Hot rolling plan arrangement method

A planning and planning technology, applied in the field of metallurgical continuous rolling, can solve the problems of low hot-rolled slab hot direct loading rate, difficulty in planning, and low degree of connection, so as to promote energy saving and consumption reduction, flexible planning, and reduce heating the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples:

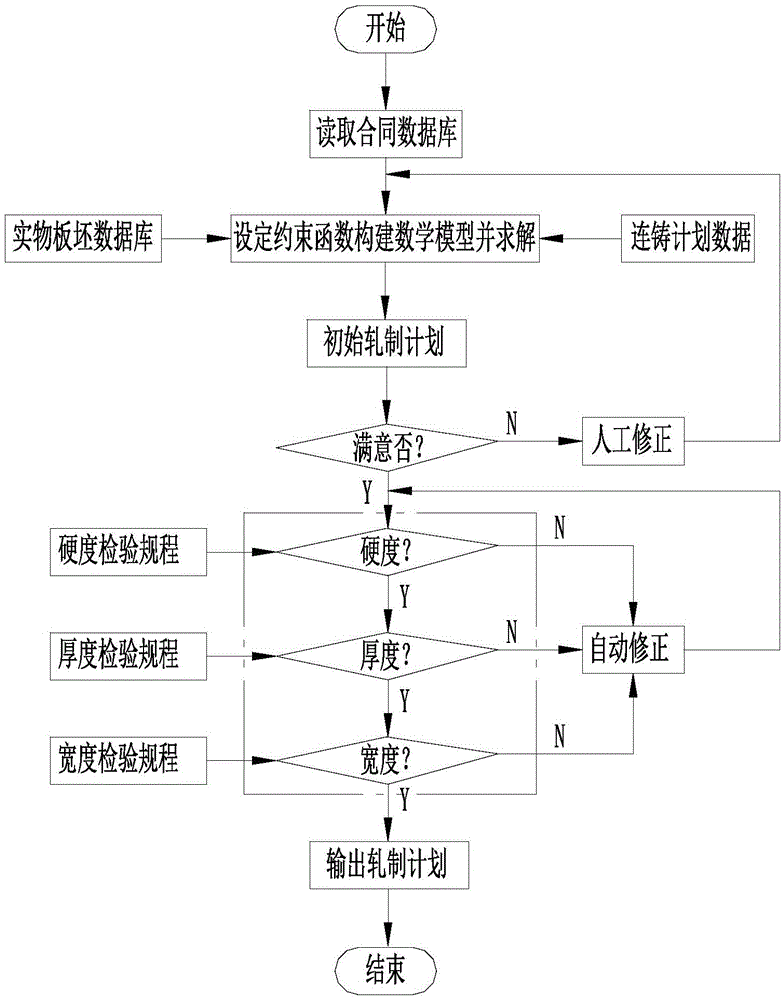

[0069] The invention relates to a hot-rolling rolling plan arrangement method, which is characterized in that a set of continuous casting and rolling production is established by programming with computer programming technology by setting constraint functions, constructing a rolling plan model, and solving the rolling plan model. Organization management mode, see the flowchart of its computer program software figure 1 Shown.

[0070] The preparation of rolling plan includes the following steps:

[0071] 1) At the beginning, read the contract database, and set all the contracts in the contract database according to the pre-set steel grade, processing quantity, width, thickness, and planned time as input conditions.

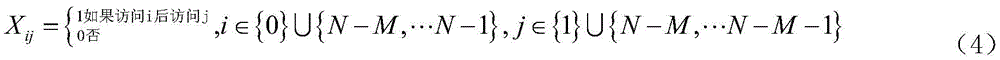

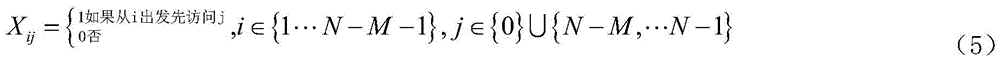

[0072] 2) Set the constraint function according to the input, read the continuous casting plan data and the physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com