fillers, and the composite thin-film material is prepared by a coaxial electrostatic spinning method. The thin-film material with the double-effect functions of heat absorption and wave absorption has the advantages that water is used as a spinning solvent, the prepared fiber is of a core-shell structure, the problem that leakage is prone to occurring when the phase change core layer is subjected to solid-liquid phase transition is solved, and the content of the phase change core layer is high. In addition, magnetic nanoparticles have high magnetic loss tangent angles and can be used for absorption and attenuation of electromagnetic waves. Therefore, the prepared composite film material has the advantages of green and environment-friendly preparation process, high phase change latent heat, good electromagnetic wave absorption performance, stable recycling performance and the like, and can simultaneously meet the multifunctional application requirements of heat absorption / wave absorption of the thin-film material.

Owner:WUHAN UNIV OF TECH

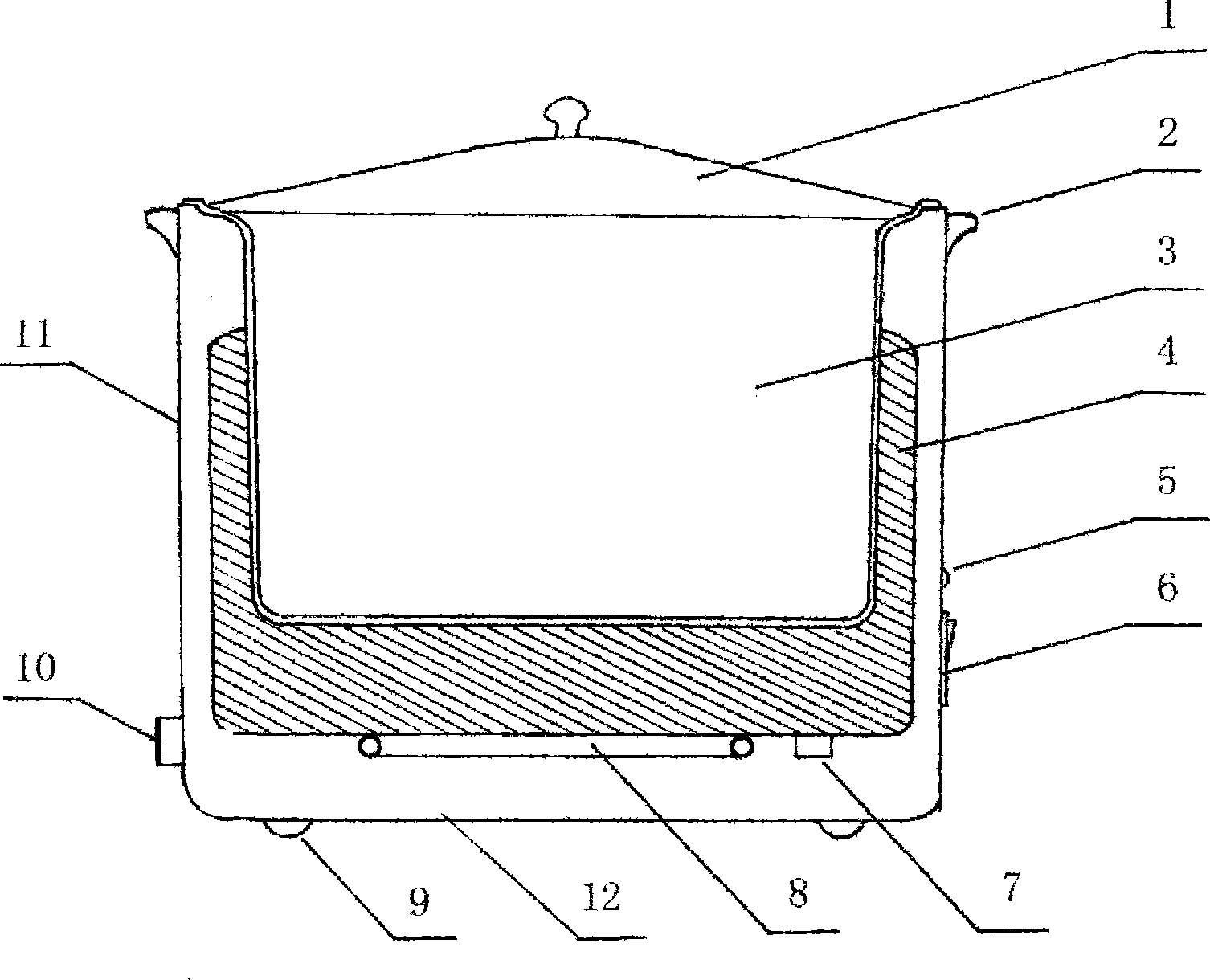

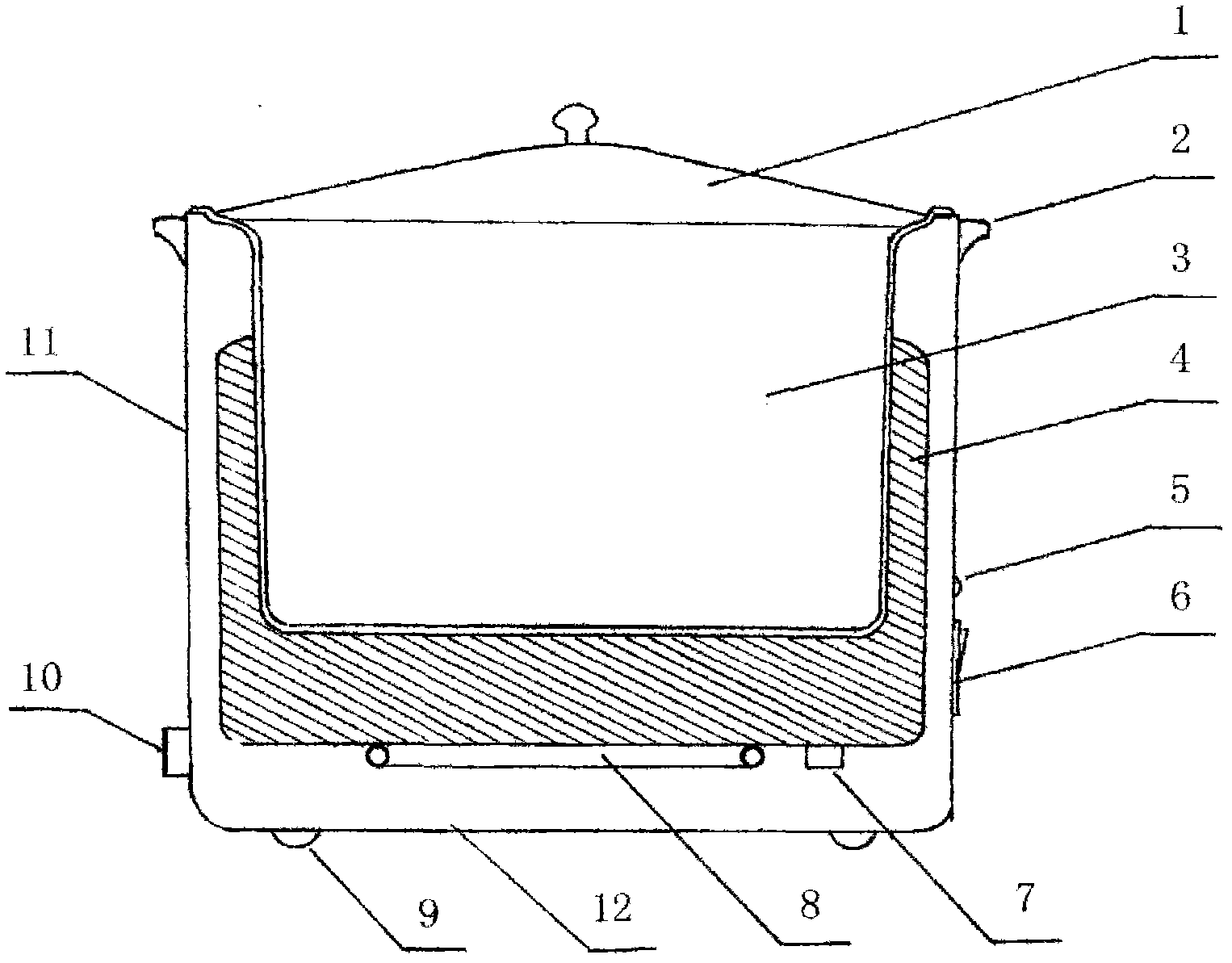

Superconductive energy-saving and heat-accumulating domestic slow cooker and manufacturing method thereof

InactiveCN102423235ASave conventional powerPhase transition melting heightSteam cooking vesselsWarming devicesEngineeringPhase change

The invention relates to an energy-saving superconductive phase-change domestic slow cooker which comprises a high-temperature glass cooker cover, a handle, a cooker liner, a superconductive medium bin, an indicator lamp, a switch, a temperature controller, an electromagnetic heating pipe, cooker feet, a power cord socket, a cooker body and a bottom cover. After the electromagnetic heating pipe arranged at the lower part of the superconductive medium bin is turned on, the electromagnetic heating pipe is heated up to activate the heating-up of phase-change superconductive media in the