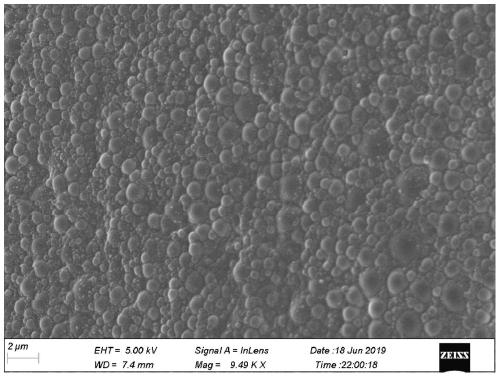

Biodegradable microcapsule cold storage agent and preparation method thereof

A cold storage agent and microcapsule technology, applied in the field of biodegradable microcapsule cold storage agent and its preparation, can solve the problems of low coating rate of hydrophilic substances, poor impact resistance, low mechanical strength, etc., and reach the phase transition temperature The effect of wide range, good sealing, and high latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Preparation of phase change cold storage core material

[0046] Add 15g of glycerin and 15g of NaCl into the three-necked flask, stir until uniform, continue to stir for 1h and then store.

Embodiment 2

[0047] The preparation of embodiment 2 core material emulsion

[0048] Take 12 g of the core material prepared in Example 1, mix it with 1.5 g of emulsifier, add it into 100 mL, stir and emulsify at a speed of 1000 r / min to obtain an emulsion.

Embodiment 3

[0049] The preparation of embodiment 3 polylactic acid prepolymer

[0050] According to the document "Changqing.Polym.Materials Sci.&Engineering [J], 1994,10 (1): 140-143. " method is synthesized lactide, is initiator with stannous octoate, initiates lactide ring-opening polymerization, the obtained After the polylactic acid prepolymer is purified, the average molecular weight measured by gel permeation chromatography is 4000.

