Battery system and temperature control method therefor

A temperature control method and battery system technology, applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as temperature uniformity of difficult battery modules, and achieve the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

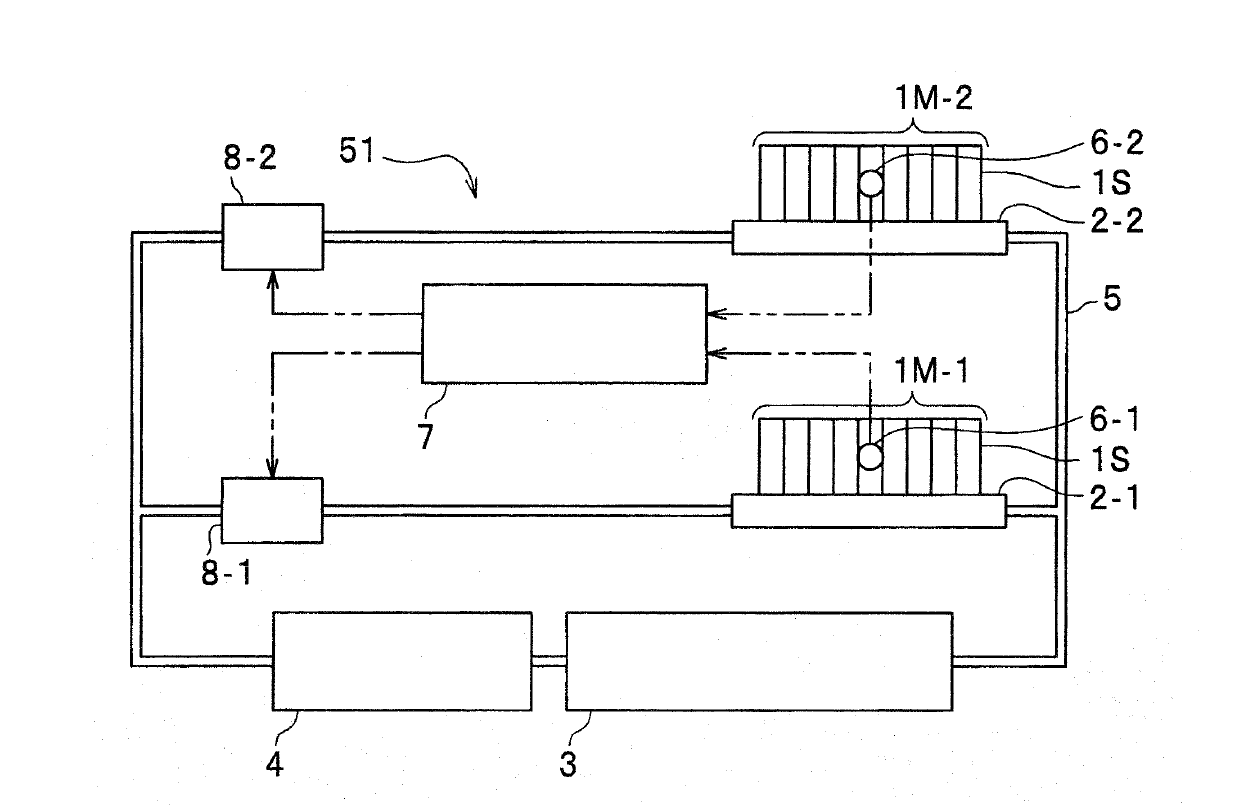

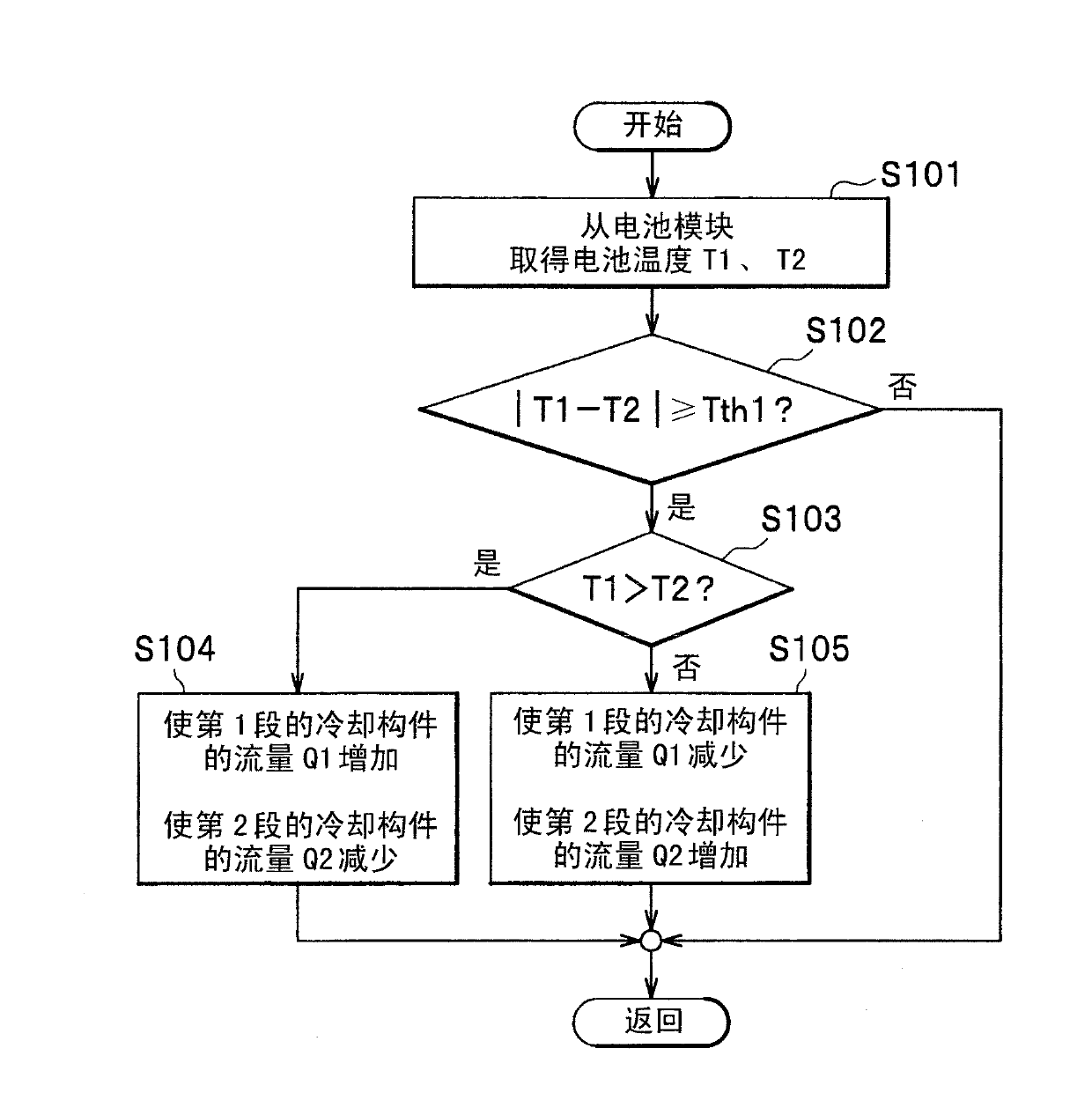

[0036] figure 1 It is a configuration diagram of the battery system according to the first embodiment of the present invention. figure 1 In this embodiment, the battery system 51 includes two battery modules 1M-1 and 1M-2 to be temperature controlled, two cooling members, a cooling device 3, a cooling medium circulation mechanism 4, a cooling medium flow path 5, and a control system. Part 7.

[0037] here, in figure 1 In , the cooling member located on the lower side is referred to as the first stage, and the cooling member located on the upper side is referred to as the second stage. The cooling means in the first stage includes a cooling plate 2-1 and a flow regulator 8-1, and controls the temperature of the battery module 1M-1. In addition, the second-stage cooling means includes a cooling plate 2-2 and a flow regulator 8-2, and controls the temperature of the battery module 1M-2.