superconductive medium bin in the slow cooker; when the temperature reaches a set range after the heating-up, the temperature controller turns off the switch, and the phase-change superconductive media in the superconductive medium bin are subjected to solid-solid phase change; and the high-temperature heat of about 150 DEG C can be radiated in the long-time solid-solid phase change process, thereby enabling the domestic slow cooker to achieve the purposes of conventional electric energy saving and long-time steaming, boiling, stewing and braising.

Owner:党庆风

EB curing copper-clad aluminum substrate heat dissipation coating

ActiveCN112961600ADoes not affect transparencyDoes not affect texturePolyurea/polyurethane coatingsEpoxy resin coatingsCoated surfaceAcrylic resin

The invention belongs to the technical field of aluminum-based copper-clad plates, and particularly relates to an EB curing copper-clad aluminum-based plate heat dissipation coating which comprises the following components in parts by weight: 20-30 parts of acrylic resin, 10-20 parts of active monomers, 30-60 parts of phase change capsules, 0.1-0.5 part of a flatting agent, 0.1-0.5 part of a dispersing agent, 0.1-0.5 part of a defoaming agent, 5-10 parts of absolute ethyl alcohol and 10-20 parts of modified inorganic powder. According to the EB curing copper-clad aluminum substrate heat dissipation coating, the phase change capsule is added, heat dissipated by an aluminum-based copper-clad plate can be rapidly absorbed and further dissipated through the surface of the coating, and the phase change capsule is obtained by coating an organic phase change material with an organic matter and has good compatibility with a coating system; and the transparency of the coating and the original texture and texture of the material are not influenced while the heat dissipation effect is improved, excessive solvents do not need to be added, and the method is more environment-friendly.

