Composite phase-change thermal storage material

A heat storage material and composite phase change technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effects of wide phase change temperature range, high equivalent thermal conductivity, and high freeze-thaw rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

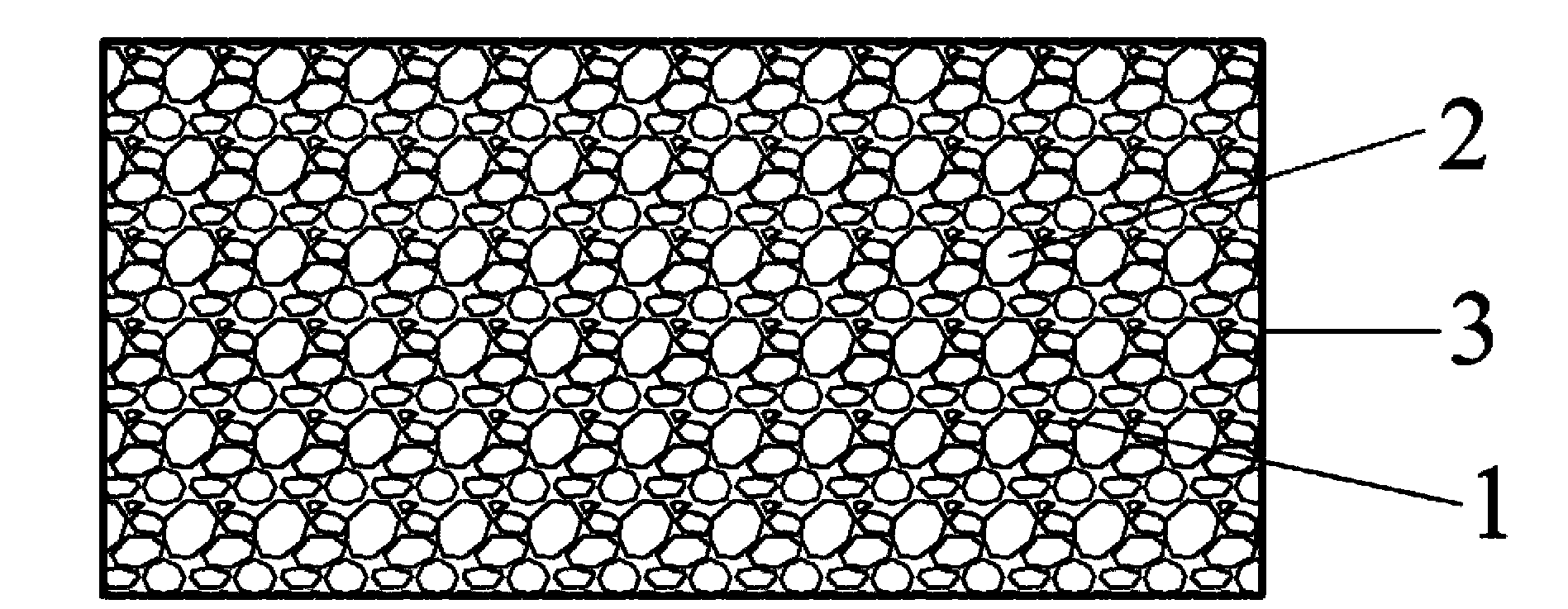

[0031] This embodiment provides a new type of phase change heat storage material with excellent thermal conductivity, which is composed of a porous material 1 with high thermal conductivity and a low melting point metal 2 ( figure 1 ), the porous material 1 is used as a supporting framework, and is embedded in the working container 3 by extrusion, and the working container 3 is a working container filled with the composite phase change heat storage material.

[0032] An interference fit is adopted between the porous material and the inner wall surface, the outer diameter of the porous material is 0.6-0.8 mm larger than the inner diameter of the working container, and the low melting point metal 2 is poured into the porous material 1 . The porous material 1 with high thermal conductivity is copper foam (purchased from Shanghai Zhonghui Aluminum Foam Co., Ltd.), with a thermal conductivity of 386W / (m·K) and a density of 1.78g / cm 3 , the pore diameter is 4mm, the porosity is 80%,...

Embodiment 2

[0036] This embodiment provides a phase-change heat storage material that combines porous materials with high thermal conductivity and metals with low melting points, wherein the porous material 1 is foamed graphite with excellent thermal conductivity (purchased from Hunan Jiuhua Carbon Hi-Tech Co., Ltd., density 0.14g / m 3 , the thermal conductivity is 150W / (m·K), and the low-melting-point metal 2 is an indium-bismuth-tin eutectic alloy (51wt%In, 32.5wt%Bi, 16.5wt%Sn), and the melting point of the eutectic alloy is 60°C. The operating temperature was maintained at 65°C during perfusion. The low melting point metal 2 is evenly distributed in the foamed graphite.

[0037] The equivalent thermal conductivity of the phase change heat storage material provided by this embodiment is 23W / (m K), which can quickly complete the heat absorption and heat release process, and can be widely used in spacecraft thermal control, chip heat dissipation, and electronic components Temperature co...

Embodiment 3

[0039] A phase-change heat storage material combining porous materials with high thermal conductivity and nano-metal fluids, wherein the porous material 1 is expanded graphite (purchased from Hunan Jiuhua Carbon Hi-Tech Co., Ltd., with a density of 0.14g / m 3 , thermal conductivity is 150W / m·K). The liquid metal in the nano metal fluid 2 is pure gallium with a melting point of 29.8°C. The nanoparticles in the nano-metal fluid 2 are nickel nanoparticles with a particle diameter of 50 nm, and the volume fraction in the nano-metal fluid is 3%. Due to the density and tension characteristics of pure gallium liquid metal itself, nickel nanoparticles are evenly distributed in the liquid metal, and deposition and accumulation are not easy to occur.

[0040] For the specific production method of nickel nanoparticles uniformly distributed in the liquid metal, refer to the content of the patent CN1955252A. The foamed graphite is embedded in the working container, the outer diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com