Continuous flame quenching heat treatment method and device for roll necks

A heat treatment method and heat treatment device technology, applied in the field of iron and steel forging, can solve the problems of shallow hardened layer, matrix hardness not reaching the ideal hardness value, and low hardness value, so as to achieve stable roll surface structure, increase hardness, prevent scratches and The effect of mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The surface of the roll neck to be quenched is processed to the required size, and the surface of the roll neck is kept smooth without burrs; the roll is hoisted to the quenching machine, and the rotation speed of the roll and the displacement speed of the quenching device are set; the quenching oxygen lance is manually ignited, and the initial part is heated When the set austenitizing temperature is -100C, the quenching device starts to move; when the quenching device starts to move, the water-cooled spray gun is turned on, and the surface quenching of the roll neck bearing position is gradually and continuously completed according to the mode of first heating and then quenching; after the quenching process is completed, First turn off the quenching oxygen lance, and then turn off the water-cooling spray gun after 3 to 5 minutes to complete the flame quenching of the roll neck; use the crane to turn the roll around, and complete the flame quenching on the surface of the ...

Embodiment 2

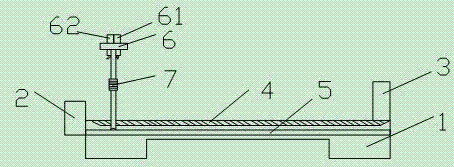

[0035] like figure 1 The shown continuous flame quenching heat treatment device for roll necks comprises a quenching machine tool 1, the two ends of the quenching machine tool 1 are respectively provided with a head box 2 and a tailstock top 3, and the quenching machine tool 1 is provided with a chuck drive 4, so that The chuck drive 4 is controlled to rotate through the bedside box 2; the outside of the quenching machine tool 1 is provided with a tool seat carriage 5, and the knife seat carriage 5 is provided with a quenching device 6, and the quenching device 6 is mounted on the knife seat carriage through the bottom pulley. 5, the quenching device 6 includes a quenching oxygen lance 61 and a water-cooled lance 62, and the angle between the nozzle of the water-cooling lance 62 and the quenching oxygen lance 62 is 30°; the height of the quenching device 6 is determined by the mechanical arm 7 Adjustments to suit different diameter rolls.

[0036] During the specific work of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com