Thermodiffusion method for manufacturing wide temperature range phase transition nickel titanium alloy

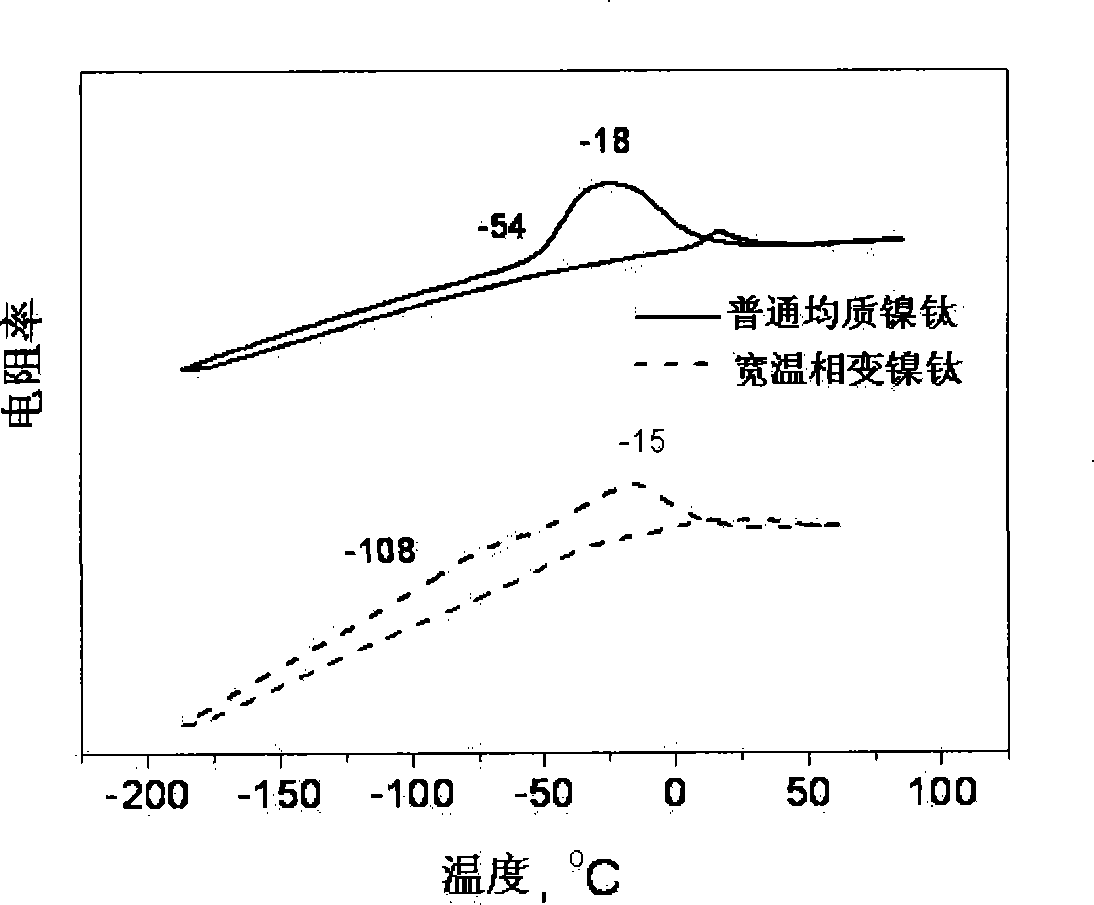

A technology of nickel-titanium alloy and thermal diffusion, which is applied in the field of wide-temperature phase-change nickel-titanium alloy and its thermal diffusion preparation, can solve the problem that homogeneous nickel-titanium alloy cannot meet the temperature range of use, and achieve good damping effect and high damping temperature The effect of large interval and wide phase transition temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

