Graphene alloy composite phase change material as well as preparation method and application thereof

A technology of composite phase change materials and olefin alloys, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as thermal conductivity that have not been reported, and facilitate promotion and industrialized large-scale production , the overall thermal conductivity is excellent, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

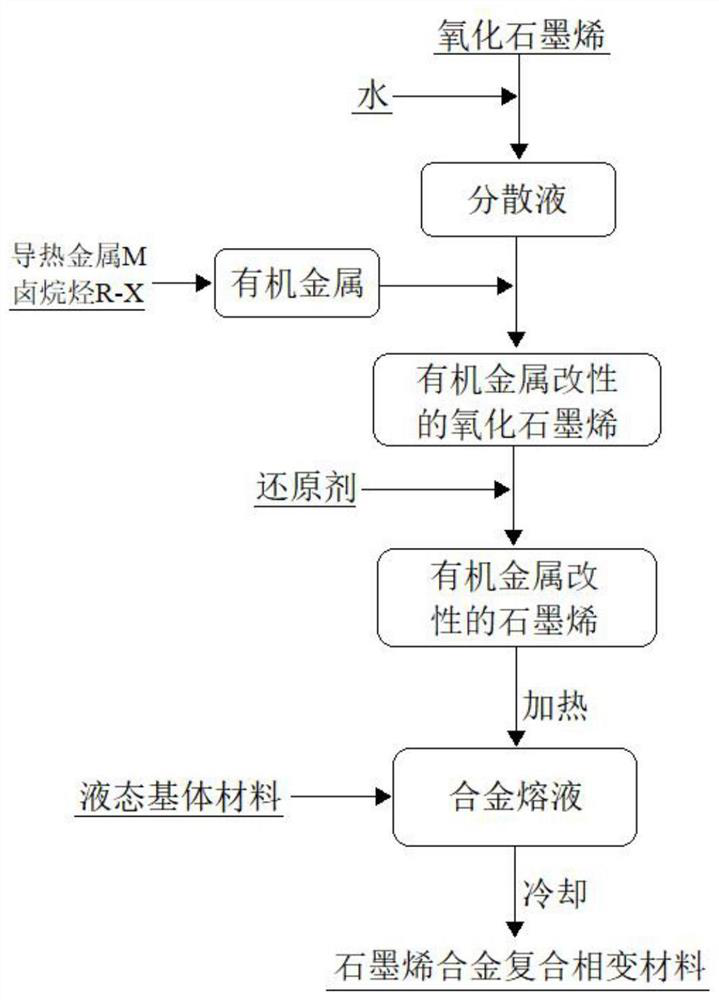

Method used

Image

Examples

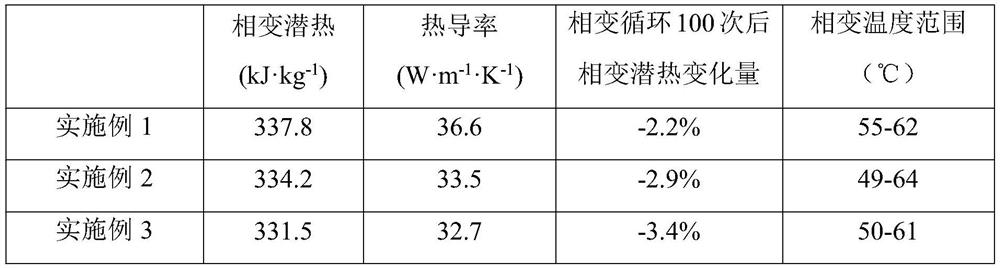

Embodiment 1

[0040] Dissolve 6.538 parts of mixed metal powder containing zinc powder (also containing 1.308 parts of indium, bismuth, tin metal powder mixed at a mass ratio of 1:1:1) and 0.03 mol of ethyl chloride in a mixed solvent of ether and tetrahydrofuran In a dry and airtight environment, the reaction was carried out, and the solvent was removed to obtain a mixture containing diethylzinc.

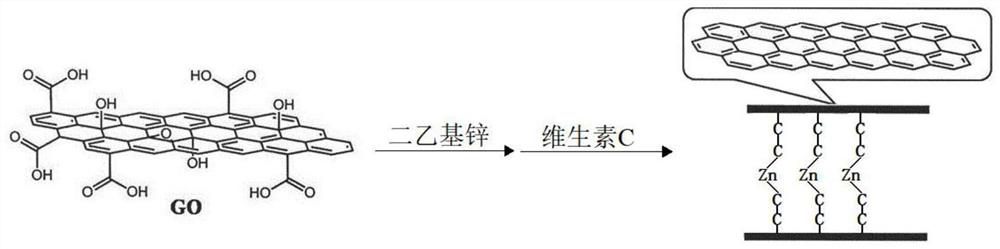

[0041] Add 150 parts of graphene oxide into water and ultrasonically disperse for 30 minutes. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 4 hours. After the reaction is complete, add 15 parts of vitamin C and continue stirring for 3 hours at 75°C. After the reaction is completed, use toluene Washed three times, and then dried to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0042] Weigh 11 parts of the graphene mixture containing diethylzinc modification and heat and melt to fo...

Embodiment 2

[0044] Dissolve 6.538 parts of mixed metal powder of zinc powder (also containing 1.308 parts of indium, bismuth, tin metal powder mixed in a mass ratio of 1:1:1) and 0.03 mol of ethyl chloride in a mixed solvent of ether and tetrahydrofuran , react in a dry and airtight environment, remove the solvent, and obtain a mixture containing diethylzinc.

[0045] Weigh 150 parts of graphene oxide into water, and ultrasonically disperse for 30 minutes. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 4 hours. After the reaction is complete, add 15 parts of vitamin C and continue stirring for 3 hours at 75°C. After the reaction is completed, use toluene Washed three times, and then dried to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0046] Weigh 8 parts of the graphene mixture containing diethylzinc modification and heat and melt to form a mixed melt, while heating and ...

Embodiment 3

[0048] Dissolve 6.538 parts of zinc powder (excess zinc powder) and 0.03 mol of ethyl chloride in a mixed solvent of ether and tetrahydrofuran, react in a dry and airtight environment, remove the solvent, and obtain a mixture of diethyl zinc.

[0049] Add 150 parts of graphene oxide into water and ultrasonically disperse for 30 minutes. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 4 hours. After the reaction is complete, add 15 parts of vitamin C and continue stirring for 3 hours at 75°C. After the reaction is completed, use toluene Washed three times, and then dried to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0050] Weigh 11 parts of the graphene mixture containing diethylzinc modification and heat and melt to form a mixed melt, while heating and melting 89 parts of paraffin to form liquid paraffin, then add the liquid paraffin to the mixed melt and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com