Phase change energy storage material prepared from oleic acid or esters of energy storage material and preparation method thereof

A phase change energy storage material, ethyl oleate technology, is applied in the field of phase change energy storage materials and their preparation, and achieves the effects of large latent heat of phase change, controllable phase change temperature and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Add 50g formic acid, 80g hydrogen peroxide, and 0.2g phosphoric acid to 50g oleic acid, control the reaction temperature to 45°C, stir and reflux, and react for 4h; after the reaction stops, remove the water phase and take the oil layer.

[0027] 2. Add 150 g of 7% sodium hydroxide solution to the oil layer, control the reaction temperature to 80°C, stir and reflux, and react for 2 hours. After the reaction stops, add hydrochloric acid to make it acidic, precipitate out, and filter with suction.

[0028] 3. The precipitate was recrystallized with 95% ethanol to obtain a white solid powder, which was dried naturally to obtain a phase change energy storage material.

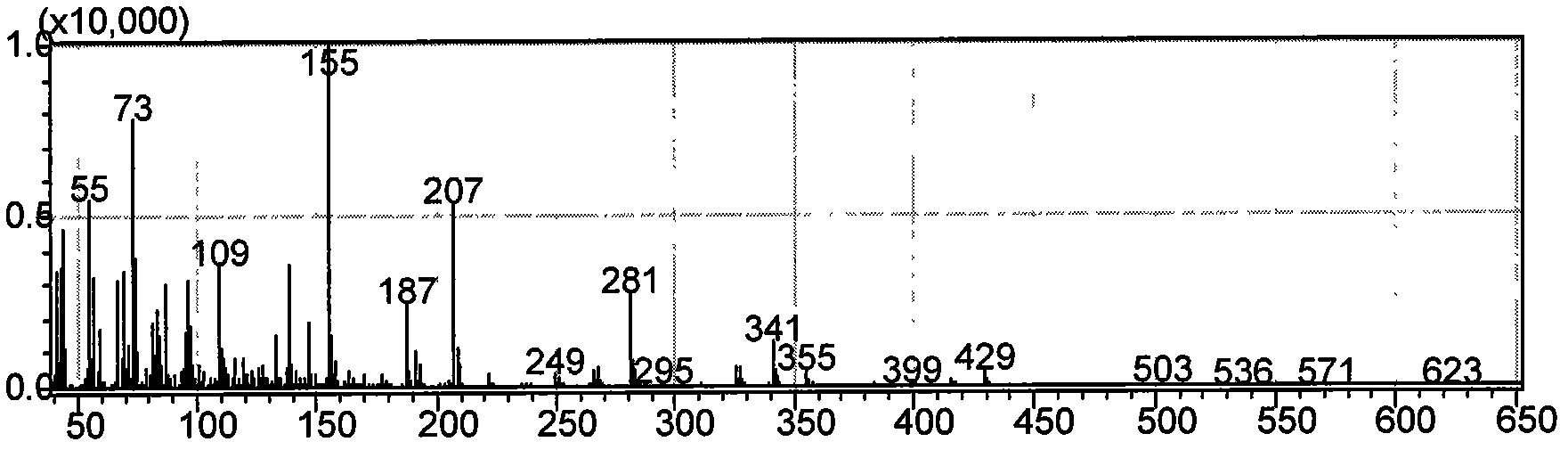

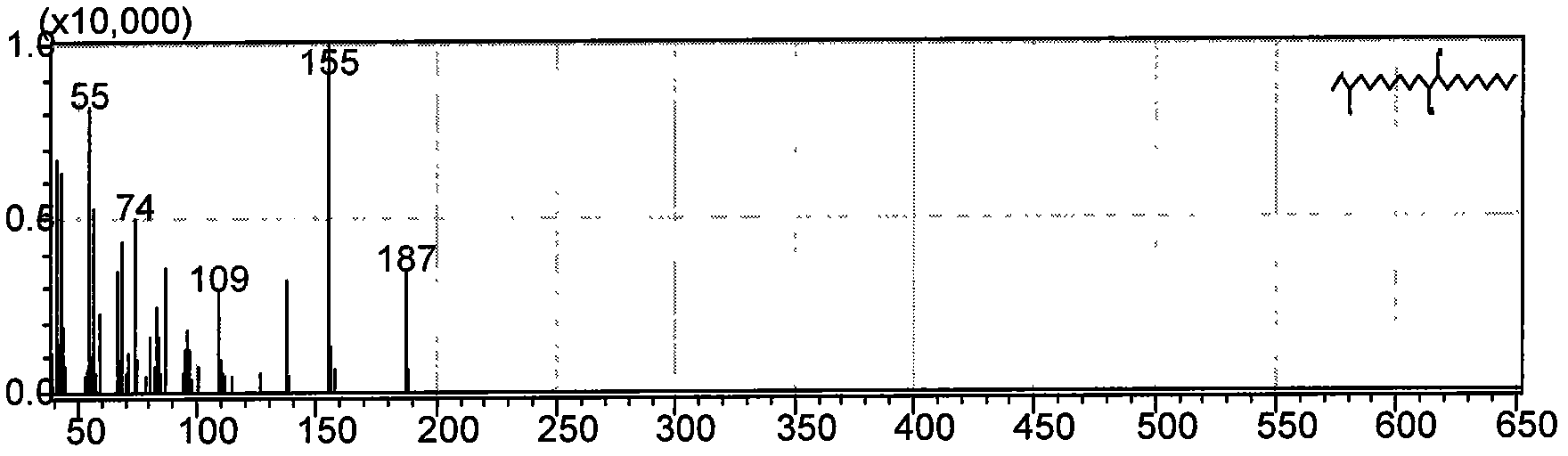

[0029] The material prepared above was analyzed by GCMS-QP2010, and compared with the standard spectrum, it was determined that the substance was C 18 h 36 o 4 , its hydroxyl value was measured to be 342mgKOH / g, thus its structure can be determined as CH 3 (CH 2 ) 7 CHOH-CHOH (CH 2 ) 7 COOH. The p...

example 2

[0031] 1. Add 40g of formic acid and 70g of hydrogen peroxide to 50g of methyl oleate, control the reaction temperature to 55°C, stir and reflux, and react for 8h; after the reaction stops, remove the water phase and take the oil layer.

[0032] 2. Add 200 g of 10% sodium hydroxide solution to the oil layer, control the reaction temperature to 90°C, stir and reflux, and react for 4 hours. After the reaction stops, add hydrochloric acid to make it acidic, precipitate out, and filter with suction.

[0033] 3. The precipitate was recrystallized with acetone to obtain a white solid powder, which was naturally dried to obtain a phase change energy storage material.

