Thin-film material with double-effect functions of heat absorption and wave absorption and preparation method thereof

A technology of film materials and wave-absorbing materials, which is applied in the fields of rayon manufacturing, filament/thread forming, fiber chemical characteristics, etc., can solve problems such as easy leakage and large volume change, so as to solve leakage problems and broaden the application field , good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

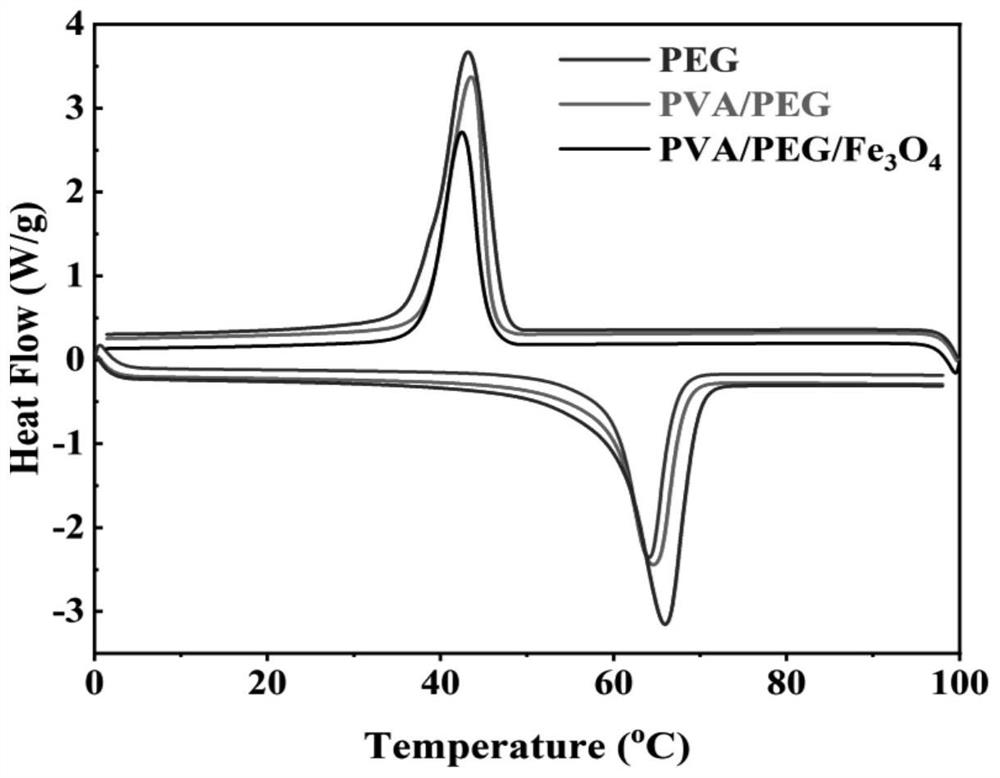

[0033] A thin film material with double-effect functions of heat absorption and wave absorption, the specific preparation method is as follows:

[0034] (1) Configuration of core spinning solution

[0035] Take 5 g of PEG with a relative molecular mass of 300,000 and mix it with 10 ml of deionized water, stir at room temperature for 3 hours and mix well to obtain a colorless and transparent liquid, which is the core spinning solution.

