Microwave heating system

a heating system and microwave technology, applied in the direction of electric/magnetic/electromagnetic heating, coupling device connection, coupling parts engagement/disengagement, etc., can solve the problems of cross-talk between separate channels, structural complexity of e.g. moderating means, etc., and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

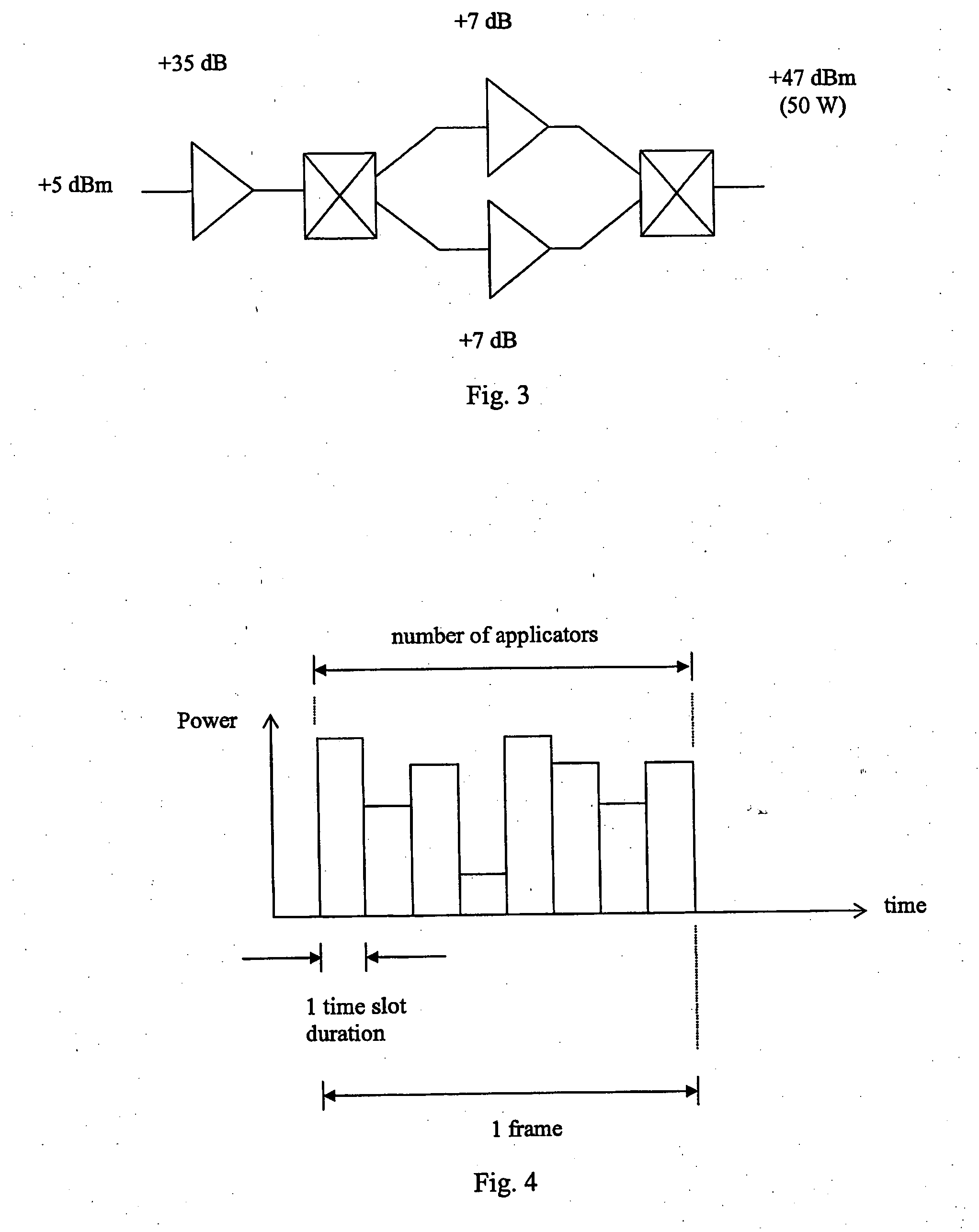

[0026] Initially a bit more should be said here about the nature of microwave heating. Maximum power is generally only required for a small percentage of the total processing time. Another percentage of the time it will require no power at all.

