Patents

Literature

43results about How to "Reduce remelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

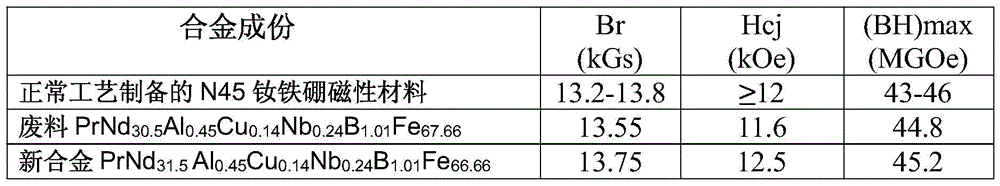

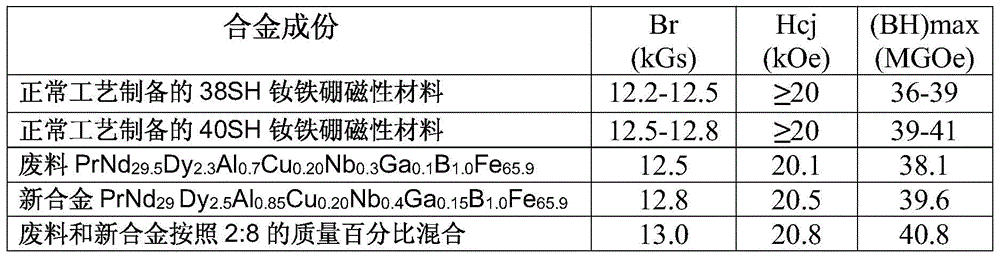

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

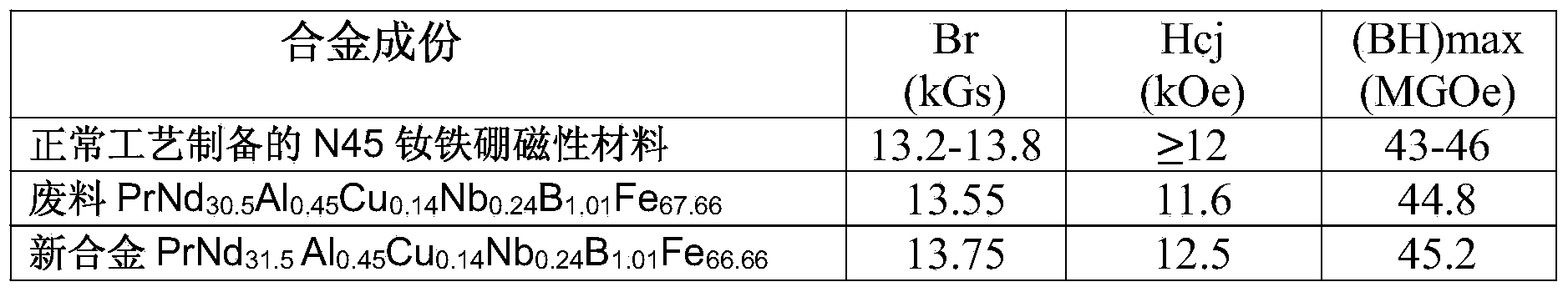

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

Converter smelting technique

InactiveCN102080136AReduce splashIncreased Metal YieldManufacturing convertersProcess efficiency improvementCarbon steelSlag

The invention relates to a steel smelting technique, in particular to a converter smelting technique. The invention aims to provide a converter smelting technique, which has the advantages of less splash, and high content of smelting end point carbon and low oxygen content in the mid-high-carbon steel during production process and greatly reduces the remelting caused by excessive carbon content in the low-carbon steel production process. The converter smelting technique comprises the following steps: (1) charging: charging molten iron and scrap steel into the converter; (2) igniting; (3) converting: within 0.5 minutes after starting converting, lowering an oxygen lance to the basic position+200mm; adding lime and lightly fired dolomite within 1.5 minutes; lowering the oxygen lance to the basic position after finishing adding the materials; slowly raising the oxygen lance to the basic position+100 to +200mm and adding lime, lightly fired dolomite, coolant and slag melting agent within 3.5-4.5 times; controlling the oxygen lance to be in the basic position to basic position+600mm within 9.5-12 minutes; and controlling the oxygen lance to be in the basic position-100mm to the basic position after 12 minutes; (4) tapping; and (5) slag splashing repair.

Owner:储鸿文 +2

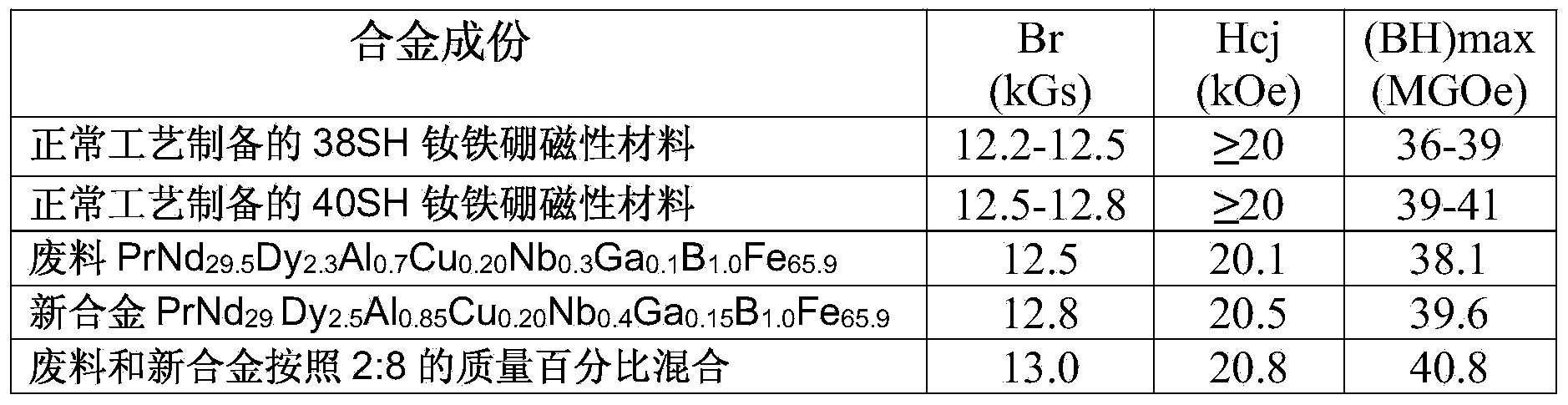

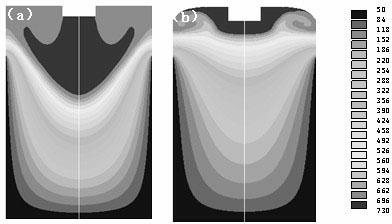

Added material manufacturing method for synchronous heat treatment

ActiveCN109175361ASufficient flow timeReduce generationAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser scanning

The invention belongs to the technical field of added material manufacturing, and in particular, discloses an added material manufacturing method for synchronous heat treatment. The method comprises the following steps: (S1) powder is paved, and is scanned by laser according to a preset scanning path to finish laser scanning of a present layer; (S2) after spacing by a period of time, the machinedpresent layer is reheated by low-power laser; and (S3) the steps (S1) and (S2) are repeated to finish laser scanning of all layers to obtain needed compact parts. The method reduces the material cooling speed during forming, prolongs the existence time of a molten pool, reduces the formation of cracks and holes, and can be applied to laser added material manufacturing of metal and metal-ceramic composite materials.