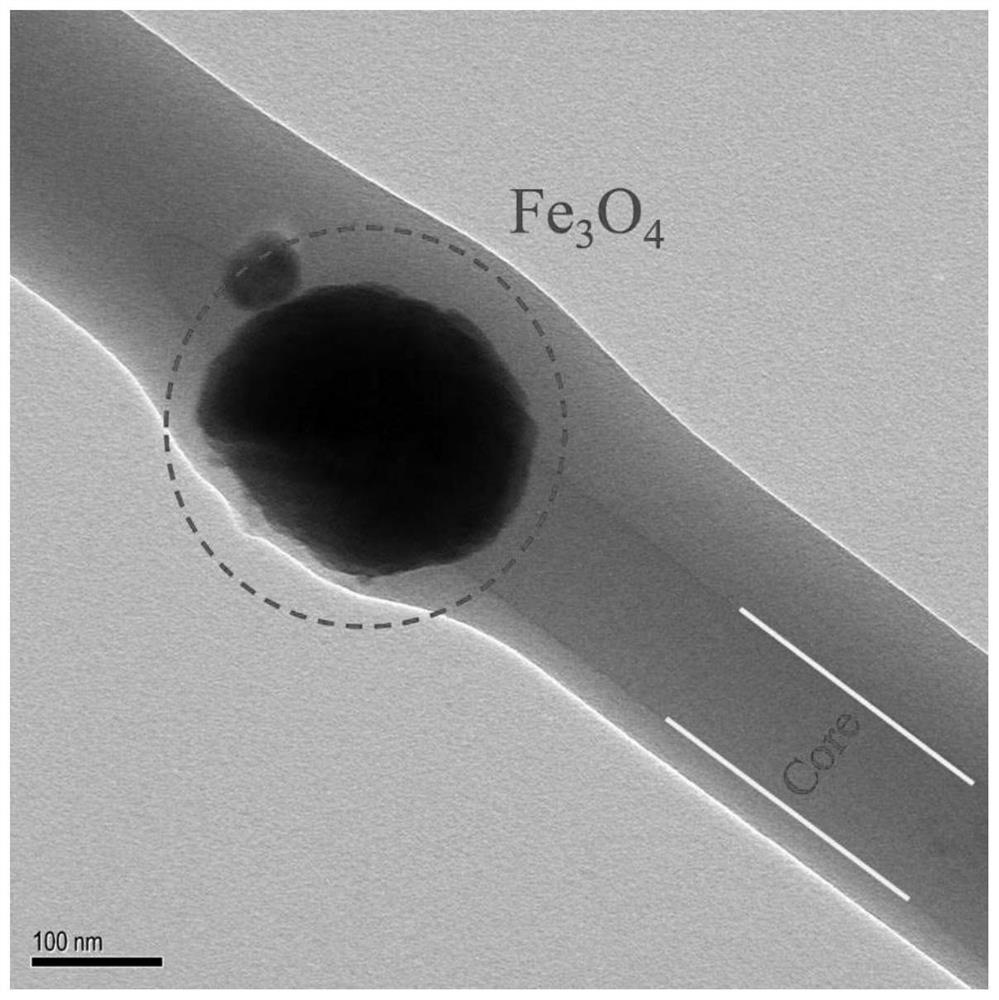

[0036] (2) Configuration of shell spinning solution

[0037] Dissolve 0.6g of PVA in 10ml of deionized water, and add 0.1g of Fe 3 O 4 The nanoparticles are mixed, stirred at 90°C for 4 hours, fully mixed, and cooled to room temperature to obtain the shell spinning solution.

