High-strength RAFM steel and novel heat treatment process thereof

A high-strength, heat-treating technology, applied in the field of metal materials, can solve problems such as inability to meet requirements and harsh service environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

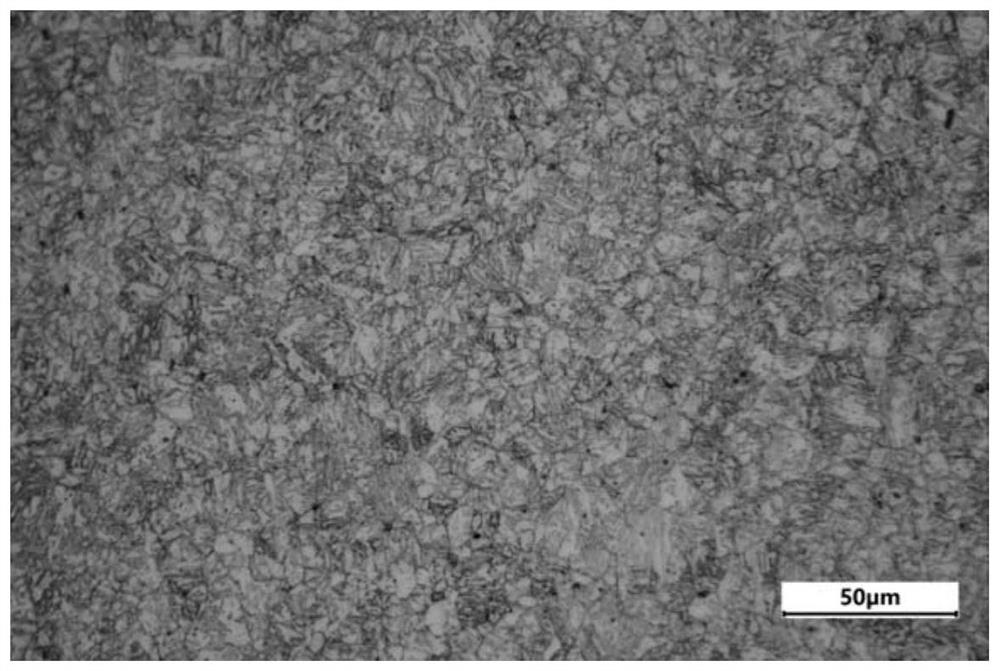

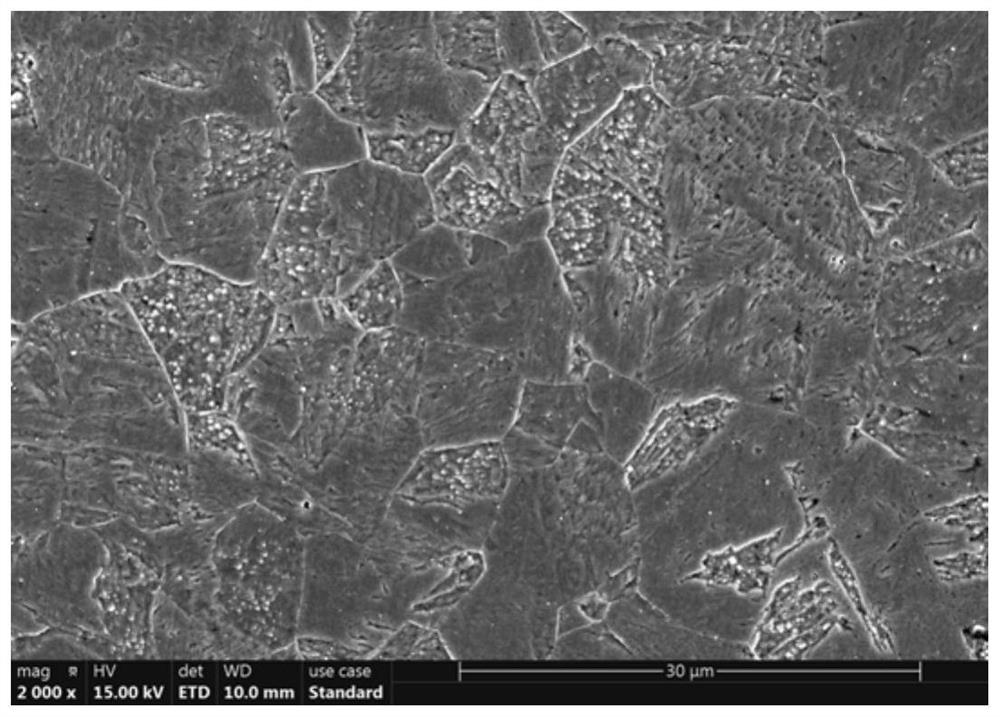

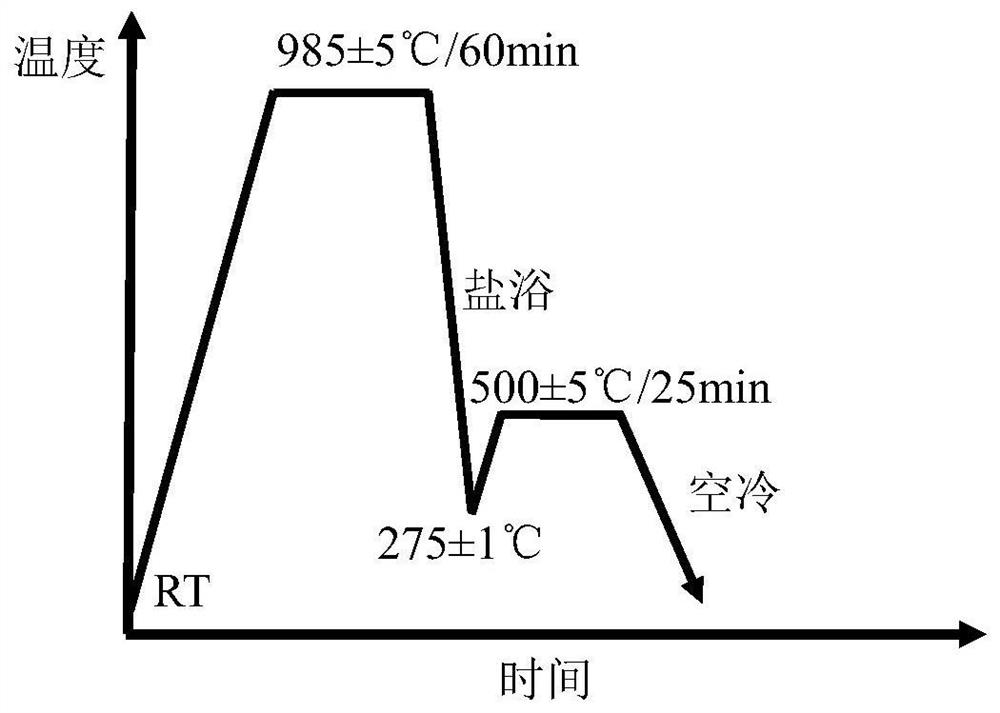

Image

Examples

Embodiment

[0021] (1) Qualified RAFM steel is prepared by adopting the composition of the present invention, the mass percent of alloying elements of the RAFM steel is: 0.128%C, 8.99%Cr, 1.89%W, 0.23%V, 0.169%Ta, 0.50%Mn , 0.22% Si, 0.04% N, 0.01% Zr, 0.03% RE, O<0.004%, P<0.004%, S<0.004%, and the balance is matrix Fe.

[0022] (2) The raw materials of the above components are cast by vacuum induction melting, and the raw materials are added in sequence according to the burning loss and volatilization characteristics of alloy elements. After the raw materials are vacuum induction smelted, ingots with qualified components are prepared.

[0023] (3) Homogenize the ingot at 1100°C for 3 hours, and then forge it with a forging ratio of about 5.

[0024] (4) First heat the cast ingot obtained in step (3) at 1150°C for 2 hours, carry out austenitization and then carry out rolling treatment. The initial rolling temperature is 1100°C, the end rolling temperature is 900°C, and the total deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com