Owner:GUANGDONG HEYGEY LIGHT CURING MATERIALS

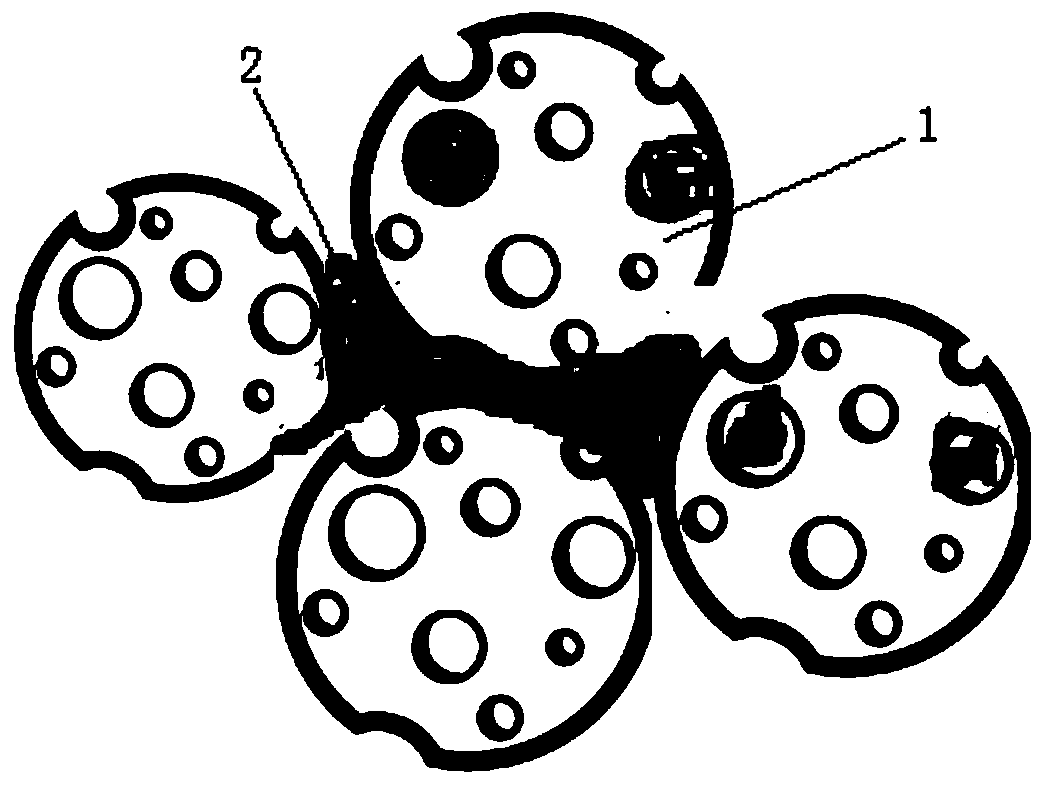

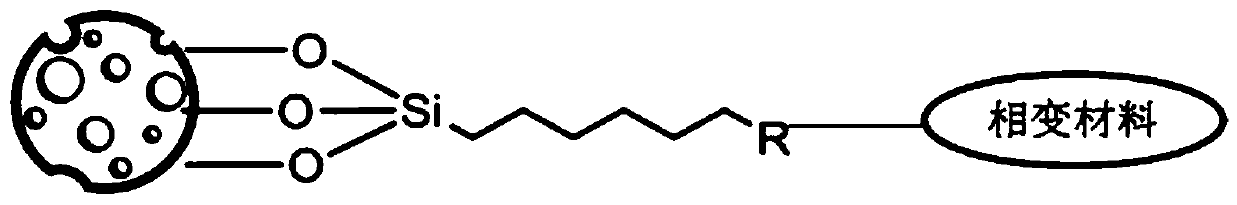

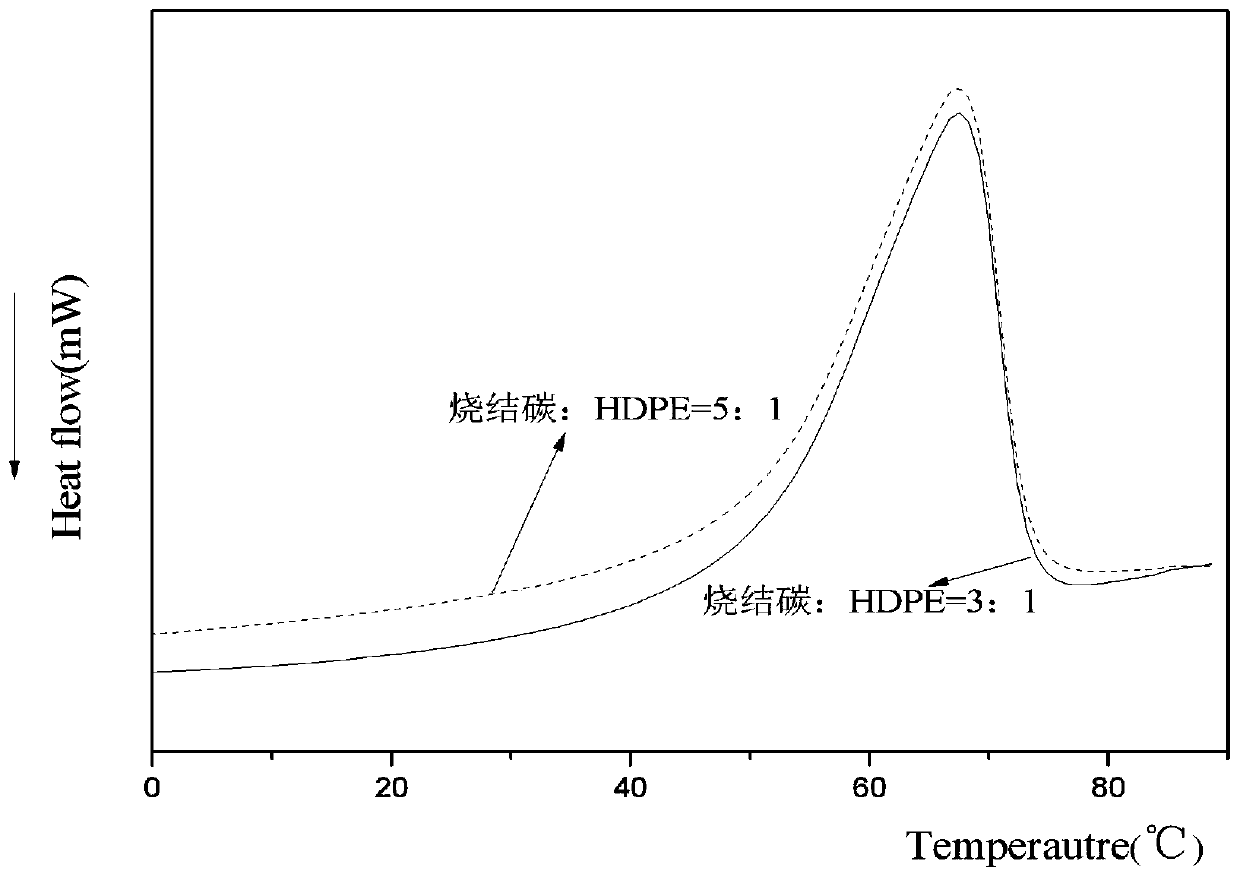

A shape-fixed phase-change material with sintered carbon as a carrier and its preparation method

ActiveCN108531139BReduce manufacturing costImprove applicabilityHeat-exchange elementsCompatibilizationPolymer

The invention discloses a shape-stabilized phase change material with shaped sintered carbon as the carrier and a preparation method thereof. The shape-stabilized phase change material with the shapedsintered carbon as the carrier and the preparation method thereof solve the technical problems easy loss of accumulated energy, low thermal conductivity, poor encapsulation properties and poor dimension and shape design of existing composite phase change materials. The shape-stabilized phase change material with the shaped sintered carbon as the carrier is composed of, by weight percentage, 85-95% of organic high-polymer phase change materials and 5-15% of the shaped sintered carbon, wherein the shaped sintered carbon is processed through surface compatibility treatment; the high-polymer phase change materials are distributed inside gaps formed among particles of the shaped sintered carbon. The preparation method of the shape-stabilized phase change material with the shaped sintered carbon as the carrier comprises preparation of the shaped sintered carbon, surface compatibility treatment, heating and melting of the phase change materials and pressurized permeation.

