Nickel-containing corrosion-resistant steel pipe for ultrahigh-strength drill rod and manufacturing method of nickel-containing corrosion-resistant steel pipe

A technology of ultra-high strength and manufacturing method, which is applied in the field of drill pipes, can solve problems such as corrosion resistance of drill pipes without consideration, achieve the effect of ensuring high strength and toughness matching, reducing manufacturing cycle, and improving service safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

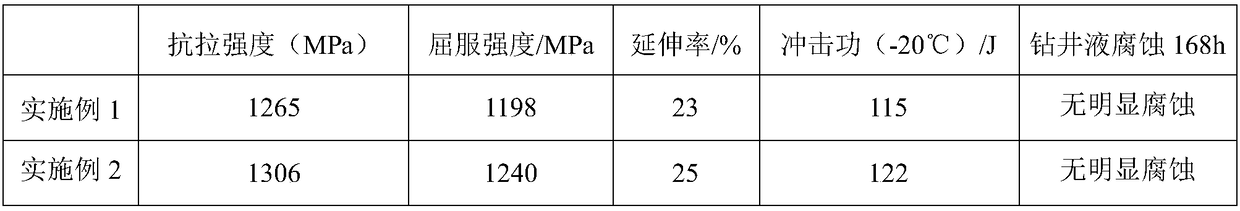

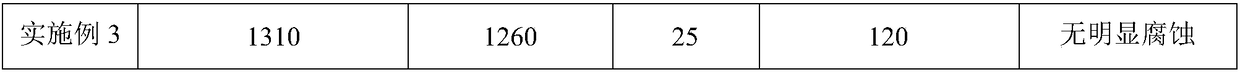

[0027] According to the composition in the following table 1, it was smelted into a round steel billet. After the steel billet is uniformly heated at 1000°C, it is rolled and pierced, and the final rolling temperature is controlled at 950°C; the steel pipe is heated to 900°C and kept for 55 minutes, and then the steel pipe is cooled to room temperature with water as the quenching liquid; the cooled steel pipe is heated to 580 ℃, heat preservation for 40 minutes, and rapid cooling to room temperature with water as the cooling medium. The mechanical properties and corrosion properties of the obtained steel pipes are shown in Table 2.

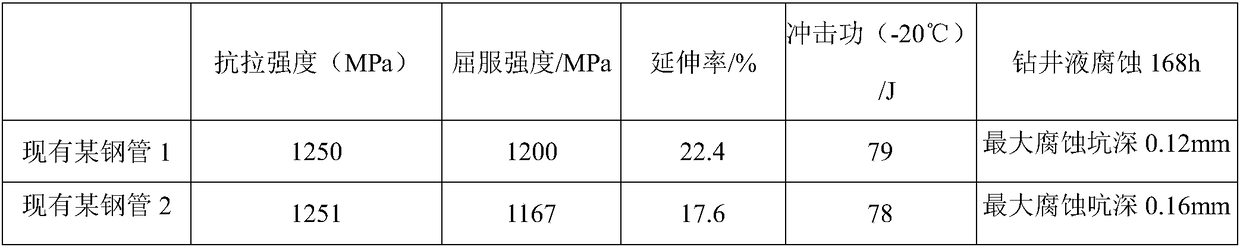

[0028] Table 1 shows the chemical composition of steel pipes for drill pipes in Examples 1 to 3 of the present invention, and Table 2 shows the test results of Examples 1 to 3 of the present invention. The performance is obviously better than that of the existing certain 2 shown in Table 3. Kind of steel pipe. The manufacturing method of embodime...

Embodiment 4

[0037] According to the following composition, it is smelted into a round billet, and its chemical composition (mass percentage) is C: 0.22%, Si: 0.20%, Mn: 1.2%, Cr: 1.0%, Mo: 1.3%, Ni: 2.0%, S≤ 0.004%, P≤0.008%, [Cr]+[Mo]+[Ni]=4.3%, the rest is iron and unavoidable impurities. After the steel billet is evenly heated at 980°C, it is rolled and pierced, and the final rolling temperature is controlled at 920°C; the steel pipe is heated to 880°C and kept for 40 minutes, and then the steel pipe is cooled to room temperature with water as the quenching liquid; the cooled steel pipe is heated to 560 ℃, keep warm for 50 minutes, and use water as the cooling medium for rapid cooling.

Embodiment 5

[0039]According to the following composition, it is smelted into a round billet, and its chemical composition (mass percentage) is C: 0.18%, Si: 0.35%, Mn: 0.8%, Cr: 0.6%, Mo: 0.9%, Ni: 3.0%, S≤ 0.003%, P≤0.009%, [Cr]+[Mo]+[Ni]=4.5%, the rest is iron and unavoidable impurities. After the steel billet is uniformly heated at 1080°C, it is rolled and pierced, and the final rolling temperature is controlled at 1020°C; the steel pipe is heated to 920°C and kept for 70 minutes, and then the steel pipe is cooled to room temperature with water as the quenching liquid; the cooled steel pipe is heated to 600 ℃, keep warm for 30 minutes, and use water as the cooling medium for rapid cooling.

[0040] The metallographic structure of the steel pipe material obtained by the present invention using the above material and heat treatment process is tempered sorbite, the yield strength is greater than 1138MPa, the tensile strength is greater than 1206MPa, the elongation is greater than 15%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com