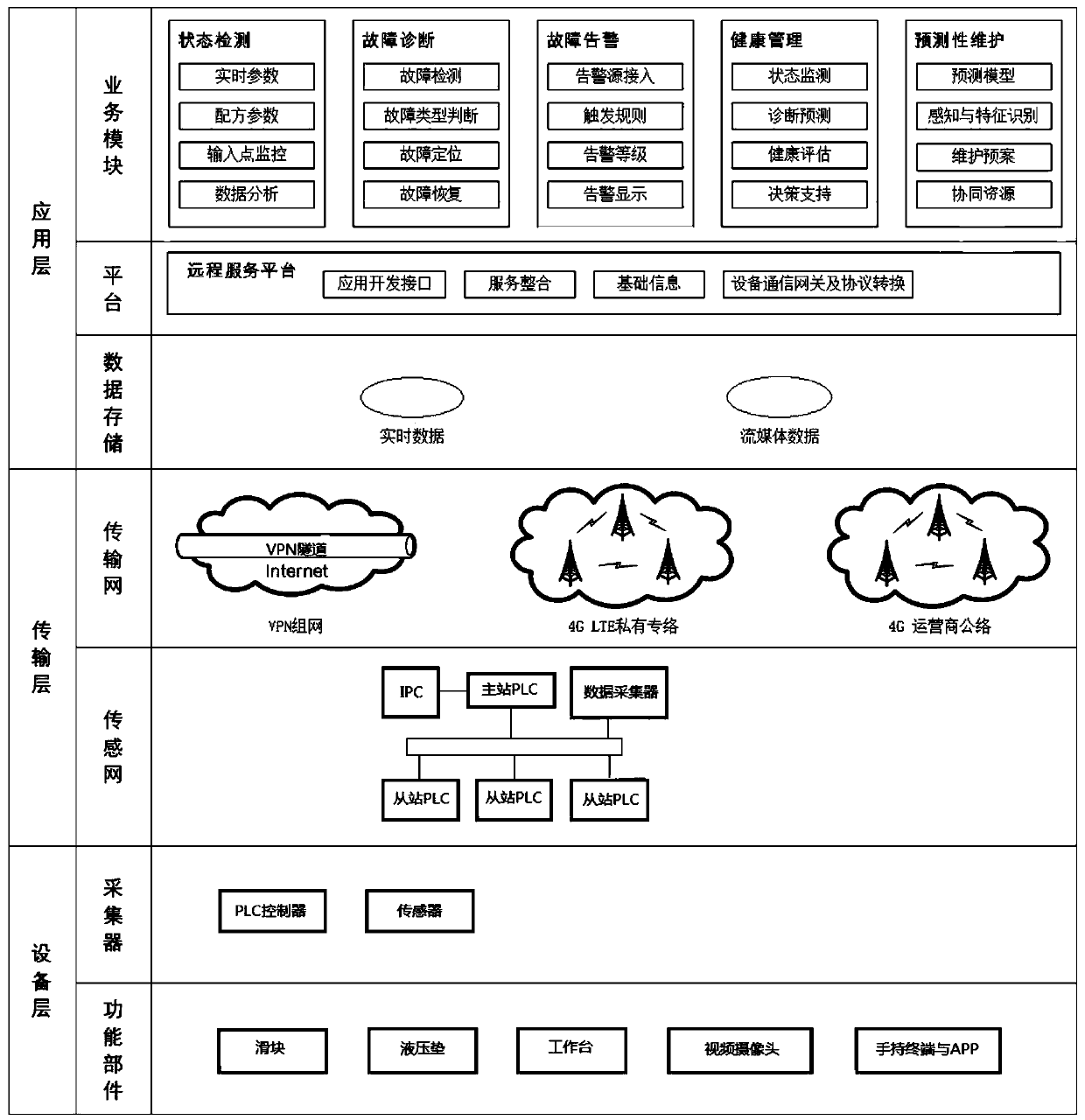

Automatic line remote monitoring system and method based on industrial cloud APP

A remote monitoring system, industrial technology, applied in general control system, control/adjustment system, program control in sequence/logic controller, etc., can solve the problem of wide distribution of equipment, poor communication of diagnosis and maintenance information, and inability to integrate business units And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