Owner:WUHAN XINBOMING TECH DEV

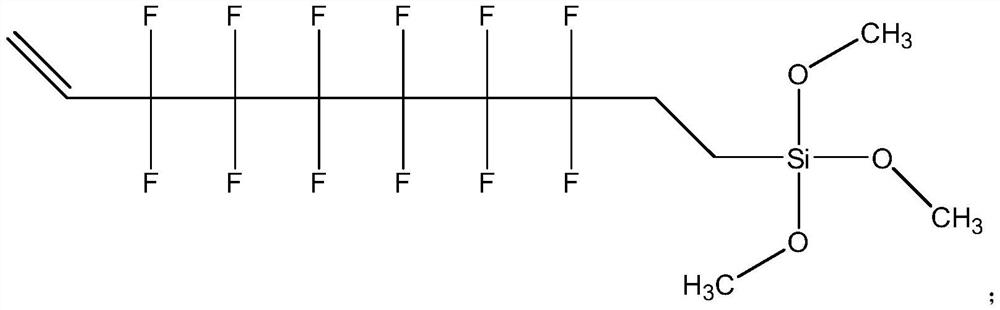

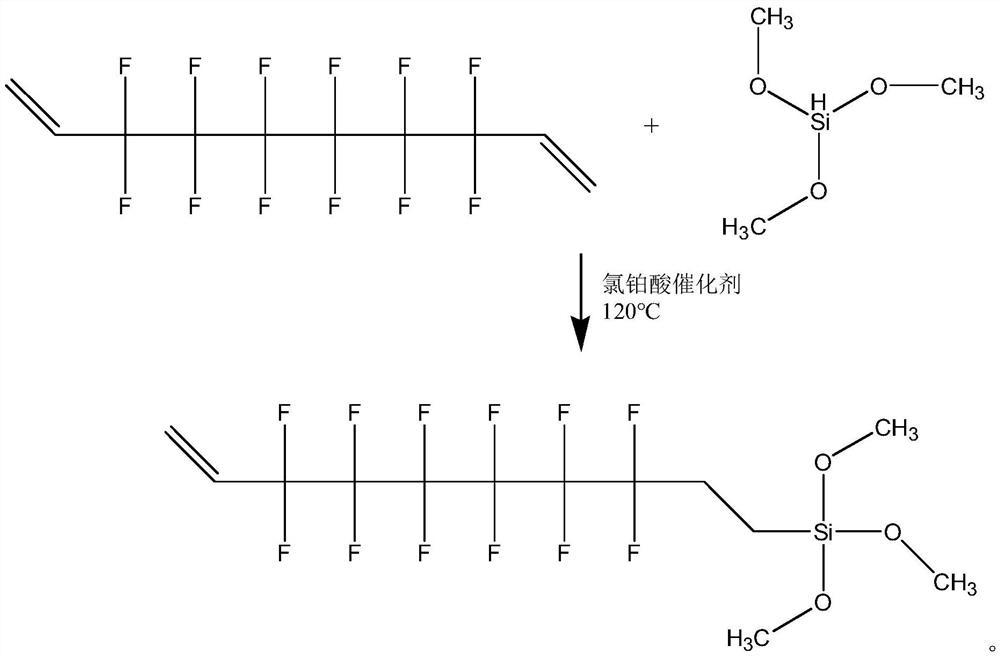

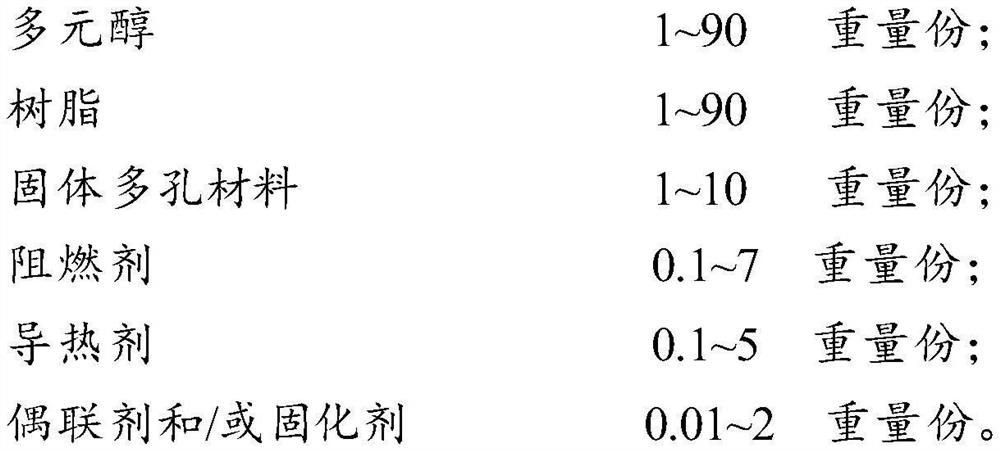

Temperature-control flame-retardant phase-change material for power lithium ion battery, preparation method of temperature-control flame-retardant phase-change material and lithium ion battery

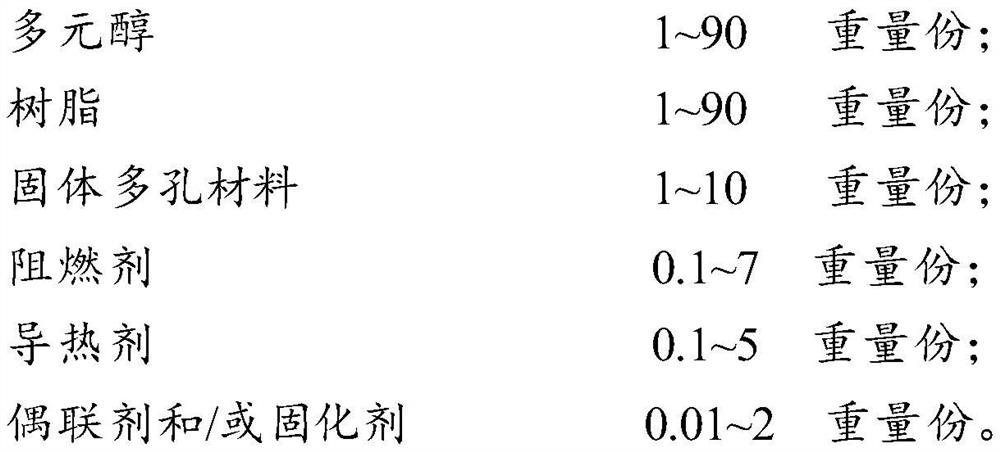

PendingCN114316910AAvoid osmosisWide phase transition temperature rangeSecondary cellsHeat-exchange elementsPolyolAlcohol

The invention provides a flame-retardant phase change material, which is prepared from the following raw materials in parts by mass: 1 to 90 parts by weight of polyhydric alcohol, 1 to 90 parts by weight of resin, 1 to 10 parts by weight of solid porous material, 0.1 to 7 parts by weight of flame retardant, 0.1 to 5 parts by weight of heat conduction agent and 0.01 to 2 parts by weight of coupling agent and / or curing agent. The temperature-control heat-conduction phase-change material is obtained by taking polyhydric alcohol and the like as a phase-change agent, taking resin as a support body of the phase-change material, taking a solid porous material as an auxiliary setting agent, combining with a specific heat-conduction agent and a flame retardant, uniformly mixing the phase-change agent, the support body, the auxiliary setting agent, the heat-conduction agent and the flame retardant, and polymerizing or curing. The solid-solid phase change composite material provided by the invention is wide in phase change temperature range, large in phase change latent heat and adjustable in phase change temperature and phase change latent heat, does not need complex use devices and packaging containers with good sealing performance, and is wider in application occasion and lower in system cost.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

Preparation method of m-phase vanadium dioxide nanopowder

ActiveCN103409768BGood dispersionInfrared transmittance changeElectrolysis componentsVanadium dioxideElectrolysis

