A fully hydraulic roller press quenching system for ultra-thin and high-strength steel plates

A high-strength steel plate and quenching system technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of poor plate shape and poor uniformity, and achieve the effect of high flatness, improved performance, and improved quenching uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

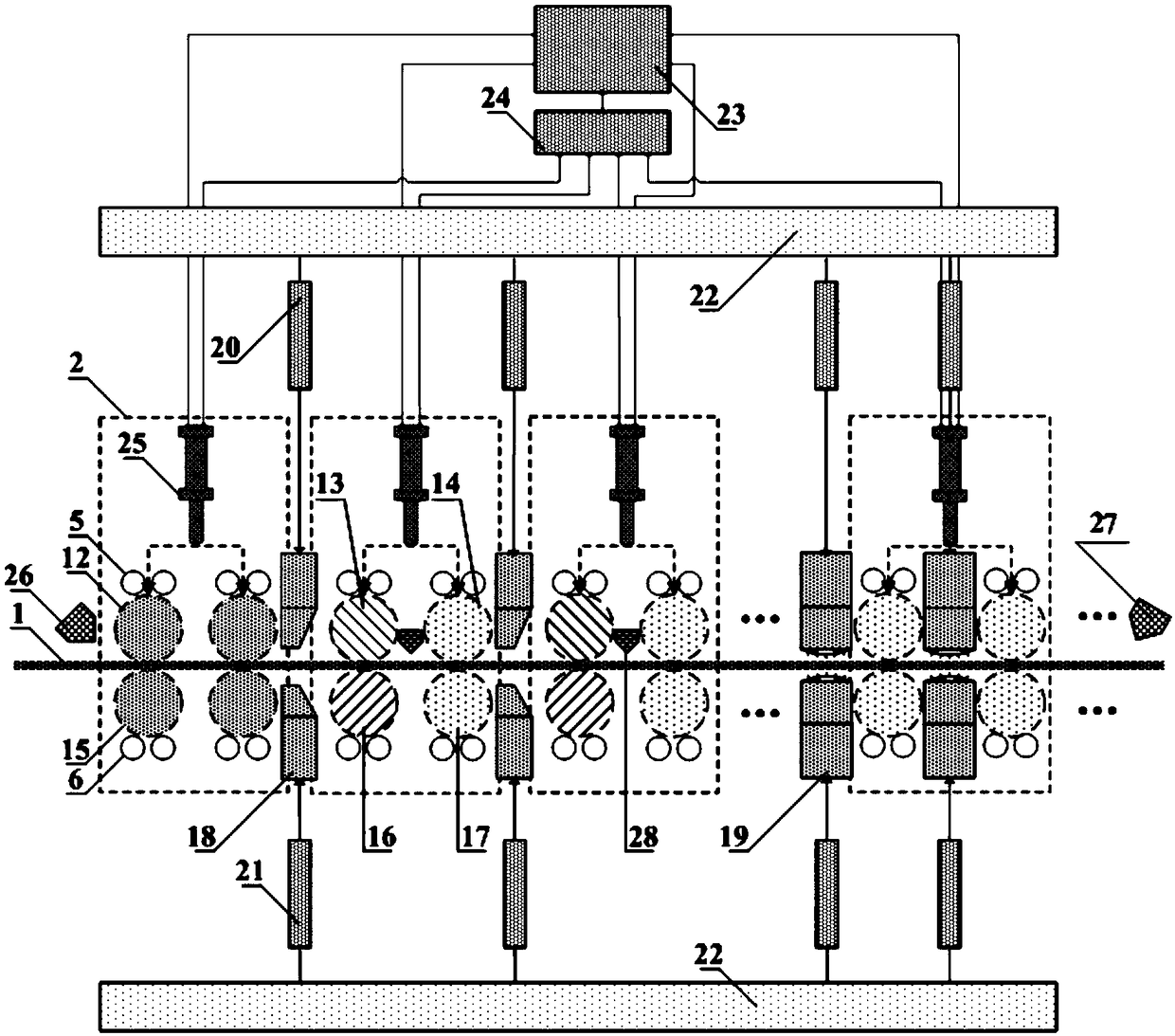

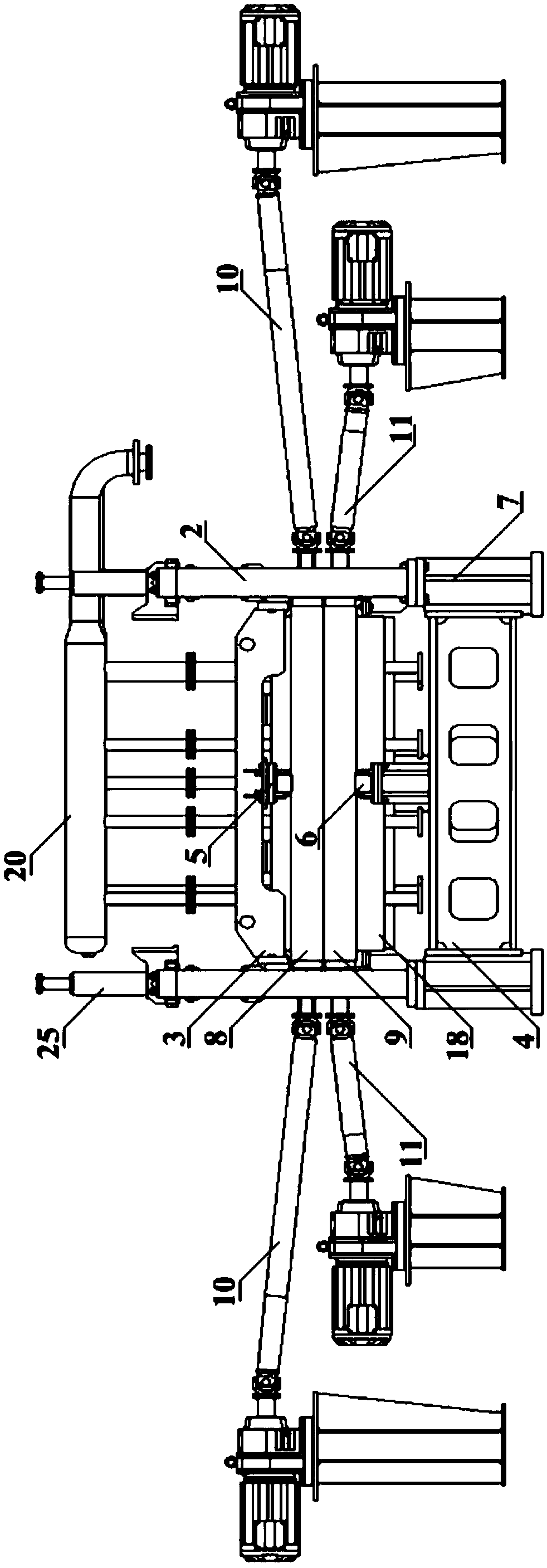

[0044] like figure 1 , figure 2 As shown in the figure, before the steel plate (1) enters the quenching system, the shunt water collection pipe (22) provides constant pressure cooling water, and controls the slit nozzle ( 18) The flow rate and opening and closing of high-density nozzles (19), each nozzle is opened according to process requirements; at the same time, the hydraulic station (23) provides a constant pressure source, and controls each hydraulic cylinder (25) through the servo control system (24), thereby controlling the upper At the position of the roller table (8), the roller gap is controlled according to the thickness of the steel plate (1); meanwhile, the upper roller table transmission system (10) and the lower roller table transmission system (11) control the upper roller table (8) and the lower roller table according to the process speed (9) Turn.

[0045] After the above conditions are satisfied, when the head of the steel plate (1) reaches the first set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com