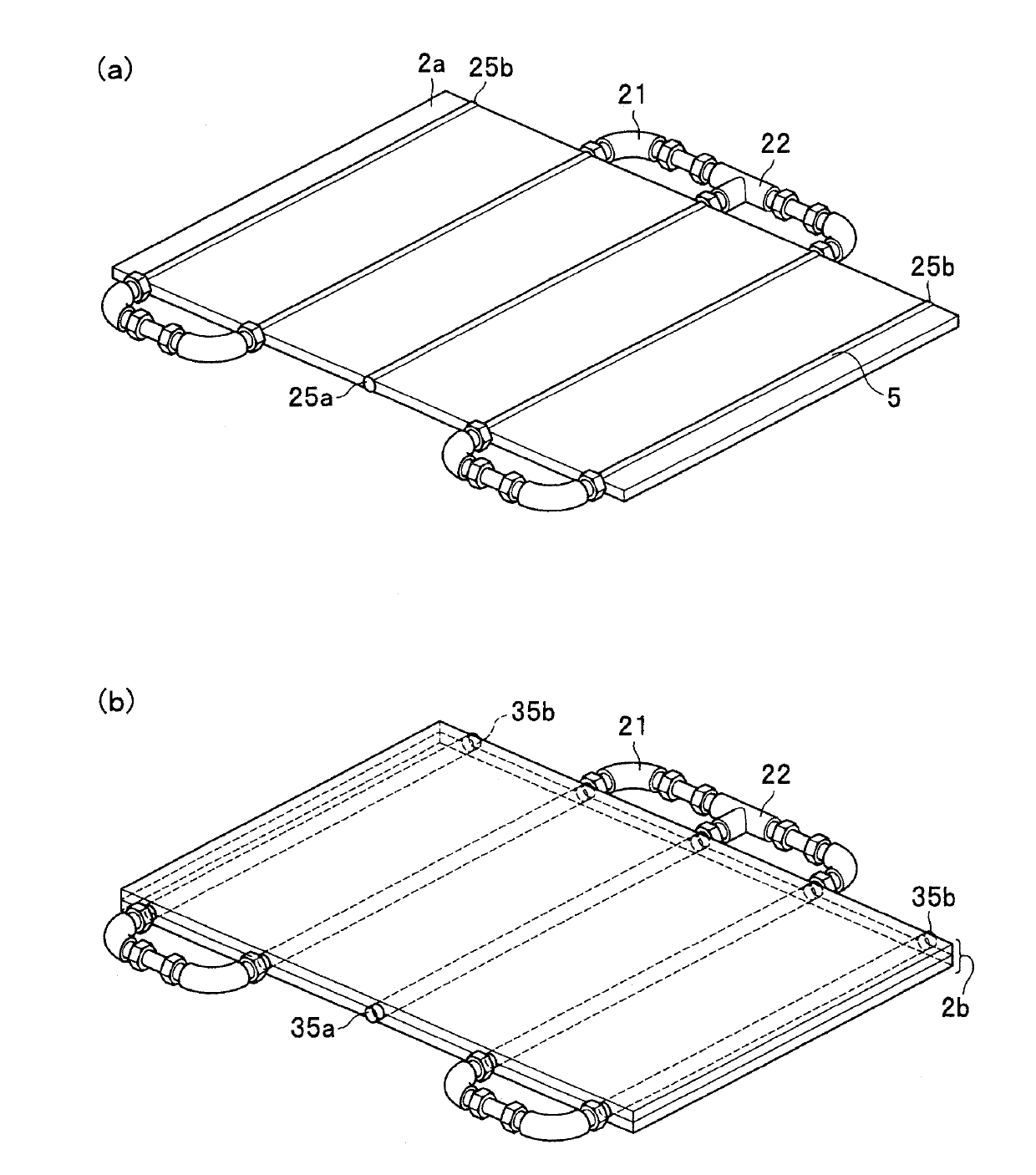

[0038] The cooling plate 2-1 and the cooling plate 2-2 are cooling members referred to i...

no. 2 Embodiment approach 〕

[0064] Next, the battery system and its temperature control method according to the second embodiment of the present invention will be described. Figure 5 It is a configuration diagram of a battery system according to a second embodiment of the present invention. Figure 5 In this embodiment, the battery system 53 includes N battery modules 11M-1 to 11M-N (N is an integer greater than or equal to 2, and the first embodiment is a configuration when N=2) to be temperature-controlled, and N cooling components, a cooling device 13 , a cooling medium circulation mechanism 14 , a cooling medium flow path 15 , and a control unit 17 .

[0065] Here, like the first embodiment, battery modules 11M-1 to 11M-N are formed by connecting a plurality of unit cells in series, and are placed on cooling plates 12-1 to 12-N, respectively. In addition, similarly to the first embodiment, temperature sensors 16 - 1 to 16 -N are provided at substantially the center of the battery modules 11M- 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com