Owner:HUAZHONG UNIV OF SCI & TECH

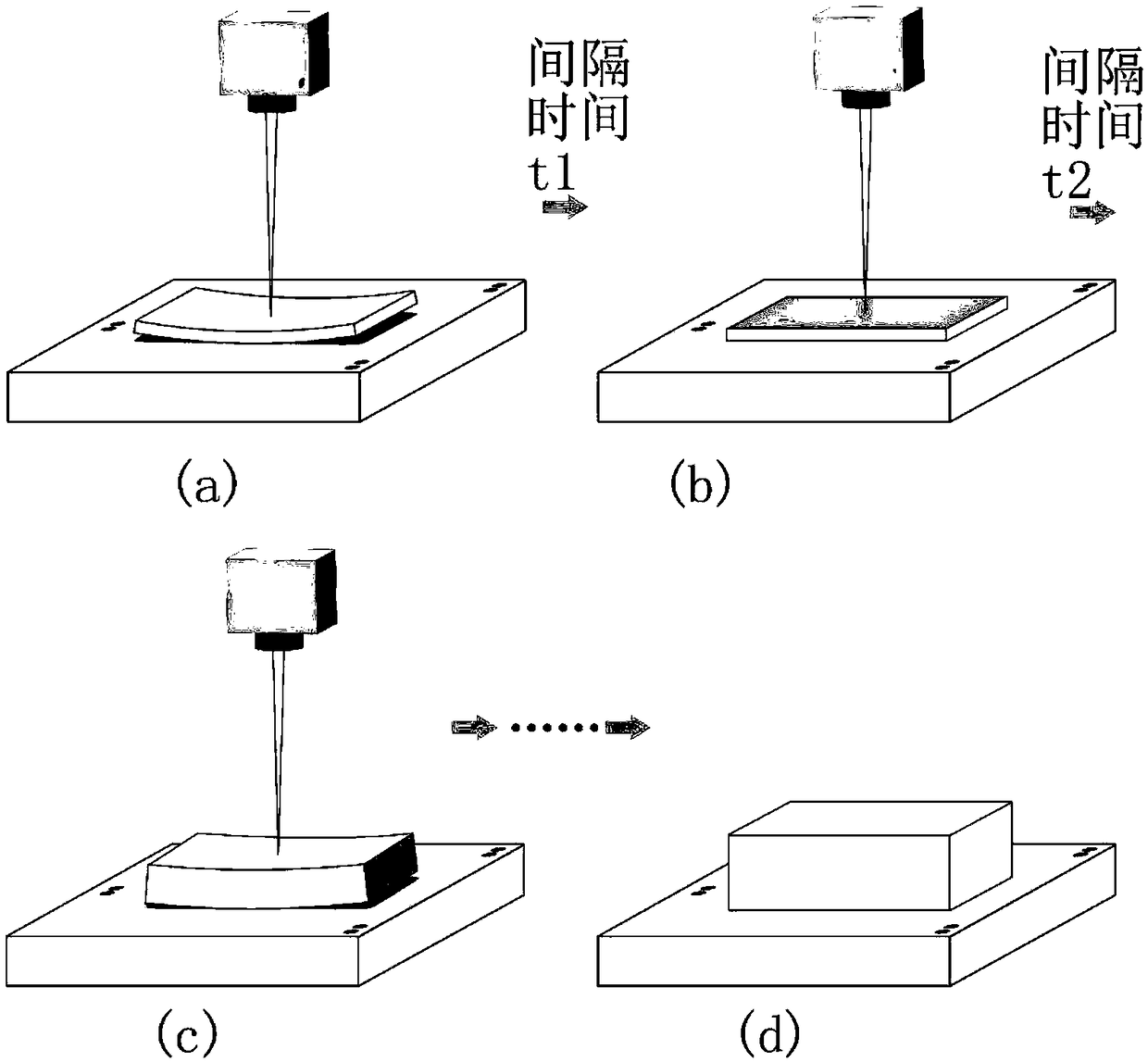

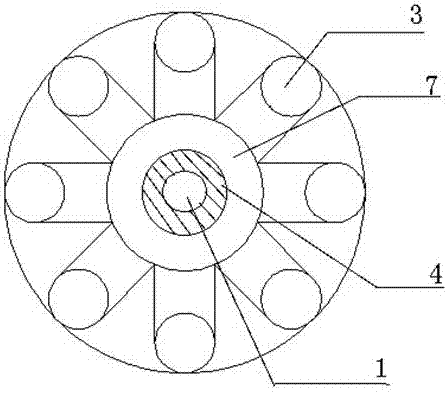

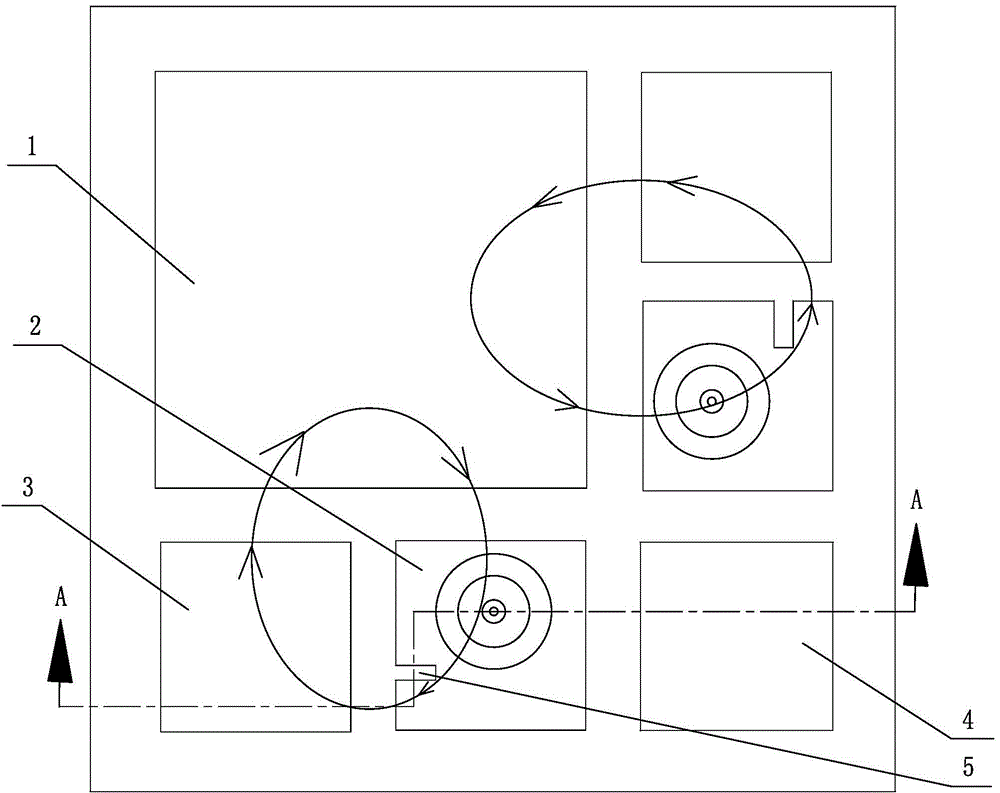

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

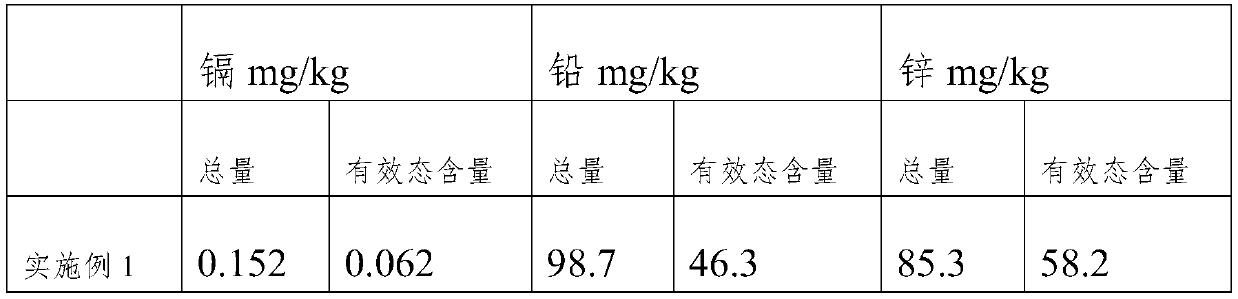

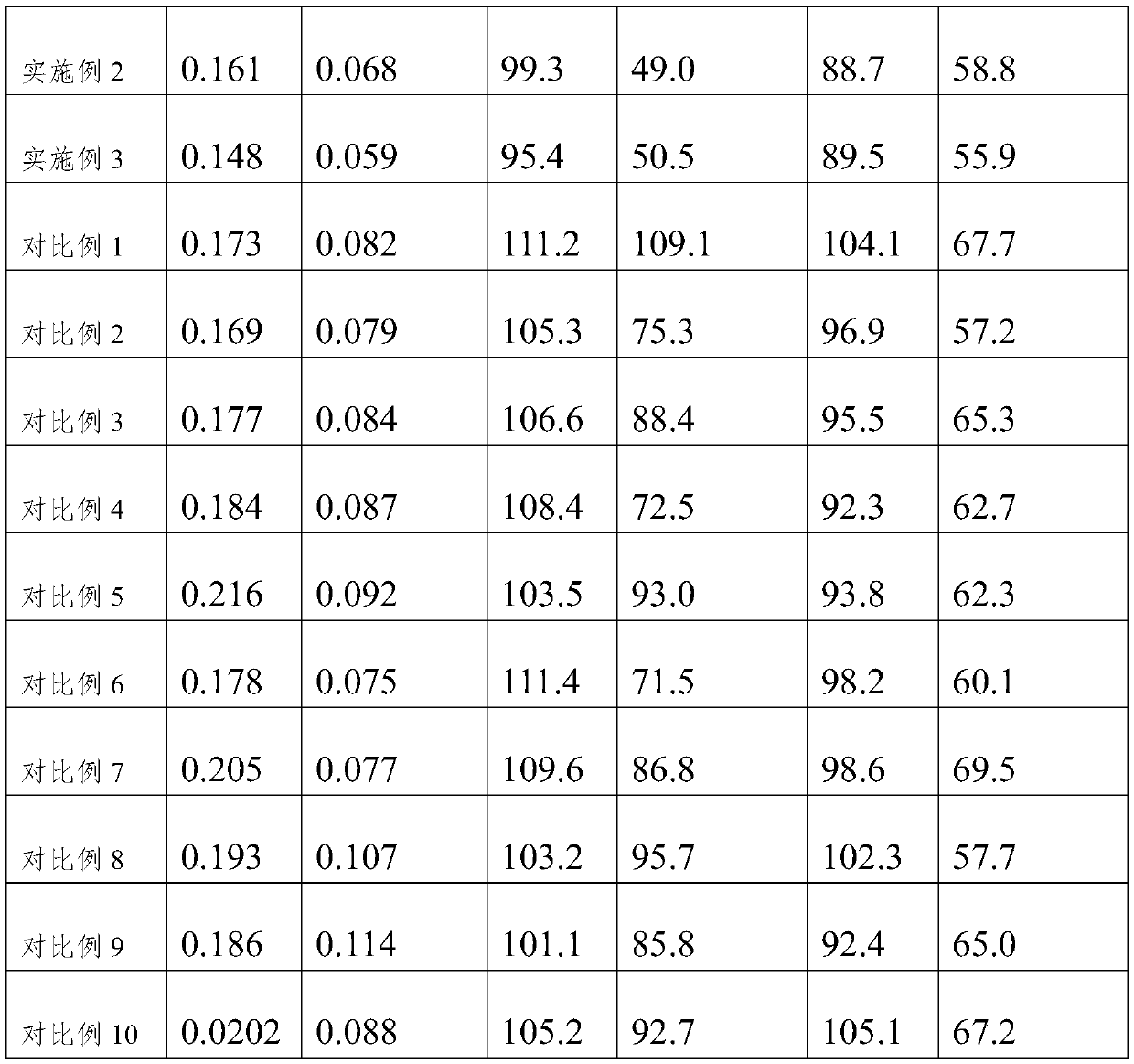

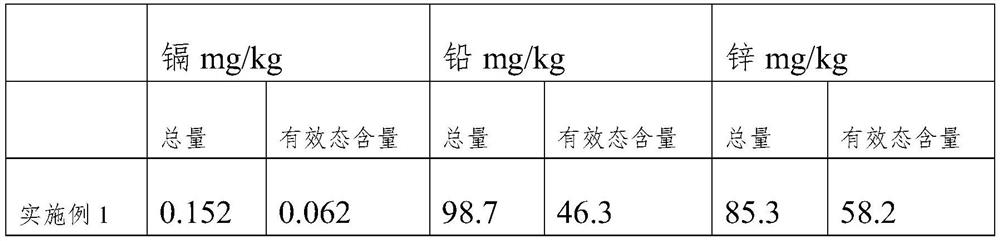

Method for remediation of lead-cadmium polluted soil

ActiveCN110586642AReduce heavy metal contentPrevention and treatment of heavy metalsContaminated soil reclamationHeavy metalsEnvironmental geology

The invention belongs to the technical field of soil remediation, and particularly relates to a method for remediation of lead-cadmium polluted soil. A combined remediation method of adsorption solidification and microbial remediation is adopted to remediate lead-cadmium polluted soil. The method particularly comprises the following steps: spreading an adsorbent and a passivator into the soil before crop seeds are sown, spraying water at the same time, then carrying out deep tillage by 5-8 cm, and standing the soil for 10-15 days; and spreading a compound bacterial preparation into the soil, carrying out shallow tillage by 3-5cm, then spraying a film forming solution into the soil, and standing the soil for 10-15 days. Through adoption of the combined remediation method of adsorption solidification and microbial remediation, heavy metals are firstly adsorbed and solidified under action of the adsorbent and the passivator, and then the adsorbed and solidified heavy metals are digested and converted by microorganisms, so that the content of the heavy metals in the soil is reduced, and the heavy metals are prevented from being dissolved again.

Owner:铜仁市万山区植保植检站

High-performance cobalt-based high-temperature alloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

Integrated energy-saving processing process for modified reprocessed plastic

InactiveCN103928726AReduce drawingReduce coolingWaste accumulators reclaimingBattery recyclingEngineeringCrusher

The invention provides an integrated energy-saving processing process for modified reprocessed plastic, relating to the technical field of resource reutilization. The integrated energy-saving processing process comprises the following process steps: (1) cutting waste storage batteries and sequentially separating plastic pieces, grids, lead plaster, lead powder and the like in the waste storage batteries out; (2) putting the separated plastic pieces into washing equipment and washing; after the washing, leaching and conveying the separated plastic pieces into disinfection equipment and disinfecting the separated plastic pieces; (3) putting the disinfected plastic pieces into a crusher, crushing the disinfected plastic pieces into grains and quantitatively adding the plastic grains into an extruder and adding other auxiliary materials according to the requirements on preparation of a product; extruding by the extruder; and (4) directly putting plastic strips extruded by the extruder into a molding mould, and de-molding to directly obtain a finished product; and carrying out surface treatment on the finished product. According to the integrated energy-saving processing process, four links of drawing wires, cooling, granulating and refusing are reduced; compared with a traditional process, the integrated energy-saving processing process has the advantages that energy-saving and environment-friendly effects are achieved; the processing efficiency is improved and the cost is saved.

Owner:JIESHOU SHUANGTE NEW MATERIAL TECH

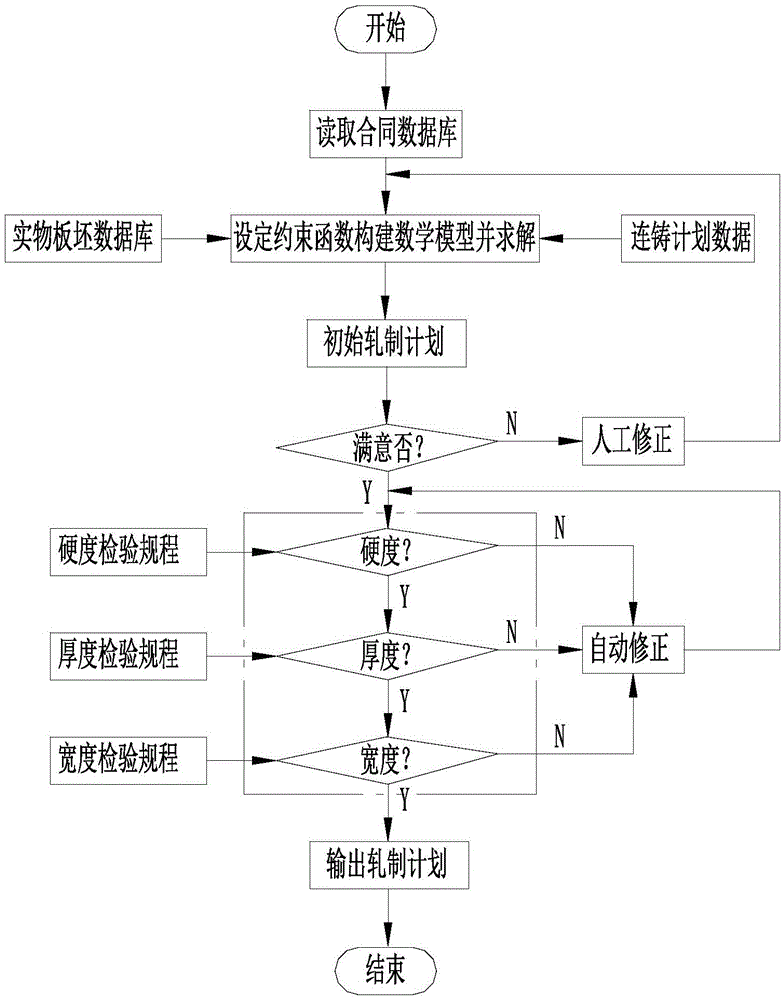

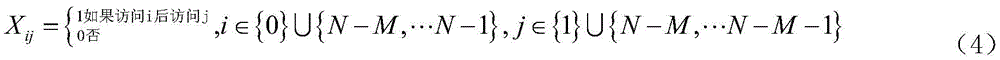

Hot rolling plan arrangement method

InactiveCN106773658ABillet hot direct loading rate is highHigh thermal direct loading rateAdaptive controlHeating timeEngineering

The invention relates to a hot rolling plan arrangement method, and belongs to the technical field of metallurgical continuous rolling. The method includes: setting a constraint function, establishing a rolling plan model, solving the rolling plan model, performing programming by employing a computer programming technology, and establishing a continuous casting and rolling production, organization, and management mode. Compared with the prior art, the beneficial effects of the method are that the plan making is flexible, mixed arrangement of different steel kinds, different thicknesses, and different widths can be performed, and crossed rolling is realized; the hot direct rolling rate of hot-rolled slabs is high, the heating time of cold-rolled plates is reduced, and energy is saved; and the function of six-in-one by three machines of the casting billet can be fully achieved, the 215OASP production line realizes tight combination of three processes including steel production, continuous casting, and rolling, and the goal of promoting energy saving and consumption reduction of steel products is achieved.

