An anode plate capable of reducing the residual rate of anode electrolysis

A technology of anode electrolysis and anode plate, which is applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problems of exhaust gas polluting the atmosphere, increasing production cost, and anode plate residue, so as to reduce pollution emissions, save costs, reduce Effect of smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

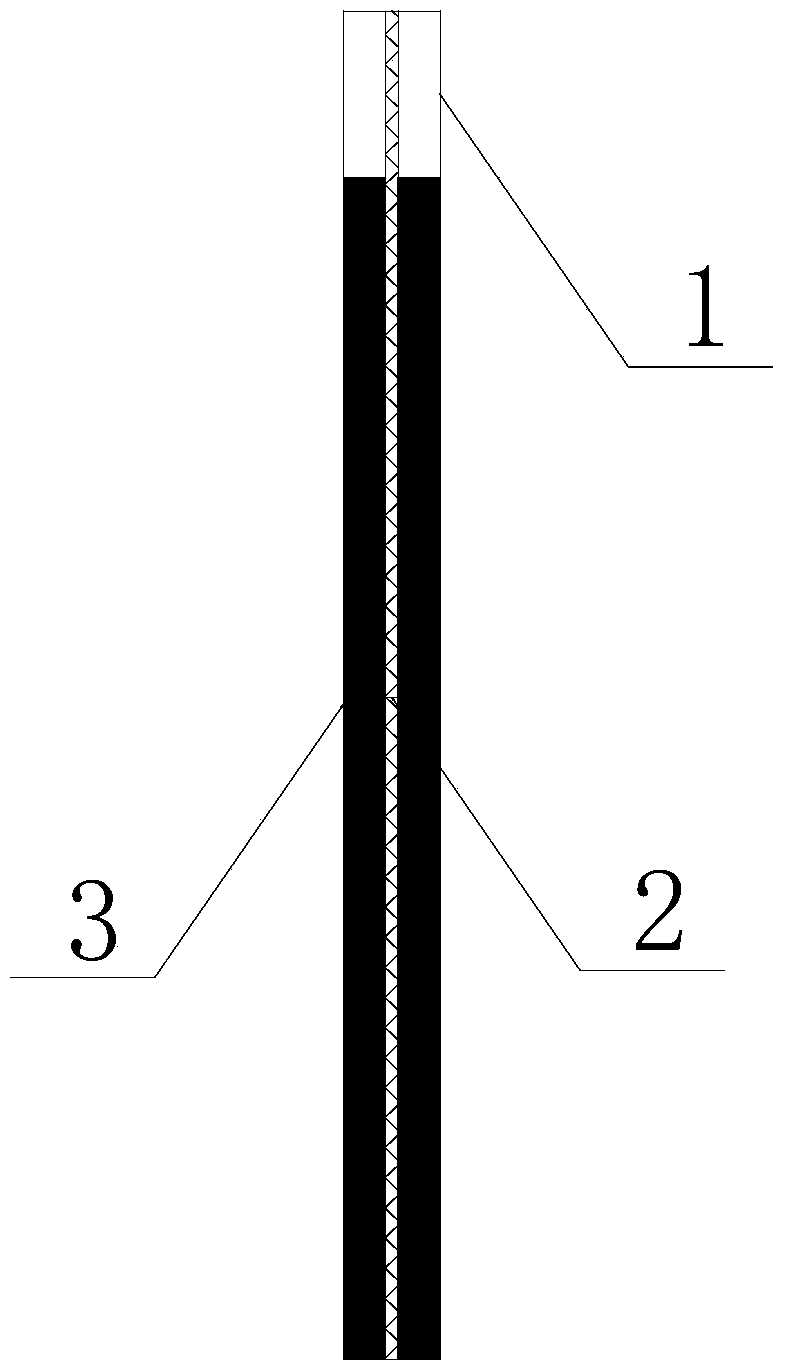

[0029] figure 1 Shown is a schematic diagram of the side structure of an anode plate provided in this embodiment, by figure 1 It can be seen that the anode plate includes a hook 1, a connecting net 2 and a metal plate 3, the connecting net 2 is fixedly connected with the hook 1, and the metal plate 3 is composed of the connecting net 2 and the electrolyzed metal cast on the surface of the connecting net 2 form. The connecting net 2 acts as a skeleton, and firmly bonds the metal plates 3 formed by the electrolyzed metal on both sides, thus ensuring that the metal plates will not break and fall off during electrolysis.

