Preparation method of paraffin/polyurethane solid-solid composite double-phase change energy storage material

An energy storage material, polyurethane technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of narrow phase change temperature range, low phase change enthalpy, and limited application fields, and achieve a wide phase change temperature range, The effect of high latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After heating and melting the polyethylene glycol with a molecular weight of 10,000, it was placed in a vacuum oven at 120°C for 4 hours of vacuum treatment. Add 40 parts of polyethylene glycol, 6.15 parts of n-octadecane, and 1 part of silicone surfactant into the reaction kettle, control the temperature of the reactants at 80°C, and stir evenly at a stirring rate of 1000 rpm under the protection of nitrogen , then add 6.04 parts of polyol-modified 4,4'-diphenylmethane diisocyanate (U-MDI) and 1.02 parts of 1,4-butanediol (BDO) dropwise in sequence, and continue stirring for 5 minutes after the addition is completed, vacuum Remove air bubbles from the above mixture. The above mixture was poured into a mold preheated to 45°C, and then the mold was put into an oven at 100°C to solidify for 4 hours, and then demoulded after cooling to obtain a light yellow paraffin / polyurethane solid-solid dual phase change energy storage material.

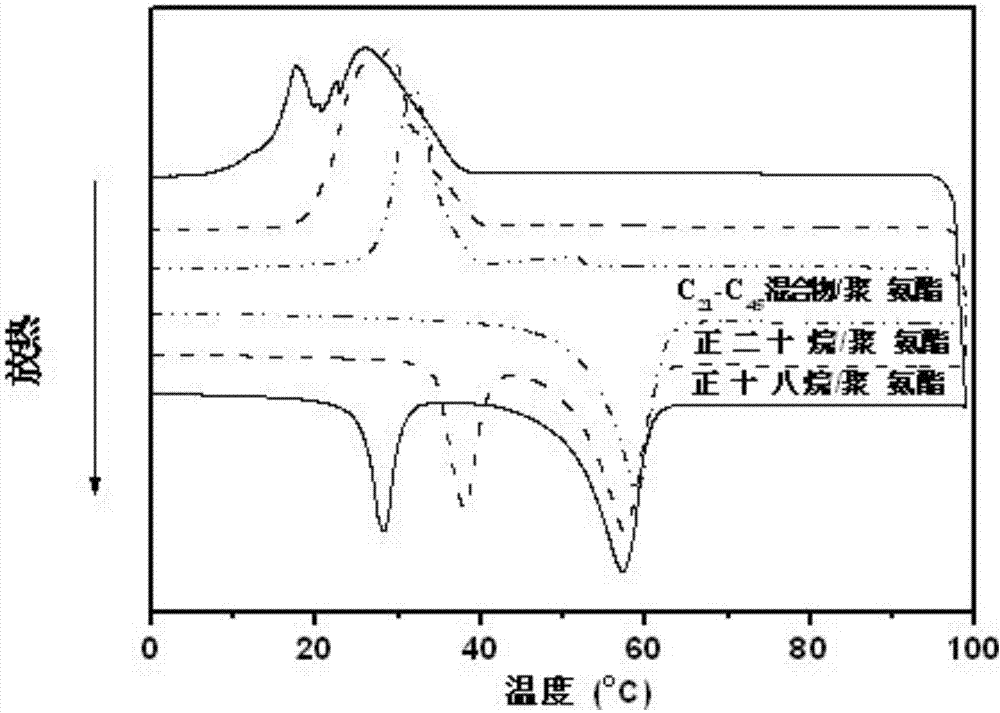

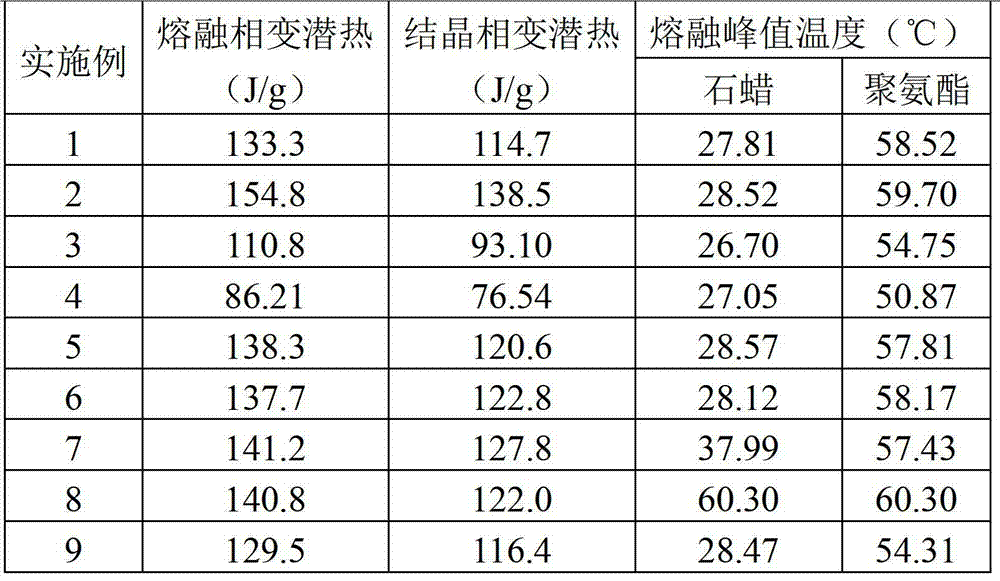

[0026] Differential scanning calorime...

Embodiment 2

[0028] After heating and melting the polyethylene glycol with a molecular weight of 10,000, it was placed in a vacuum oven at 120°C for 4 hours of vacuum treatment. Add 25 parts of polyethylene glycol, 5.56 parts of n-octadecane, and nonylphenol polyethylene glycol (NP-10) into the reactor, control the temperature of the reactants at 60°C, and under nitrogen protection, at 1000rpm Stir evenly at a stirring rate, then add 2.37 parts of U-MDI and 0.41 parts of BDO dropwise in sequence, continue stirring for 5 minutes after the addition is complete, and remove the air bubbles in the above mixture in a vacuum. The above mixture was poured into a mold preheated to 45°C, and then the mold was put into an oven at 100°C to solidify for 4 hours, and then demoulded after cooling to obtain a light yellow paraffin / polyurethane solid-solid dual phase change energy storage material. The latent heat of melting phase transition of the prepared material is 154.8 J / g, the latent heat of crystal...

Embodiment 3

[0030] Polyethylene glycol with a molecular weight of 6000 was selected as the soft segment, heated and melted, and placed in a vacuum oven at 120°C for 4 hours of vacuum treatment. Add 40 parts of polyethylene glycol, 6.15 parts of n-octadecane, and 1.0 part of polyethylene glycol octylphenyl ether (OP-10) into the reaction kettle, and control the temperature of the reactants at 60°C. , Stir evenly at a stirring rate of 1000rpm, then add 6.04 parts of U-MDI and 1.02 parts of BDO dropwise in sequence, continue stirring for 1 min after the addition is completed, and remove the air bubbles in the above mixture in a vacuum. The above mixture was poured into a mold preheated to 45°C, and then the mold was put into an oven at 100°C to solidify for 4 hours, and then demoulded after cooling to obtain a light yellow paraffin / polyurethane solid-solid dual phase change energy storage material. The latent heat of melting phase transition of the prepared material is 110.8 J / g, the latent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com