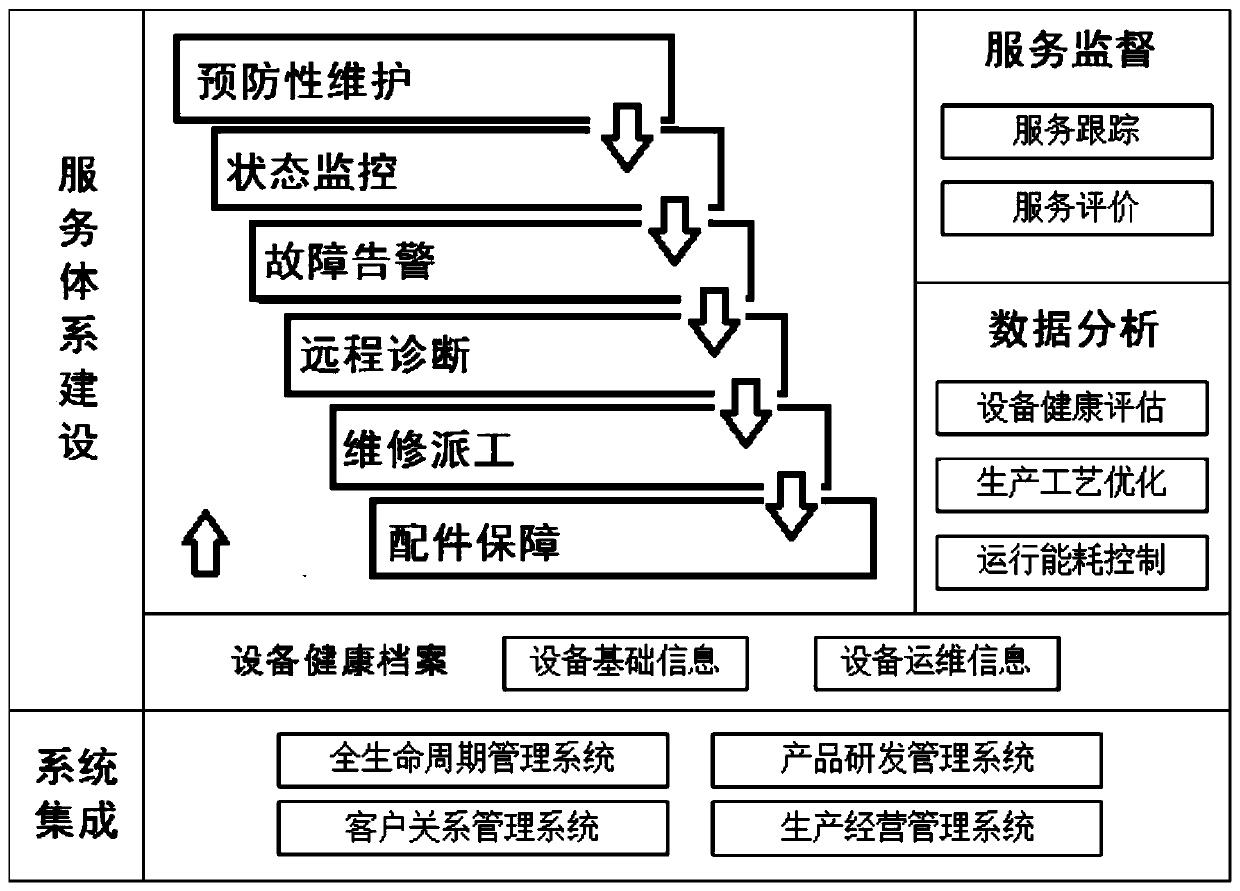

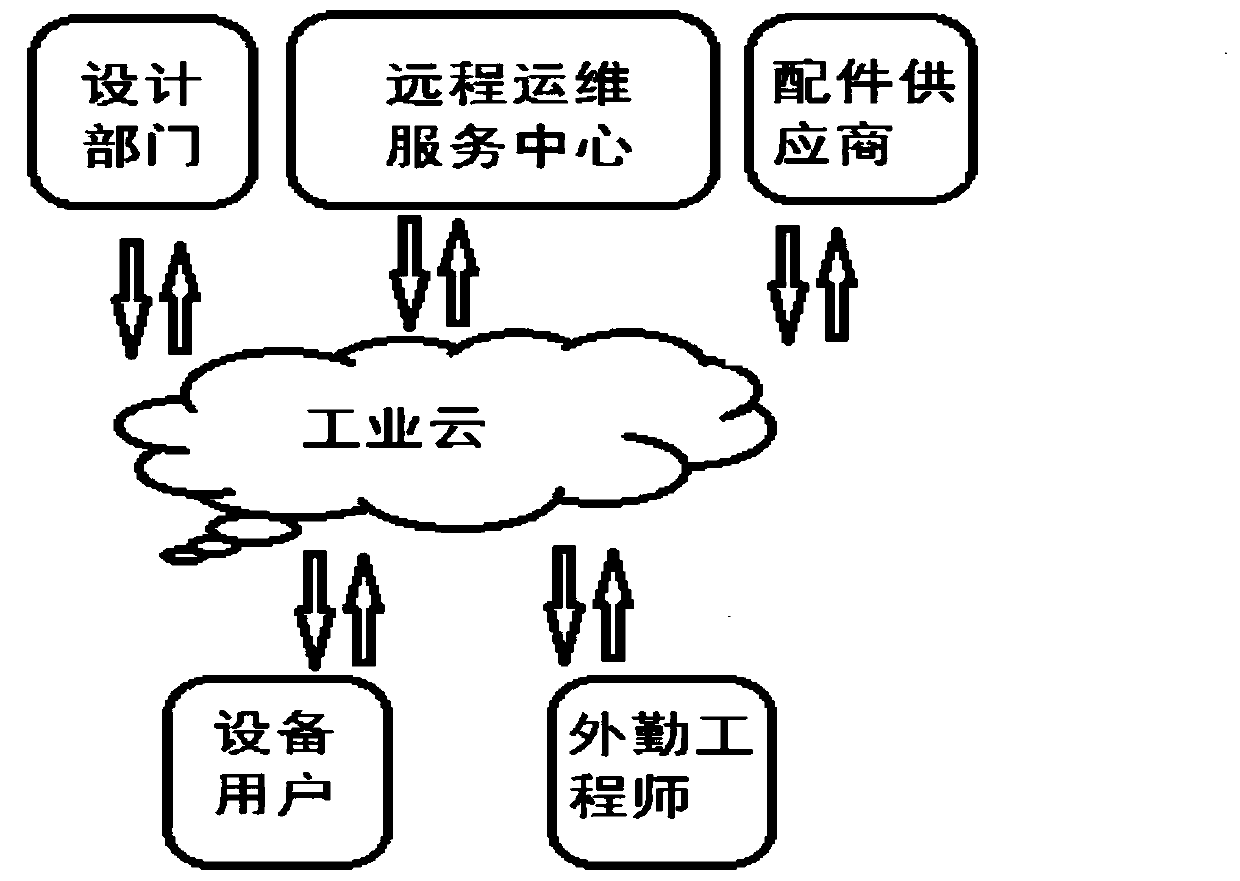

[0028] The present invention adopts the above-mentioned technical scheme, and the main functions of the present invention include functions such as remote data collection and analysis, remote fault early warning diagnosis, remote spare parts procurement, maintenance personnel positioning dispatch, maintenance result report, etc., which can not only realize remote fault diagnosis, but also develop special automation The online APP can realize interactive diagnosis of voice and image through the handheld terminal and the remote center; based on the industrial cloud APP, users can purchase spare parts and request maintenance assistance according to the usage of the equipment; the remote diagnosis center can also analyze the on-site operation data,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com