A method for preparing neodymium-iron-boron by regeneration of waste materials containing neodymium-iron-boron

A technology of NdFeB and waste materials, which is applied in the direction of magnetic materials, process efficiency improvement, magnetic objects, etc., can solve the problems of NdFeB magnetic properties, low recycling rate, limited practical value, etc., and achieve improved resistance Oxidation performance, accurate analysis results, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

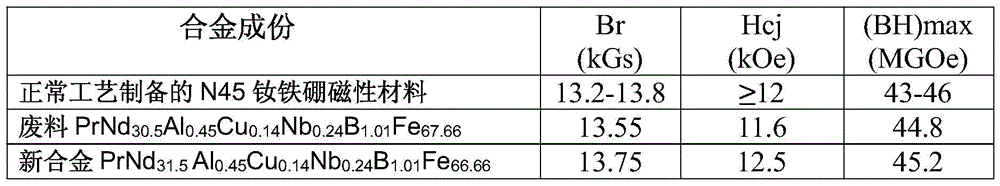

[0019] Produce N45 products from N45 waste.

[0020] Take N45 waste, put it in an ultrasonic cleaner, and ultrasonically clean it in an aqueous solution of trisodium phosphate for 10 minutes. After the surface is free of oil stains, take out the waste and clean the surface with water until there is no adhesion on the surface, then put it in an oven Bake at 300°C for 2 hours. Then polish it in a shot blasting machine for 5 minutes until the surface of the material is silver-white in the color of the metal matrix.

[0021] Under the protection of inert gas, the previously treated waste is crushed into 10mm-sized particles in the crusher, and then mixed in the mixer for 50 minutes, and the samples are taken and its chemical composition is accurately analyzed:

[0022] Its mass percentage is PrNd 30.5 Al 0.45 Cu 0.14 Nb 0.24 B 1.01 Fe 67.66

[0023] Design product composition PrNd 31.5 Al 0.45 Cu 0.14 Nb 0.24 B 1.01 Fe 66.66

[0024] Composition design is carried ou...

Embodiment 2

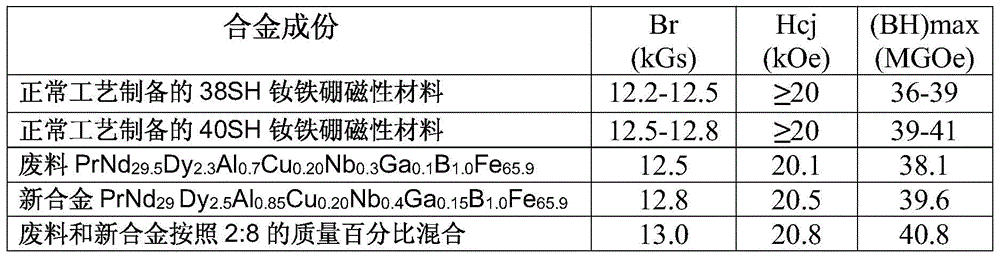

[0029] 40SH products are produced from 38SH waste.

[0030] Take 38SH waste, put it in an ultrasonic cleaner, and ultrasonically clean it in an aqueous solution with detergent for 15 minutes. After the surface is free of oil stains, take out the waste and clean the surface with clean water until there is no adhesion on the surface, then put it in an oven Bake at 300°C for 1.5 hours. Then polish it in a shot blasting machine for 6 minutes until the surface of the material is silver-white in the color of the metal matrix.

[0031] Under the protection of inert gas, the previously treated waste is crushed into 8mm-sized particles in the crusher, and then mixed in the mixer for 60 minutes. Samples are taken and its chemical composition is accurately analyzed:

[0032] Its mass percentage is PrNd 29.5 Dy 2.3 Al 0.7 Cu 0.20 Nb 0.3 Ga 0.1 B 1.0 Fe 65.9

[0033] Design product composition PrNd 29 Dy 2.5 Al 0.85 Cu 0.20 Nb 0.4 Ga 0.15 B 1.0 Fe 65.9

[0034] Compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com