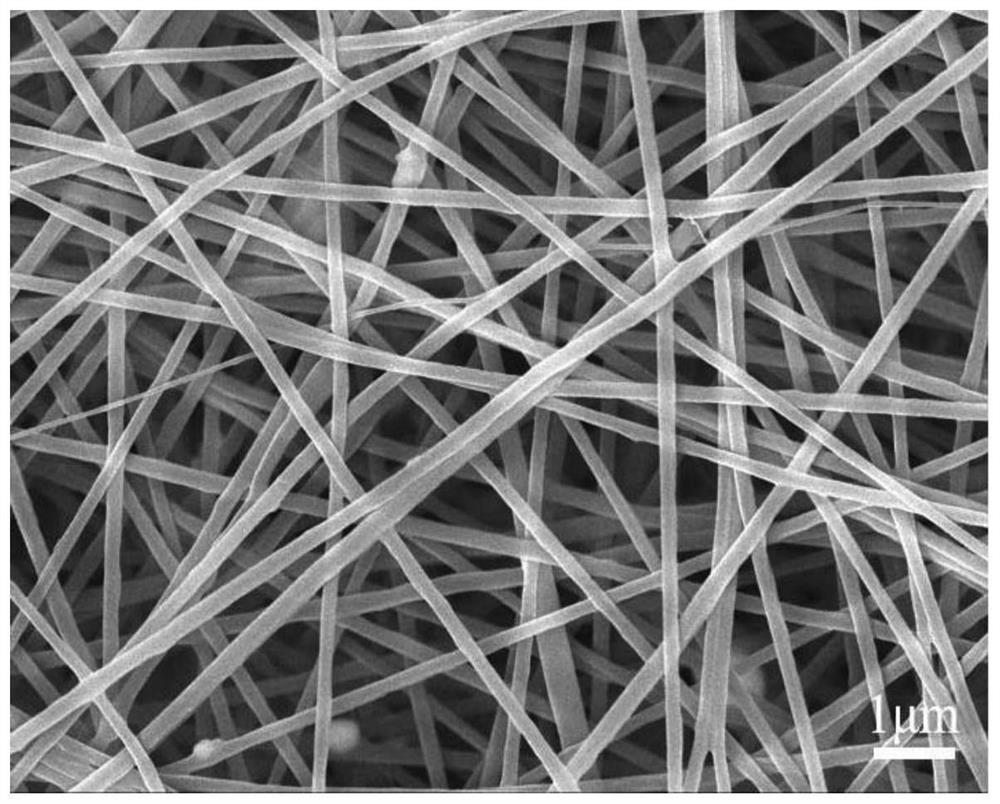

[0038] (3) Preparation of composite phase change film materials by electrospinning

[0039] Add the spinning solution prepared in step (1) and step (2) to a 10ml syringe respectively, connect it to a special coaxial needle, set the receiving distance to 15cm, the posi...

Embodiment 2

[0041] (1) Configuration of core spinning solution

[0042] Take 5 g of PEG with a relative molecular mass of 200,000 and mix it with 10 ml of deionized water, stir at room temperature for 3 hours and mix well to obtain a colorless and transparent liquid, which is the core spinning solution.

[0043] (2) Configuration of shell spinning solution

[0044] Dissolve 1g of sodium alginate in 10ml of deionized water, add 0.5g of NiO nanoparticles and mix, stir at 90°C for 4 hours to fully mix, cool to room temperature to obtain the shell spinning solution.

[0045] (3) Preparation of composite phase change materials by electrospinning

[0046] Add the spinning solution prepared in step (1) and step (2) to a 10ml syringe respectively, connect it to a special coaxial needle, set the receiving distance to 15cm, the positive high voltage to 18kv, and the negative high voltage to -2.5kv , the drum is covered with a layer of aluminum foil, the aluminum foil indicates that it is cleaned ...

Embodiment 3

[0048] (1) Configuration of core spinning solution

[0049] Take 5 g of PEG with a relative molecular mass of 10000 and mix it with 10 ml of deionized water, stir at room temperature for 3 hours and mix well to obtain a colorless and transparent liquid, which is the core spinning solution.

[0050] (2) Configuration of shell spinning solution

[0051] Dissolve 0.6g of sodium carboxymethylcellulose in 10ml of deionized water, and add 0.1g of CoFe 2 O 4 The nanoparticles were mixed, and stirred at room temperature for 4 hours to fully mix and evenly obtain the shell spinning solution.

[0052] (3) Preparation of composite phase change materials by electrospinning

[0053] Add the spinning solution prepared in step (1) and step (2) to a 10ml syringe respectively, connect it to a special coaxial needle, set the receiving distance to 15cm, the positive high voltage to 18kv, and the negative high voltage to -2.5kv , the drum is covered with a layer of aluminum foil, the aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com