Polyalcohol solid-solid phase-change composite material and preparation method thereof

A phase-change composite material and a technology for phase-change materials, which are applied in the field of phase-change energy storage composite materials and their preparation, can solve the problems of difficulty in large-scale batch preparation, complex preparation processes and methods of composite materials, and the like, and reach the phase-change temperature range. The effect of wide and large latent heat of phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

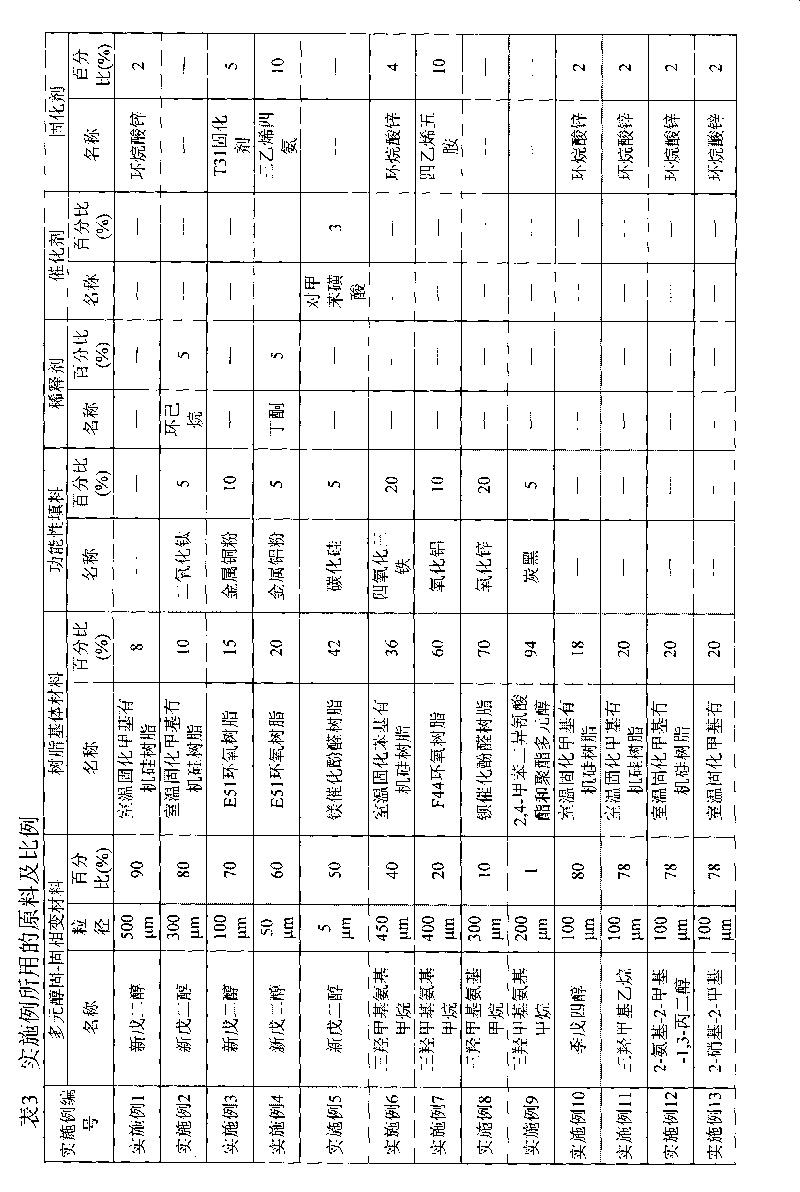

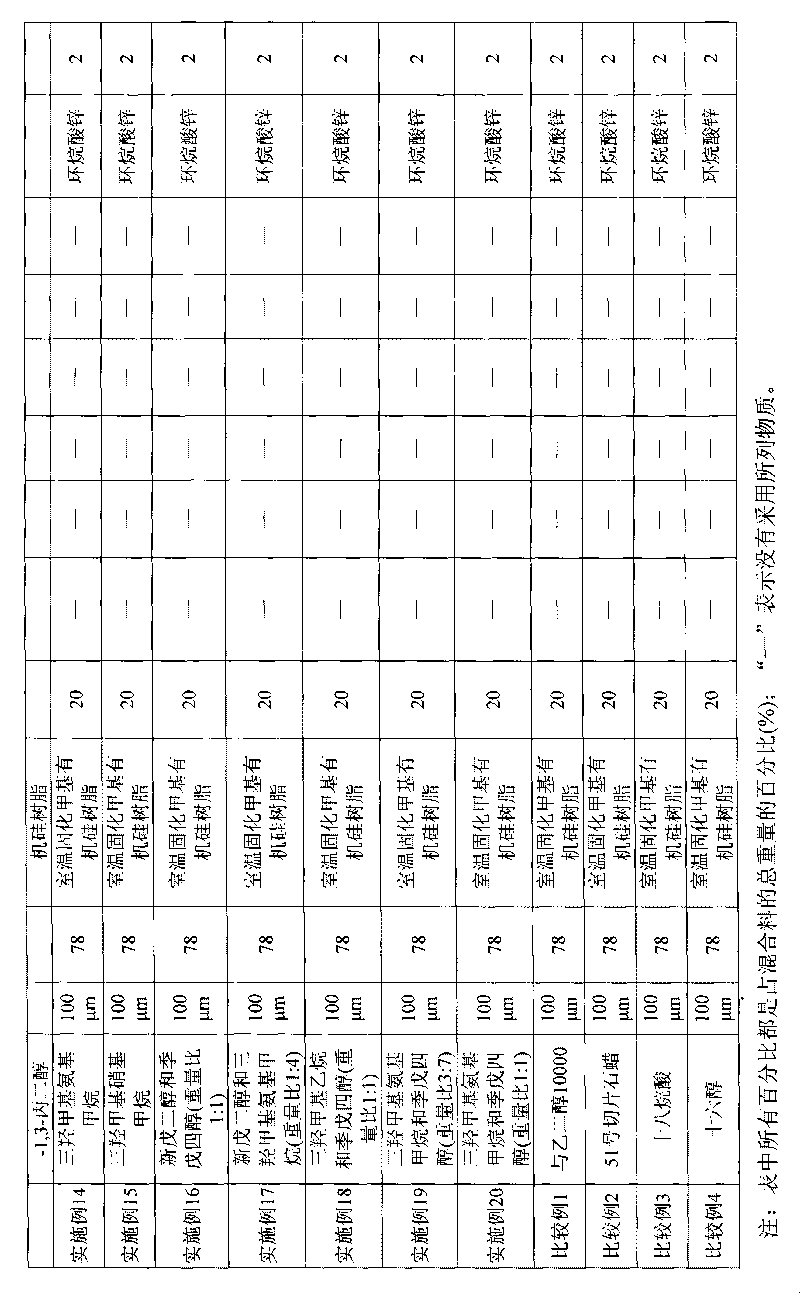

Examples

Embodiment 1

[0091] Example 1: Preparation of neopentyl glycol / room temperature curing silicone rubber phase change composite material

[0092] (1) Mechanically pulverize neopentyl glycol (chemically pure, Beijing Chemical Reagent Company) and sieve to make its particle size less than 500 μm;

[0093] (2) After mixing 90g of neopentyl glycol, 8g of room temperature curing methyl silicone resin (developed by Beijing Institute of Chemistry) and 2g of zinc naphthenate curing agent powder evenly, spread them evenly in the mold, and after closing the mold, place the mold at room temperature Press and form at 5MPa, and then remove the mold and take out the prefabricated block.

[0094] (3) After curing the prefabricated block at room temperature for 48 hours (hours), the neopentyl glycol / room temperature curing silicone rubber phase change composite material is obtained.

[0095] After DSC (differential scanning calorimeter (METTLER DSC822e type produced in Germany), the test parameter is N 2 ...

Embodiment 2

[0096] Example 2: Preparation of neopentyl glycol / room temperature curing silicone rubber phase change composite material

[0097] (1) Mechanically pulverizing neopentyl glycol and sieving to make the particle size less than 300 μm;

