Method for repairing metal part through laser additive protected by mud mold

A metal parts, laser additive technology, applied in the direction of additive processing, metal material coating process, coating, etc., can solve the problems of difficult manufacturing, waste of resources, high production cost, etc., achieve good plasticity and reduce the cost of remelting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

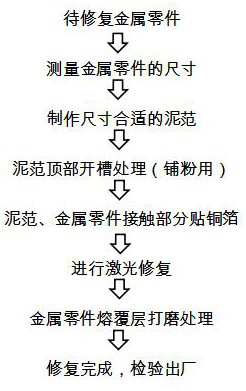

Image

Examples

Embodiment 2

[0033] On the basis of the above embodiment, in this embodiment, in the step S1, if the shape of the metal part is regular, its size is L+X, W+X, H+X, where L, W, and H are The length, width, and height of the finished metal part, X is the increment of the length, width, and height of the finished metal part, if the metal part is irregular, measure its highest point and lowest point, the leftmost and rightmost Distance difference x, y; In the step S3, the slotting width of the top of the mud fan is d, which should not be too large, and the height difference h between the top of the mud fan and the top of the metal part depends on the specific circumstances; the size in the step S1 The range of X is 0.5-2 mm; in the step S3, the groove width d is 0.5-1 mm, and the height difference h is 0.5-2 mm.

Embodiment 3

[0035] On the basis of the foregoing embodiments, in this embodiment, metal parts with regular shapes are repaired, and the specific steps are as follows:

[0036] Step S1: Clean and dry the surface of the metal part to be repaired; measure the size of the metal part to be repaired, and record the measurement data.

[0037] Step S2: According to the measured size data, make a mud form larger than half of the finished metal part volume, ensure that the surface of the mud form is smooth, and the water content of the mud form is moderate. The mud fan is cut into two pieces of the same size, and the metal parts are sandwiched between the two mud fans, and then modified to ensure that the two are tightly fitted.

[0038] Step S3: Groove the surface of the metal part to be repaired and the contact part of the clay fan. Use a utility knife to cut a 0.5~1mm groove on the part where the two are closely attached. Keep a height difference of 0.5~2mm between the surface to be repaired an...

Embodiment 4

[0043] On the basis of the above-mentioned embodiments, in this embodiment, the irregular and curved metal parts are repaired, and the specific steps are as follows:

[0044] Step S1: Clean and dry the surface of the metal part to be repaired; measure the size of the metal part to be repaired, mainly measure the distance difference between the lowest point and the highest point, the leftmost and the rightmost, and record the measurement data.

[0045] Step S2: According to the measured size data, make a mud form larger than half of the finished metal part volume, ensure that the surface of the mud form is smooth, and the water content of the mud form is moderate. The mud fan is cut into two pieces of the same size, and the metal parts are sandwiched between the two mud fans, and then modified to ensure that the two are tightly fitted.

[0046] Step S3: Groove the surface of the metal part to be repaired and the contact part of the clay fan. Use a utility knife to cut a 0.5~1mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com