Silicon nitride-modified phase-change and energy-storage microcapsule and preparation method thereof

A phase-change energy storage and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problem of large difference in structure between inorganic rigid particles and organic phases, failure to achieve beneficial properties, and damage to polymers. Performance and other issues, to achieve good interface performance, property improvement, and improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

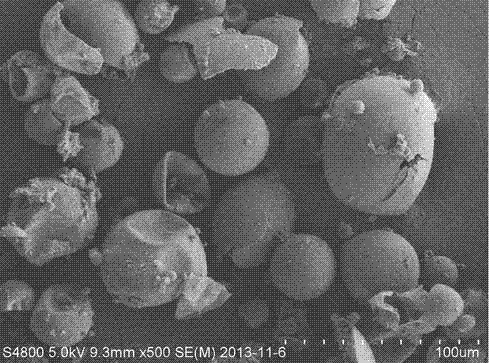

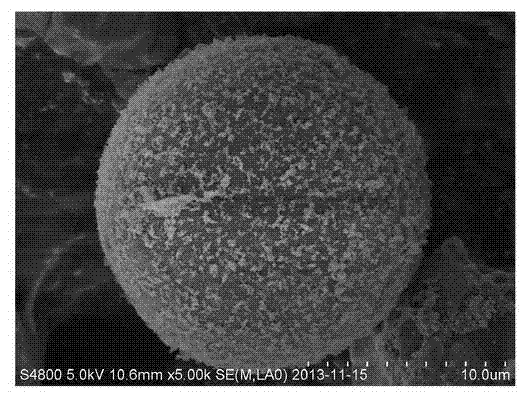

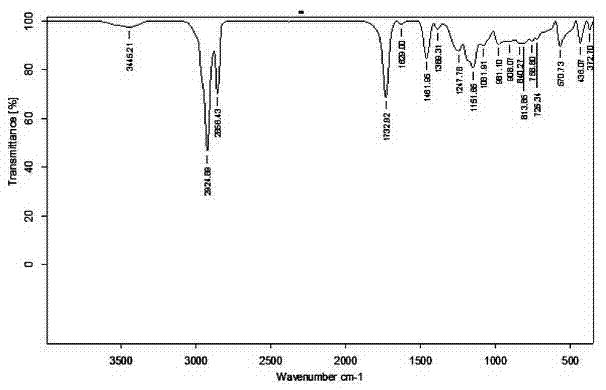

Embodiment 1

[0035]1) Weigh 3g of γ-methacryloxypropyltrimethoxysilane (KH570) and add it into 10g of ethanol to make an alcoholic solution, then add 1.5g of silicon nitride powder, ultrasonicate for 15min, then soak for 48h, at 50℃ drying in an oven to obtain grafted silicon nitride powder. 2) Heat up 12g of n-octadecane to melt, while maintaining the temperature, add 0.5g of grafted silicon nitride powder obtained in step 1), 1g of styrene-maleic anhydride copolymer, stir at 600rpm for 15min, and then Sonicate for 15 minutes to form an emulsion. 3) Add the emulsion prepared in step 2) to 200g of deionized water, then add 1g of sodium lauryl sulfate and 2g of styrene-maleic anhydride copolymer, and stir at 6000rpm for 10min with a high-speed shear emulsifier . 4) Add 1g of the grafted silicon nitride powder obtained in step 1), 3g of pentaerythritol tetraacrylate, and 0.3g of azobisisobutylcyanide into 10g of methyl methacrylate, and use a high-speed shear emulsifier at 6000rpm Stir fo...

Embodiment 2

[0037] 1) Weigh 3g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560) and add it into 30g of methanol to prepare an alcohol solution, then add 2g of silicon nitride powder, ultrasonicate for 10min, and then soak After 10 hours, dry in an oven at 50°C to obtain grafted silicon nitride powder. 2) Warm up 50g of n-butyl stearate to melt, while maintaining the temperature, add 1g of grafted silicon nitride powder obtained in step 1), 1g of styrene-maleic anhydride copolymer, stir at 600rpm for 10min, then Sonicate for 15 minutes to form an emulsion. 3) Add the emulsion prepared in step 2) to 500g of deionized water, add 1g of sodium lauryl sulfate, 2g of styrene-maleic anhydride copolymer, and stir for 5min at 5000rpm with a high-speed shear emulsifier . 4) Add 1g of the grafted silicon nitride powder obtained in step 1), 1g of pentaerythritol tetraacrylate, and 0.1g of azobisisobutylcyanide to 50g of methyl methacrylate, and use a high-speed homogenizer at a speed of 6000rpm...

Embodiment 3

[0039] 1) Weigh 30g of γ-methacryloxypropyltrimethoxysilane (KH570) and add it into 100g of ethanol to make an alcohol solution, then add 15g of silicon nitride powder, ultrasonically treat for 40min, then soak for 60h, and dry naturally at room temperature. The grafted silicon nitride powder was obtained. 2), heat up 70g of n-butyl stearate to melt, while maintaining the temperature, add 5g of grafted silicon nitride powder obtained in step 1), 1g of styrene-maleic anhydride copolymer, stir at 800rpm for 20min, then Ultrasonic treatment for 50 minutes was performed to form an emulsion. 3) Add the emulsion prepared in step 2) to 800g of deionized water, add 2g of sodium lauryl sulfate, 10g of styrene-maleic anhydride copolymer, and stir for 20min at 10,000rpm with a high-speed shear emulsifier . 4) Add 10g of the grafted silicon nitride powder obtained in step 1), 10g of divinylbenzene, and 4g of azobisisobutylcyanide to 50g of methyl methacrylate, and use a high-speed shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com