Solder powder and preparation method for solder paste using said powder

A solder powder and slurry technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of uneven melting, poor bonding, poor melting, etc., and achieve difficult remelting and joint strength. the reducing effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

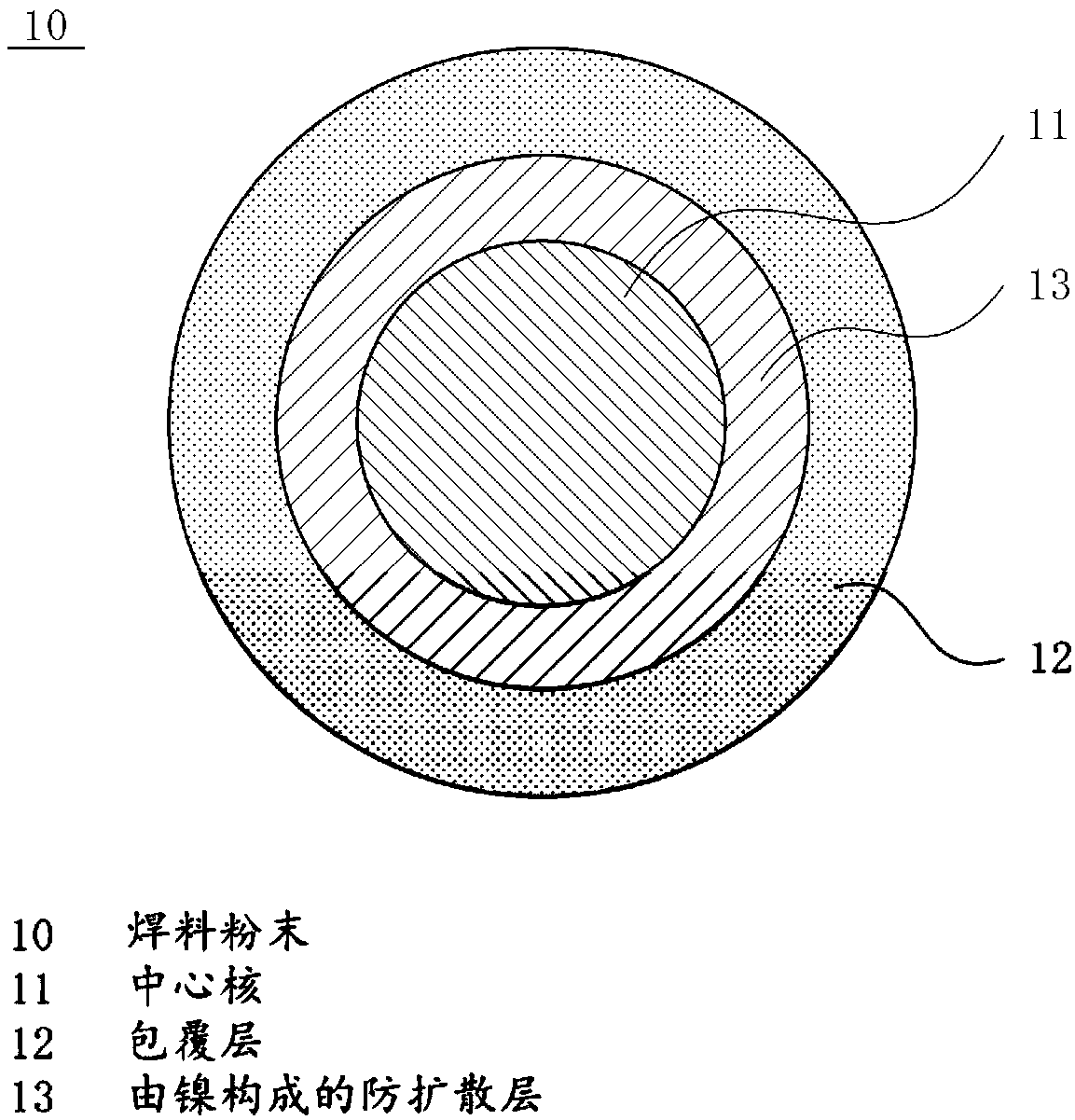

Image

Examples

preparation example Construction

[0037] As the solvent suitable for the preparation of the above-mentioned soldering flux, diethylene glycol monohexyl ether, diethylene glycol monobutyl ether, diethylene glycol monobutyl ether acetate, tetraethylene glycol, 2- Organic solvents with boiling points above 180°C, such as ethyl-1,3-hexanediol and α-terpineol. Moreover, as rosin, gum rosin, hydrogenated rosin, polymerized rosin, ester rosin, etc. are mentioned.

[0038] In addition, as a thixotropic agent, hardened castor oil, fatty acid amide, natural oil, synthetic oil, N,N'-ethylenebis-12-hydroxystearic acid amide, 12-hydroxystearic acid, 1, 2 ,3,4-Dibenzylidene-D-sorbitol and its derivatives.

