A Method for Preventing Closing Deformation During Magnetic Core Sintering

A sintering process and magnetic core technology, which is applied in the manufacture of inductors/transformers/magnets, furnaces, lighting and heating equipment, etc., can solve problems such as lack of fastening on the surface, easy deformation of the magnetic core closure, and weak positioning of the blank, and achieve The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

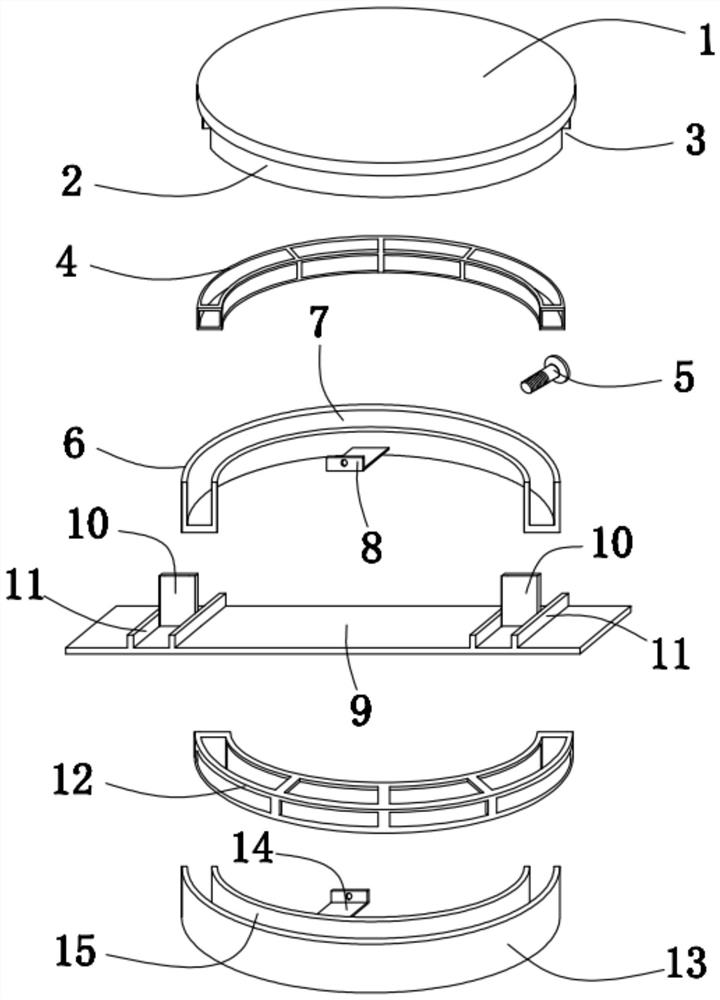

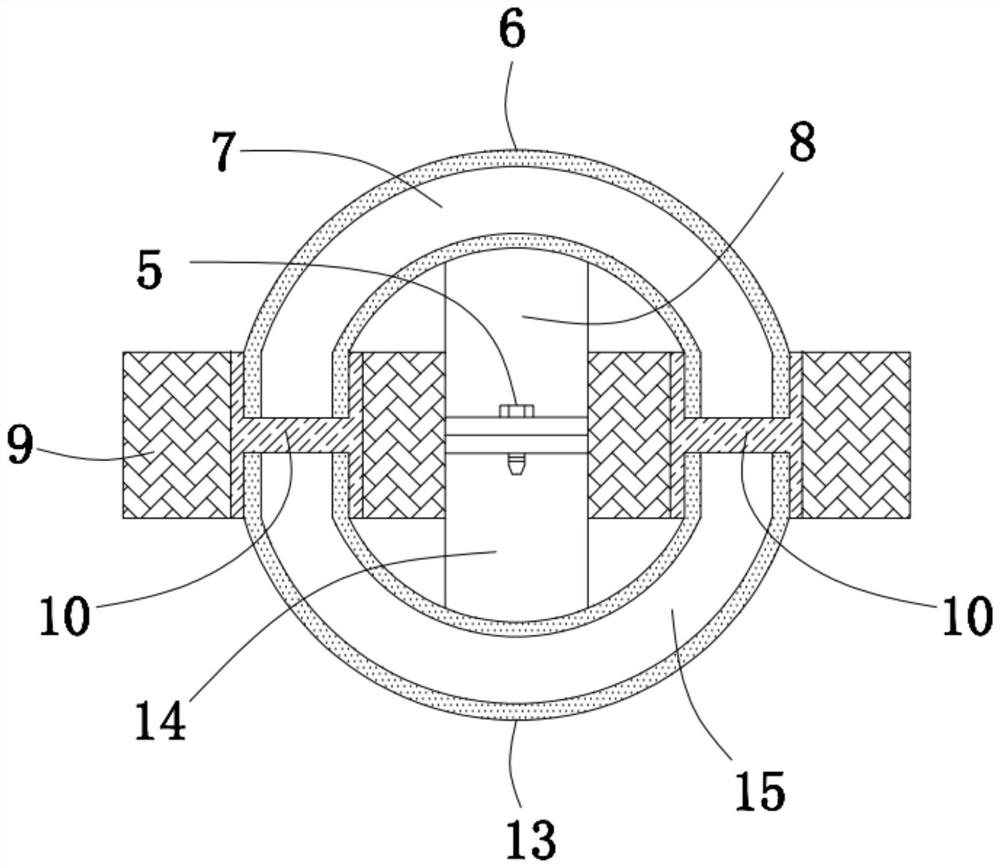

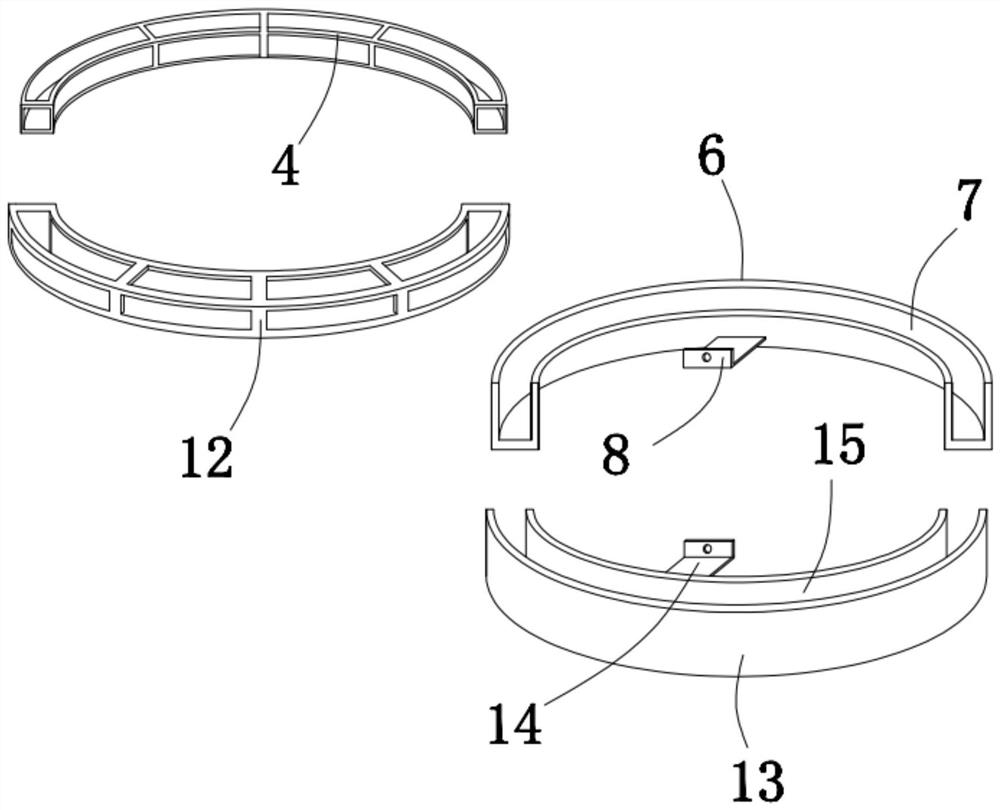

[0022] The present invention provides such as Figure 1-3 A method for preventing the deformation of the closure during the sintering process of the magnetic core, comprising the following steps:

[0023] S1: Press and form the magnetic core material with the first arc-shaped ferrule 4 and the second arc-shaped ferrule 12 respectively, so that the magnetic core raw material is formed with the first arc-shaped ferrule 4 and the second arc-shaped ferrule 12 respectively a first semicircular magnet blank and a second semicircular magnet blank;

[0024] S2: Place the first semicircular magnet blank and the second semicircular magnet blank in the first semicircular positioning groove 7 and the second half of the first semicircular mold 6 and the second semicircular mold 13 respectively In the circular positioning groove 15;

[0025] S3: Then insert the two ends of the first semicircular mold 6 and the second semicircular mold 13 into the sliding joint seats 11 on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com