Two-way heat transfer heat pipe

A two-way heat transfer and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as inability to work, and achieve the effect of solving energy storage problems and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

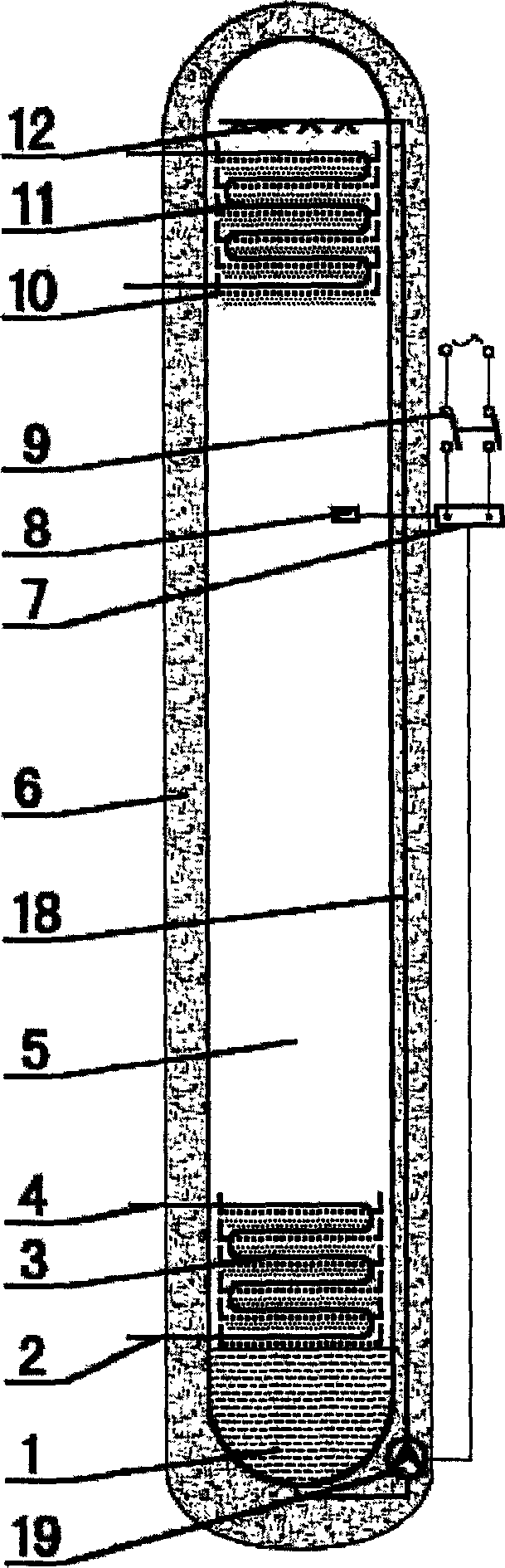

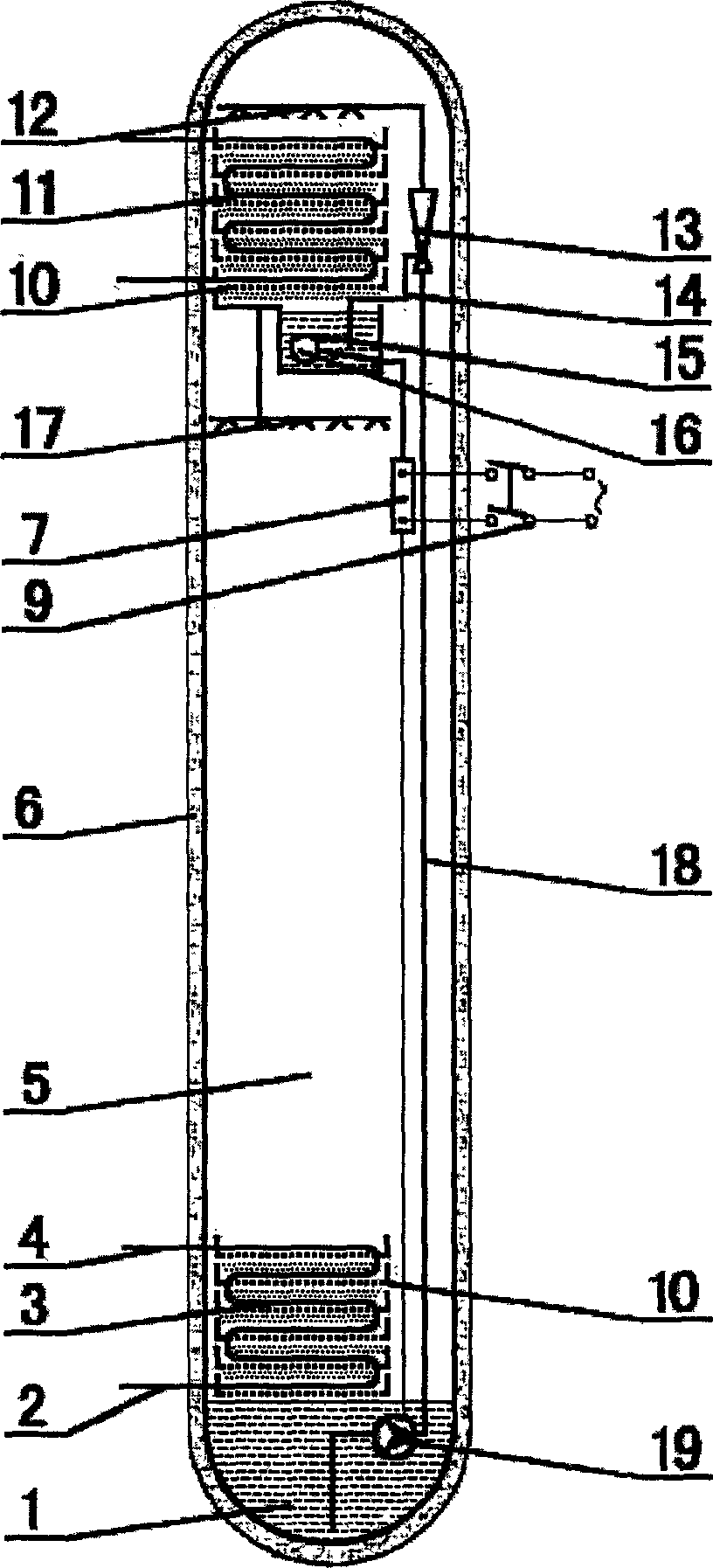

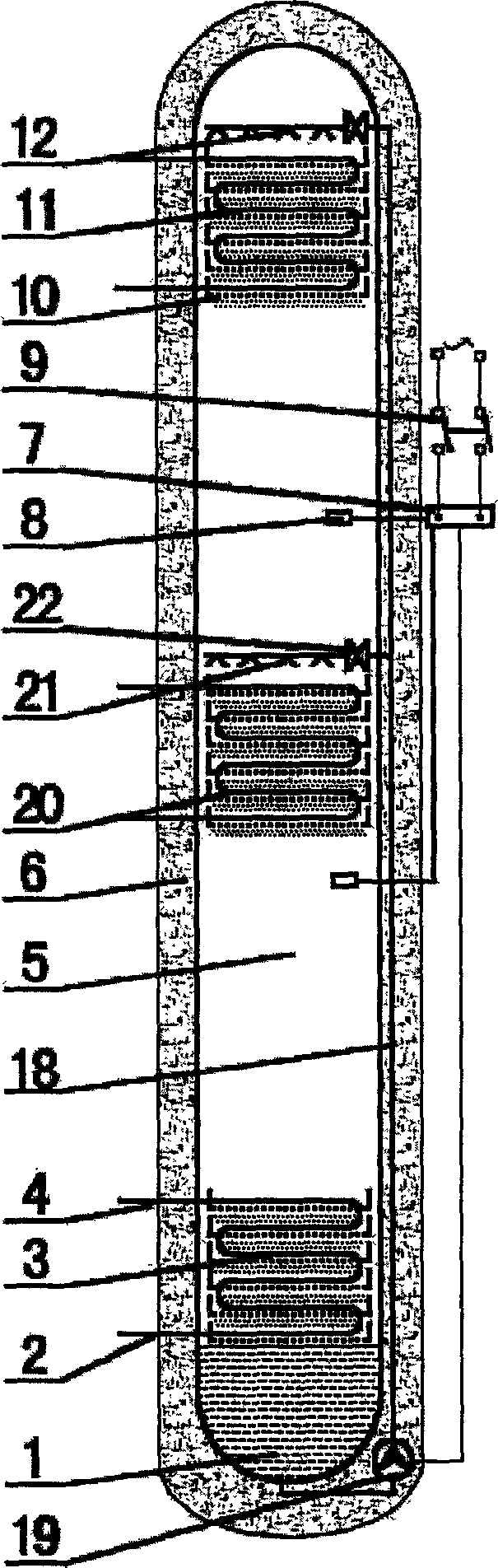

[0032] exist figure 1 Middle: When the lower heat exchanger 3 of the two-way heat transfer heat pipe is the evaporating section, and the upper heat exchanger 11 is the condensation section, the two-way heat transfer heat pipe is a passive heat pipe, and no external power is required. The effect of gravity can make the upper heat exchanger 11 The phase-change heat medium 1 condensed on the top flows back to the lower displacement heat exchanger 3 to realize heat conduction. During this process, the medium passing through the lower heat exchanger 3 is cooled, and the medium passing through the upper heat exchanger 11 is heated. When the lower displacement heat exchanger 3 is the condensation section and the upper displacement heat exchanger 11 is the evaporation section, the condensed phase-change heat medium 1 accumulates at the lower end of the heat pipe, and the phase-change heat medium 1 is pumped by the phase-change heat medium pump 19. Enter the liquid distribution device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com