Latent-heat storage material, cooling tool, cooler box, distribution packaging container, and cooling unit

A latent heat storage and packaging container technology, which is applied to heat exchange materials, heat storage equipment, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0057] [Composition of latent heat storage material]

[0058] The latent heat storage material of the present invention is a latent heat storage material containing a sodium chloride aqueous solution, which comprises: a sodium chloride aqueous solution with a eutectic concentration; and disodium hydrogen phosphate relative to the sodium chloride aqueous solution with a eutectic concentration It has an amount greater than the saturation concentration at 0°C.

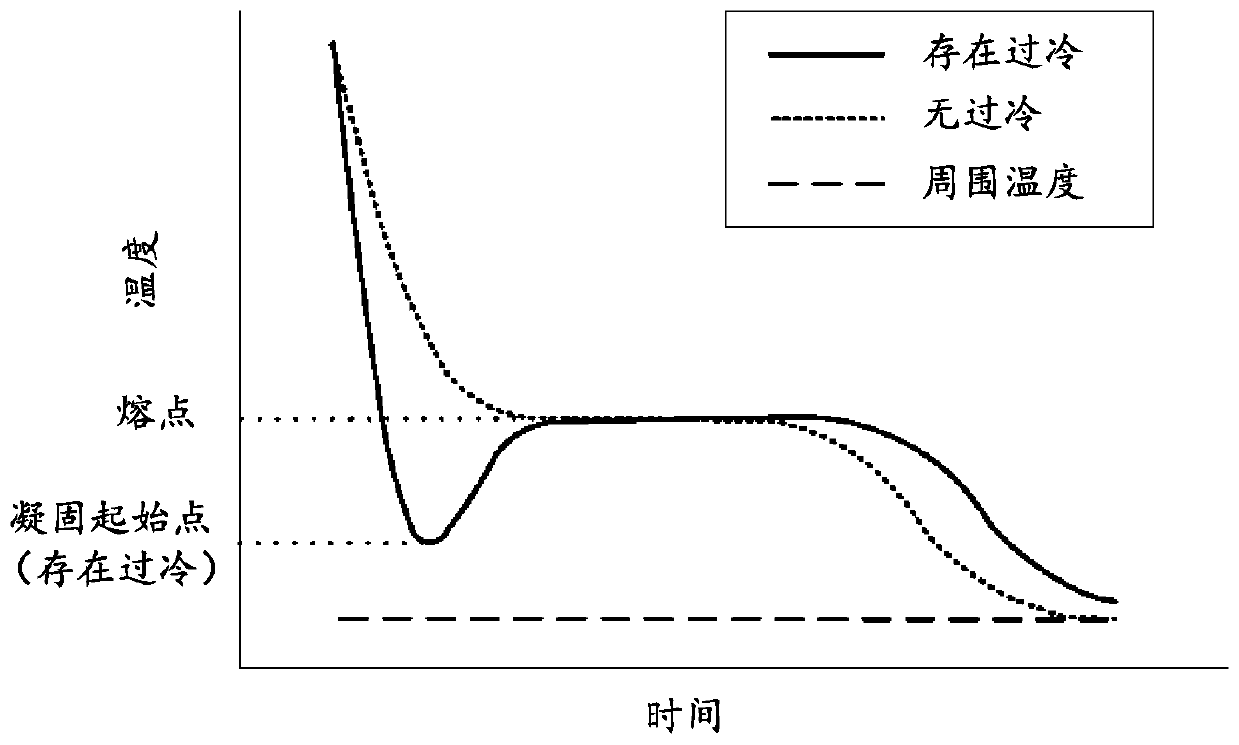

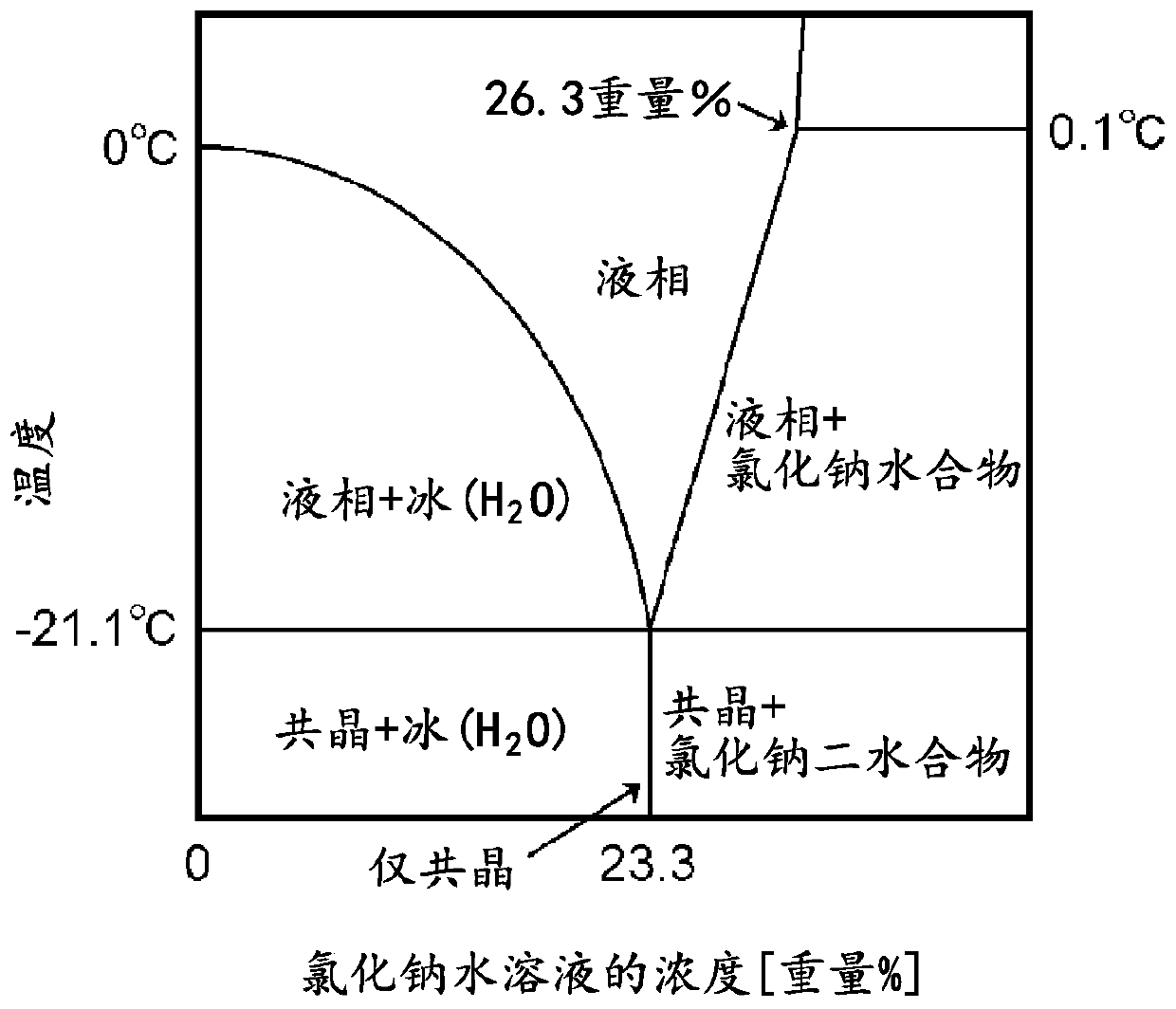

[0059] The sodium chloride aqueous solution, which is the main heat storage agent of the latent heat storage material, has a eutectic concentration. Such as figure 2 As shown in the phase diagram, the sodium chloride aqueous solution has a single melting point near -21°C at the eutectic concentration (concentration at which only the eutectic of water and solute is formed during solidification), and the latent heat becomes the maximum at this time.

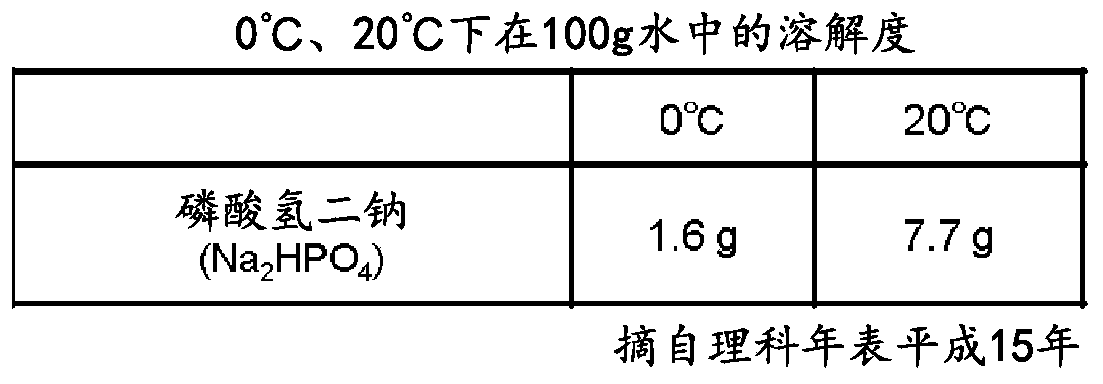

[0060] The disodium hydrogen phosphate contained in the latent heat storage ma...

Embodiment 1

[0076] Each of Example 1 and Comparative Example 1 maintained the temperature of the solution by endothermic phase (3h~6.5h), which is equivalent to melting, and the maintained temperature is around -21°C, which confirms the addition of disodium hydrogen phosphate The effect on the melting point is almost non-existent. In