Method for preparing ethylene and propone with oxocompound

A compound and ethylene technology, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, ethylene production, organic chemistry, etc., can solve the problem of low yield of ethylene and propylene, poor guarantee of the average carbon deposition level of the catalyst, and insufficient regeneration of the catalyst by carbon burning. Good control and other issues to achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

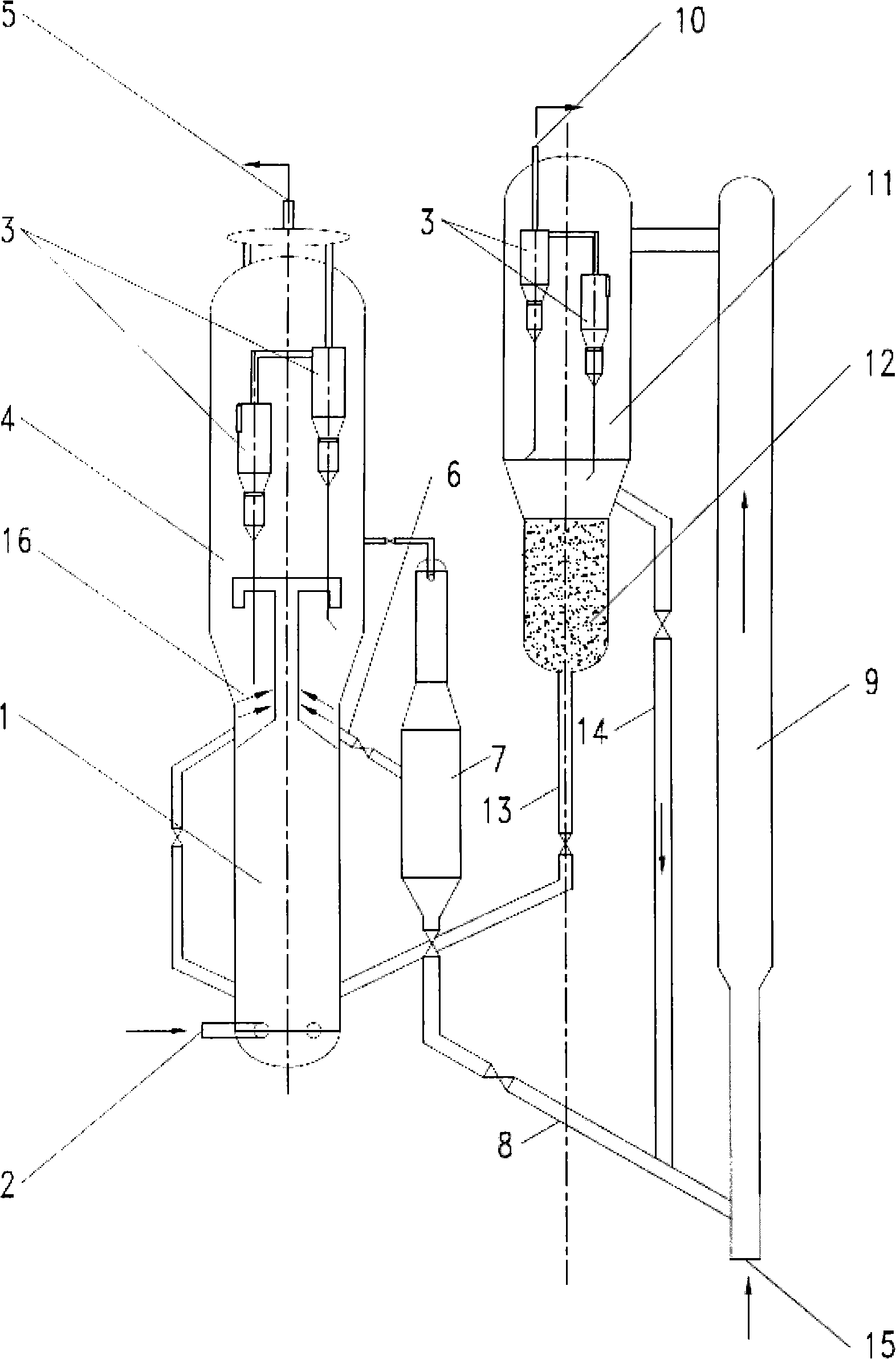

[0023] In a small circulating fluidized bed reactor, the flow form of the reverse system is the same as figure 1 same. The regenerator adopts a riser, the lifting gas is air, and the regeneration temperature is 600°C. The average carbon deposition amount of the regenerated catalyst is adjusted by changing the superficial velocity of the gas in the riser regenerator. The reactor adopts a fast fluidized bed, the gas superficial velocity is 1.2 m / s, the reaction temperature is 425°C, pure methanol is fed, and the methanol weight space velocity is 3 hours -1 , the reaction and regeneration pressures are both 0MPa in gauge pressure. The terminator is injected into the gas-solid rapid separation zone 17 from the pipeline 16, the terminator is water, the weight ratio of methanol to the terminator is 20:1, and the feed temperature of the terminator is 100°C. The sampling ports of the regenerated agent and the spent agent are respectively located on the pipeline 13 and the pipeline 8...

Embodiment 5~7

[0027] According to the conditions described in Example 2, only the temperature of the regenerator was changed, and the experimental results are shown in Table 2.

[0028] Table 2

[0029]

Embodiment 8~12

[0031] According to the conditions described in Example 3, only the reactor temperature was changed, and the experimental results are shown in Table 3.

[0032] table 3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com