[0039] In addition, as the active agent, an amine hydrohalide salt is preferred, and specific examples include triethanolamine, diphenylguanidine, ethanolamine, butylamine, aminopropanol, polyoxyethylene oleylamine, and polyoxyethylene laurylamine , Polyoxyethylene stearamide, diethylamine, triethylamine, methoxypropylamine...

Embodiment

[0047] Next, examples of the present invention will be described in detail together with comparative examples.

[0048]

[0049] First, add 4.92×10 to 50mL of water -3 mol of nickel(II) sulfate, 1.1×10 -3 mol of sodium phosphinate, 3.88×10 -4 mol of sodium citrate was stirred with a stirrer at a rotation speed of 300 rpm for 5 minutes to prepare a solution. After the pH of the solution was adjusted to 5.0 with sulfuric acid, 0.2 g of polyvinyl alcohol 500 (polyvinyl alcohol with an average molecular weight of 500) was added as a dispersant, and further stirred at a rotation speed of 300 rpm for 10 minutes. Next, the dispersion was added to the solution, and 0.2 g of polyvinyl alcohol 500 (polyvinyl alcohol with an average molecular weight of 500) was dissolved in 50 mL of water as a dispersant, and the dispersion had an average particle size of 0.32 μm. The silver powder is 3.41g. Then, the mixture was stirred at a rotation speed of 500 rpm for 10 minutes to obtain a dispersion ...

Embodiment 2~41、 comparative example 1~36

[0052] In Examples 2 to 41 and Comparative Examples 1 to 36, the particle size of the silver powder used, the amount of silver powder added, the amount of nickel sulfate (II) and tin sulfate (II), and other ingredients were also adjusted. The solder powder was obtained in the same manner as in Example 1 except that the ratio of φ was controlled to the predetermined silver core radius, the thickness of the nickel diffusion prevention layer and the tin outermost layer, and the predetermined particle size of solder powder.

[0053]