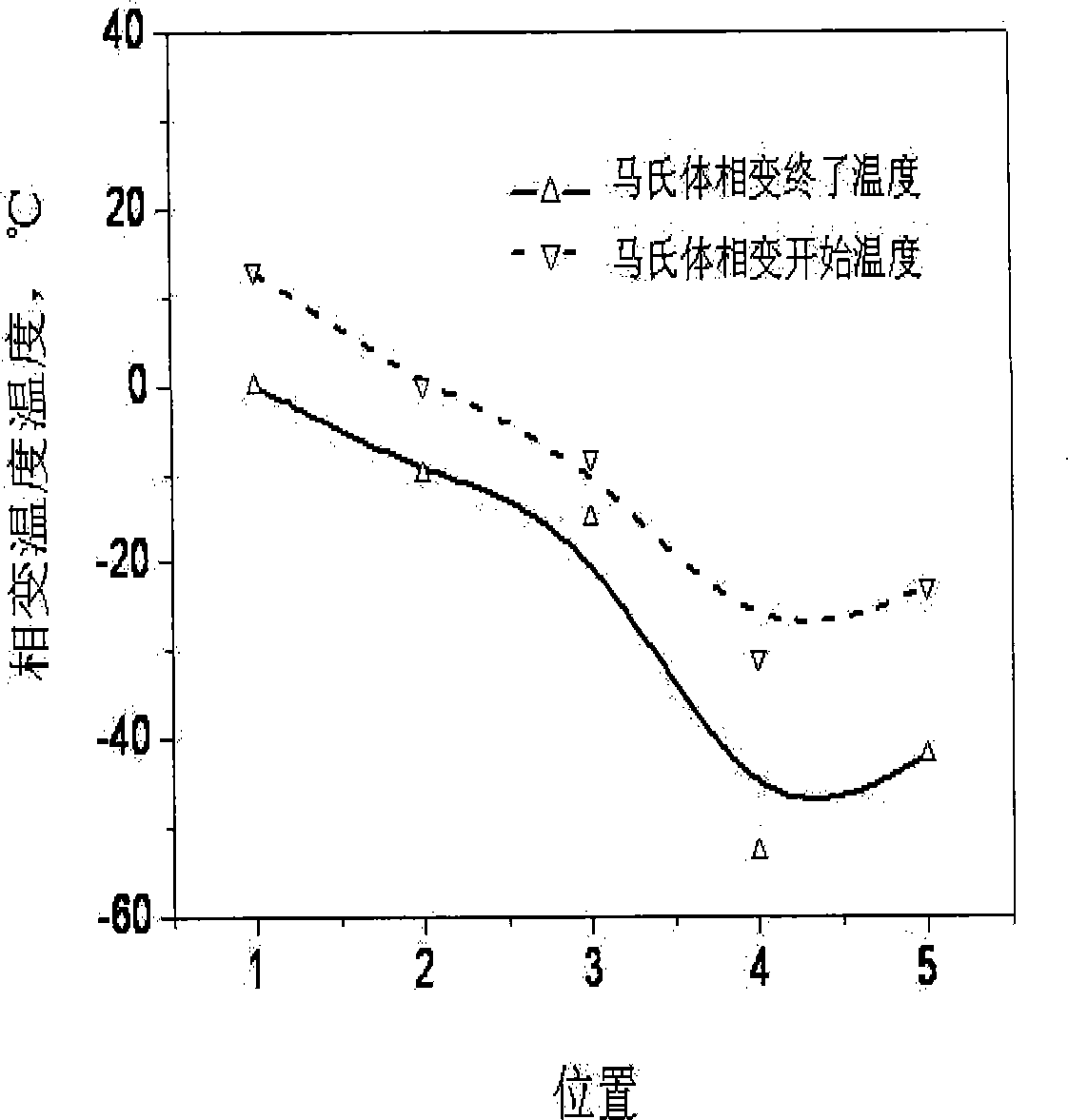

Examples

Embodiment 1

[0020] (1) Materials and equipment

[0021] (1-1) Nickel-titanium alloy, the composition is Ni50.9-Ti, and a hot-rolled sheet material with a thickness of 2 mm.

[0022] (1-2) Chemical reagents such as ethanol, hydrofluoric acid, and nitric acid are chemically pure.

[0023] (1-3) Argon, pure argon.

[0024] (1-4) Box-type resistance furnace.

[0025] (2) Sample preparation

[0026] (2-1) Cut the test piece by wire cutting method, and the size of the test piece is 2mm×5mm×30mm.

[0027] (2-2) Chemical cleaning sample, the pickling solution is HF:HNO 3 :H 2 O=1:2:10 (v / v), after the surface oxide falls off, rinse with plenty of water and dry with hot air.

[0028] (2-3) The test piece is solution treated in an argon protection furnace, the solution temperature is 850°C, the heating time is 15 minutes, and it is quenched into water immediately after being out of the furnace.

[0029] (2-4) Take out the test piece from the water and dry it with hot air.

[0030] (3) therm...

Embodiment 2

[0038] (1) Materials and equipment

[0039] (1-1) Nickel-titanium alloy, the composition is Ni51.3-Ti, a hot-rolled rod with a diameter of Φ20mm.

[0040] (1-2) Chemical reagents such as ethanol, hydrofluoric acid, and nitric acid are chemically pure.

[0041] (1-3) Argon, pure argon.

[0042] (1-4) Box-type resistance furnace.

[0043] (2) Sample preparation

[0044] (2-1) Cut the test piece by wire cutting method, and the size of the test piece is Φ20mm×10mm.

[0045] (2-2) Chemical cleaning sample, the pickling solution is HF:HNO 3 :H 2 O=1:2:10 (v / v), after the surface oxide falls off, rinse with plenty of water and dry with hot air.

[0046] (2-3) The test piece is solid solution treated in an argon protection furnace, the solid solution temperature is 850°C, the heating time is 30min, and it is immediately quenched into water after being out of the furnace.

[0047] (2-4) Take out the test piece from the water and dry it with hot air.

[0048] (3) thermal diffusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com