Roller water-entering/returning pipeline system device for two-roll calender

A technology of return water pipes and system devices, which is applied in the field of calender roller machinery, can solve the problems of affecting the speed of water flow, affecting the production time of equipment, and the failure of production of covered sticky rollers, so as to reduce the downtime of equipment cleaning and reduce the The number of equipment failures and the effect of flexible ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

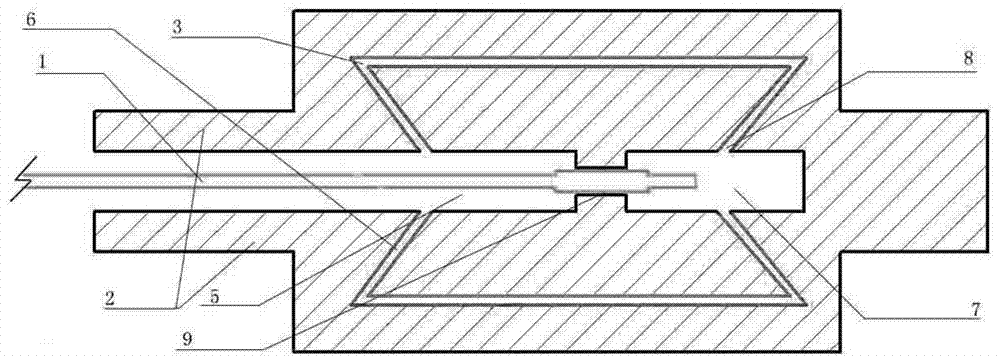

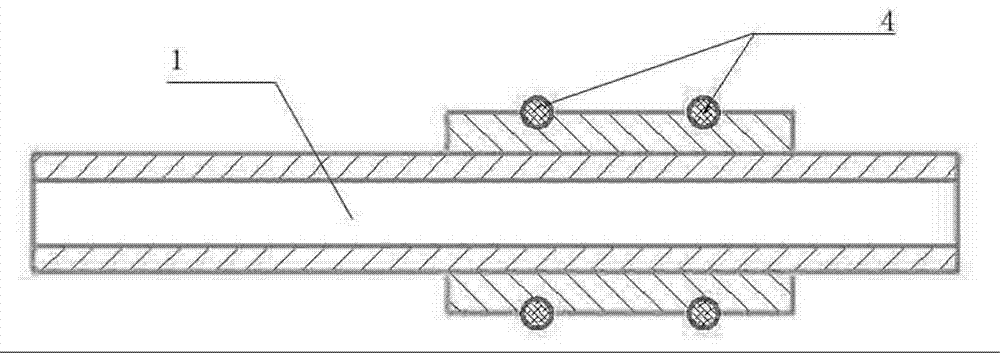

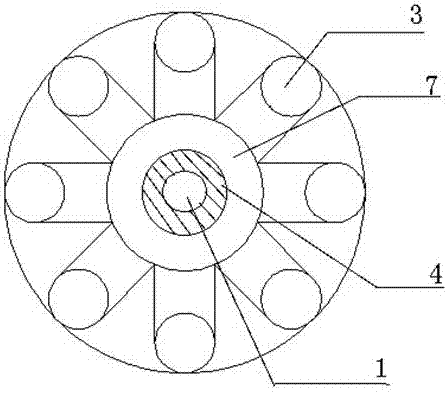

[0013] refer to Figure 1-3 , a two-roll calender roller inlet and return pipeline system device, which includes roller 2, return water channel 5, intermediate transition channel 9, distribution pipeline 7, water inlet pipe 1, cooling flow channel 3, and the inside of the roller is designed with The water inlet and return pipes are divided into the return water channel 5, the intermediate transition channel 9, and the distribution pipe 7. The cooling flow channel 3 is arranged inside the roller 2 close to the outer wall of the roller 2. The water inlet branch of the cooling flow channel 3 The channel 8 and the outlet branch channel 6 are respectively connected to the distribution pipe 7 and the return channel 5, and the return channel 5 is formed between the water inlet pipe 1 and the inner wall of the roller 2, and the water inlet pipe 1 passes through the return channel 5 and passes through the intermediate transition channel 9, Extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com