Heat-treatment method of high-chromium wear-resistant white cast iron Cr28

A heat treatment method, white cast iron technology, applied in the field of heat treatment of high chromium wear-resistant white cast iron Cr28, can solve the problems of machining, frequent replacement, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

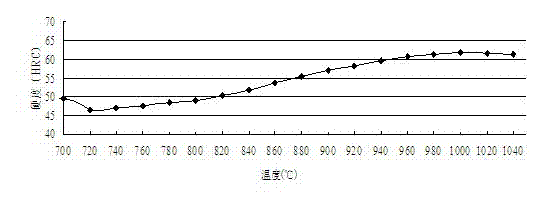

Embodiment 1

[0019] Quenching: Take high-chromium wear-resistant white cast iron Cr28 and heat it to 1050°C, keep it warm for 1.5h, and air-cool to room temperature;

[0020] High-temperature tempering: Heat the quenched cast iron Cr28 to 720°C, keep it warm for 2 hours, and air-cool to room temperature.

[0021] The obtained cast iron Cr28 hardness is 46HRC.

Embodiment 2

[0023] Quenching: Take high-chromium wear-resistant white cast iron Cr28 and heat it to 1000 ° C, keep it warm for 3 hours, and air cool to room temperature;

[0024] High temperature tempering: Heat the quenched cast iron Cr28 to 730°C, keep it warm for 1.5h, and air cool to room temperature.

[0025] The obtained cast iron Cr28 hardness is 47HRC.

Embodiment 3

[0027] Machining: get the cast iron Cr28 that embodiment one obtains and process into required workpiece;

[0028] Quenching: heat the processed workpiece to 1050°C, keep it warm for 1.5h, and air cool to room temperature;

[0029] Low temperature tempering: heat the quenched workpiece to 500°C, keep it warm for 1.5h, and air cool to room temperature;

[0030] Repeat the low-temperature tempering step to obtain the product.

[0031] The hardness of the final cast iron Cr28 workpiece is 61HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com