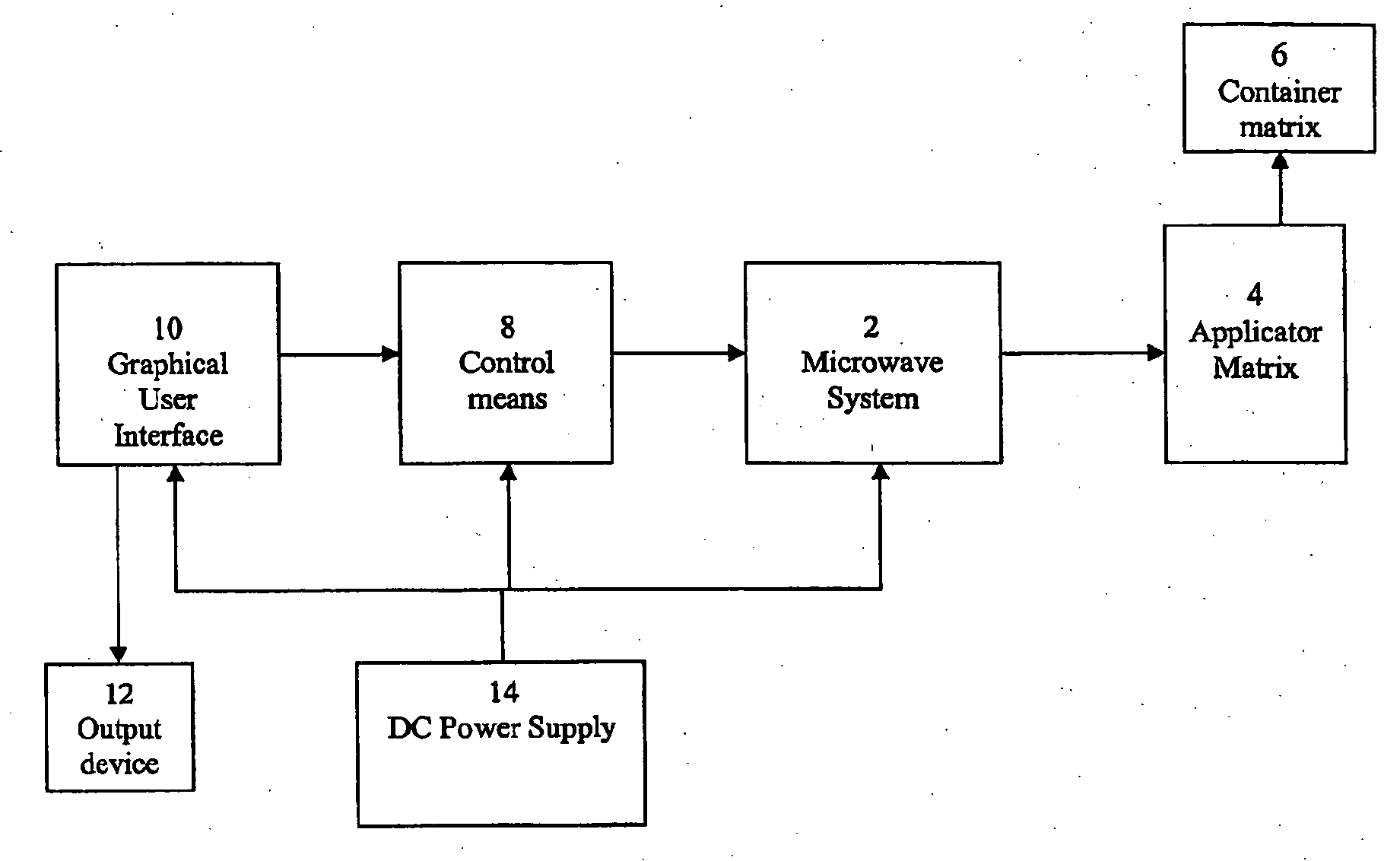

[0027] As mentioned above, the goal of the present invention is to achieve a system adapted to heat as many individual chemical reactions as possible in the shortest period of time to the lowest cost per sample as possible. There will naturally be a compromise between total process time, number of reactions and power available for heating.

