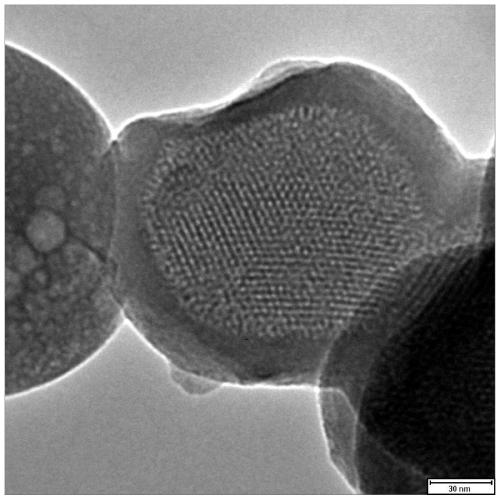

A "core-shell" mesoporous silica/organic phase change material composite nanocapsule and its preparation method

A technology of mesoporous silica and nanocapsules, which is applied in nanotechnology, microcapsule preparations, chemical instruments and methods for materials and surface science, and can solve the problems of slow heat conduction rate, large degree of supercooling, and phase change control. In order to improve heat storage efficiency, reduce subcooling degree, improve heat conduction and thermal response rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of non-water dispersible "oil-in-water" emulsion

[0033] Mix 5.0g of n-eicosane and 6.5g of tetraethyl orthosilicate in a 250ml three-necked reaction flask at a mixing temperature of 50°C and keep stirring at a speed of 300rpm for 30min to obtain a stable and uniform oil phase solution; in another In a large beaker, dissolve 1.0g of cetyltrimethylammonium bromide as a cationic surfactant in 75ml of formamide, stir magnetically at 50°C until the surfactant is completely dissolved, then pour it into three In the reaction flask, the stirring was continued for 5 hours to obtain a stable non-water dispersible "oil-in-water" emulsion.

[0034] (2) Hydrolysis of silicon source, silica sol / organic phase change material three-dimensional composite micellar self-assembly and micellar interfacial polycondensation

[0035] Keep the reaction temperature in the step (1) at 50°C, slowly add 75ml of pH-0.24 aqueous hydrochloric acid as an initiator in a three-necked r...

Embodiment 2

[0037] (1) Preparation of non-water dispersible "oil-in-water" emulsion

[0038] Mix 5.0g of n-octadecane and 6.5g of tetraethyl orthosilicate in a 250ml three-necked reaction flask at a mixing temperature of 45°C and keep stirring at a speed of 350rpm for 30min to obtain a stable and uniform oil phase solution; in another In a large beaker, dissolve 1.0g of cetyltrimethylammonium bromide as a cationic surfactant in 75ml of formamide, stir magnetically at 45°C until the surfactant is completely dissolved, then pour it into three In the reaction flask, the stirring was continued for 5 hours to obtain a stable non-water dispersible "oil-in-water" emulsion.

[0039] (2) Hydrolysis of silicon source, silica sol / organic phase change material three-dimensional composite micellar self-assembly and micellar interfacial polycondensation

[0040] Keep the reaction temperature in the step (1) constant at 45°C, slowly add 75ml of pH-0.24 aqueous hydrochloric acid as an initiator in a thr...

Embodiment 3

[0042] (1) Preparation of non-water dispersible "oil-in-water" emulsion

[0043] Mix 5.0g of n-docosane and 6.5g of tetraethyl orthosilicate in a 250ml three-necked reaction flask, the mixing temperature is 55°C, and the stirring is continued at a speed of 300rpm for 30min to obtain a stable and uniform oil phase solution; In a large beaker, dissolve 1.0g of cetyltrimethylammonium bromide as a cationic surfactant in 75ml of formamide, stir magnetically at 55°C until the surfactant is completely dissolved, then pour it into In the three-necked reaction flask, the stirring was continued for 5 hours to obtain a stable non-water-dispersible "oil-in-water" emulsion.

[0044] (2) Hydrolysis of silicon source, silica sol / organic phase change material three-dimensional composite micellar self-assembly and micellar interfacial polycondensation

[0045] Keep the reaction temperature in the step (1) at 55°C, slowly add 75ml of pH-0.24 aqueous hydrochloric acid as an initiator in a three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com