Preparation method of normal-temperature phase-change microcapsule heat storage board

A technology of phase change microcapsules and normal temperature, which is applied in the direction of microcapsule preparation, preparation of microspheres, heat exchange materials, etc. It can solve the problems of unsuitable for normal temperature energy storage, leakage of phase change materials, poor structural strength, etc., and achieve phase change The effect of wide temperature range, protection of phase change materials, and improvement of overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

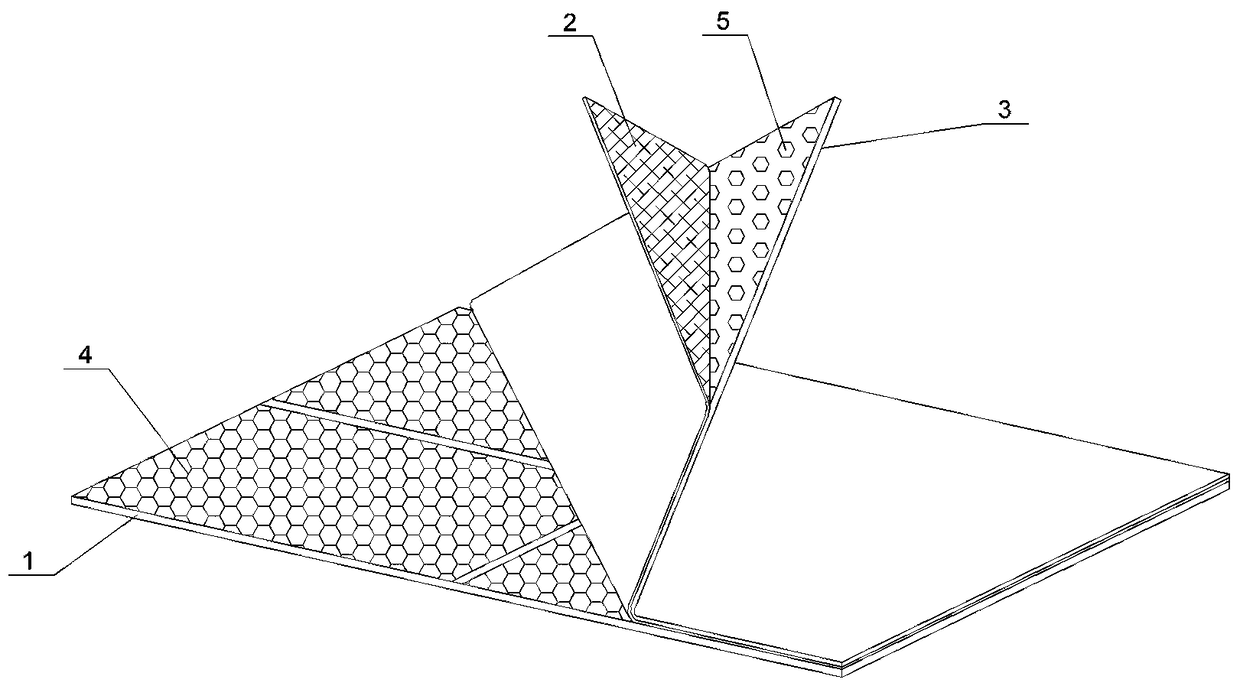

Image

Examples

Embodiment 1

[0019] Embodiment 1: A preparation method of a normal temperature phase change microcapsule heat storage plate, the preparation method includes the following steps:

[0020] (1) Preparation of phase change capsule core at room temperature: first weigh the capsule core according to the proportion, the capsule core is 2kg of 44# paraffin, 2kg of liquid paraffin and 1kg of dodecanol. Then heat and melt at 45°C, stir at a stirring speed of 2000r / min, and stir for 5min to make it fully mixed and uniform into a transparent liquid.

[0021] (2) Dispersion of the phase change capsule core at room temperature: Add 0.1 kg of Span, 0.1 kg of Tween 80, and 20 liters of deionized water under the conditions of the preparation method, and continue stirring for 20 minutes.

[0022] (3) Lay the substrate on the bottom of the incubator at 40-140°C, with honeycomb continuous grooves distributed on the upper side of the substrate; lay the mixed solution stirred in step (2) on the side of the subs...

Embodiment 2

[0029] Example 2: Another method for preparing a normal-temperature phase-change microcapsule heat storage plate, the preparation method includes the following steps:

[0030](1) Preparation of phase change capsule core at room temperature: first weigh the capsule core according to the proportion, the capsule core is 44# paraffin, liquid paraffin, lauryl alcohol, the ratio is 2 ~ 3:2 ~ 3:1; then at 45 ° C Heating and melting at low temperature, the stirring speed is 2000r / min, and stirring for 5 minutes, so that it is fully mixed and evenly formed into a transparent liquid.

[0031] (2) Dispersion of the phase change capsule core at room temperature: Add the mixture of Span 80, Tween 80, and deionized water under the conditions of the preparation method, and the ratio is 1:1:200, and continue to stir for 20 minutes.

[0032] (3) Capsule wall polymer layer coating: the capsule wall is acrylic resin obtained by polycondensation reaction of methyl methacrylate, methacrylic acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com