The invention discloses a preparation method for phase-M vanadium dioxide nanometre powder. The preparation method comprises the following steps: mixing polyhydric alcohol with a carbon chain length of 3 to 10 with monohydric alcohol with a carbon chain length of 1 to 5 in a volume ratio of 1: (6 to 15), so as to obtain a mixed alcohol solution; then adding quaternary ammonium salt with a carbon chain length of 1 to 16 in the mixed alcohol solution, so as to obtain electrolyte, wherein the concentration of quaternary ammonium salt in the electrolyte is 1-5 g / L; then using a vanadium metal block as an anode, using a platinum metal block or a vanadium metal block as a cathode, keeping a distance between the anode and the cathode to be 2 mm to 5 cm, placing the anode and the cathode in the electrolyte, and electrolysing for 1 to 3 hours under a voltage of 2 to 30 V, so as to obtain a reaction solution containing precipitates; then performing a solid-liquid treatment and a washing treatment on the reaction solution, so as to obtain an intermediate product; and after that, annealing the intermediate product for 1 to 3 hours at a temperature of 350 to 450 DEG C and under a pressure of 10 to 100 Pa, so as to prepare the target product with a particle size of 50 to 100 nm. The preparation method has the characteristics of being time-saving, energy-saving, environment-friendly, low in preparation cost, and easy to realize large-scale industrialized production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

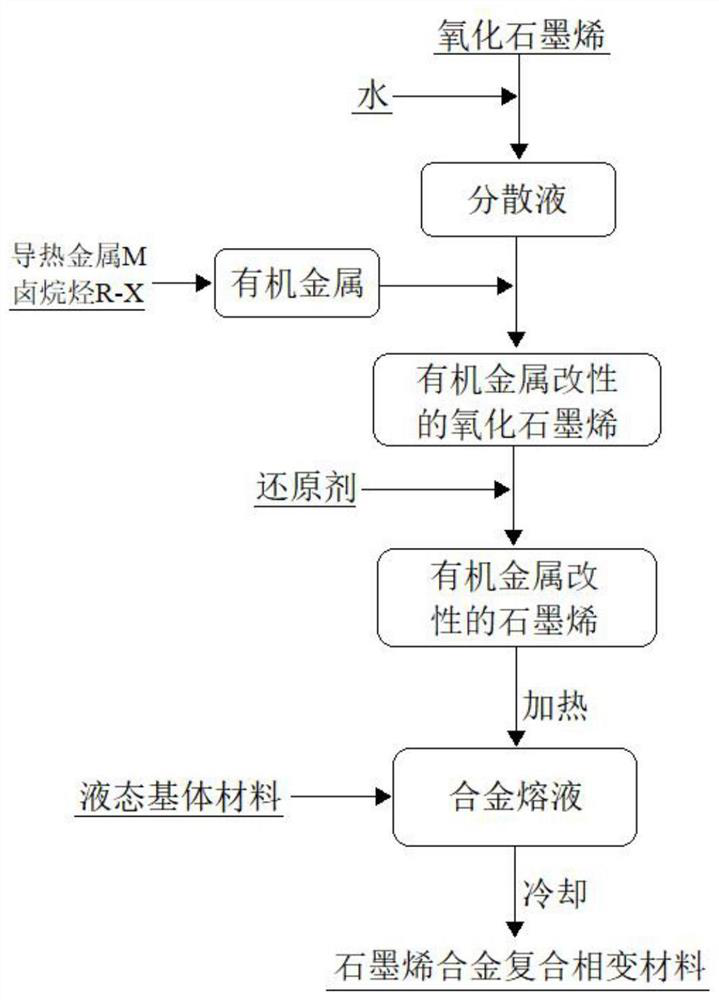

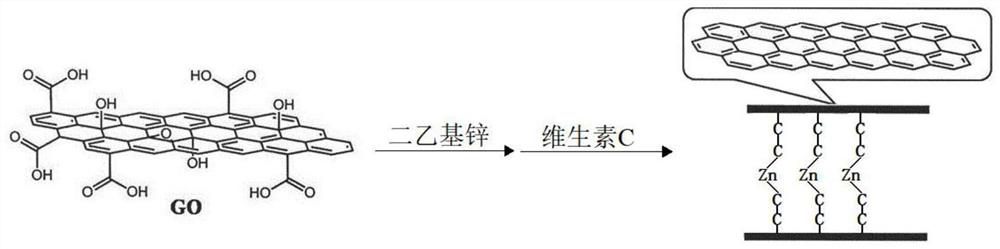

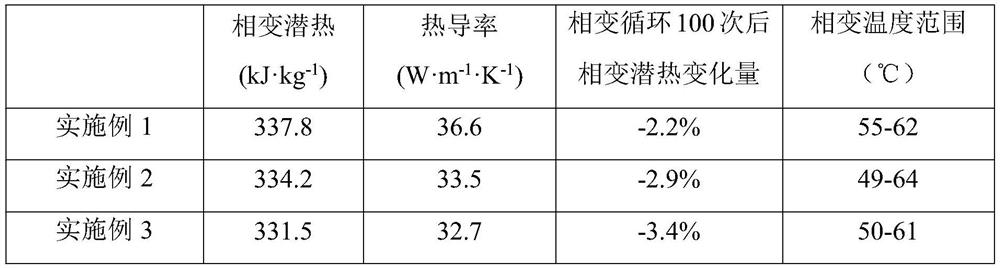

Graphene alloy composite phase change material as well as preparation method and application thereof

ActiveCN113980654AImprove internal thermal conductivityEnhance heat storage and heat release rateChemical industryHeat-exchange elementsLiquid metalAlloy composite

The invention discloses a graphene alloy composite phase change material as well as a preparation method and application thereof, an organic metal compound is adopted to modify graphene, the internal heat conductivity coefficient between graphene layers is greatly improved, and meanwhile, liquid metal with a very high heat conductivity coefficient is used for dopping, and the graphene alloy is compounded with a phase change matrix material to obtain the novel graphene alloy composite phase change material. The anisotropic heat-conducting property of the graphene is greatly improved by the organic metal modified graphene, and the heat-conducting property of the composite phase change material is further improved.

