Temperature-control flame-retardant phase-change material for power lithium ion battery, preparation method of temperature-control flame-retardant phase-change material and lithium ion battery

A lithium-ion battery and phase-change material technology, applied in the field of lithium-ion battery flame-retardant materials, temperature-controlled flame-retardant phase-change materials for power lithium-ion batteries and their preparation, can solve volume expansion, poor thermal stability, and reduced diaphragm thickness Short-circuit risk and other issues, to achieve the effect of mild conditions, good shapeability, and good latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

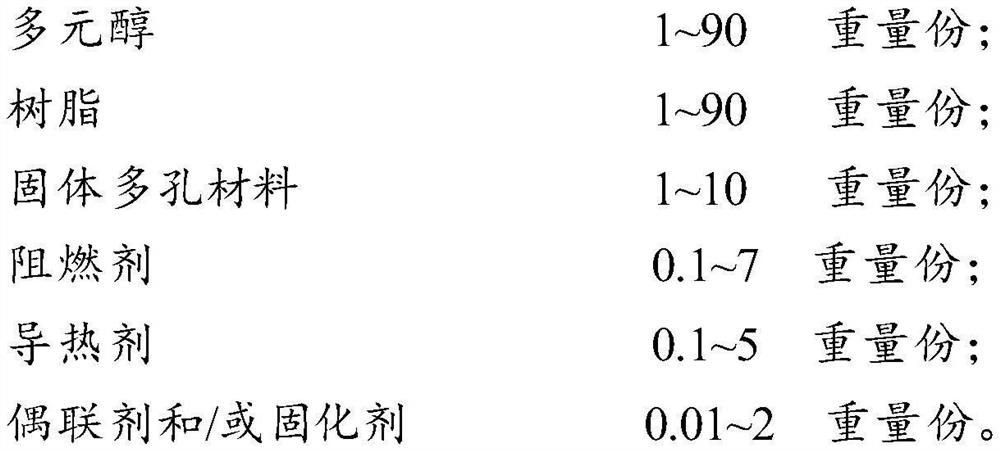

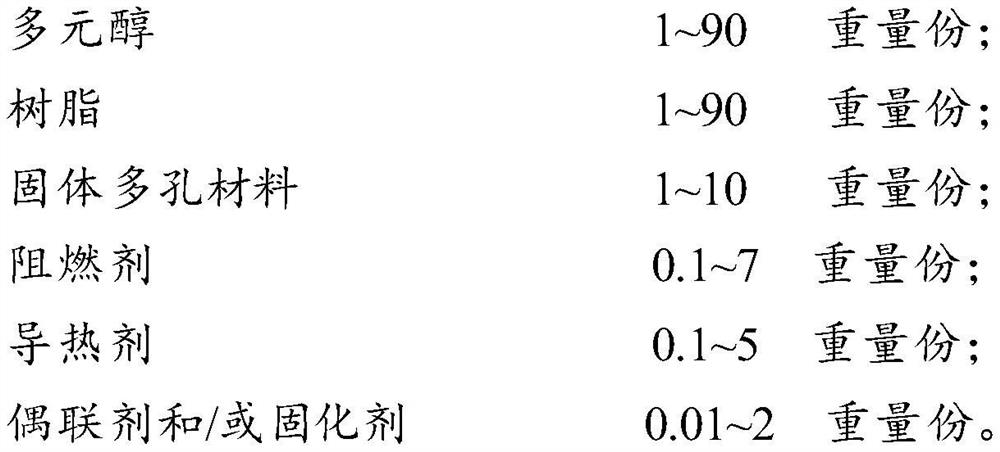

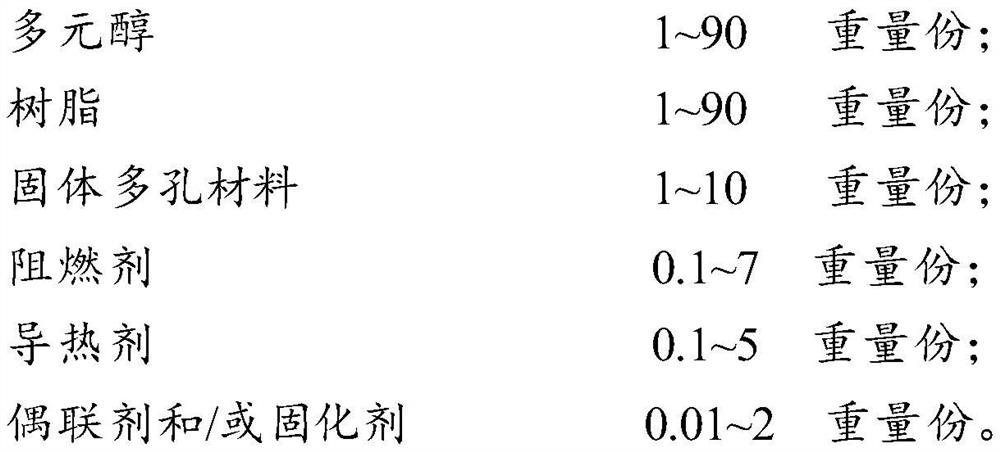

[0060] The present invention also provides a method for preparing a flame-retardant phase-change material, comprising the following steps:

[0061] 1) After heating and mixing diluent, resin, solid porous material, polyester polyol and / or polyether polyol, flame retardant and heat conduction agent, then add coupling agent or curing agent and continue stirring and mixing to obtain a mixture ;

[0062] 2) After curing and pressing the mixture obtained in the above steps, a flame-retardant phase change material is obtained.

[0063] In the preparation method of the flame-retardant phase change material of the present invention, the type, selection and addition amount of raw materials, and the corresponding preferred principles are the same as the type, selection and addition amount of the raw materials in the aforementioned flame-retardant phase change material, and the corresponding The optimization principles can all be corresponding, and will not be repeated here.

[0064] I...

Embodiment 1