Owner:ANGANG STEEL CO LTD

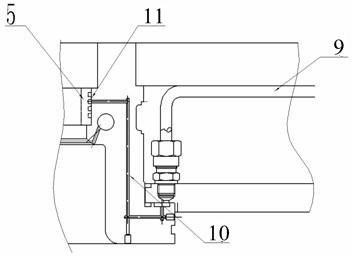

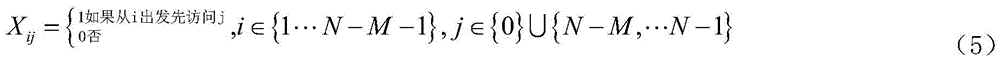

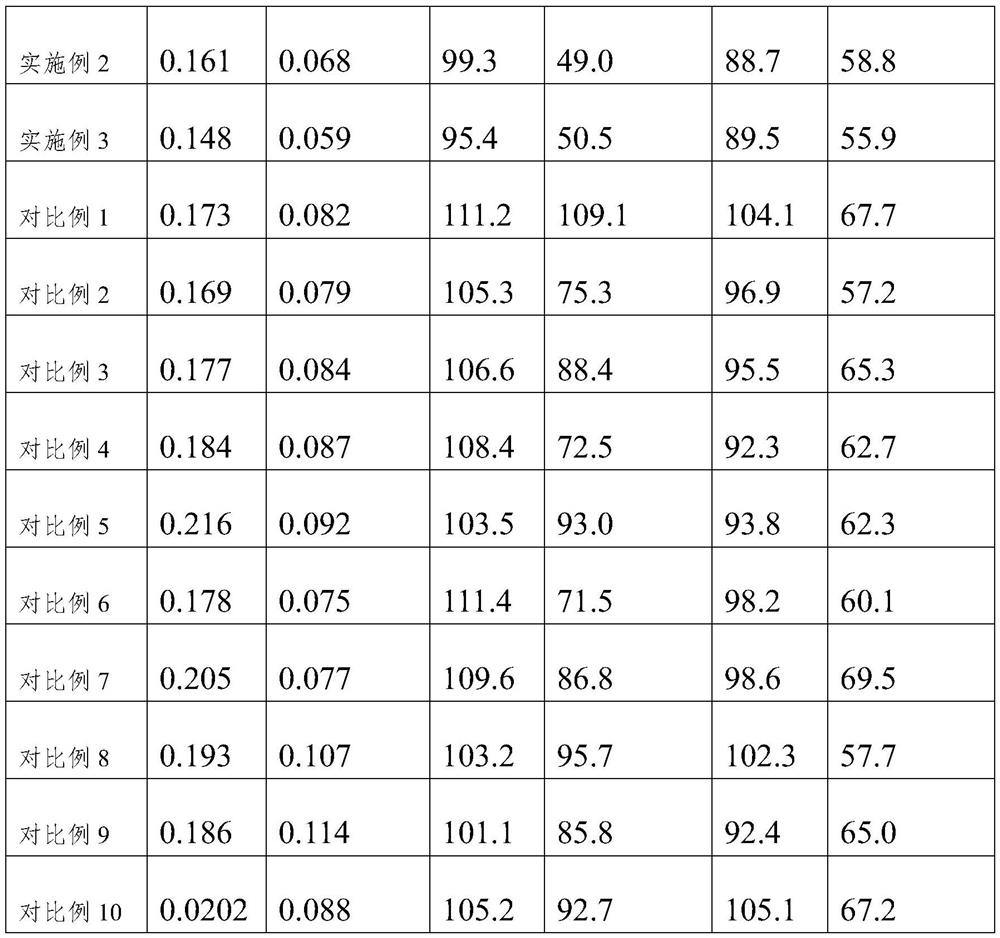

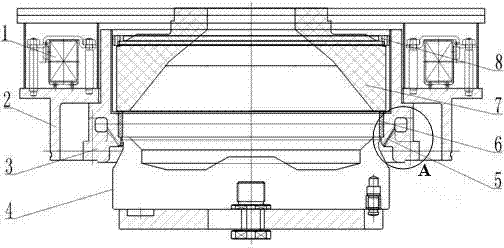

Roller water-entering/returning pipeline system device for two-roll calender

The invention relates to a roller water-entering / returning pipeline system device for a two-roll calender. The device comprises a roller, a water returning channel, a middle transition channel, a distribution pipeline, a water entering pipe and a cooling channel, wherein the water-entering / returning pipeline is designed in the roller; the water-entering / returning pipeline is divided into the water returning channel, the middle transition channel and the distribution pipeline; the cooling channel is arranged in the roller close to the outer wall of the roller; a water entering branch and a water draining branch of the cooling channel are respectively connected with the distribution pipeline and the water returning channel; the water returning channel is formed between the water entering pipe and the inner wall of the roller; and the water entering pipe passes by the water returning channel, penetrates through the middle transition channel, extends into the distribution pipeline and is in sealing connection with a matching joint of the water entering pipe in the middle transition channel and the inner wall of the roller. The roller water-entering / returning pipeline system device has the advantages of simple and convenient design, flexible conception, high sealing property, high water pressure in the roller and capabilities of increasing the circulating speed of water in the cooling channel, promoting the cooling effect, reducing the cleaning and halting time of the device and the fault times of the device and reducing the labor intensity of the operator.

