Bulletproof steel plate and heat treatment method thereof

A heat treatment method and bulletproof steel plate technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of too fast martensite transformation, poor plasticity bulletproof steel plate, large internal stress, etc., reduce oxidation phenomenon, improve steel plate Effect of plasticity and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with specific embodiment:

[0022] Example.

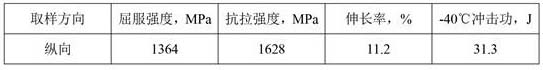

[0023] The chemical element composition of the bulletproof steel plate is: C0.24%, Si0.44%, Mn1.15%, Al0.03%, Ni0.54%, Cr0.5%, Mo0.3%, Nb0.025%, Ti0. 025%, B0.0017%, P0.006%, S0.0018%, N0.0035%, O0.0018%, and the rest are inevitable impurities of Fe element. The length of the steel plate is 6.0 meters, the width of the steel plate is 1.8 meters, and the thickness of the steel plate is 4 mm.

[0024] Its heat treatment operation steps are as follows:

[0025] 1) Heating the steel plate, using a roller hearth quenching furnace to heat the steel plate, using a thermocouple to detect the temperature in the furnace, the heating temperature is 900°C, and starting to keep warm after the tail of the steel plate reaches the heating temperature, the holding time is 20 minutes, and using an oxygen analyzer to detect the temperature in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com