[0086]The preparation method of solid-solid phase change material: Weigh the raw materials according to the mass ratio of neopentyl glycol, epoxy resin, graphene, and hexafluorocyclotriphosphazene at 65:25:8:2, and mechanically pulverize the neopentyl glycol to 50 μm; add crushed neopentyl glycol, epoxy resin, graphene, and hexafluorocyclotriphosphazene into the stirring tank, heat to 80°C and stir for 3 hours; then add epoxy resin with a mass ratio of 1% for curing The agent triethylenetetramine is continuously stirred for a certain period of time; the above-mentioned mixed material is pressed and solidified at a high temperature of 150°C according to the sheet structure to obtain a solid-solid phase change composite material.

[0087] The above-mentioned solid-solid phase change composite material is wrapped around the battery cell or pasted inside the battery PACK for use.

[0088] Performance testing was performed on the temperature-controlled flame-retardant organic phase...

Embodiment 2

[0095] The preparation method of solid-solid phase change material: weigh 1,6-hexanediol, phenolic resin, expanded shale, graphene, hexamethylcyclotriphosphazene according to the mass ratio of 70:20:5:3:2, First, mechanically crush 1,6-hexanediol and expanded shale to 50 μm, then physically mix with graphene and hexamethylcyclotriphosphazene; then add phenolic resin to the stirring tank, heat to 70°C and stir for 2 hours; Then add a curing agent hexamethylenetetramine with a weight ratio of 2% of epoxy resin, and continue to stir for a certain period of time; press and cure the above-mentioned mixed material at a high temperature of 170°C according to the sheet structure to obtain a solid-solid phase change composite material .

[0096] The above-mentioned solid-solid phase change composite material is wrapped around the battery cell or pasted inside the battery PACK for use.

[0097] Performance testing was performed on the temperature-controlled flame-retardant organic phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com