A shape-fixed phase-change material with sintered carbon as a carrier and its preparation method

A shape-setting phase-change material and a technology for phase-change materials, which are applied in the field of shape-setting phase-change materials with shaped sintered carbon as a carrier and their preparation, can solve the problems of low thermal conductivity, poor encapsulation, easy loss of energy storage and the like, and achieve low manufacturing costs. , The effect of wide phase transition temperature range and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

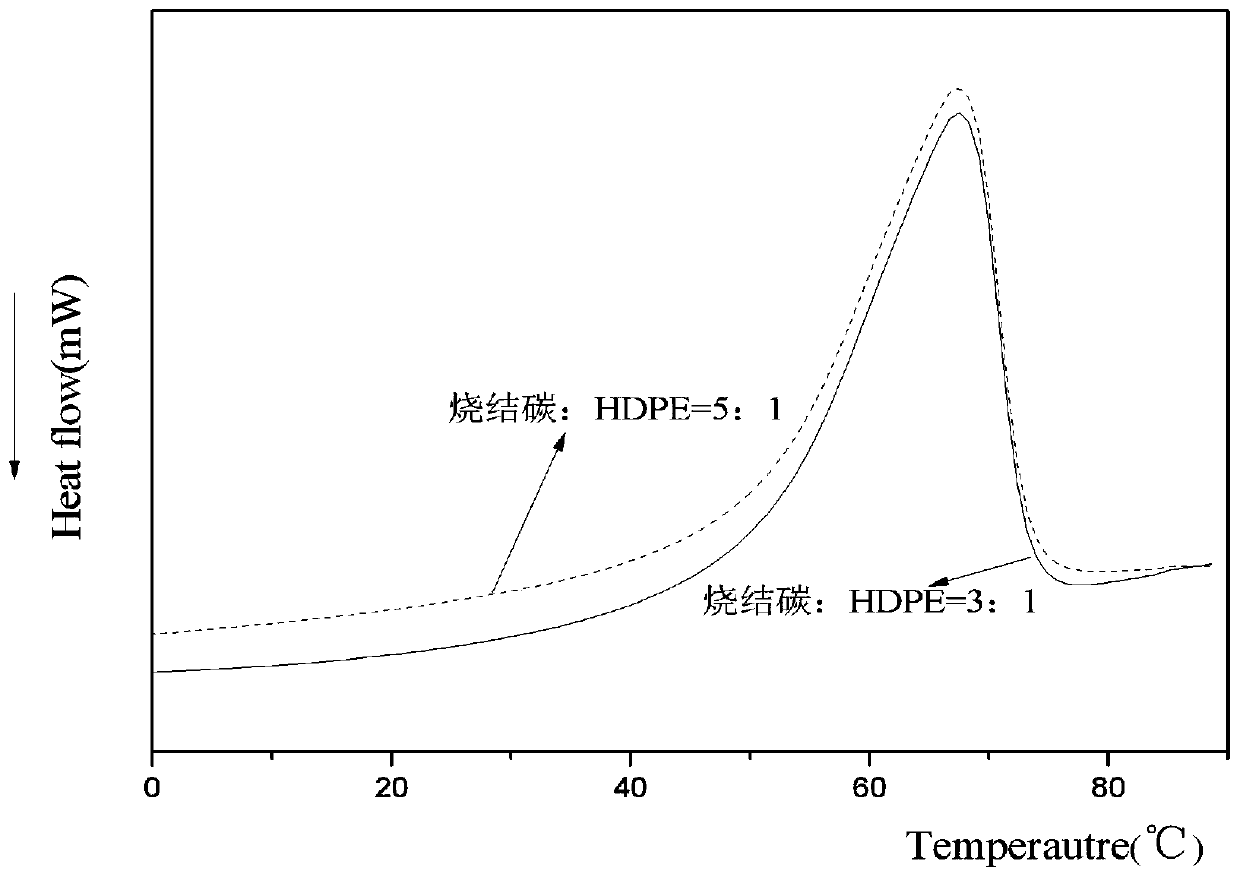

Embodiment 1

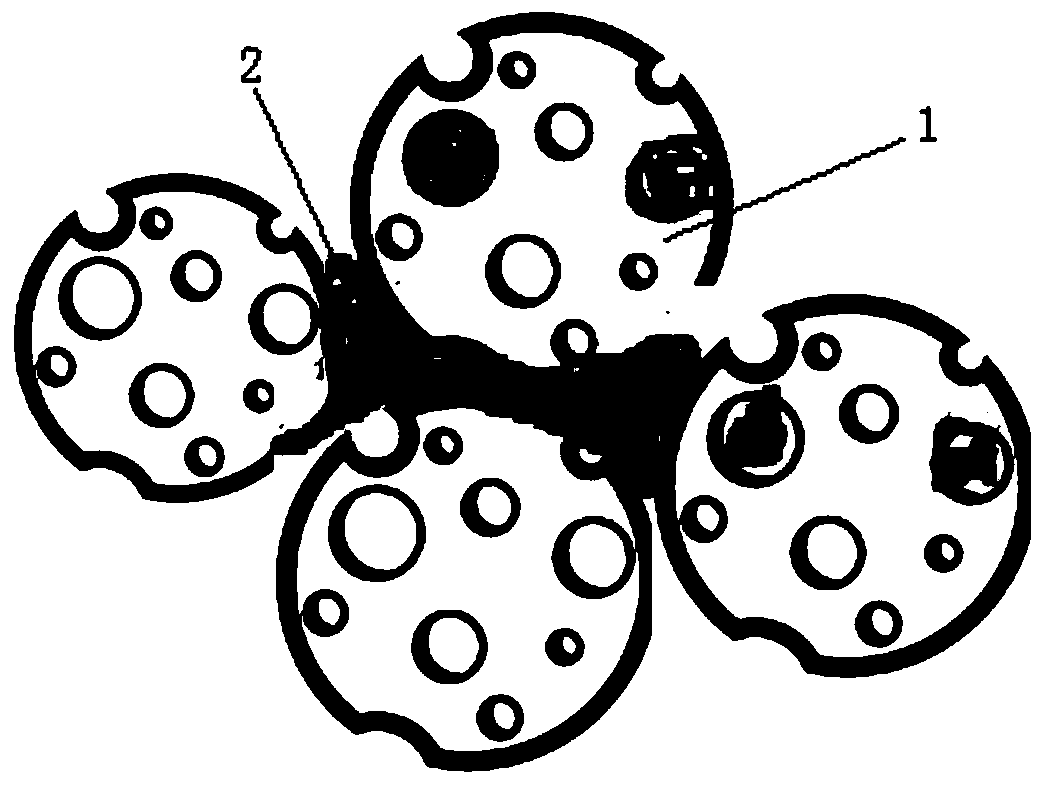

[0033] Step 1: Preparation of molded sintered carbon

[0034] Mix coconut shell powder activated carbon particles with high density polyethylene (HDPE) at a mass ratio of 5:1, mix them evenly, and put them into a forming mold at a temperature of 150°C and a pressure of 10-15MPa for 30 minutes to form the desired shape. Sintered carbon.

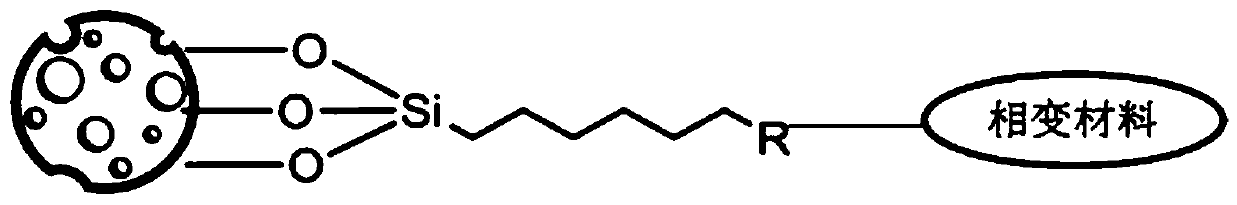

[0035] Step 2: Surface compatibility treatment of molded sintered carbon

[0036] First mix 95% ethanol and 5% water into an alcohol-water solution, add acetic acid to make the pH 4.5-5.5, add the silane coupling agent KH570 under stirring to make the concentration reach 2%, hydrolyze for 5 minutes, and then add the obtained in step 1 The sintered carbon material is added to it, configured into a 20g / L solid-liquid suspension, heated to 45°C, treated for 1 hour, filtered and dried at low temperature after the treatment.

[0037] Step 3: Preparation of shaped sintered carbon composite shaped phase change material

[0038] Put the molded sintered carbon...

Embodiment 2

[0041] Step 1: Preparation of molded sintered carbon