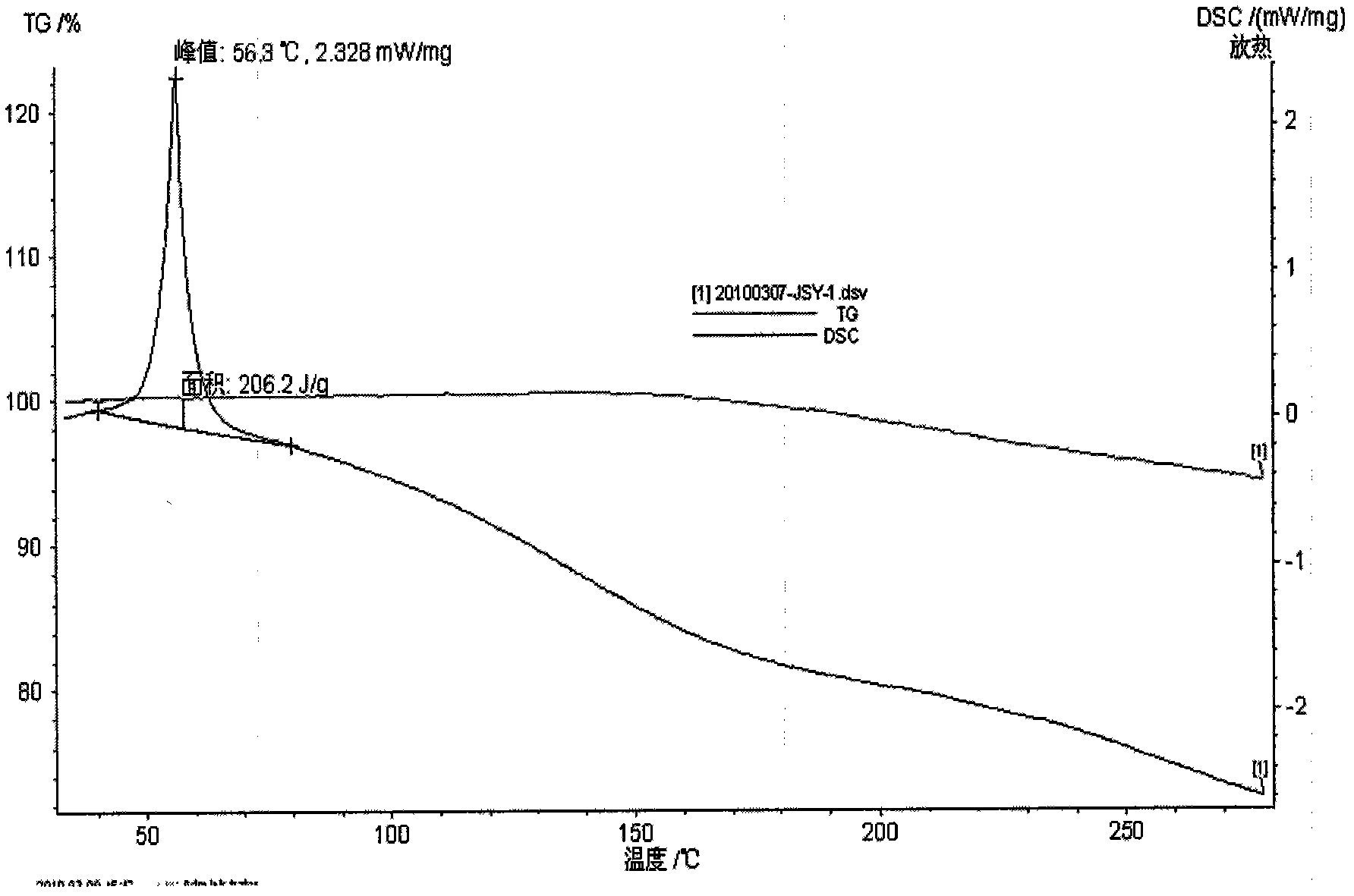

[0034] The material prepared above was analyzed by GCMS-QP2010 as C 18 h 36 o 4 , the hydroxyl value is 360mgKOH / g, and the STA409PC / PG comprehensive thermal analyzer of Germany is used for detection. The phase transition peak temperature of the melting curve of the material is 130°C, and the latent heat of phase tra...

example 3

[0036] Take 20 g of the product obtained in Example 2, add 100 ml of methanol and 3 ml of concentrated sulfuric acid, stir and reflux at 55 ° C for 6 h, and rotate to evaporate the alcohol after the reaction is stopped. The product is washed to neutral and naturally dried to obtain a white solid. Analyzed as C 19 h 38 o 4 , the hydroxyl value is 338mgKOH / g, and the German NETZSCH STA409PC / PG comprehensive thermal analyzer is used for detection. It is measured that the phase transition peak temperature of the melting curve of the material is 106°C, and the phase transition latent heat is 147J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com