Owner:XIANGTAN UNIV

Nematic liquid crystal composition

ActiveCN102433133BReduce box thicknessQuick responseLiquid crystal compositionsRefractive indexThermal stability

The invention relates to a nematic liquid crystal composition. The composition contains at least a nematic liquid crystal compound as shown in the formula (I), at least a nematic liquid crystal compound as shown in the formula (II), at least a nematic liquid crystal compound as shown in the formula (III), at least a nematic liquid crystal compound as shown in the formula (IV), at least a nematic liquid crystal compound as shown in the formula (V) and at least an optionally optically active compound. The nematic liquid crystal composition provided by the invention has high birefringence, low visco-elastic coefficient ratio gamma 1 / k11 and a wide phase transition temperature range. In addition, the liquid crystal composition has high ultraviolet ray stability and high thermal stability.

Owner:SUPERD CO LTD

A composite phase change heat storage material

ActiveCN104140786BHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of organic phase change heat storage material and its production method

InactiveCN103555280BLess prone to seepageSolve compatibility issuesHeat-exchange elementsThermodynamicsEmulsion

The invention relates to an organic phase change thermal storage material and a production method thereof. The method comprises the following steps: preparing organic phase change material emulsion, preparing an organic phase change thermal storage material and the like. According to the method, the problems of dispersion and compatibility of the organic phase change material in ardealite are effectively solved, the prepared ardealite composite phase change energy storage material is stable in performance, the organic phase change material difficultly diffuses, and the adopted technical scheme is simple in steps and easy to implement. The technology can be widely applied to a process of compounding gypsum materials and organic phase change materials and has good application prospects.

