Cold treatment process for carburized gear part

A technology of gear parts and cold treatment, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of restricting the internal quality of gear parts, prolonging the production cycle, increasing production costs, etc., and suppressing the risk of grinding cracks and processing time Short, less liquid nitrogen consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

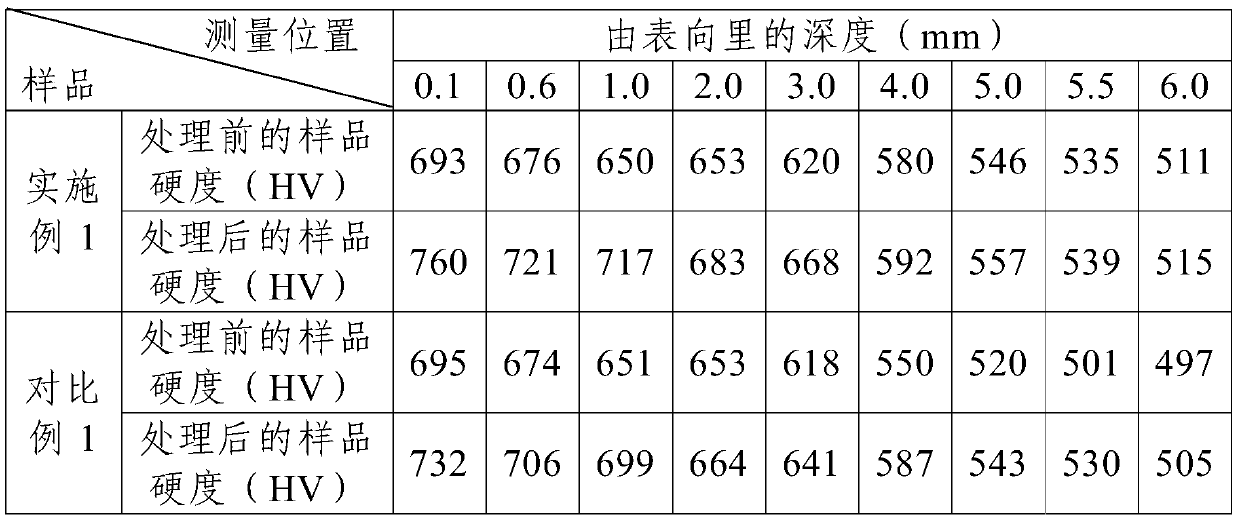

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] Step one, will (diameter × height) gear parts of 20Cr2Ni4A material are carburized to obtain carburized gear parts; the depth of the carburized layer on the gear parts is 4.8mm after detection;

[0028] Step 2. Carburized gear parts are subjected to high-temperature tempering treatment, and then quenching treatment; the high-temperature tempering treatment is carried out twice, and the condition of the high-temperature tempering treatment is to keep warm at 680° C. for 3.2 hours, and the quenching treatment Carried out at 800°C;

[0029] Step 3, performing a low-temperature tempering treatment on the carburized gear parts after the quenching treatment in step 2; the low-temperature tempering treatment is kept at 180° C. for 3.2 hours;

[0030] Step 4. Perform cold treatment on the carburized gear parts after the low-temperature tempering treatment in step 3; the cold treatment process is: use liquid nitrogen to c...

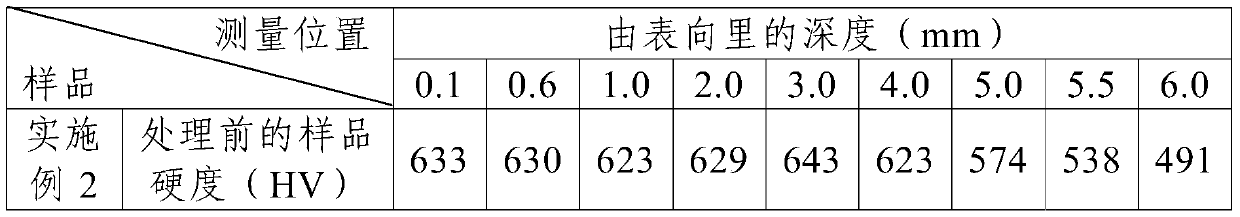

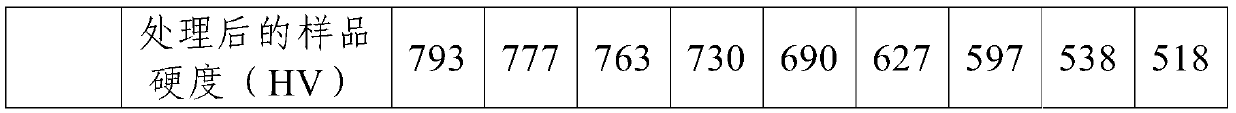

Embodiment 2

[0046] This embodiment includes the following steps:

[0047] Step one, will (diameter × height) gear parts of 18Cr2Ni4WA material are carburized to obtain carburized gear parts; the depth of the carburized layer on the detected gear parts is 5.3mm;

[0048] Step 2. Carburized gear parts are subjected to high-temperature tempering treatment, and then quenching treatment; the high-temperature tempering treatment is carried out 3 times, and the condition of the high-temperature tempering treatment is to keep warm at 670 ° C for 3.5 hours, and the quenching treatment Carried out at 815°C;

[0049] Step 3, performing a low-temperature tempering treatment on the carburized gear parts after the quenching treatment in step 2; the low-temperature tempering treatment is kept at 200° C. for 3 hours;

[0050] Step 4. Perform cold treatment on the carburized gear parts after the low-temperature tempering treatment in step 3; the cold treatment process is: use liquid nitrogen to cool th...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step one, will (diameter × height) gear parts of 18Cr2Ni4WA material are carburized to obtain carburized gear parts; the depth of the carburized layer on the gear parts is 4.6mm after detection;

[0061] Step 2. Carburized gear parts are subjected to high-temperature tempering treatment, and then quenching treatment; the high-temperature tempering treatment is carried out 3 times, and the condition of the high-temperature tempering treatment is to keep warm at 690 ° C for 3 hours, and the quenching treatment is carried out at Carried out at 795°C;

[0062] Step 3, performing low-temperature tempering treatment on the carburized gear parts after quenching treatment in step 2; the low-temperature tempering treatment is kept at 160° C. for 3.5 hours;

[0063] Step 4. Perform cold treatment on the carburized gear parts after the low-temperature tempering treatment in step 3; the cold treatment process is: use liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com