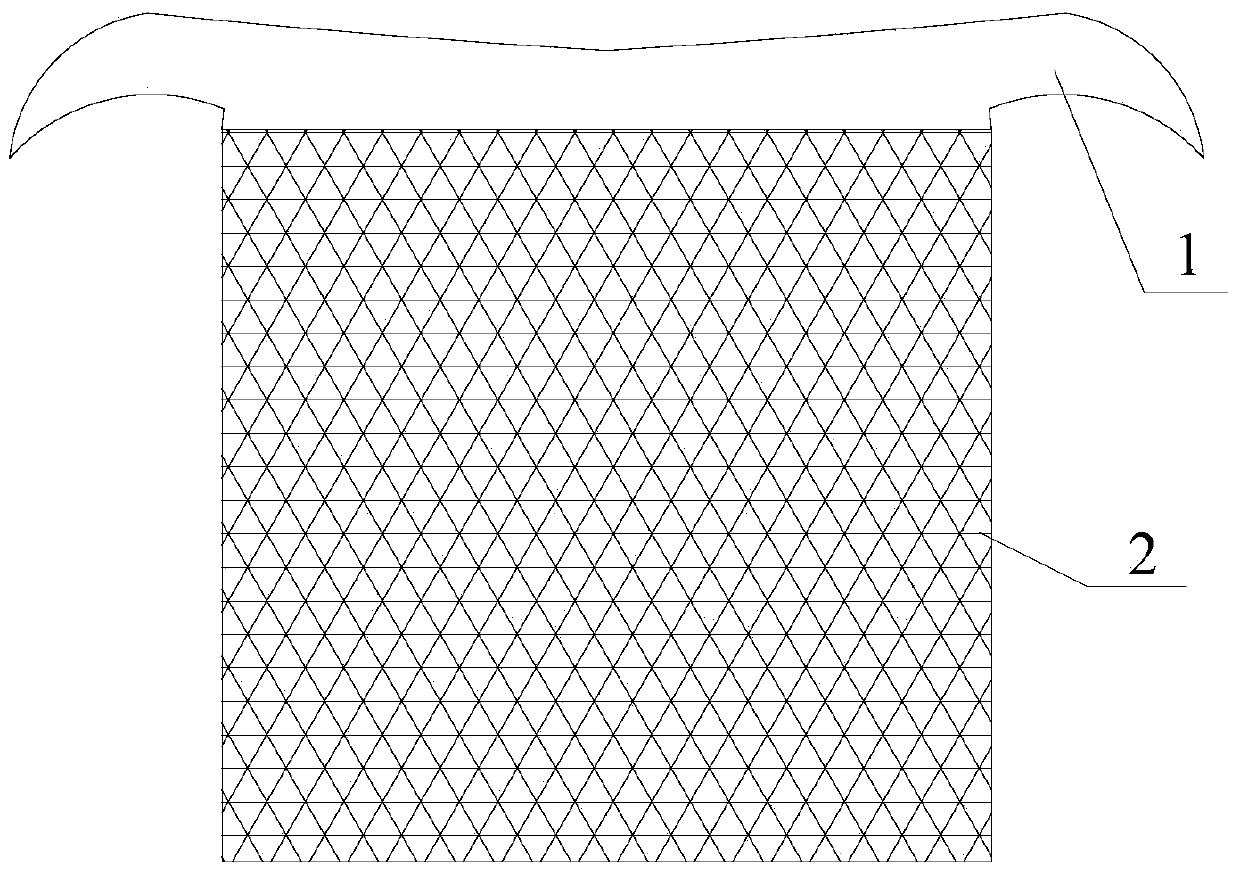

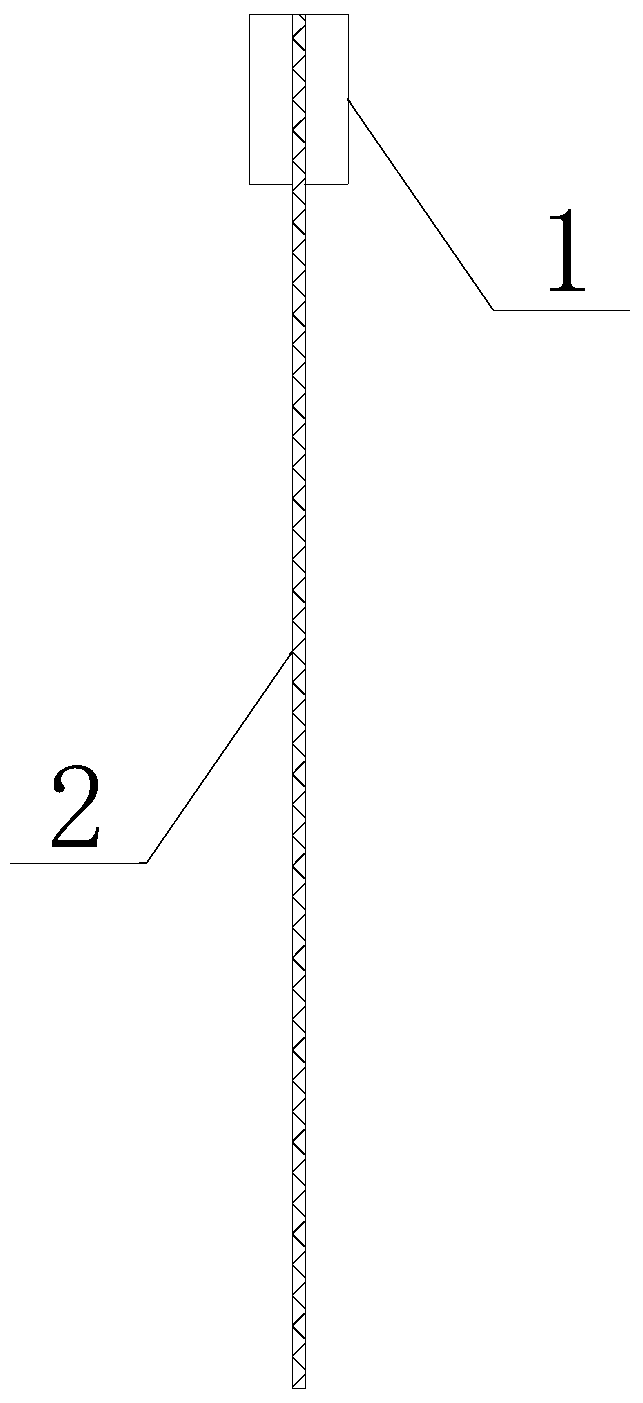

[0030] figure 2 It is a schematic diagram of the front structure of the hook in the anode plate connected with the connecting net provided in this embodiment; image 3 It is a schematic diagram of the side structure of the hook and the connecting net in the anode plate provided by this embodiment, see figure 2 and image 3 As shown: the hook 1 casted by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com