Owner:ZHENGZHOU UNIV

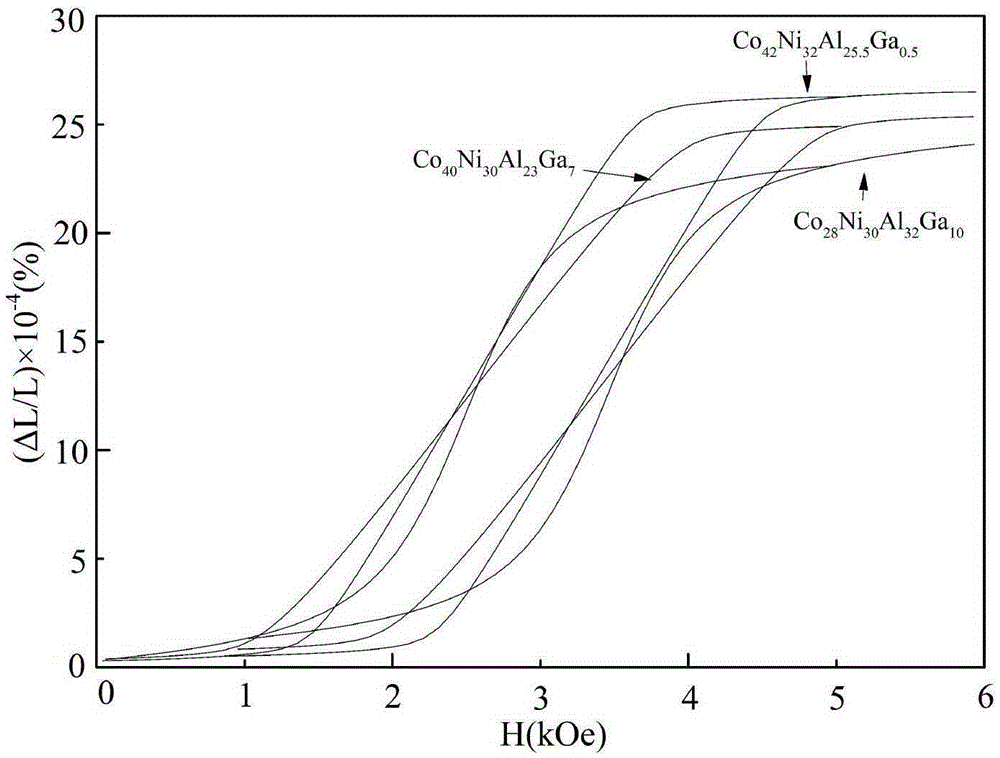

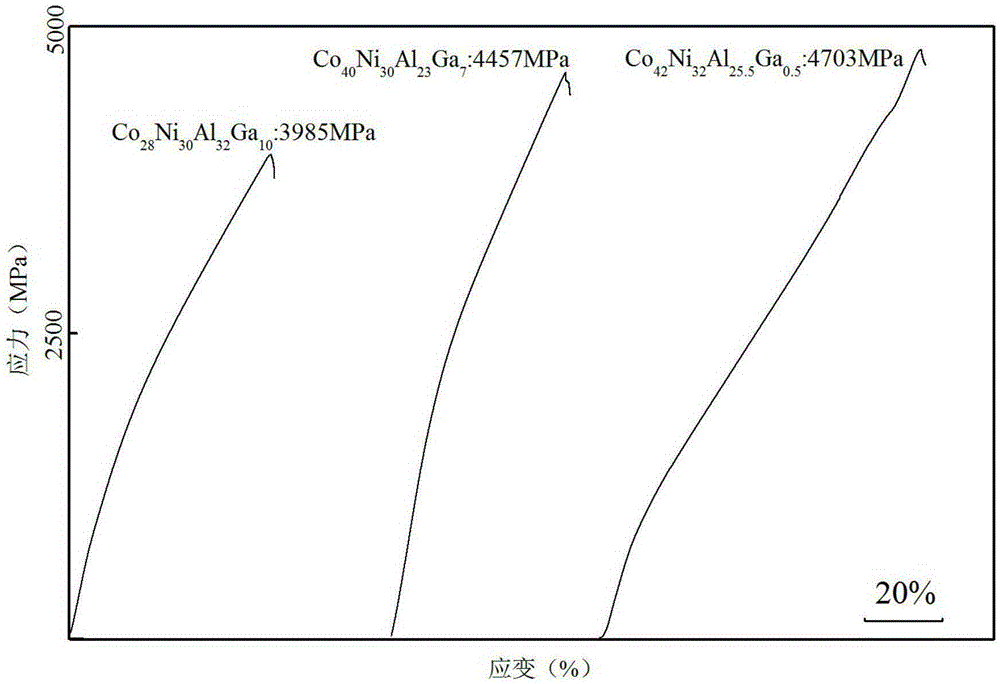

Magnetic material with magnetic field-driven martensitic twin rearrangement and preparation method thereof

ActiveCN103952615BWide range of ingredientsSmall amount of magnetic strainNoise controlShape-memory alloy

The invention discloses a magnetic material with a magnetic field for driving martensite twin crystal rearrangement and a preparation method thereof. The material has ferromagnetism and a two-way shape memory effect, and is a novel magnetically controlled shape memory alloy capable of driving martensite twin crystal rearrangement to generate macro-strain by an outer magnetic field, wherein the chemical component is CoxNiyAlzGaj, x is less than or equal to 42 and greater than or equal to 28; y is less than or equal to 32 and greater than or equal to 25, z is less than or equal to 35 and greater than or equal to 23, j is less than or equal to 10 and greater than or equal to 0.5, x+y+z+j =100, and x, y, z and j represent the molar percentage content. Compared with the existing alloy, the magnetically controlled shape memory alloy CoxNiyAlzGaj disclosed by the invention has large magnetic strain, a wide martensite phase transformation temperature range and good mechanical property, and has important application to the field such as a high-power underwater sonar, a micro positioner, vibration and noise control, a linear motor, a microwave device, a robot and the like.

Owner:SOUTHEAST UNIV

liquid crystal composition

ActiveCN104388100BWide phase transition temperature rangeHigh resistivityLiquid crystal compositionsHigh resistanceRapid response

The invention discloses a liquid crystal composition. The liquid crystal composition has a wide phase transition temperature scope, high resistance, high stability, high double refraction anisotropy and rapid response and good high- and low-temperature stability, can still produce fast response at a low temperature of 0-30 DEG C and is especially suitable for industrial control instruments and vehicle-carried TNTFT-LCD. The liquid crystal composition comprises 1-20wt% of a compound I, 1-50wt% of a compound II, 1-30wt% of a compound III, 1-50wt% of a compound IV, 1-20wt% of a compound V and 0.05-0.5wt% of an optical rotation component.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Liquid crystal composition for TFT (Thin-Film Transistor) display

