A method for preparing light olefins by catalytic conversion of oxygen-containing compounds

A technology of catalytic conversion and low-carbon olefins, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, organic chemistry, and chemical recovery. It can solve problems such as high methanol feed temperature, unfavorable safe and balanced operation of devices, and increased micropore volume. Achieve high yield of low-carbon olefins, reduce carbon deposition selectivity, and increase circulation speed

Active Publication Date: 2015-11-25

CHINA PETROLEUM & CHEM CORP +1

View PDF11 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this method, the reaction material distributor is completely immersed in the catalyst bed, and the methanol feed temperature is too high, resulting in the occurrence of side reactions

[0011] US6023005 separates a part of the carbon-containing catalyst (2% to 3% of the total reaction volume) for regeneration, and then mixes the regenerated molecular sieve catalyst with the unregenerated catalyst to keep the amount of carbon deposited on the catalyst within an appropriate range, and The homogeneous mixing of catalysts increases the amount of micropores required for the effective conversion of methanol into low-carbon olefins, and improves the selectivity of ethylene and propylene. However, this method has many slide valves, multiple cycles, complicated operation, and methanol directly enters materials, the possibility of high-temperature contact between methanol and metal materials may occur, resulting in side reactions

[0012] US6737556 discloses a method for catalytic conversion of methanol to generate low-carbon olefins. The method adopts a new feeding method, and adopts a material with less side reaction activity of methanol to manufacture a reactor. It also points out that the side reaction activity of chromium and aluminum is relatively weak. Titanium is a better inert substance, but this will greatly increase equipment investment and affect economic benefits

Ceramics and other materials also have good methanol reaction inertness, but the impact resistance of ceramics is poor, which is not conducive to the safe and balanced operation of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

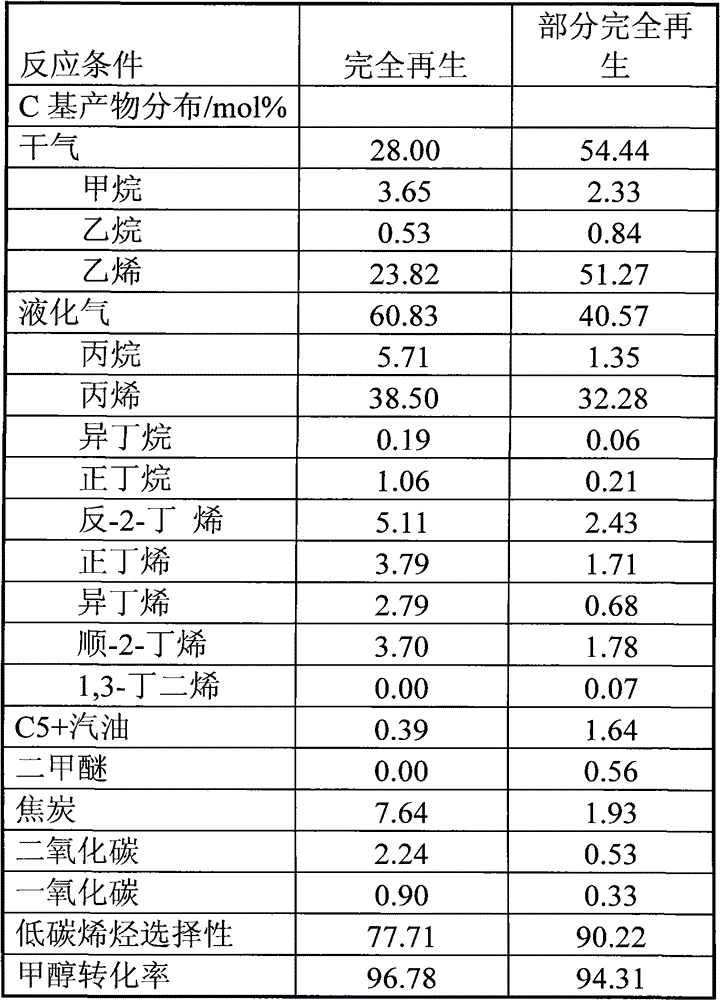

Embodiment 1

[0061] Example 1 illustrates the effect of the method for preparing light olefins by catalytic conversion of oxygenates provided by the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