addition, there is almost no difference in the time until the temperature is completely melted and the temperature starts to rise with the temperature in the tester, which confirms that the decrease in the amount of latent heat due to the addition of disodium hydrogen phosphate is also almost not seen.

[0077] Picture 9 This is a table showing the melting points of Examples 1 and 2 and Comparative Example 1 obtained by experiments under the above-mentioned conditions. Even if disodium hydrogen phosphate was added to 4.0% by weight, the melting point hardly changed, and it was confirmed that the melting point of the main agent was not affected.

[0078] Picture...

no. 2 Embodiment approach

[0093] [Composition of cold storage]

[0094] This embodiment is an embodiment of a refrigerator using the cold storage appliance of the first embodiment. Figure 15A It is a cross-sectional view showing an example of refrigerator 400 of this embodiment. Refrigerator 400 includes refrigerating room 410 and cold storage device 100 of the first embodiment. In addition, refrigerator 400 includes an electric cooling device that cools the refrigerating compartment (not shown), and has a control temperature capable of freezing at least the cold storage device 100.

[0095] The refrigerator compartment 410 is provided in the inside of the refrigerator 400, and accommodates a cold preservation object. As a result, the electric cooling device is used to keep the cold storage object cold when energized, and the latent heat and sensible heat of the latent heat storage material 150 included in the cooling appliance 100 are used to keep the cold storage object cold when the energization is sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com