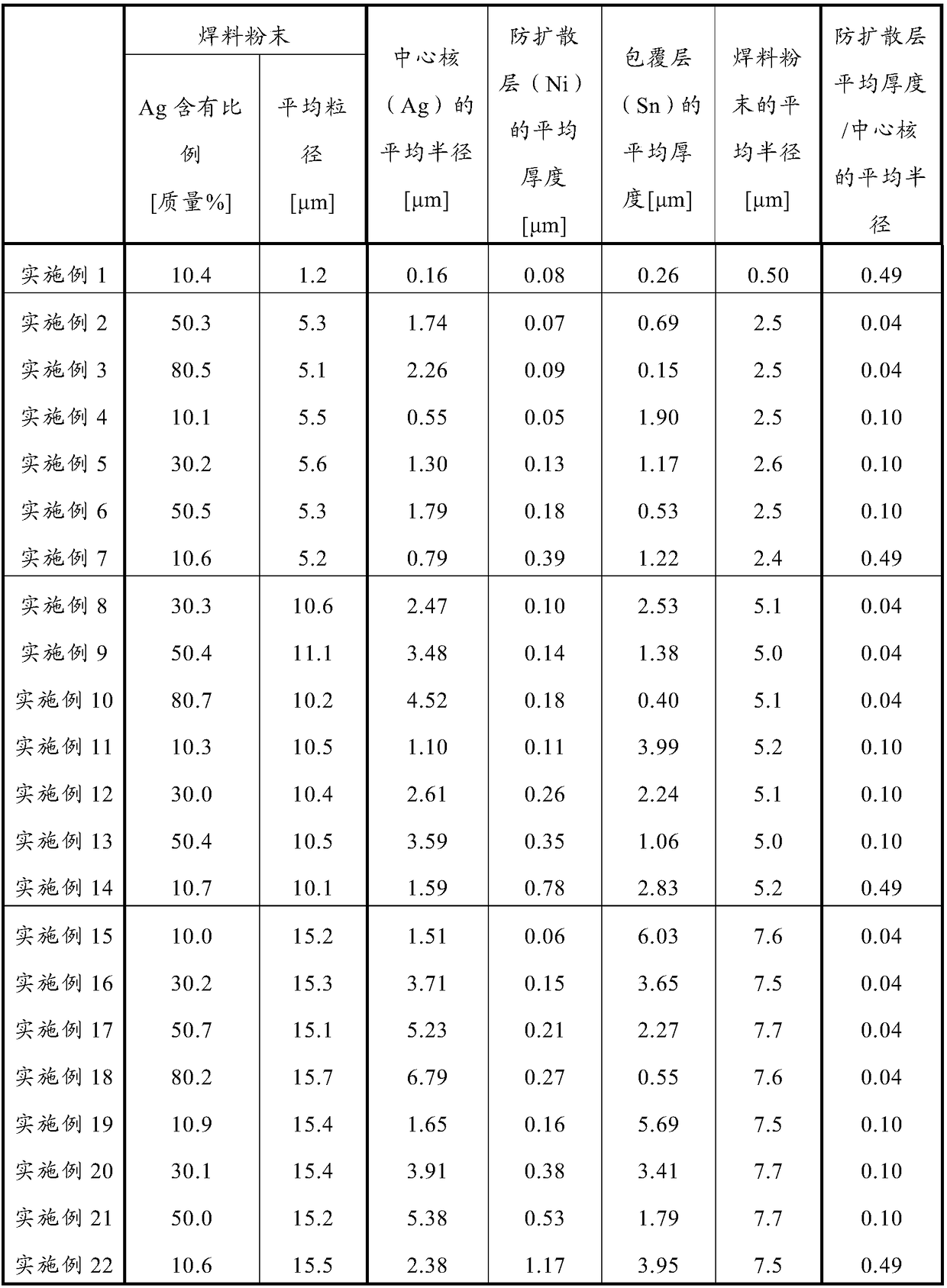

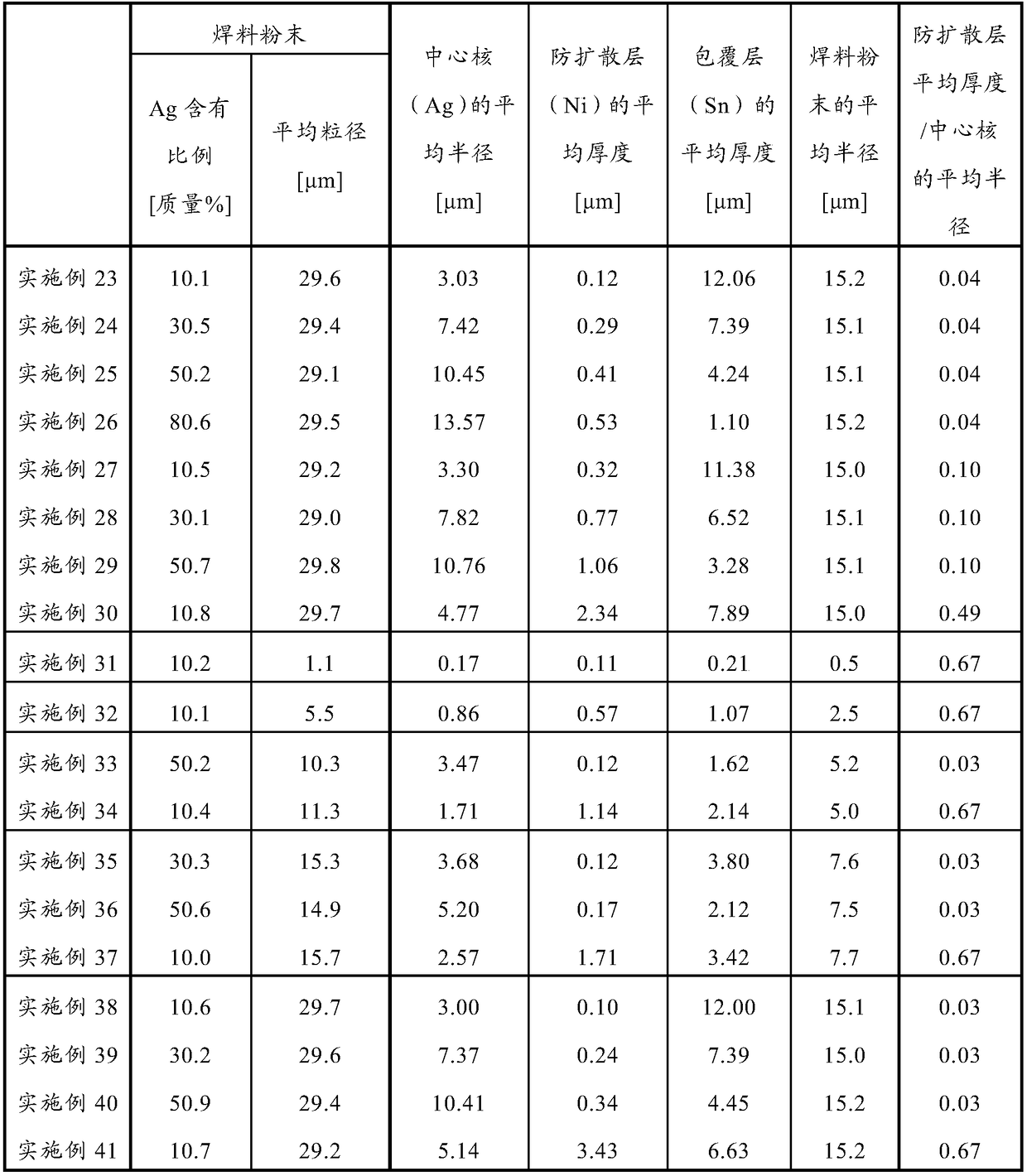

[0054] For the solder powders obtained in Examples 1 to 41 and Comparative Examples 1 to 36, the silver content [mass%], average particle size [μm], and composition of the solder powder were measured by the method described below. The average radius of the central core [μm], the average thickness of the diffusion prevention layer made of nickel [μm], and the average thickness of the coating layer made of tin [μm]. These results are shown in Tables 1 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com