[0098] (2) After mixing 80g of neopentyl glycol, 10g of room temperature curing methyl silicone resin, 5g of titanium dioxide with a particle size of less than 10μm, and 5g of cyclohexane diluent, spread them evenly in the mold, and after closing the mold, place it at room temperature with 5MPa compression molding, and then remove the mold to take out the prefabricated block.

[0099] (3) After the prefabricated block was cured at room temperature for 48 hours, it was placed in an oven at 50° C. for another 48 hours to obtain the neopentyl glycol / room-temperature-cured silicone rubber phase-change composite material.

[0100] According to DSC measurement, the phase transition temperature of the prepared neopentyl glycol / room temperature curing s...

Embodiment 3

[0101] Embodiment 3: Preparation of neopentyl glycol / epoxy resin phase change composite material

[0102] (1) Mechanically pulverizing neopentyl glycol and sieving to make the particle size less than 100 μm;

[0103](2) 70g neopentyl glycol, 15g E51 epoxy resin (industrial product), 5g T31 curing agent (industrial product) and 10g of metal copper powder with a particle size of 100 μm or less are evenly mixed and spread evenly in the mold, After the mold is closed, it is pressed and formed at 3MPa, and the mold is removed to take out the prefabricated block.

[0104] (3) After the prefabricated block was cured at room temperature for 48 hours, the prefabricated block was placed in an oven at 50° C. for another 48 hours to obtain a neopentyl glycol / epoxy resin phase change composite material.

[0105] According to DSC measurement, the phase transition temperature of the prepared neopentyl glycol / room temperature curing silicone rubber phase change composite material is 45°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com