Reinforcing thermal treatment technology for pipe end of petroleum steel pipe in quenching and tempering condition

A petroleum steel pipe, quenching and tempering treatment technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as oil field production economic losses, pipe end deformation, tripping, etc., to eliminate easy deformation or even breakage, and improve service safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

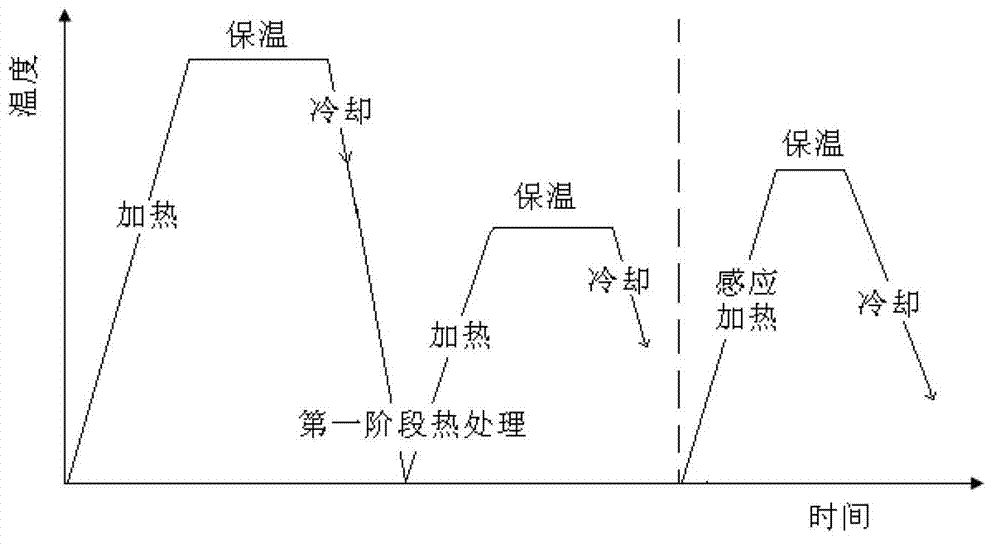

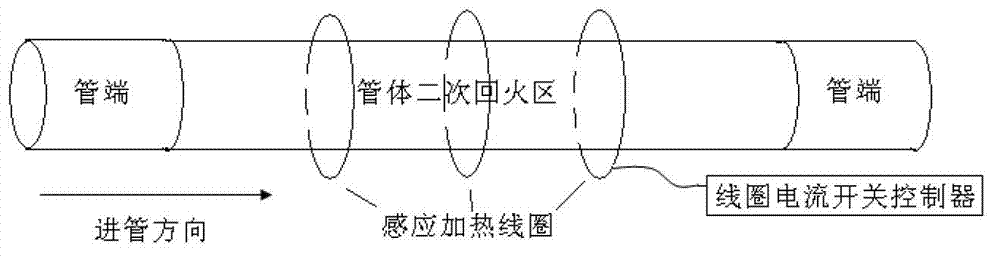

Method used

Image

Examples

Embodiment 1~4

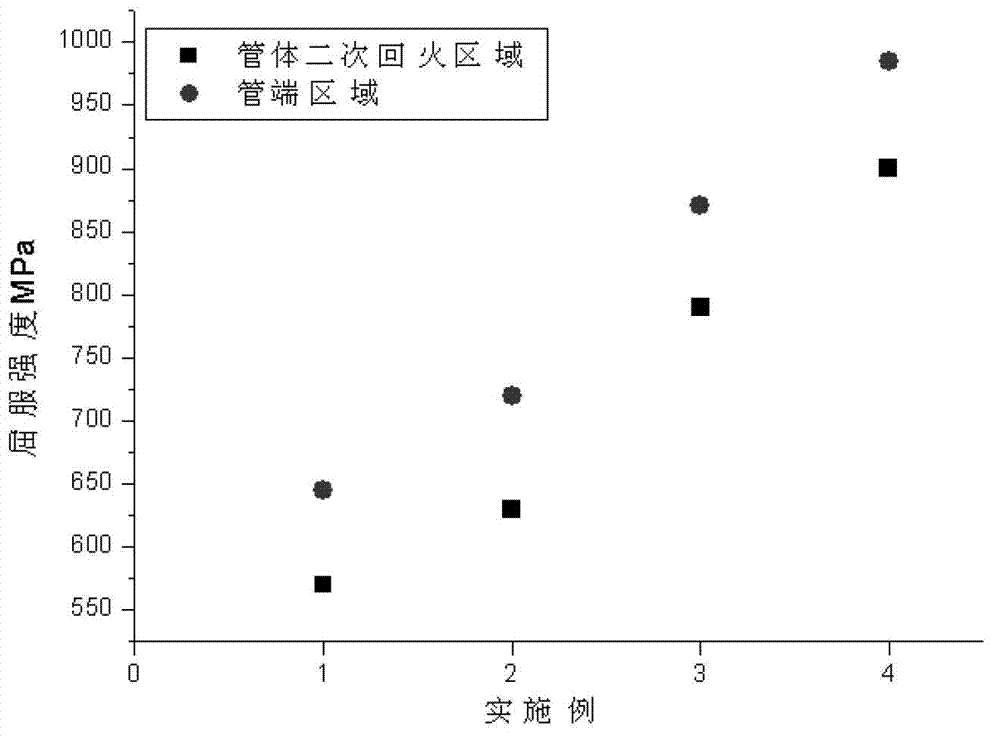

[0028] The technical parameters and performance parameters of the steel pipes in the heat treatment process treated by the quenched and tempered petroleum steel pipe end enhanced heat treatment process provided by Examples 1 to 4 of the present invention are shown in Tables 1 to 2 and attached image 3 shown.

[0029] Table 1 embodiment 1~4 heat treatment process parameter

[0030]

[0031] Table 2 Performance parameters of different parts of the steel pipe obtained in Examples 1 to 4

[0032]

[0033] The middle part of the pipe body of the steel pipe is subjected to secondary tempering treatment by applying the quenched and tempered petroleum steel pipe end enhanced heat treatment process provided by the invention. In terms of yield strength performance parameters, in Example 1, the strength of the pipe end is 6450MPa, and the strength of the middle part is 570MPa; in Example 2, the strength of the pipe end is 720MPa, and the strength of the middle part is 630MPa; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com