[0028] System equations and heating profiles will determine the maximum dedicated slot time a reaction may be allowed in order for the chemical reaction to be maintained. This will naturally be dependent on the rate of microwave absorption of the chemistry and heating profile parameters can be changed at any time.

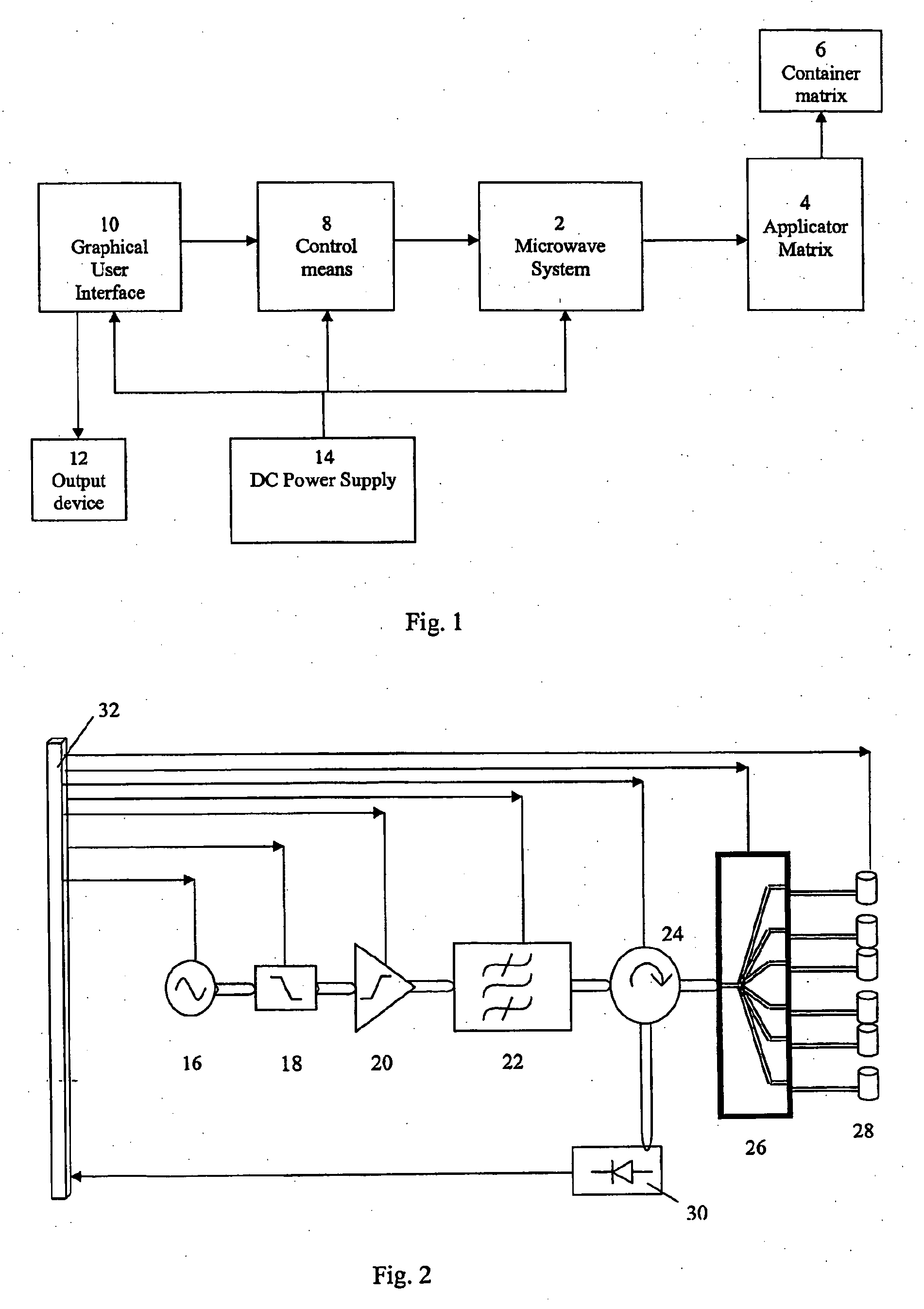

[0029] In order to design the system hardware it will be necessary to determine how many power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com