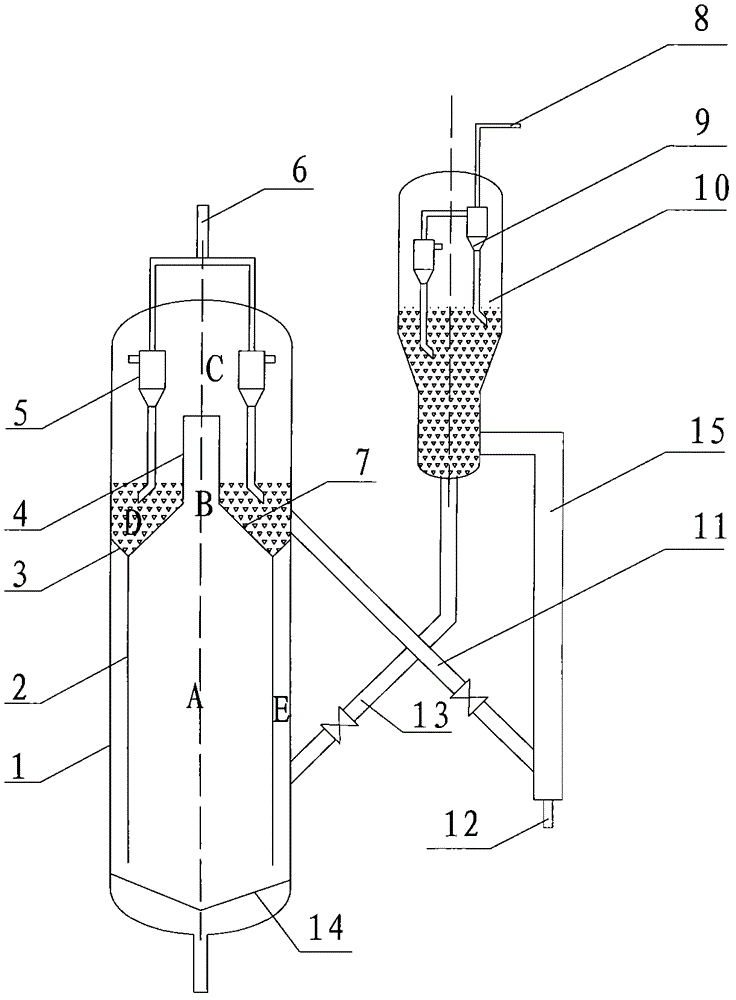

The invention provides a method for preparation of light olefins through catalytic conversion by an oxygen-containing compound. According to the method, an oxygen-containing compound raw material is introduced into an internal circulation gas-solid fluidized bed reactor from the bottom of the reactor and contacts with a cracking catalyst in a reaction zone, and the oxygen-containing compound and the catalyst move upward together and undergo alkylation and a cracking reaction; reacted oil gas and a coked catalyst undergo gas-solid separation in a gas-solid separation zone at the upper part of the reaction zone, and separated oil gas is subjected to further separation in a subsequent separating system; the separated coked catalyst is deposited in a steam stripping zone, steam stripping is carried out to remove oil gas adsorbed and carried by the catalyst, a part of the coked catalyst in the steam stripping zone enters into a catalyst descending zone, moves downward and enters into the bottom of the reaction zone for cyclic utilization through a gap at the bottom of the catalyst descending zone; and the other part of the coked catalyst is introduced into a catalyst regenerator for charring and regeneration through an inclined to-be-generated catalyst pipe, and a regenerated catalyst is returned to the internal circulation gas-solid fluidized bed reactor for cyclic utilization. The reactor provided by the invention can be used in the method for preparation of light olefins by using the oxygen-containing compound, and the advantages of simple operation and high yield of light olefins are obtained.

Description

technical field [0001] The present invention relates to a method for catalytic conversion of oxygen-containing compounds in the absence of hydrogen, more specifically, a method for catalytic conversion of oxygen-containing compounds to produce light olefins. Background technique [0002] Low-carbon olefins (ethylene, propylene, butene) are the basic raw materials for many important chemical products (such as ethylene oxide, polyethylene, polyvinyl chloride, polypropylene and butyl rubber, etc.). With the development of the world economy, the demand for low-carbon olefins, especially ethylene and propylene, is increasing day by day. Due to the rapid growth of my country's economy, the annual growth rate of my country's ethylene and propylene demand exceeds the world average level. It is of great significance to increase the production capacity of low-carbon olefins . [0003] At present, the steam cracking technology of light raw materials such as naphtha is mainly used to pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C11/04C07C11/06C07C11/08C07C1/20

CPCY02P20/584Y02P30/42Y02P20/52Y02P30/20Y02P30/40

Inventor 张同旺武雪峰宗保宁侯栓弟罗一斌李明罡李黎声张占柱

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com