Owner:DOUBLE COIN GRP JIANGSU TIRE

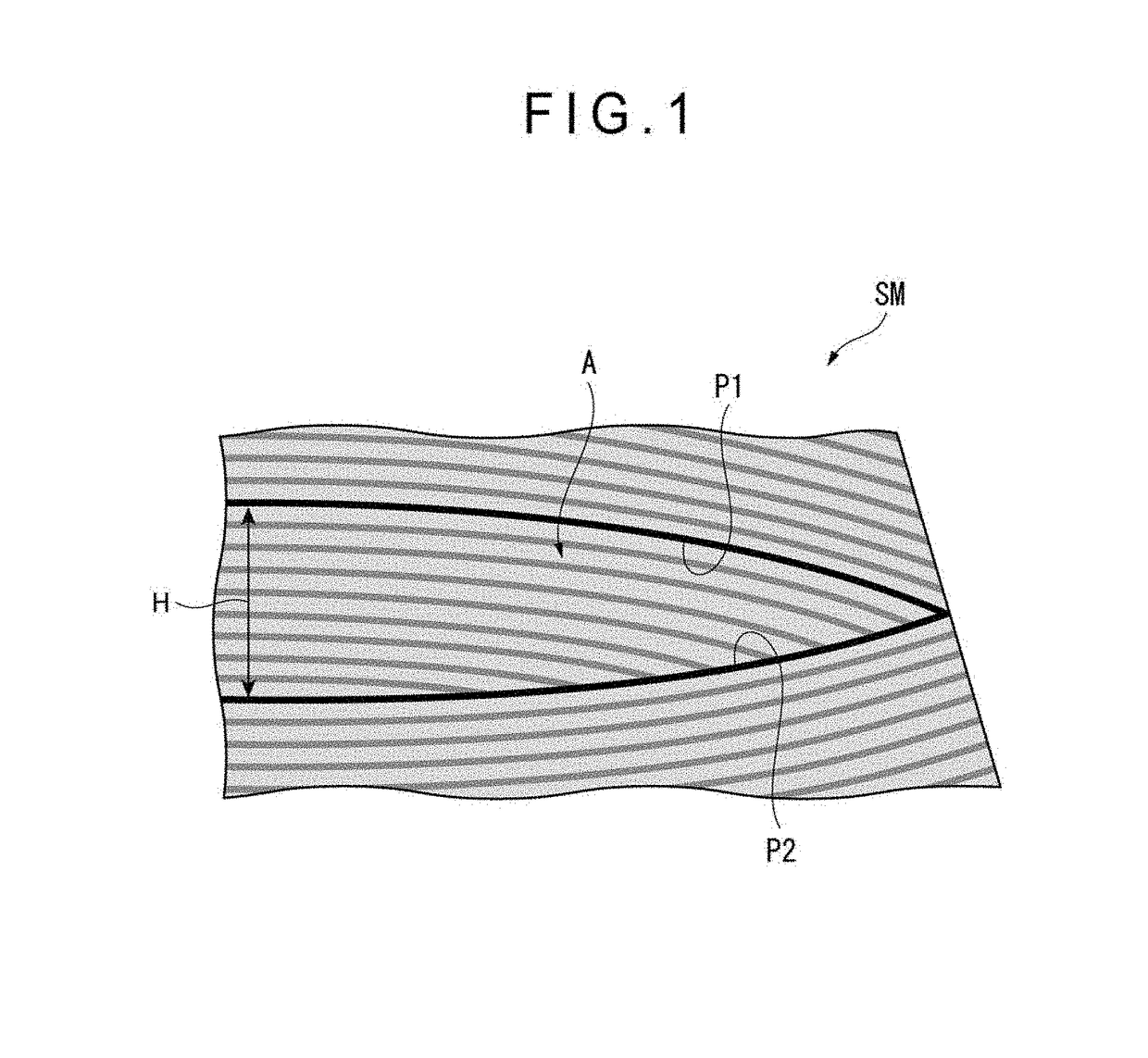

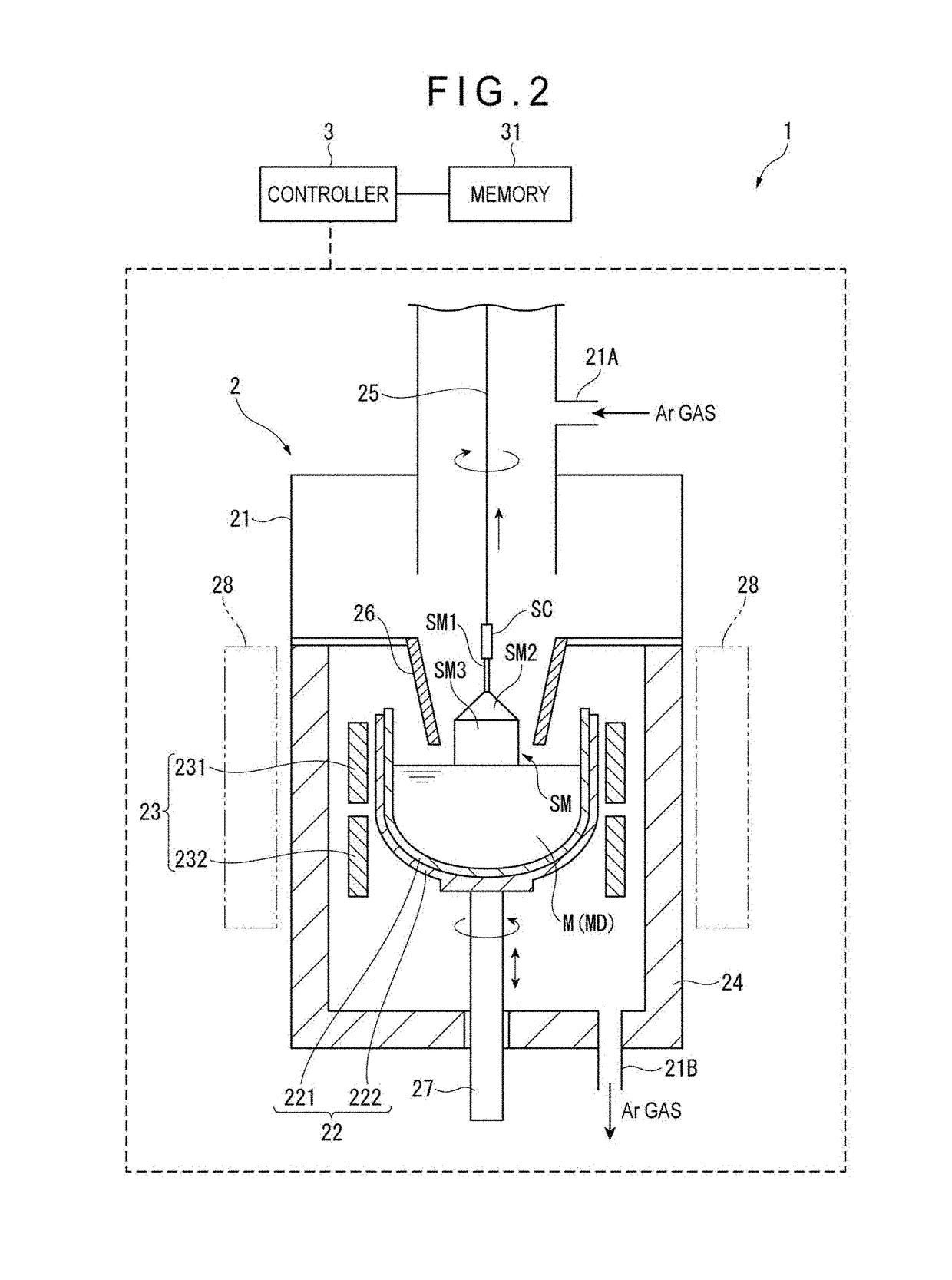

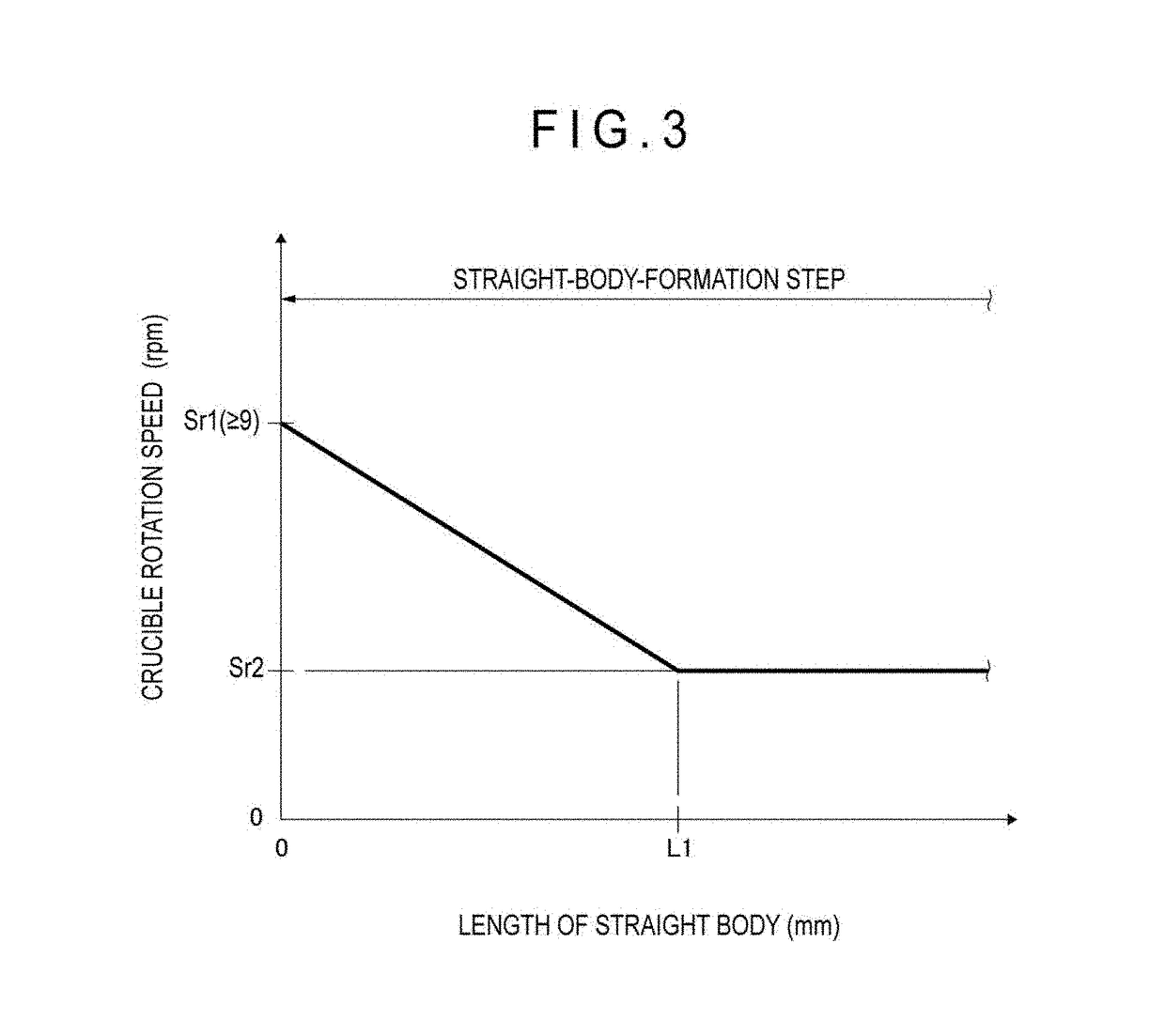

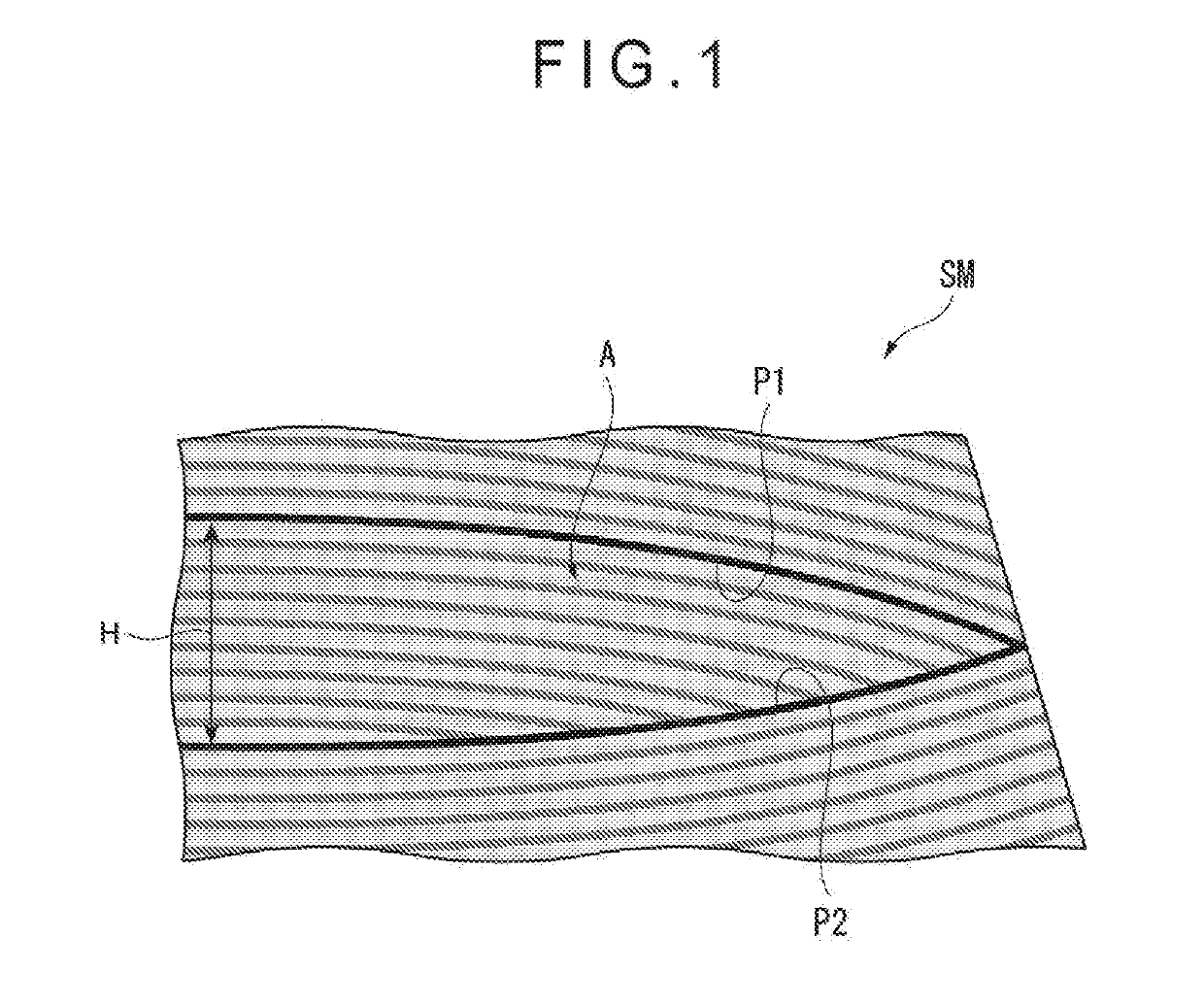

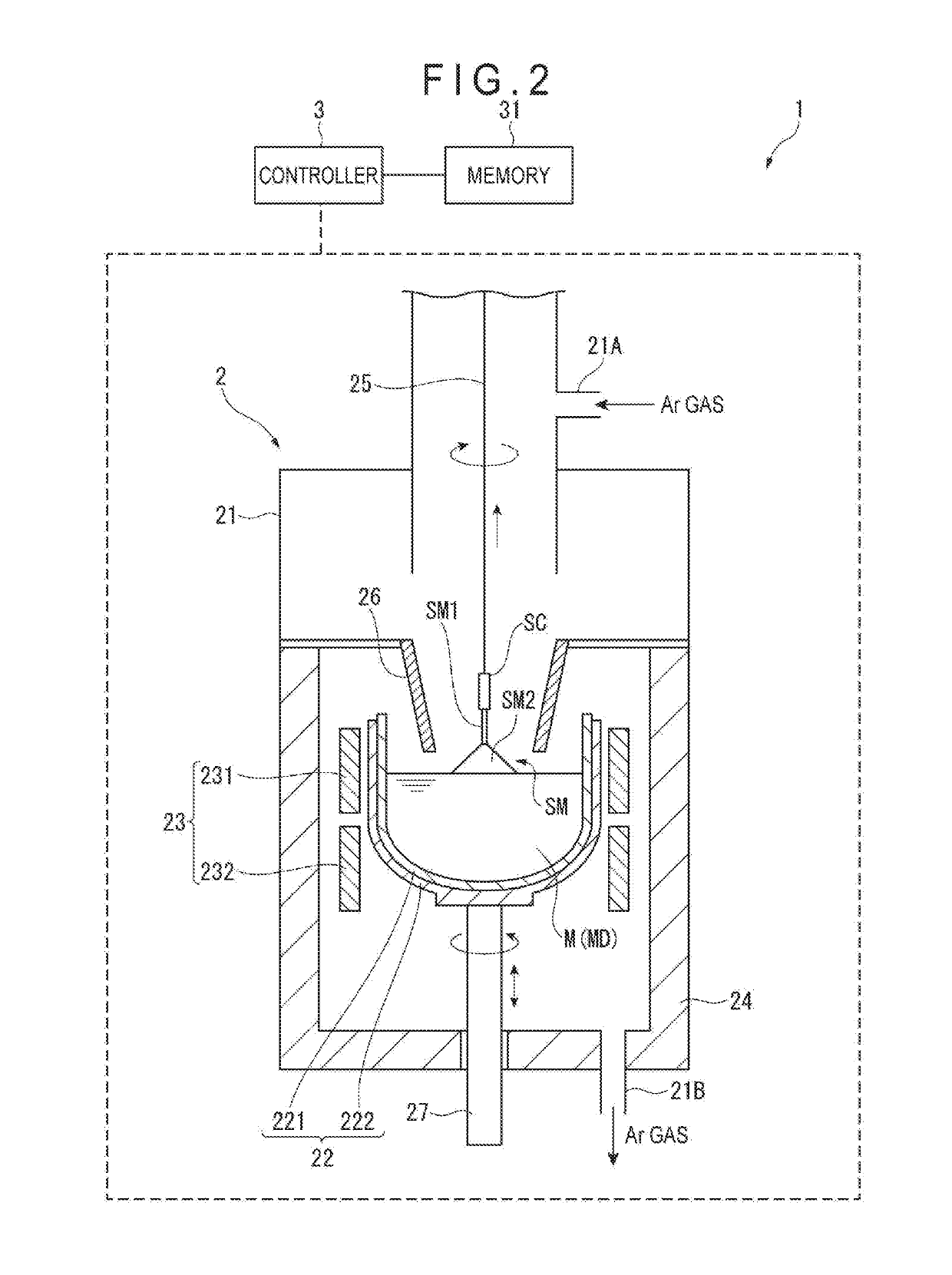

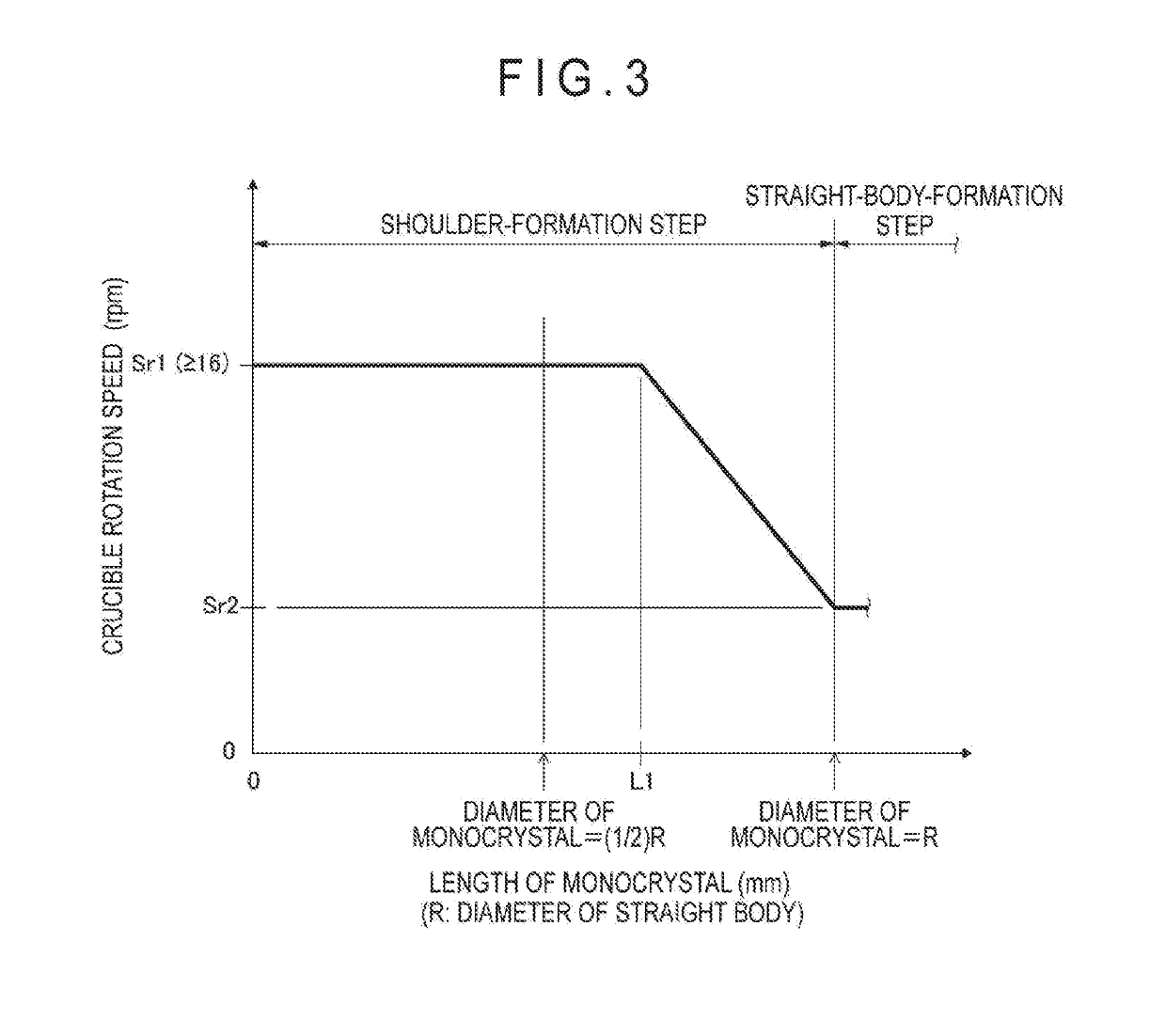

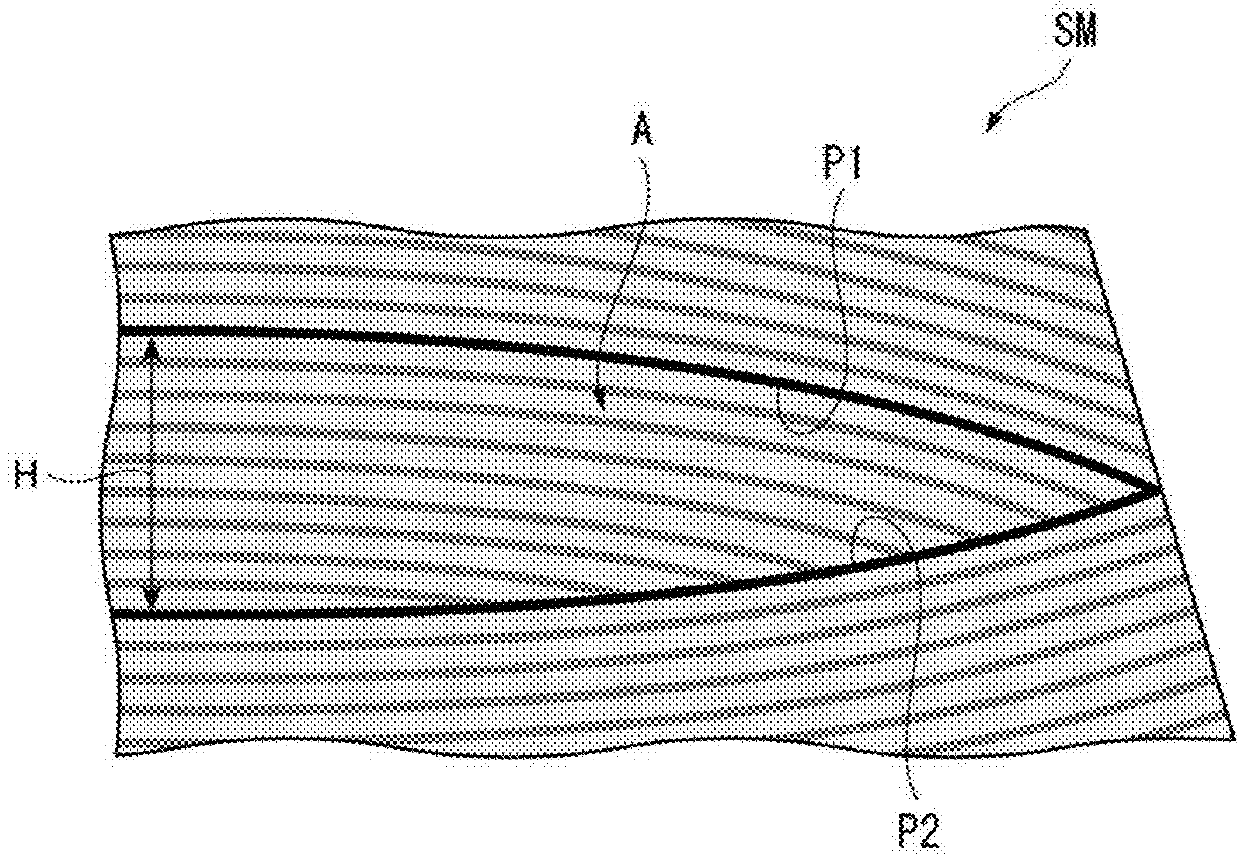

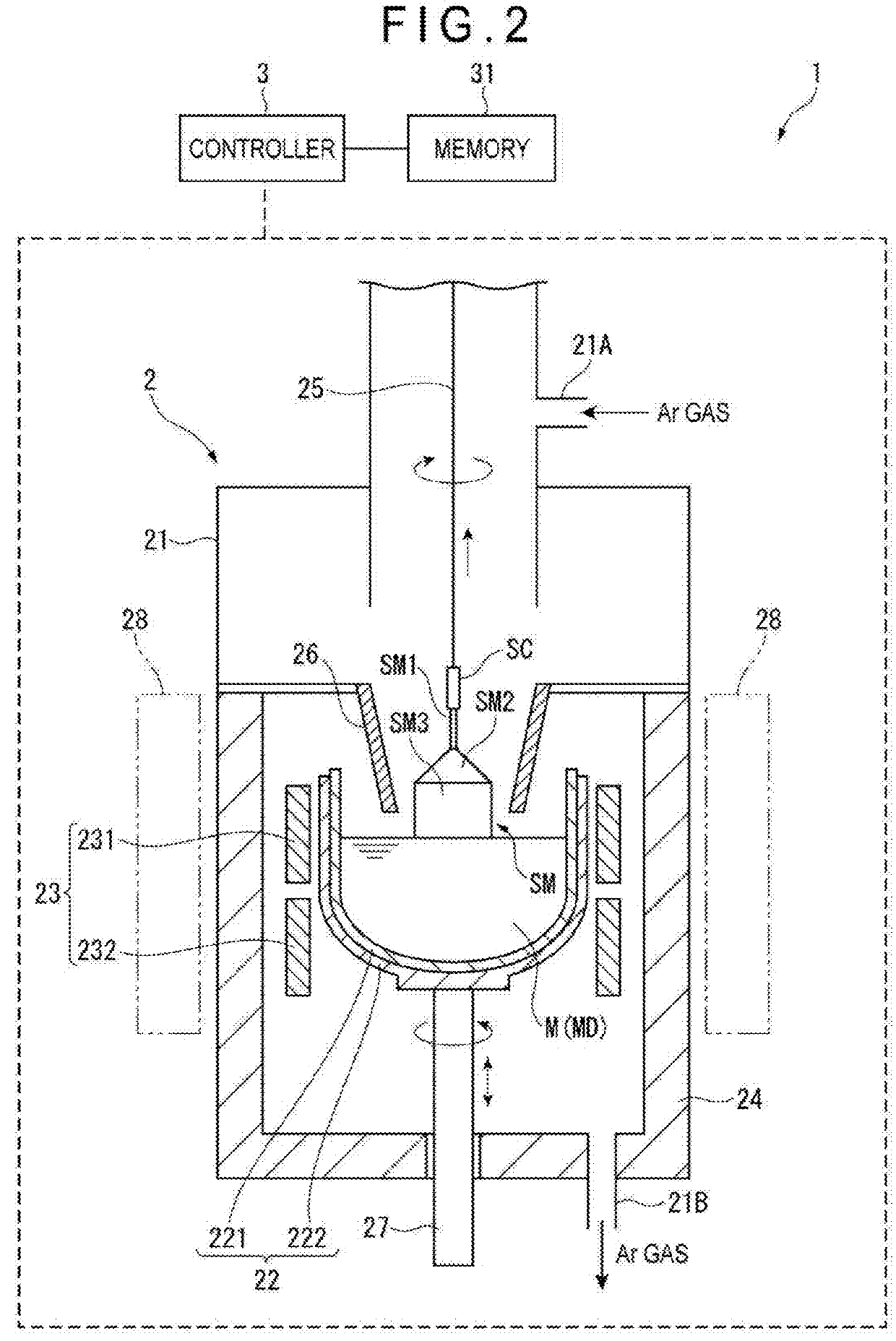

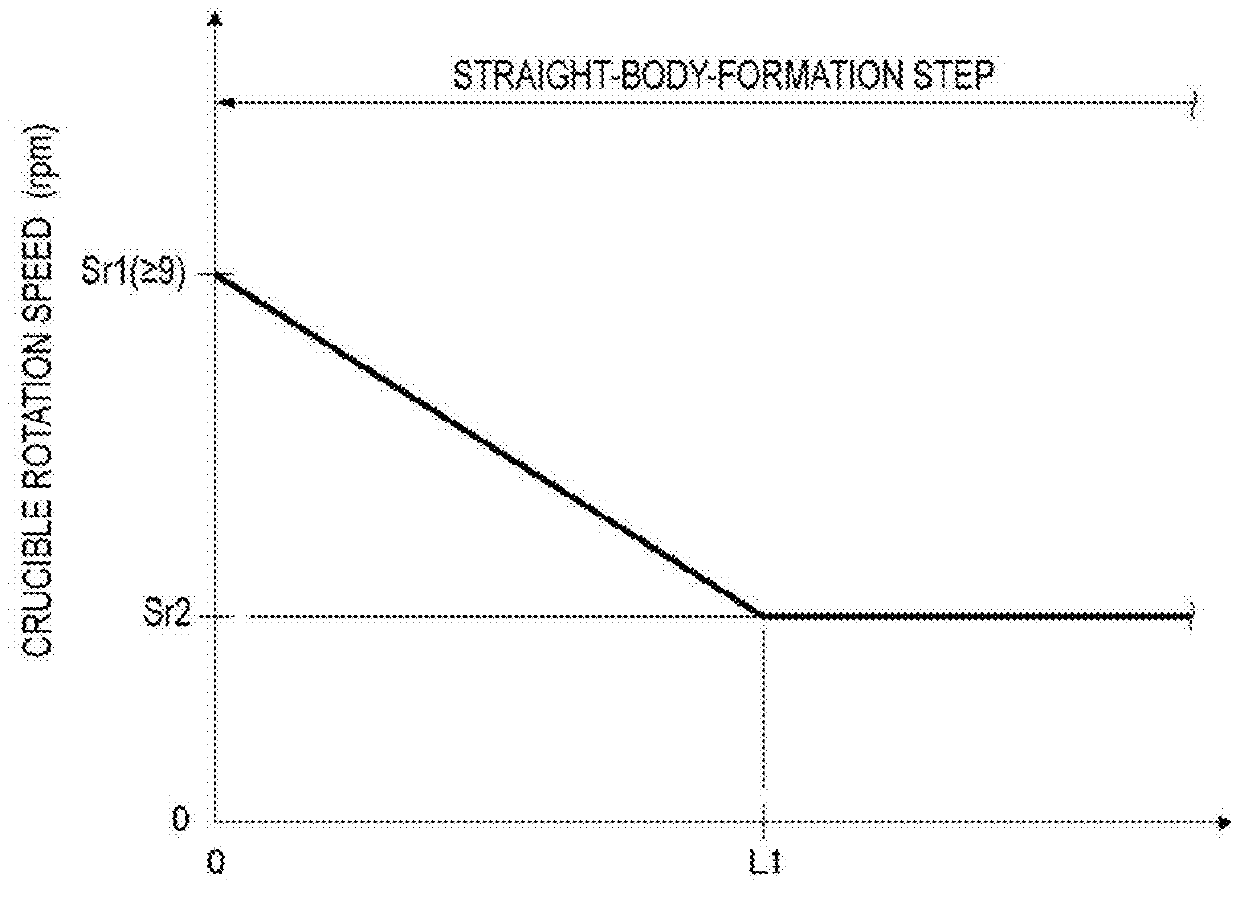

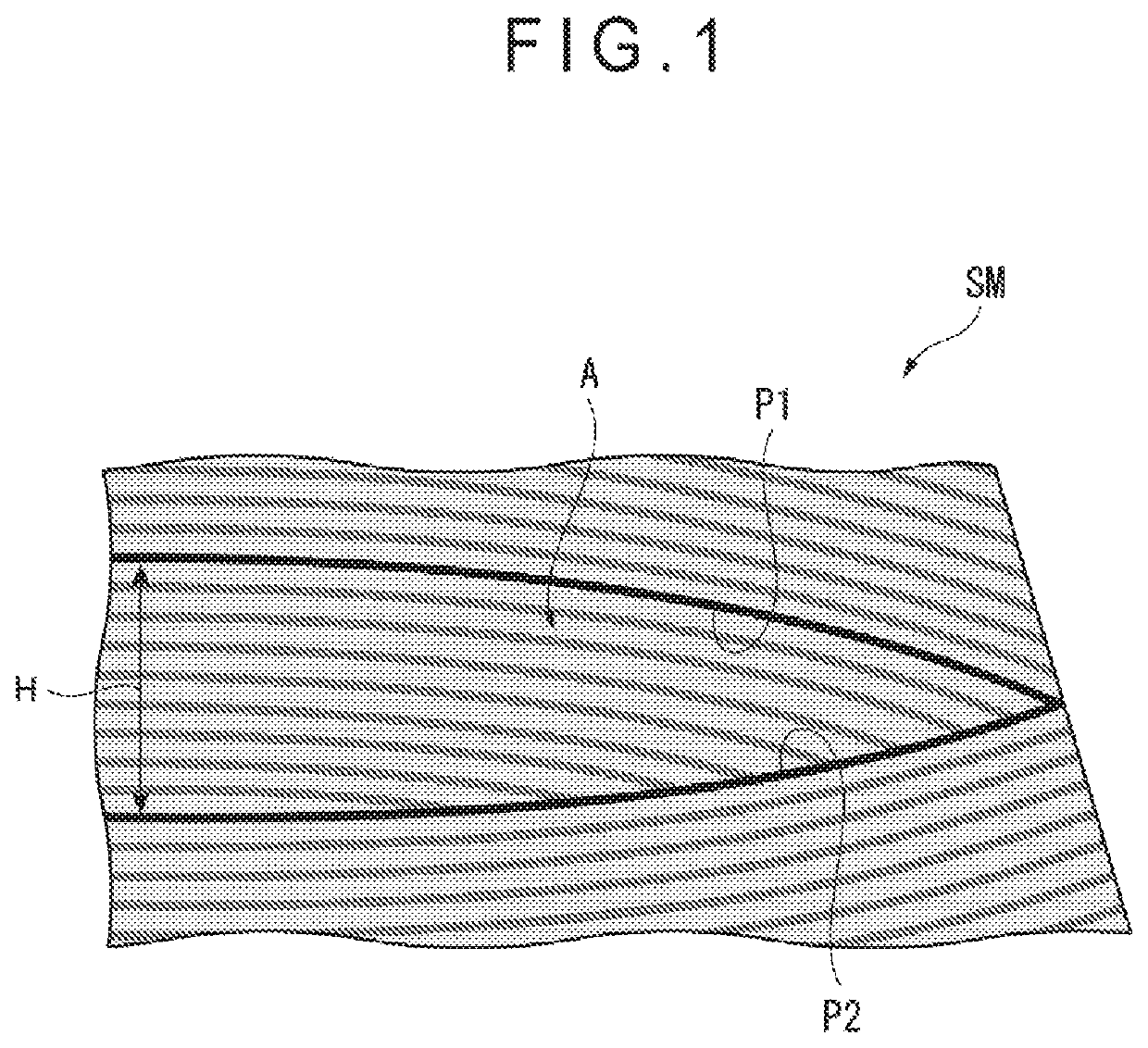

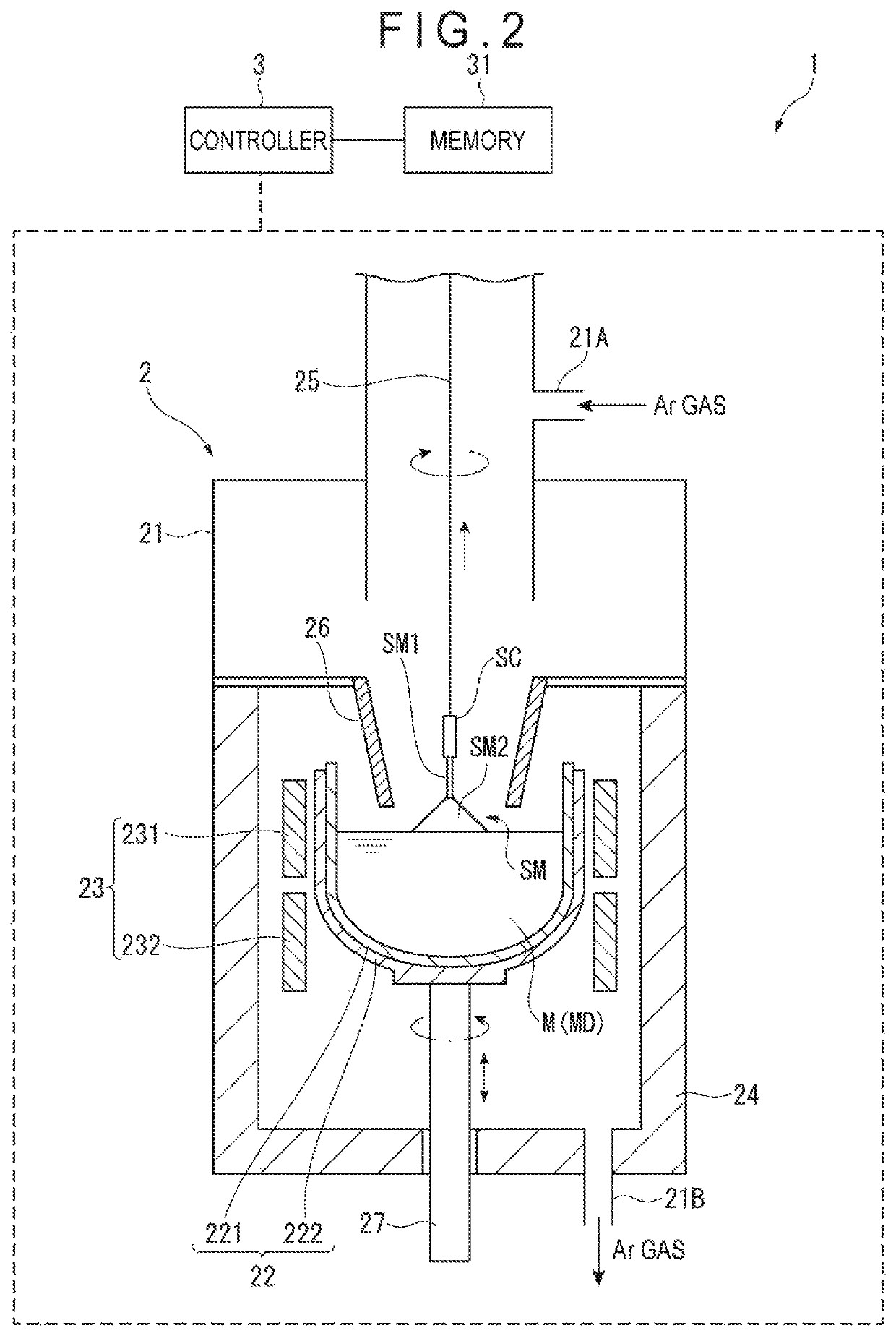

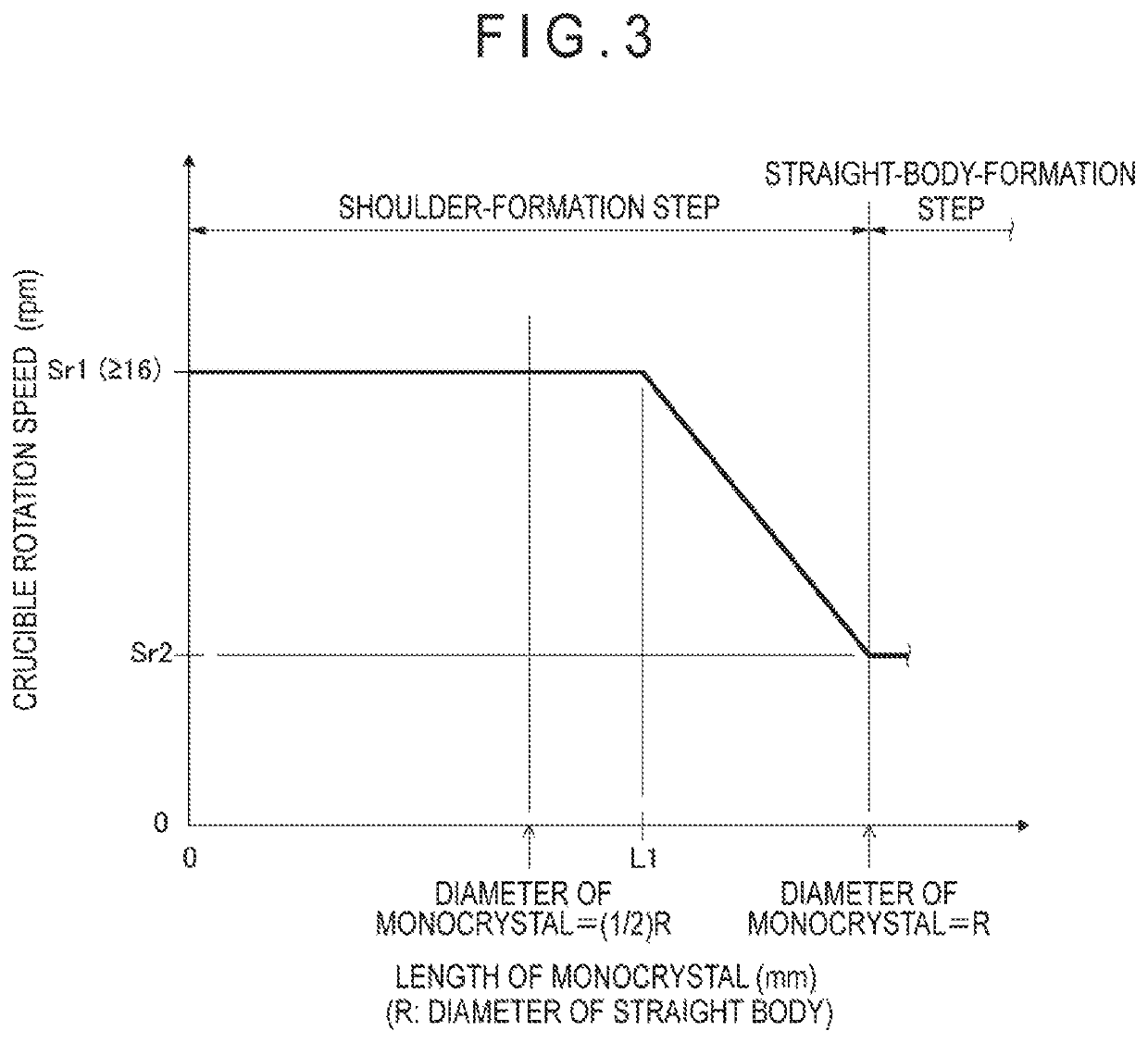

Manufacturing method of monocrystalline silicon and monocrystalline silicon

ActiveUS10233564B2Quality improvementReduce remeltingPolycrystalline material growthBy pulling from meltMaterials scienceSingle crystal silicon

A smonocrystalline silicon include a straight body formed without generating a remelt growth area of 200 μm or more in a height in a growth direction. Growth striations, which are formed radially across the straight body, include a growth striation with an outer end interrupted by another growth striation not to reach a peripheral portion of the straight body. The remelt growth area has the growth striation with the interrupted outer end.

Owner:SUMCO CORP

A method for preparing neodymium-iron-boron by regeneration of waste materials containing neodymium-iron-boron

ActiveCN103866127BFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementHydrogenEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

Silicon monocrystal production method

ActiveUS20190186042A1Quality improvementReduce convectionPolycrystalline material growthBy pulling from meltSingle crystalMaterials science

A production method of a monocrystalline silicon includes: forming a shoulder of the monocrystalline silicon; and forming a straight body of the monocrystalline silicon. In forming the shoulder, the shoulder is formed such that a part of growth striations, which extend radially across the shoulder, has an outer end interrupted by another part of the growth striations not to reach a peripheral portion of the shoulder and that no remelt growth area with a height of 200 μm or more in a growth direction is generated.

Owner:SUMCO CORP

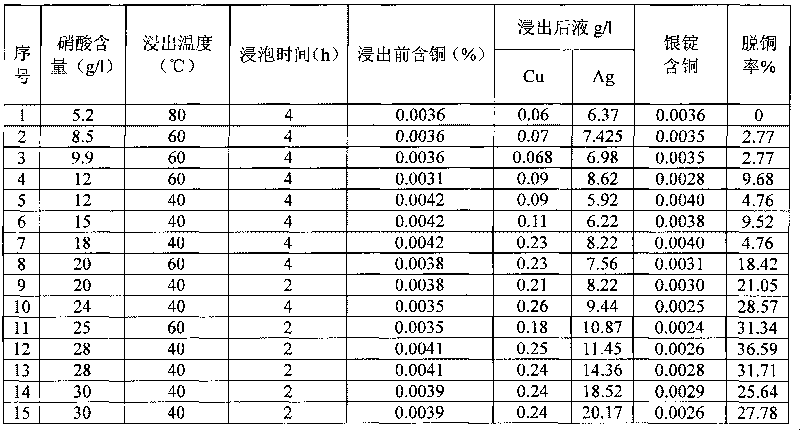

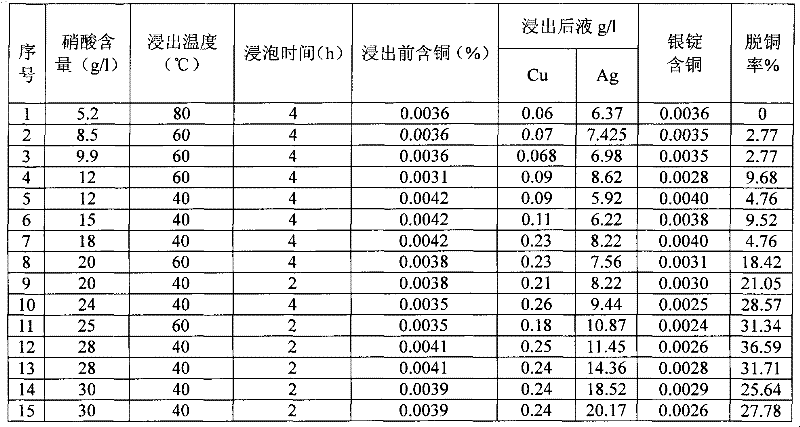

Method for increasing quality of cathode silver power

