Method and apparatus for improving square degree and corrosion resistance of demagnetizing curve of sintered neodymium iron boron

A technology of demagnetization curve and corrosion resistance, applied in the field of improving the magnetic properties of sintered NdFeB, can solve the problems of demagnetization and thin thickness, and achieve the effect of small input-output ratio, reducing risks and increasing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

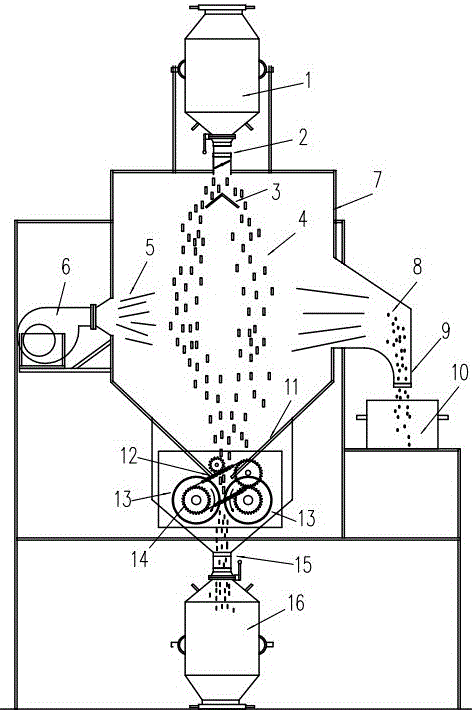

Method used

Image

Examples

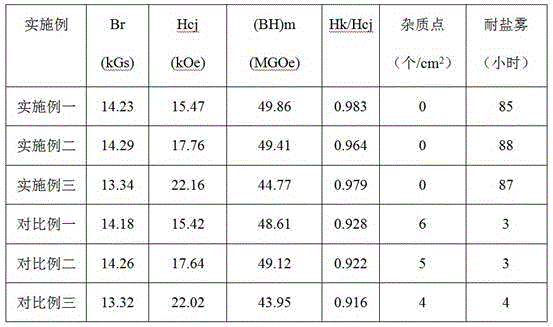

Embodiment 1

[0020] ① Use vacuum induction quick-setting furnace to prepare the initial alloy of quick-setting sheet for sintered NdFeB, and the alloy composition is Nd 31 Fe bal. co 1 Al 0.2 Cu 0.1 B 0.97 (mass percentage), the raw material weight of smelting alloy is 1000 kg;

[0021] ② Take out 500 kg of the quick-setting sheet in ①, and clean and crush the quick-setting sheet according to the cleaning and crushing method of the aforementioned NdFeB quick-setting sheet;

[0022] ③ The roughly crushed quick-setting tablets are subjected to hydrogen crushing to obtain a coarse powder with a particle size of 100-500 microns, and the hydrogen crushing process is a conventional process;

[0023] ④ Jet mill the crushed powder separately, and the process parameters of the jet mill are consistent, and the powder with an average particle size of 3 μm is obtained;

[0024] ⑤ The powder is made into a compact of 52 mm*52 mm*27 mm on an orientation forming press, the forming orientation magne...

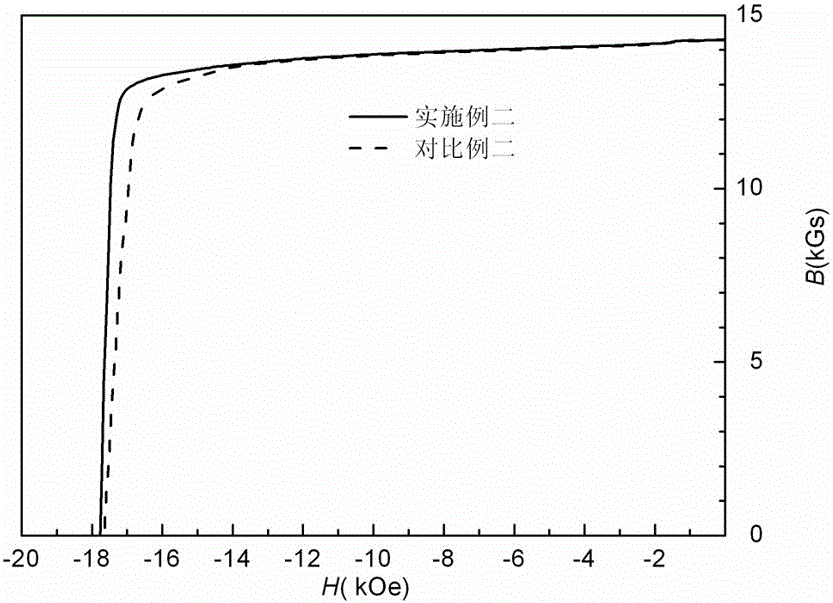

Embodiment 2

[0028] Embodiment 2 The mass percent of the alloy composition is: (Pr 0.2 Nd 0.8 ) 30.5 Dy 0.5 co 1 Al 0.2 Cu 0.1 B 0.98 , and the rest of the process steps are the same as in Example 1.

Embodiment 3

[0029] Example 3 The mass percentage of the alloy composition is: (Pr 0.2 Nd 0.8 ) 29 Dy 2 Ga 0.5 co 1 Al 0.2 Cu 0.1 B 0.98 , and the rest of the process steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com