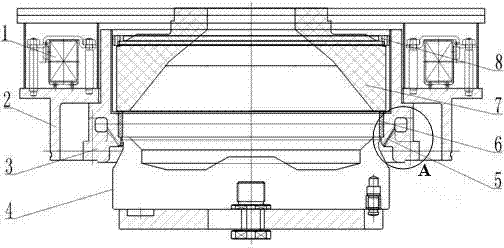

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

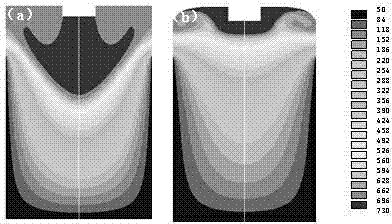

A technology of aluminum alloy and round ingot, applied in the field of aluminum alloy casting, can solve the problems such as the quality of aluminum processing products affecting the product yield, uneven structure, surface scratches, etc., to improve the internal metallurgical quality, fine and uniform grains, The effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

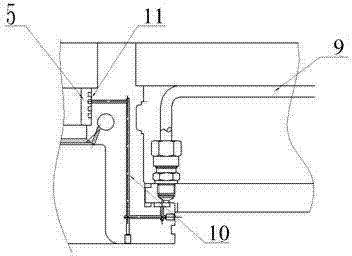

Method used

Image

Examples

Embodiment 1

[0037](1) The dummy head is lifted into the crystallizer under the lifting of the casting machine. The upper edge of the dummy head is 1mm away from the lower edge of the graphite ring. After the dummy head is in place, turn on the cooling water switch, and the cooling water enters the crystallizer through the water tank. And it is sprayed out from the water hole in the lower part of the crystallizer, and acts on the surface of the ingot;

[0038] (2) Open the oil valve, and after lubricating oil appears on the surface of the graphite ring, introduce the aluminum liquid into the cavity formed by the dummy head, the graphite ring and the heat preservation cap;

[0039] (3) The molten aluminum is solidified in the cavity for 5 seconds. After forming the slab shell, it moves down under the traction of its own weight and the dummy head, and starts the casting machine to start casting an ingot with a diameter of 380mm. The initial starting speed is 10mm / min, and then The casting sp...

Embodiment 2

[0048] (1) The dummy head is lifted into the crystallizer under the lifting of the casting machine. The upper edge of the dummy head is 1mm away from the lower edge of the graphite ring. After the dummy head is in place, turn on the cooling water switch, and the cooling water enters the crystallizer through the water tank. And it is sprayed out from the water hole in the lower part of the crystallizer, and acts on the surface of the ingot;

[0049] (2) Open the oil valve, and after lubricating oil appears on the surface of the graphite ring, introduce the aluminum liquid into the cavity formed by the dummy head, the graphite ring and the heat preservation cap;

[0050] (3) The molten aluminum is solidified in the cavity for 5 seconds. After forming the billet shell, it moves down under the traction of its own weight and the dummy head, and starts the casting machine to start casting an ingot with a diameter of 300mm. The initial starting speed is 15mm / min, and then The casting...

Embodiment 3

[0054] (1) The dummy head is lifted into the crystallizer under the lifting of the casting machine. The upper edge of the dummy head is 1mm away from the lower edge of the graphite ring. After the dummy head is in place, turn on the cooling water switch, and the cooling water enters the crystallizer through the water tank. And it is sprayed out from the water hole in the lower part of the crystallizer, and acts on the surface of the ingot;

[0055] (2) Open the oil valve, and after lubricating oil appears on the surface of the graphite ring, introduce the aluminum liquid into the cavity formed by the dummy head, the graphite ring and the heat preservation cap;

[0056] (3) The molten aluminum is solidified in the cavity for 5 seconds. After forming the billet shell, it moves down under the traction of its own weight and the dummy head. Start the casting machine to start casting an ingot with a diameter of 200mm. The initial starting speed is 50mm / min, and then The casting spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com