An improved quenching partition for thin ring parts and its processing method

A technology of ring parts and partitions, which is applied in the field of parts processing, can solve the problems of easy warping and deformation of quenching partitions, and achieve the effects of avoiding hardness soft spots, improving quenching uniformity, and expanding the support range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

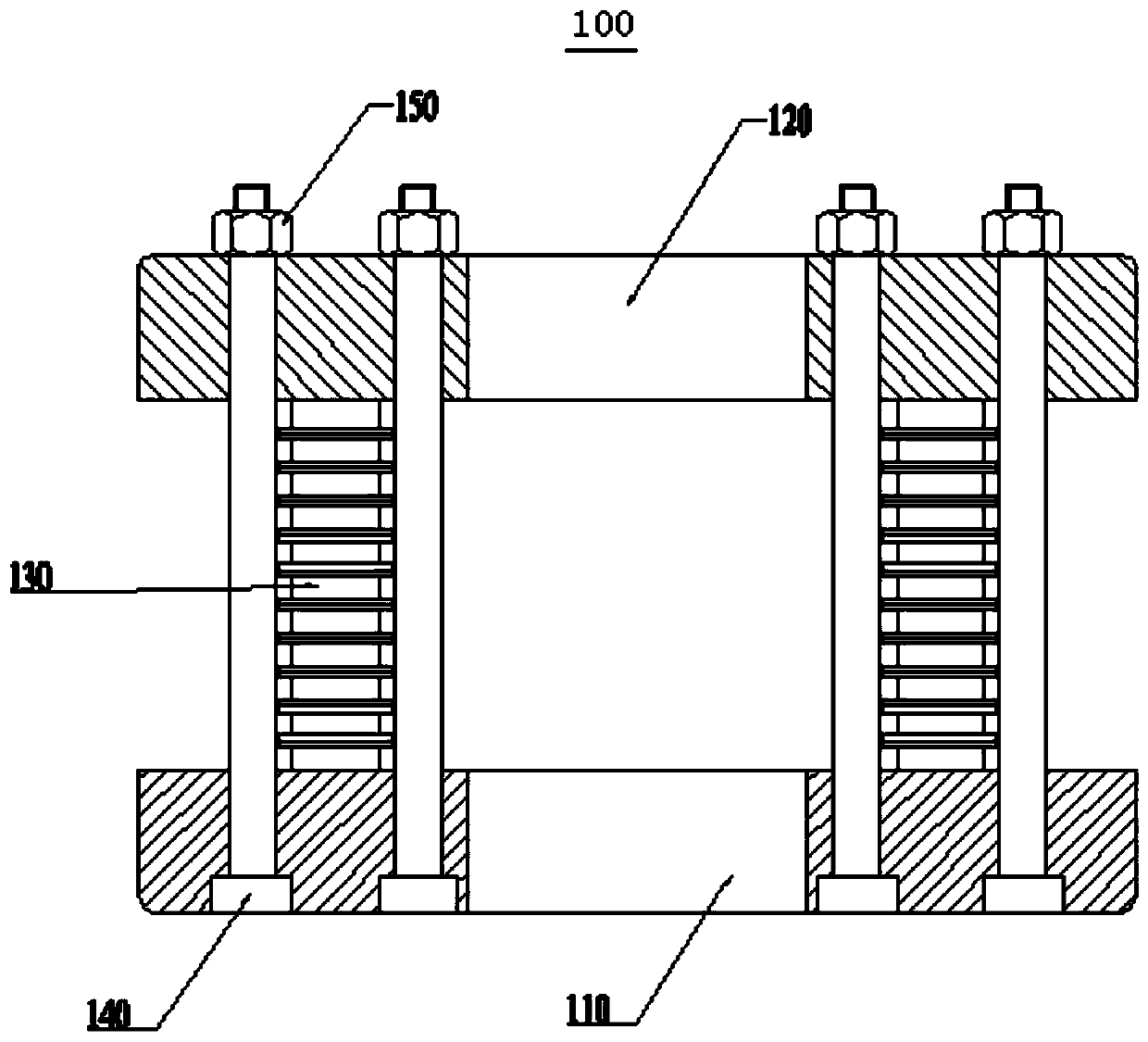

[0029] Such as Figure 6-8 As shown, it is an improved thin circular ring quenching partition 200 of a preferred embodiment of the present invention, which includes a circular ring main body 201 and a number of external teeth 202 radially extending along the circular ring main body 201, two adjacent outer teeth 202 The space between the tooth 202 and the outer ring side of the ring-shaped main body 201 forms a liquid passage groove 204, and the front and back sides of the external tooth 202 are all milled with an external tooth liquid passage square groove 205, and the groove width of the external tooth liquid passage square groove 205 is the same as that of the outer tooth. The teeth 202 have the same width, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com