Strength mismatching heat treatment process for petroleum steel tube in hardened and tempered state

A petroleum steel pipe and process technology, which is applied in the field of quenched and tempered petroleum steel pipe strength mismatch heat treatment process, can solve the problems of oilfield economic loss, pipe end deformation, tripping, etc., improve service safety, and eliminate the problems of easy deformation or even fracture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

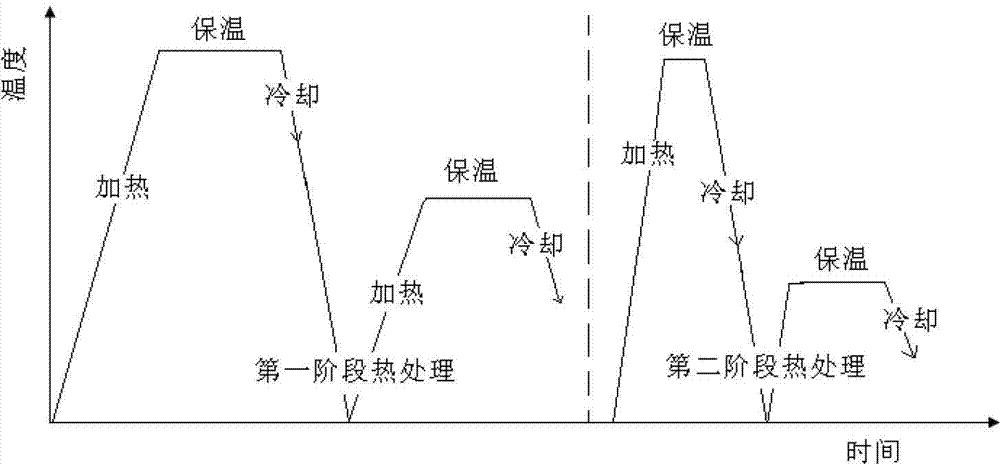

[0030] See attached figure 1 , the quenched and tempered oil steel pipe strength mismatch heat treatment process provided by the present invention comprises the following steps:

[0031] S1: The first stage of whole tube quenching and tempering treatment. Among them, S11: heating the steel pipe as a whole to 880°C to 940°C, and keeping it warm for 45min to 90min. Wherein, the heating furnace adopted for overall heating of the steel pipe is a general overall heating furnace. S12: Put the whole steel pipe obtained in step S11 into water to complete austenitization and quenching. S13: heating the whole steel pipe obtained in step S12 to 580° C. to 660° C., keeping it warm for 45 minutes to 90 minutes, and completing tempering. S14: cooling the steel pipe obtained in step S13 into water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com