The invention discloses a method for increasing quality of cathode silver power, aiming to solve the problem that the copper impurity in the cathode silver power exceeds standard. The method comprises the following steps: preparing cathode silver power by controlling the compositions of electrolyte to comprise 90-120g / l of Ag, 8-10g / l of HNO3 and less than 35-60g / l of Cu, and using 20-28g / l of dilute nitric acid to dissolve, soak and rinse the cathode silver power when the copper content in the electrolyte is more than 35g / l, wherein the soaking temperature is 40-50 DEG C, the soaking time is 2h, and the rinsing temperature is 80-90 DEG C. By using the method of the invention, the cost of the 1# cathode silver is reduced and the mass of the product silver ingot is increased. The method has the advantages of low operating intensity, simple equipment, low production cost, capability of not changing the original processing equipment, and the like.

Owner:BAIYIN NONFERROUS GROUP

Metal smelting furnace

InactiveCN104439218AReduce the temperatureReduce temperature differenceMolten metal conveying equipmentsImpellerLiquid surfaces

The invention discloses a metal smelting furnace, and belongs to the field of metal smelting devices. According to an existing smelting and thermal insulating system, when metal liquid in a soup taking chamber is oversupplied, the temperature is prone to being reduced to be below the temperature required by casting. A refining chamber is arranged on at least one side of a thermal insulating furnace, a soup taking chamber is arranged on one side of the refining chamber, the bottom of the refining chamber is communicated with the bottom of the thermal insulating furnace through a channel, an impeller is arranged at the bottom of the refining chamber, a channel port of the channel is located below the impeller, an air conveying channel capable of conveying air to the part below a liquid surface is arranged in the refining chamber, the impeller rotates to scatter and refine metal liquid entering the refining chamber and provides force for lifting metal liquid upwards so that the metal liquid surface in the refining chamber can be higher than the metal liquid surface in the thermal insulating furnace, a liquid conveying through hole is formed in a partition wall between the soup taking chamber and a cavity of the refining chamber so that the soup taking chamber and the refining chamber can be communicated with each other, and a return through hole capable of returning and conveying metal liquid in the soup taking chamber to the thermal insulating furnace is formed in a partition wall between the soup taking chamber and a cavity of the thermal insulating furnace.

