Thermal treatment method of 42CrMo workpiece

A heat treatment method and workpiece technology, applied in the field of heat treatment, can solve the problems of uncoordinated deformation, peeling off, and reduced processing efficiency of the surface hardened layer, and achieve the effects of uniform and fine metallographic structure, elimination of quenching stress, and optimization of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

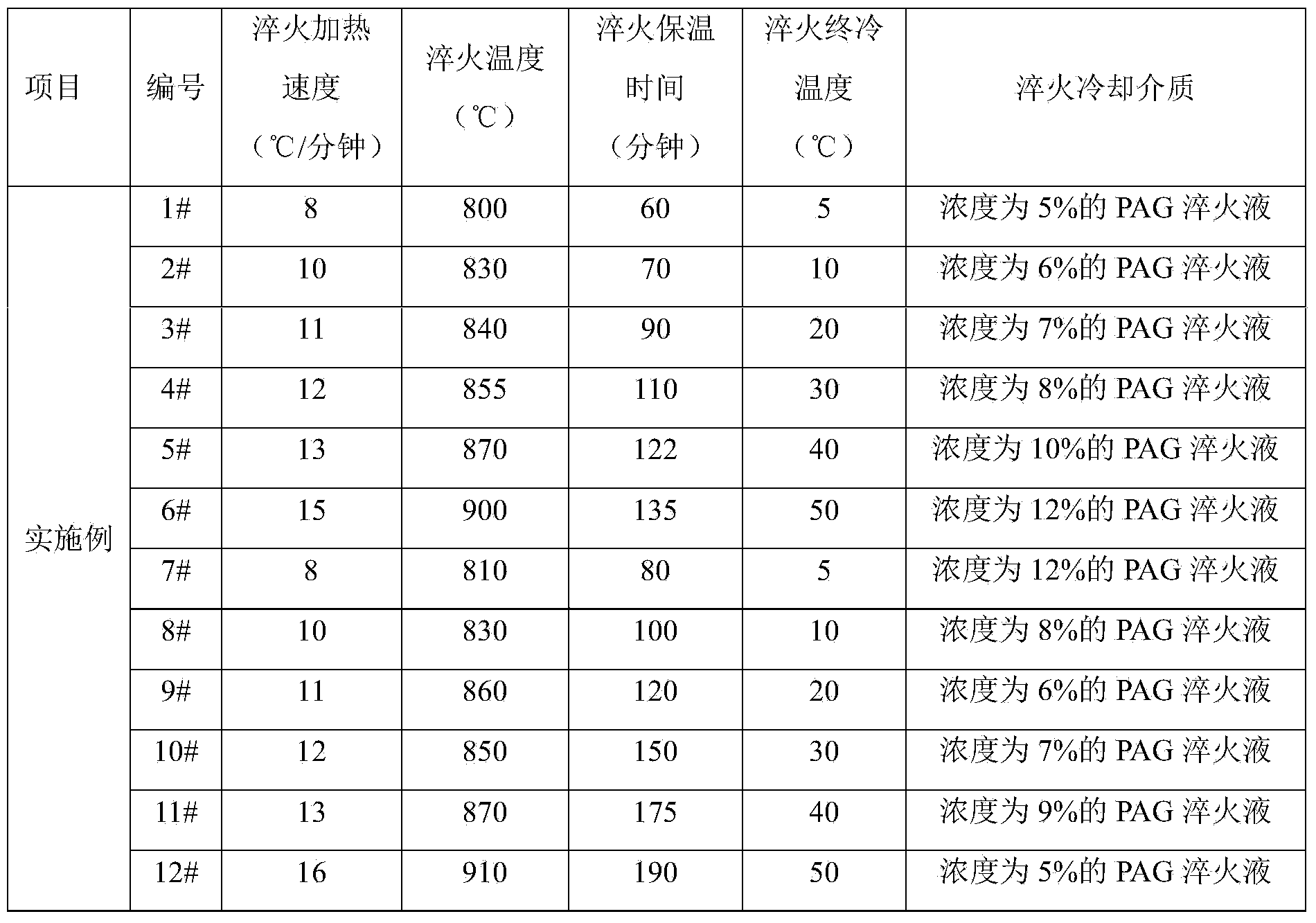

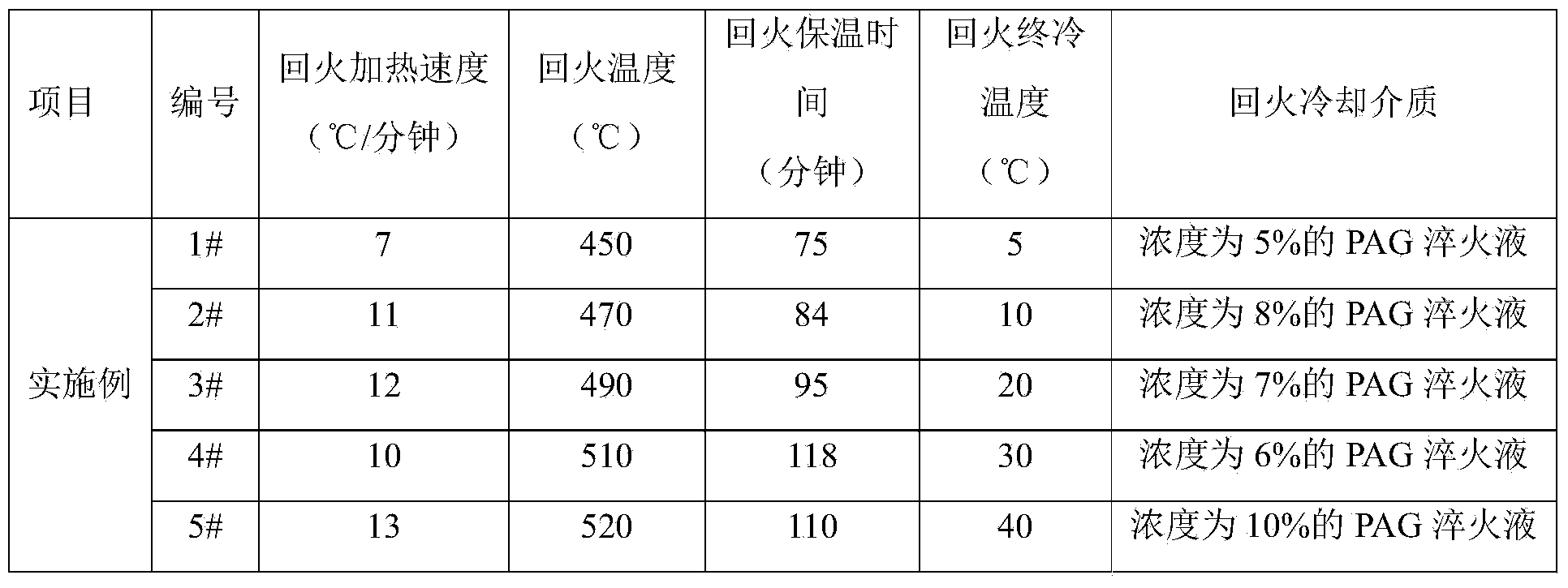

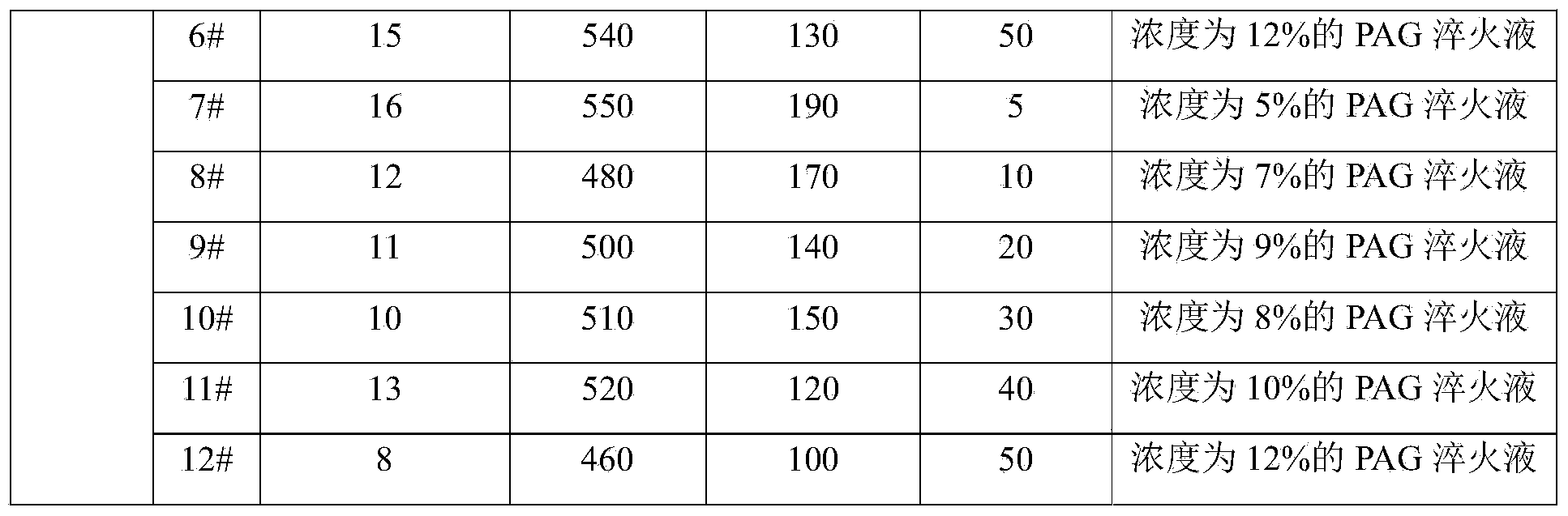

[0033] Carry out heat treatment to 42CrMo track pin, the diameter of track pin in embodiment 1-6 is 35 millimeters, the diameter of track pin in embodiment 7-12 is 50 millimeters, track pin is carried out quenching treatment and tempering treatment successively: in quenching treatment In the process, the track pins are heated to the quenching temperature at the quenching heating rate, and the track pins are kept at the quenching temperature for the quenching and holding time, and then the track pins are cooled to the quenching final cooling temperature in the quenching cooling medium; in the tempering process, the Tempering heating speed Heat the track pins to the tempering temperature, keep the track pins at the tempering temperature for a tempering holding time, and then cool the track pins to the tempering final cooling temperature in the tempering cooling medium. The quenching heating rate, quenching temperature, quenching holding time, quenching final cooling temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com