High-strength and high-toughness super-thick quenched and tempered hydroelectric steel plate and preparation method thereof

A high-strength and toughness, steel plate technology, applied in the field of alloy steel, can solve the problems of long process flow and limited maximum thickness, and achieve the effect of simple production process, strong toughness and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below by examples.

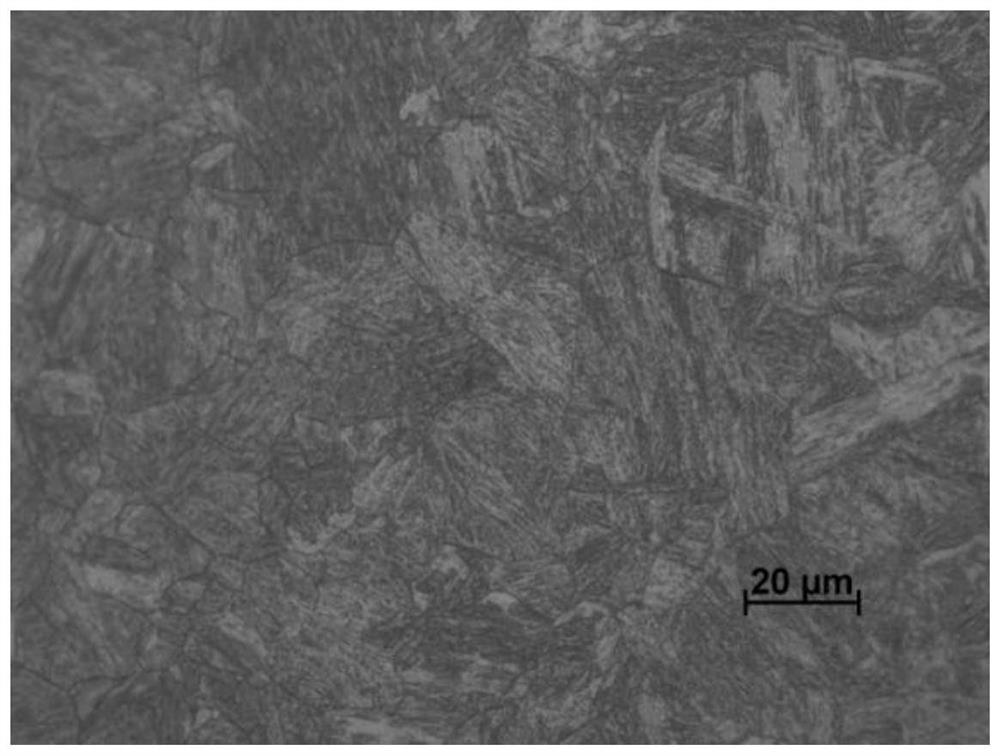

[0055] like figure 1As shown, the steel plate metal tissue of the present invention is "slate martensite + slab bellite".

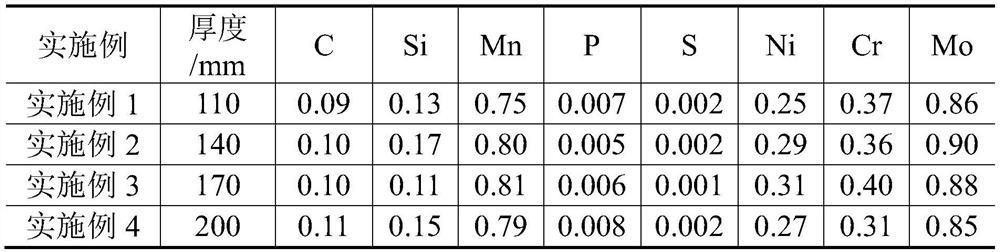

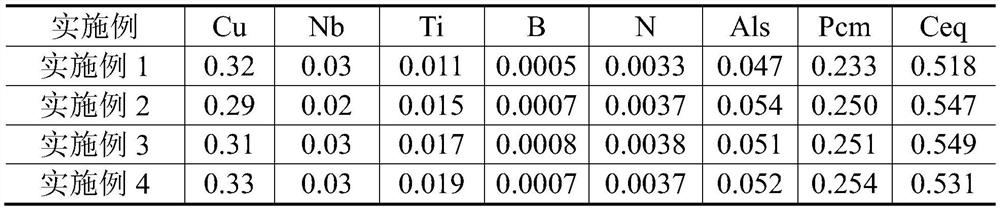

[0056] The chemical composition of the embodiment of the present invention is shown in Table 1;

[0057] The manufacturing process is shown in Table 2, Table 3, Table 4;

[0058] Mechanical properties are shown in Table 5, 6.

[0059] Table 1 Chemical composition table

[0060]

[0061] Table 2 Chemical composition table

[0062]

[0063] C eq (%) = C + Mn / 6 + Si / 24 + Ni / 40 + CR / 5 + MO / 4 + V / 14.

[0064] P cm (%) = C + Si / 30 + Mn / 20 + Cu / 20 + Ni / 60 + CR / 20 + MO / 15 + V / 10 + 5B.

[0065] Table 3 Steelmaking and Casting Process

[0066]

[0067] Table 4 Heating and rolling process

[0068]

[0069] Table 5 Heat treatment process

[0070]

[0071] Table 6 Template Steel Plate Performance (1 / 4 horizontal thickness)

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com