Owner:ZHEJIANG HENGTONG MACHINERY

Vermicular graphite cast iron manufacturing process for automobile engine

InactiveCN110343941AImprove alloy utilizationReduce processing costsProcess efficiency improvementCast ironTreatment costs

The invention discloses a vermicular graphite cast iron manufacturing process for an automobile engine. The vermicular graphite cast iron manufacturing process comprises the following steps that S1, the content of a graphite interference element in the raw molten iron is firstly taken into consideration, so that the adding amount of the vermicularizing agent is greatly influenced, due to the factthat the vermicular elements in the molten iron are added, a part is consumed in chemical reaction, the process is mainly used for removing oxygen and desulfurization, only the creep elements remaining in the cast iron are effective in changing the shape of the graphite, and if in the molten iron is treated, S, O and graphite are extremely low in interference element content, the amount of the consumed vermicularizing agent is small, the production cost is low, so that when the furnace burden is prepared, a pure material with low sulfur and graphite interference element content should be selected, and the use amount of the material returning is not more than 50%. The alloy is high in alloy utilization rate by adopting a wire feeding method, less in additive consumption, low in treatment cost, low in labor cost, safe and reliable in operation, and small in environmental pollution.

Owner:湖北玛尔帕斯动力科技有限公司

Manufacturing method of monocrystalline silicon and monocrystalline silicon

ActiveUS20180094360A1Reduce misalignmentQuality improvementPolycrystalline material growthBy pulling from meltMaterials scienceSingle crystal silicon

A smonocrystalline silicon include a straight body formed without generating a remelt growth area of 200 μm or more in a height in a growth direction. Growth striations, which are formed radially across the straight body, include a growth striation with an outer end interrupted by another growth striation not to reach a peripheral portion of the straight body. The remelt growth area has the growth striation with the interrupted outer end.