[0042] The powdered activated carbon particles made from coconut shell and high-density polyethylene (HDPE) are mixed at a mass ratio of 3:1, stirred evenly, and then put into a forming mold at a temperature of 150°C, a pressure of 10-15 MPa, and a pressure of 30 minutes to form the desired shape.

[0043] Step 2: Surface compatibility treatment of molded sintered carbon

[0044] First mix 95% ethanol and 5% water into an alcohol-water solution, add acetic acid to make the pH 4.5-5.5, add the silane coupling agent KH570 under stirring to make the concentration reach 2%, hydrolyze for 5 minutes, and then add the obtained in step 1 The sintered carbon material is added to it, configured into a 20g / L solid-liquid suspension, heated to 45°C, treated for 1 hour, filtered and dried at low temperature after the treatment.

[0045] Step 3: Preparation of shaped sintered carbon composite shaped phase change material

[0046] Put the molded ...

Embodiment 3

[0049] Step 1: Preparation of molded sintered carbon

[0050] Mix coconut shell powder activated carbon particles with high density polyethylene (HDPE) at a mass ratio of 5:1, stir evenly, and put them into a forming mold at a temperature of 150°C and a pressure of 10 to 15 MPa for 30 minutes to form a desired shape and sinter carbon.

[0051] Step 2: Surface compatibility treatment of molded sintered carbon

[0052] First mix 95% ethanol and 5% water into an alcohol-water solution, add acetic acid to make the pH 4.5-5.5, add the silane coupling agent KH550 under stirring to make the concentration reach 2%, hydrolyze for 5 minutes, and then add the obtained in step 1. The sintered carbon material is added to it, configured into a 20g / L solid-liquid suspension, heated to 45°C, treated for 1 hour, filtered after the treatment, and dried at low temperature.

[0053] Step 3: Preparation of shaped sintered carbon composite shaped phase change material

[0054] Put the molded sintered carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com