PUM

| Property | Measurement | Unit |

|---|---|---|

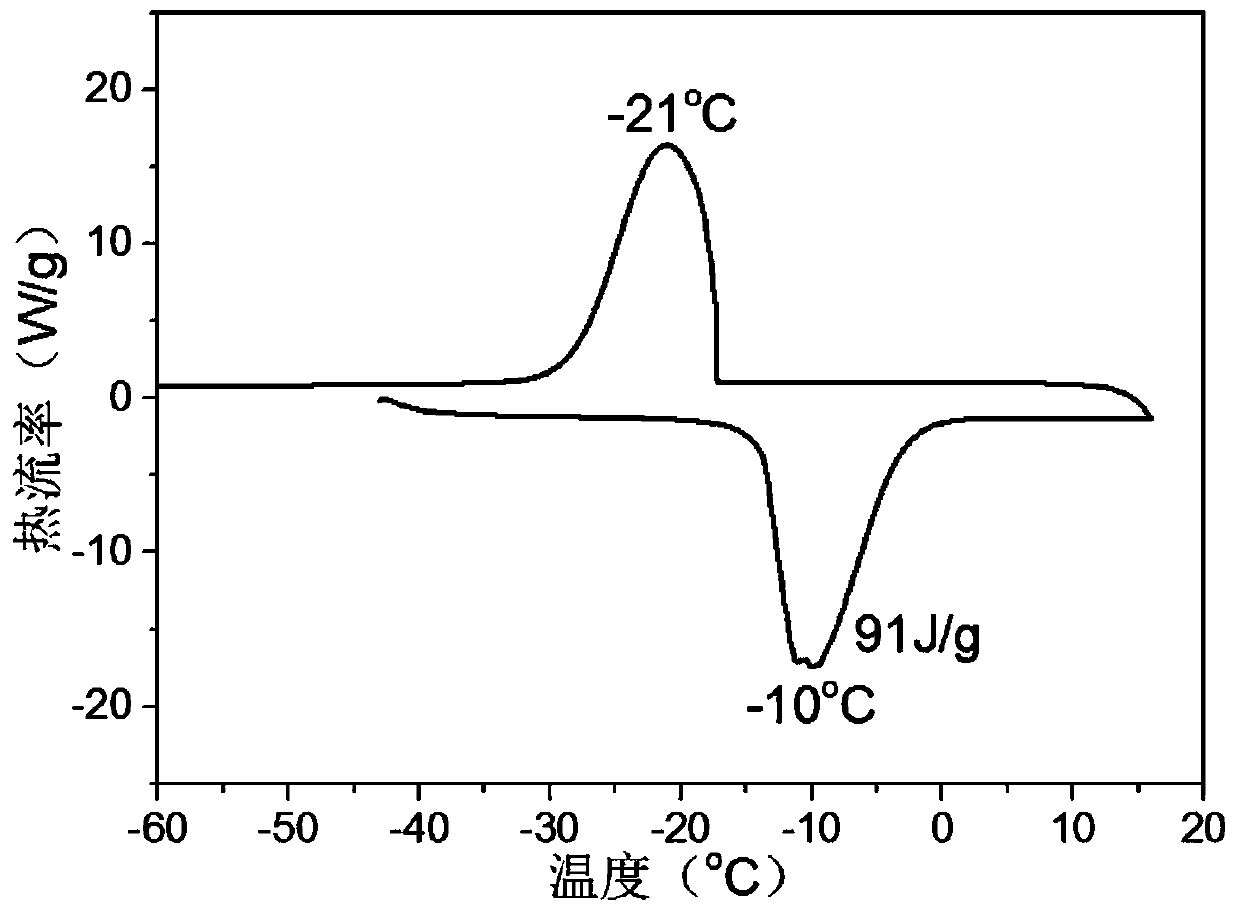

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

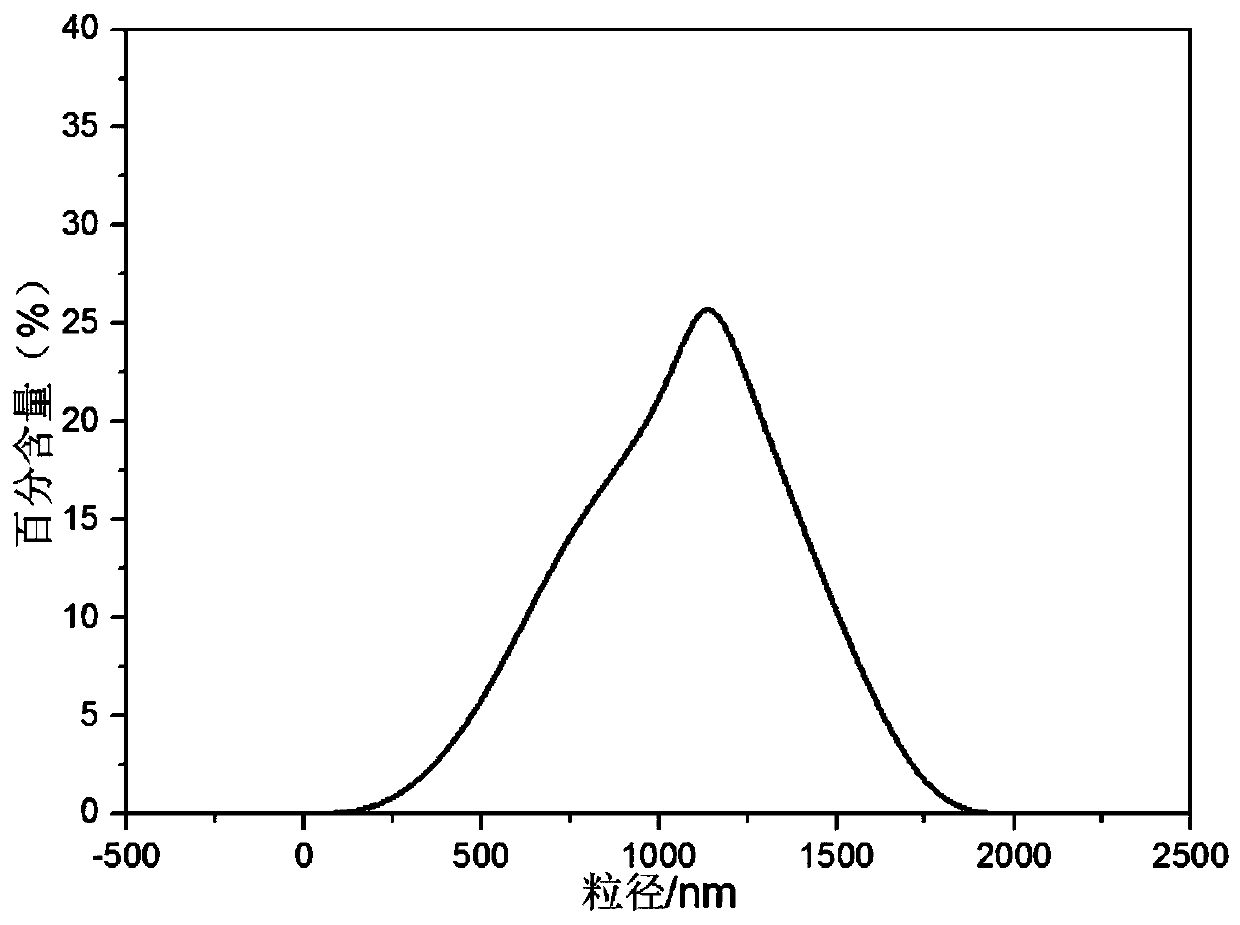

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com