Owner:SUMCO CORP

Laser cladding method for processing debris

PendingCN110541166AReduce manufacturing costsImprove economySolid waste disposalMetallic material coating processesHigh energyOptoelectronics

The invention provides a laser cladding method for recovering and reusing processing debris. In order to overcome the problem of high price of laser cladding powder. The laser cladding method selectsto recover a turning processing debris, uses high-energy ball milling mechanical agitation to remove an oxide film on the surface of a powder material, continues high-energy ball milling and agitationafter cleaning, until the debris is crushed into powder, so as to replace the laser cladding material to realize the secondary reuse of waste material. Finally, the powder is preset with the surfaceof the base material, and the coating is prepared by the laser cladding equipment. The laser cladding method adapts the method of reusing the turning processing debris, so that the manufacturing costof laser cladding powder is saved and the utilization rate of resources is improved; and is a green manufacturing mode with significant benefits.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

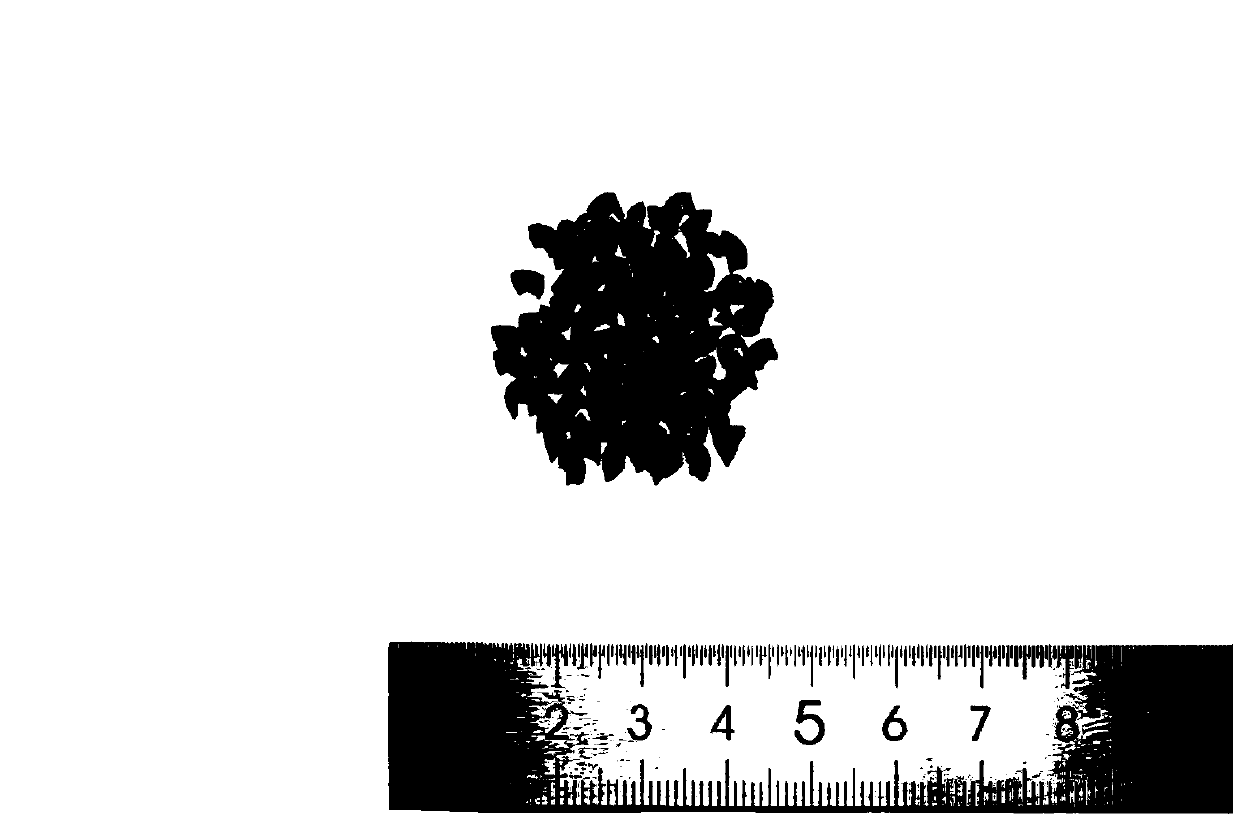

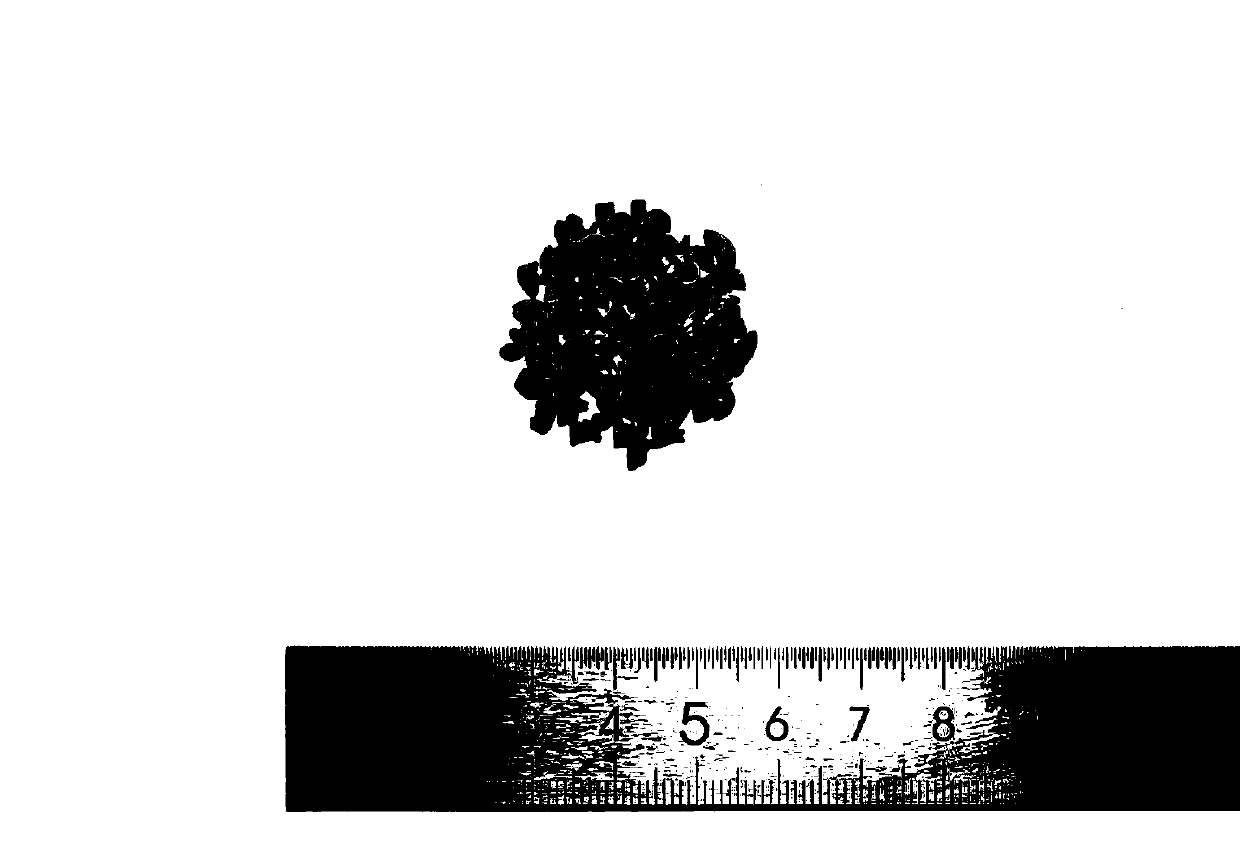

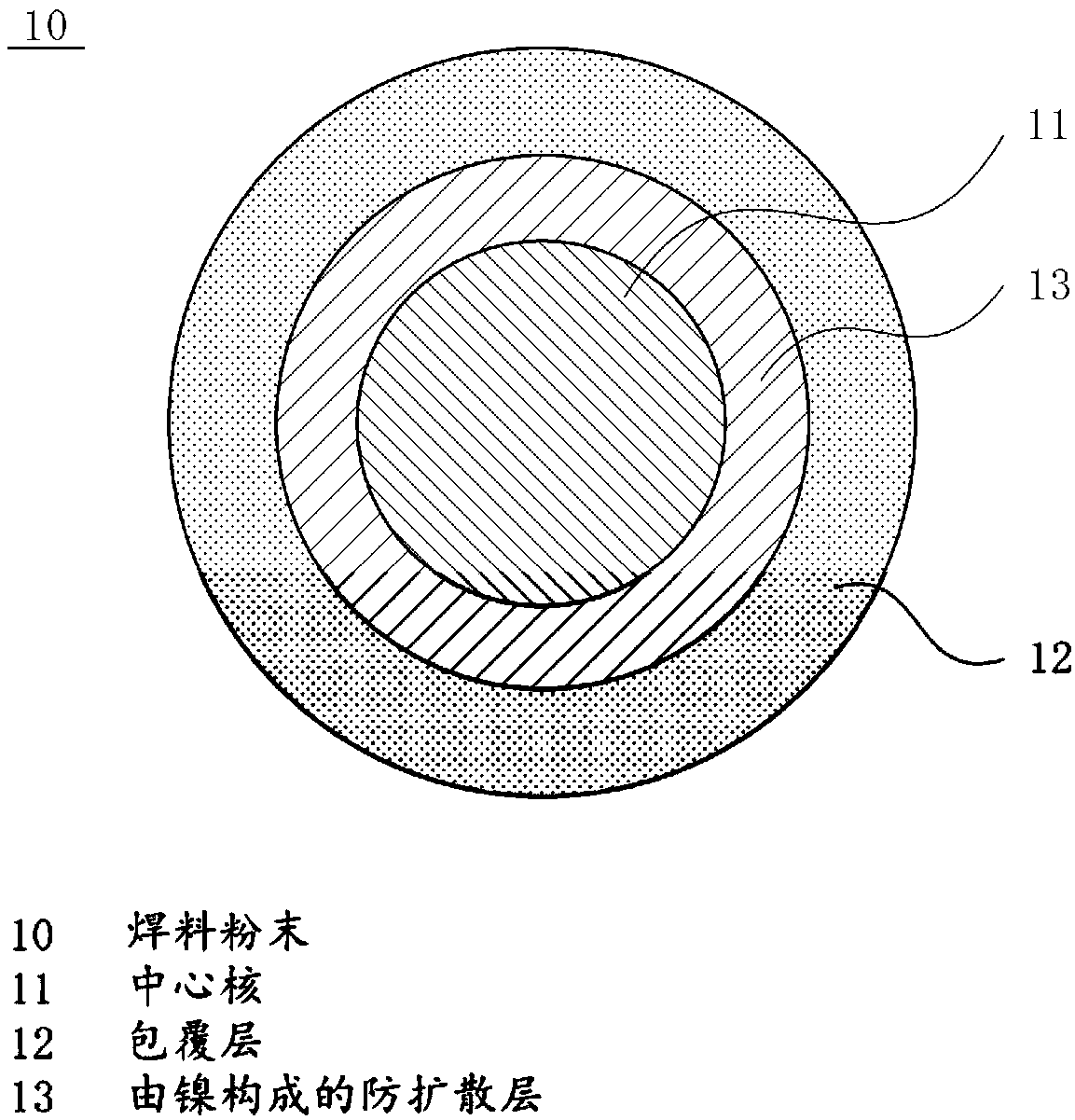

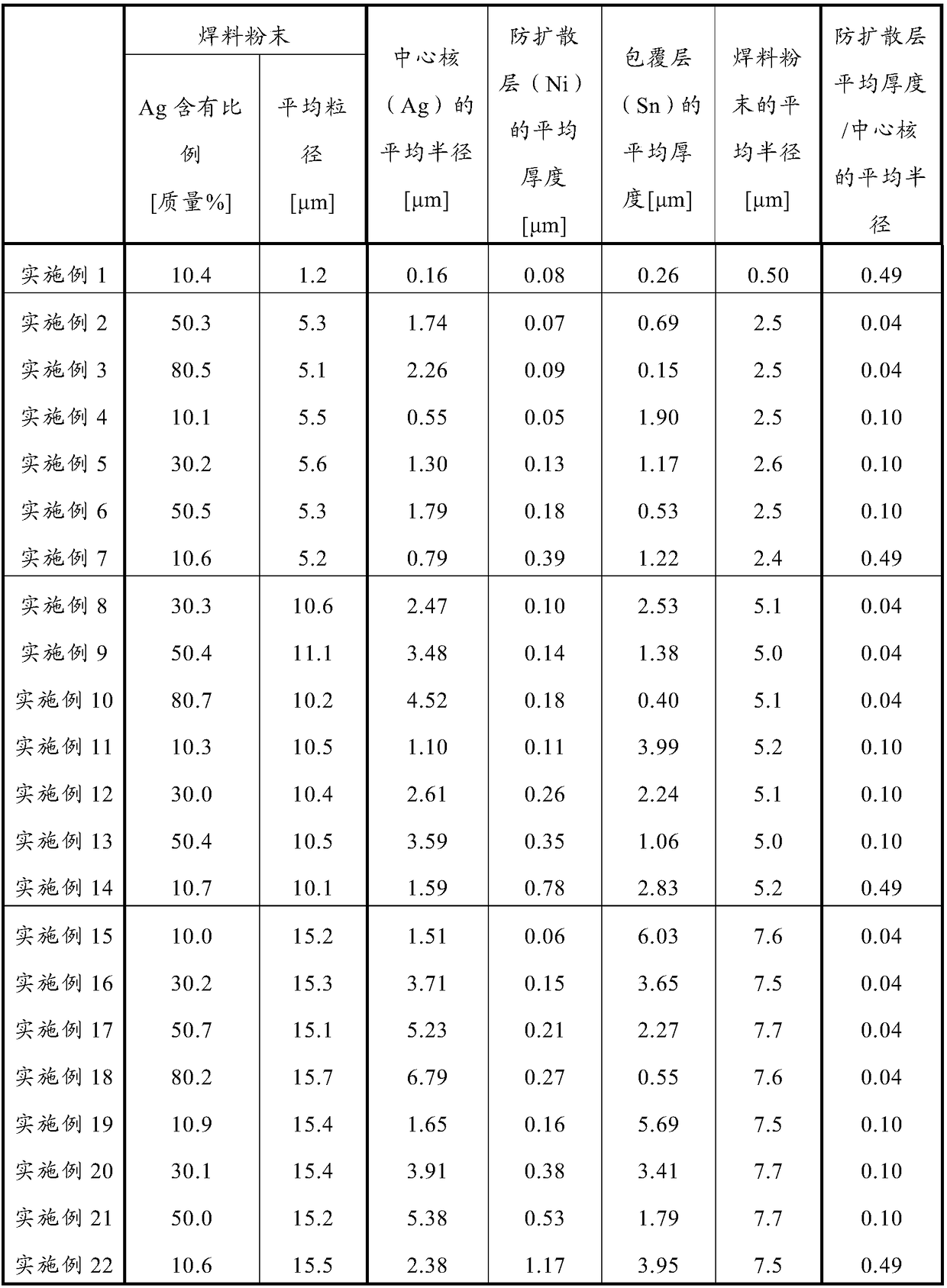

Solder powder and preparation method for solder paste using said powder

ActiveCN108430689APrevent proliferationReduce remeltingPrinted circuit assemblingWelding/cutting media/materialsSolder pasteComposite material

A solder powder (10) of the present invention comprises a core (11) made of silver, a coating layer (12) that coats the core (11) and is made of tin, and a diffusion-preventing layer (13) that is madeof nickel and is between the core and the coating layer. The average grain diameter of the solder powder (10) is 1 [mu]m to 30 [mu]m. The proportional content of silver relative to 100 mass% of the entire amount of the solder powder (10) is 10 mass% to 81 mass%. In a solder powder (10) of the present invention, the thickness of the diffusion-preventing layer (13) made of nickel is proportionally0.04-0.50 if the radius of the core (11) is taken as 1. A method for preparing a solder paste of the present invention is a method in which a solder paste is prepared by mixing a solder powder (10) ofthe present invention with a flux for solder and converting the mixture to a paste.