ActiveCN101831307BImprove performanceLower average response timeLiquid crystal compositionsHigh resistanceLiquid-crystal display

The invention provides a liquid crystal composition for TFT (Thin-Film Transistor) display. The liquid crystal composition is prepared from the following components in percentage by weight: 1-40 percent of I-type compound, 1-70 percent of II-type compound, 1-40 percent of III-type compound, 0-45 percent of IV-type compound and 0-20 percent of V-type compound. The liquid crystal composition has excellent performance, extremely low total response time (ttot=ton+toff), lower voltage, high resistance ratio and voltage retention ratio, and can also have different threshold voltages, clearing points and delta n characteristics by adjusting the contents of the components, thereby being particularly suitable for manufacturing rapid-response TN-TFT liquid crystal displays.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Preparation method and application of a shape-fixed phase change heat insulation and cooling pavement material suitable for high temperature areas

The invention discloses a preparation method and an application of a shape-stabilized phase change heat insulation and cooling pavement material applicable to high-temperature regions. The method comprises steps as follows: silica sol is prepared with tetraethoxysilane as a precursor with a sol-gel technology; a proper amount of expanded perlite is modified with an organic modifier, and modified perlite is obtained; molten calcium chloride hexahydrate is subjected to emulsification dispersion under the ultrasonic condition under the emulsification dispersion effect of laurinol, and a stable emulsion is formed; modified perlite is added to silica sol and dispersed uniformly, an obtained mixed solution is placed in a vacuum oven, proper amounts of stearic acid, cellulose diacetate and the obtained emulsion are added, the obtained mixture is vacuumized, left to stand at the room temperature for 30 min and reacts at 70-80 DEG C under the normal pressure for 5 h, drying is performed at the normal temperature, and the pavement material is obtained. The obtained material is stable in structure, has better heat storage, cooling and heat insulation performance and has wide phase change temperature range, and the asphalt pavement rut problem in the high-temperature regions can be effectively solved.

Owner:NANCHANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com