Low-carbon quasi-single crystal ingot furnace and method for adopting low-carbon quasi-single crystal ingot furnace for ingot casting

A carbon quasi-single crystal and ingot furnace technology, applied in the field of ingot furnace and ingot casting, can solve the problem of high inclusion content of silicon carbide, and achieve the effect of eliminating delay and hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

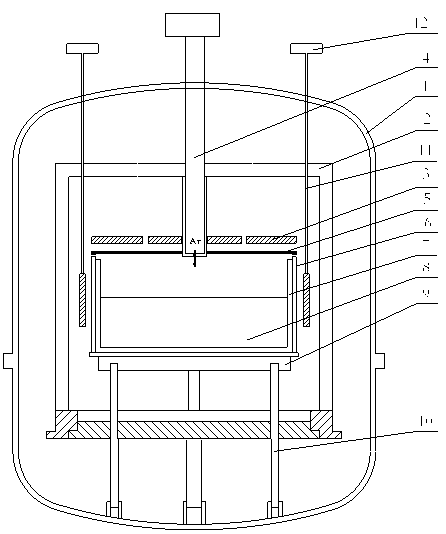

[0035] Such as figure 1 As shown, the low-carbon quasi-single crystal ingot casting furnace includes a furnace body 1, a heat insulation cage 2 arranged in the furnace body, and a heat exchange platform 9 arranged in the heat insulation cage 2, and a Crucible 7, the crucible 7 is a quartz crucible, the top of the crucible 7 is provided with a heater A3, and heaters B8 are distributed around it, the upper end of the crucible 7 is also provided with a cover plate 5, and the upper end of the furnace body 1 is provided with a vent , the vent is provided with a bushing 4, the bushing 4 passes through the heat insulation cage 2 and the cover plate 5 to communicate with the crucible 7, and the heater B8 is connected by a heater lifting rod 11 The traction device 12 outside the furnace body 1 .

[0036] Further, the above-mentioned heat exchange platform 9 is fixed by a support 10 , one end of the support 10 is installed on the bottom surface of the heat exchange platform 9 , and the...

Embodiment 2

[0050] Such as figure 1 As shown, the low-carbon quasi-single crystal ingot casting furnace includes a furnace body 1, a heat insulation cage 2 arranged in the furnace body, and a heat exchange platform 9 arranged in the heat insulation cage 2, and a Crucible 7, the crucible 7 is a quartz crucible, the top of the crucible 7 is provided with a heater A3, and heaters B8 are distributed around it, the upper end of the crucible 7 is also provided with a cover plate 5, and the upper end of the furnace body 1 is provided with a vent , the vent is provided with a bushing 4, the bushing 4 passes through the heat insulation cage 2 and the cover plate 5 to communicate with the crucible 7, and the heater B8 is connected by a heater lifting rod 11 The traction device 12 outside the furnace body 1 .

[0051] Further, the above-mentioned heat exchange platform 9 is fixed by a support 10 , one end of the support 10 is installed on the bottom surface of the heat exchange platform 9 , and the...

Embodiment 3

[0065] Such as figure 1 As shown, the low-carbon quasi-single crystal ingot casting furnace includes a furnace body 1, a heat insulation cage 2 arranged in the furnace body, and a heat exchange platform 9 arranged in the heat insulation cage 2, and a Crucible 7, the crucible 7 is a quartz crucible, the top of the crucible 7 is provided with a heater A3, and heaters B8 are distributed around it, the upper end of the crucible 7 is also provided with a cover plate 5, and the upper end of the furnace body 1 is provided with a vent , the vent is provided with a bushing 4, the bushing 4 passes through the heat insulation cage 2 and the cover plate 5 to communicate with the crucible 7, and the heater B8 is connected by a heater lifting rod 11 The traction device 12 outside the furnace body 1 .

[0066]Further, the above-mentioned heat exchange platform 9 is fixed by a support 10 , one end of the support 10 is installed on the bottom surface of the heat exchange platform 9 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com