Owner:MITSUBISHI MATERIALS CORP

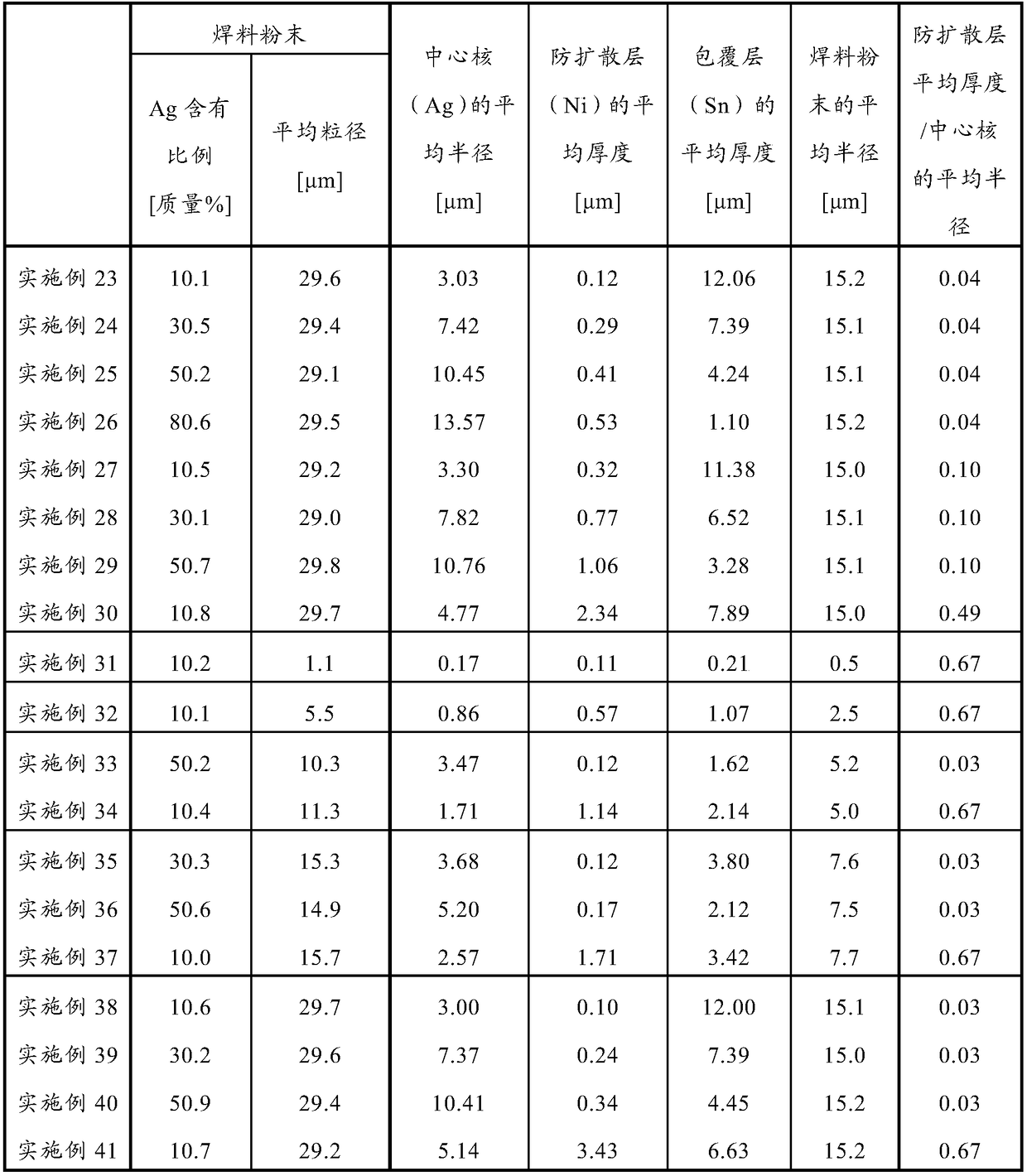

A technical method for improving the on-line recovery rate of recycled waste miscellaneous aluminum melting ash

ActiveCN108588435BReduce burning lossReduce aluminum contentProcess efficiency improvementAluminum canIngot

The invention provides a technique for increasing on-line recovery rate of regenerated scrap aluminum melted ash residues. The technique comprises the following steps: mixing scrap broken primary aluminum and scrap broken wrought aluminum according to a certain ratio, taking the obtained mixture as a base material, covering massive ingot materials, then dissolving, adding a small quantity of scrapbroken material in batches for multiple times, turning on big fire flame when the temperature is about 590 DEG C after all the materials in a furnace hearth are dissolved, stirring ash residues on the surface of aluminum melt liquid, separating the melted ash residues and aluminum liquid, and pouring the melted ash residues and the aluminum liquid out; pulling iron parts at the bottom of the furnace to a furnace platform slope, scattering a fluxing medium, instantly turning on the flame, separating molten aluminum liquid attached on the iron parts, putting the hot ash residues in a rotary furnace, pouring the hot ash residues into heat insulation ladles when the temperature is at 640 DEG C, and transporting and holding the heat insulation ladles in a melting furnace. Through the techniquefor increasing the on-line recovery rate of regenerated scrap aluminum melted ash residues, the burning loss of the scrap aluminum can be greatly reduced; the secondary remelting of the recycled aluminum ingots can be avoided; the content of aluminum in the melted ash residues can be reduced; the melting energy consumption can be greatly reduced; the melting rate of the scrap aluminum can be increased; the problem that the iron parts outside the scrap aluminum can be avoided; and a large amount of the scrap aluminum containing the iron parts can be continuously used.

Owner:JIANGXI TANTAI ALUMINUM

High-performance cobalt-based superalloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

A method for repairing lead and cadmium polluted soil

ActiveCN110586642BReduce heavy metal contentAvoid remeltingBacteriaContaminated soil reclamationMicroorganismSoil science

The invention belongs to the technical field of soil remediation, and specifically relates to a method for remediating lead-cadmium-contaminated soil. Aiming at the combined remediation of lead-cadmium contaminated soil, a combined remediation method of adsorption solidification and microbial remediation is adopted, which specifically includes the following steps: Sprinkle the soil with adsorbent and passivation agent, spray water at the same time, then deep plow 5-8cm, and place it for 10-15 days; sprinkle the compound bacterial preparation into the soil, shallow plow 3-5cm, then spray the film-forming liquid on the soil, set aside 10‑15 days; adopt the combined repair method of adsorption solidification and microbial repair, firstly absorb and solidify heavy metals through the action of adsorbents and passivators, and then use microorganisms to digest and transform the adsorbed and solidified heavy metals, Then reduce the content of heavy metals in the soil and prevent heavy metals from redissolving.

Owner:铜仁市万山区植保植检站

The treatment method for the scratches on the surface of continuous casting slabs occurred on the wide foot roll or bending section of the crystallizer

ActiveCN112756576BReduce temperatureReduce remeltingCasting parameters measurement/indication devicesUltimate tensile strengthContinuous caster

The invention provides a treatment method for the scratches on the surface of continuous casting slabs occurring on the wide-face foot roll or the bending section of the crystallizer, which includes the following steps: Step S1: Prepare new bending sections and mold spare parts, and wait for continuous casting Replacement when the machine stops production; step S2: reduce the casting speed, increase the cooling intensity, and carry out the stop operation of the drawing and leveling machine, insert the accumulated iron oxide scale into the slab shell and take it out of the continuous casting machine; step S3: use it in the tundish After the service life reaches the standard, the production of the continuous casting machine is stopped and the spare parts prepared in step S1 are used to replace the new horizontal section. When the oxide scale is accumulated on the wide-face foot roll and the bending section of the crystallizer by using the present invention, when the molten steel temperature is sufficient, the probability of taking the accumulated oxide scale out of the continuous casting machine is more than 90%.

Owner:广西柳钢华创科技研发有限公司 +1

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

A kind of anti-high temperature oxidation and wear-resistant cobalt-based alloy wire and its preparation method

ActiveCN106756257BGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodWear resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Method for increasing quality of cathode silver power

The invention discloses a method for increasing quality of cathode silver power, aiming to solve the problem that the copper impurity in the cathode silver power exceeds standard. The method comprises the following steps: preparing cathode silver power by controlling the compositions of electrolyte to comprise 90-120g / l of Ag, 8-10g / l of HNO3 and less than 35-60g / l of Cu, and using 20-28g / l of dilute nitric acid to dissolve, soak and rinse the cathode silver power when the copper content in the electrolyte is more than 35g / l, wherein the soaking temperature is 40-50 DEG C, the soaking time is2h, and the rinsing temperature is 80-90 DEG C. By using the method of the invention, the cost of the 1# cathode silver is reduced and the mass of the product silver ingot is increased. The method has the advantages of low operating intensity, simple equipment, low production cost, capability of not changing the original processing equipment, and the like.

Owner:BAIYIN NONFERROUS GROUP

A kind of cadmium arsenic contaminated soil remediation agent

ActiveCN110669524BImprove adsorption capacityAvoid remeltingAgriculture tools and machinesContaminated soil reclamationMolten stateArsenic pollution

The invention belongs to the technical field of soil remediation agents, and specifically relates to a cadmium-arsenic contaminated soil remediation agent, which is obtained by mixing manganese slag and goethite slag until passing through a 200-mesh sieve to obtain a mixed powder; calcining the mixed powder until it is melted State, after adding 15-20% surfactant of mixed powder and heat preservation treatment for 20-30min, cool to normal temperature, and get final product through flash explosion treatment and passivation treatment; the restoration agent of the present invention is effective for the soil polluted by cadmium and arsenic Restoration, but also has the function of inhibiting harmful microorganisms, and also prevents heavy metals from re-dissolving. Use goethite and manganese slag as solidifying agents for cadmium and arsenic to reduce ion mobility and resolvation, and improve solidification. By adding surfactants in the molten state, the specific surface area is increased and the resistance to cadmium and arsenic in the soil is increased. The adsorption capacity enables cadmium and arsenic in the soil to enter the lattice.

Owner:铜仁市万山区植保植检站

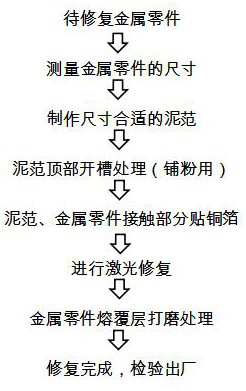

Method for repairing metal part through laser additive protected by mud mold

ActiveCN112170844AImprove plasticityReduce remeltingAdditive manufacturing apparatusIncreasing energy efficiencyCopper foilMachining

The invention discloses a method for repairing a metal part through a laser additive protected by a mud mold. The method is characterized by comprising the following steps that (1) the surface of themetal part to be repaired is cleaned and dried, and size measurement and appearance analysis are conducted on the metal part to be repaired; (2) the mud mold with the proper size is manufactured; (3)the metal part to be repaired is tightly attached to the mud mold; (4) grooving treatment is conducted on the top of the mud mold; (5) copper foil pasting treatment is conducted on the tight contact part of the mud mold and the metal part and the grooving part; (6) powder is laid on the grooving part, and laser cladding treatment is conducted; and (7) finish machining treatment is conducted on a cladding layer formed in the step (6). The method has the advantages that the mud mold has very good plasticity and can be tightly attached, the mud mold contains water, evaporation of the water can absorb a large amount of heat, and the influence of heat input on a base material is reduced.

Owner:ZHEJIANG UNIV OF TECH

Silicon monocrystal production method

ActiveUS10982350B2Quality improvementReduce convectionPolycrystalline material growthBy pulling from meltCrystallographyCondensed matter physics

A production method of a monocrystalline silicon includes: forming a shoulder of the monocrystalline silicon; and forming a straight body of the monocrystalline silicon. In forming the shoulder, the shoulder is formed such that a part of growth striations, which extend radially across the shoulder, has an outer end interrupted by another part of the growth striations not to reach a peripheral portion of the shoulder and that no remelt growth area with a height of 200 μm or more in a growth direction is generated.

Owner:SUMCO CORP

An anode plate capable of reducing the residual rate of anode electrolysis

ActiveCN105714335BSave energyReduce smelting costsPhotography auxillary processesProcess efficiency improvementElectrolysisEnergy consumption

Owner:上海珮钧科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com