Motorcycle sprocket regeneration method

A motorcycle and sprocket technology, which is applied in the field of motorcycle sprocket regeneration, can solve the problems of low regeneration efficiency and cumbersome process routes, and achieve the effect of low regeneration cost, high efficiency, and increased original strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

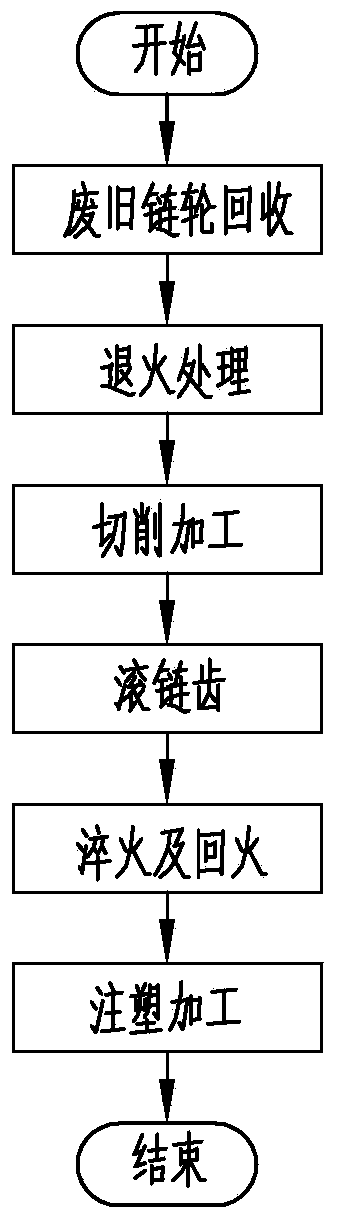

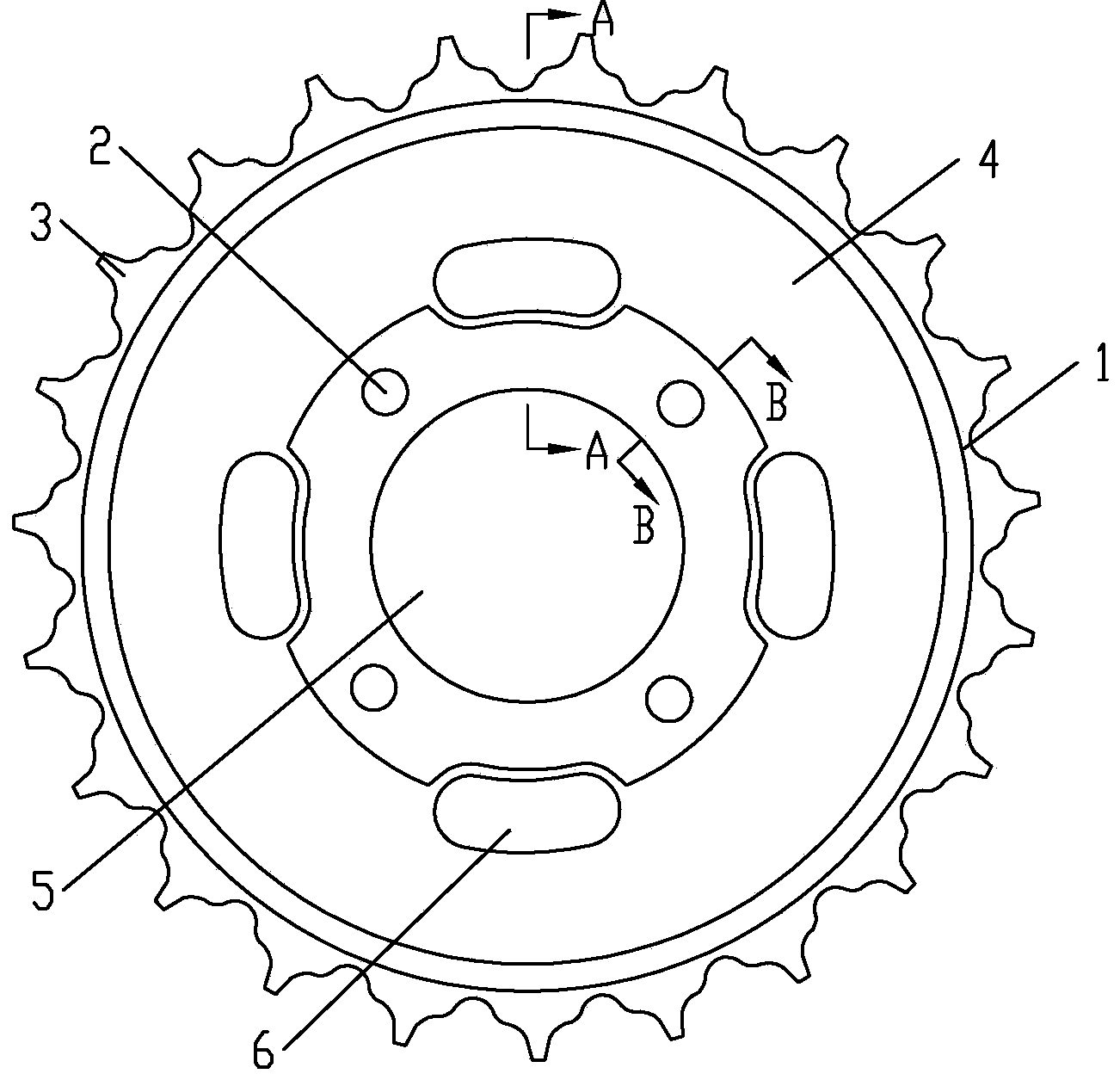

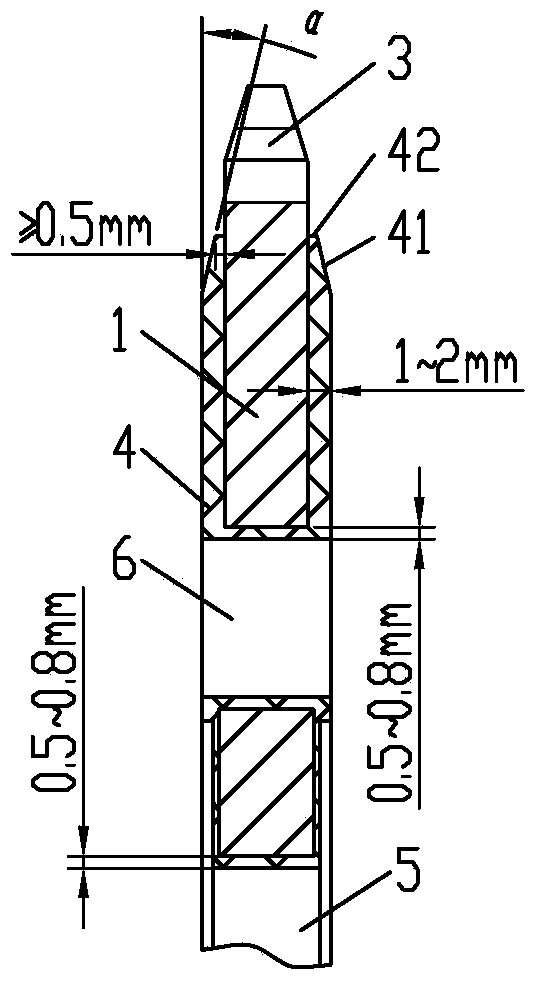

[0023] Example 1 see figure 1 , figure 2 , image 3 , Figure 4 A method for regenerating motorcycle sprockets is used for galvanized or painted waste sprockets, comprising the following steps:

[0024] The first step, waste sprocket recovery: selectively recycle waste motorcycle sprockets with no cracks in the sprocket body. Shaped weight-reducing holes and 4 one-way screw connection holes 2;

[0025] The second step, annealing treatment: tempering the waste sprocket;

[0026] The third step, cutting process: use a lathe to cut off the sprockets of the waste sprocket by cutting, forming the addendum circle of the regenerated sprocket 3 and the chamfers on both sides of the regenerated sprocket 3; and positioning the one-way clutch of the waste sprocket The hole expands 1.0mm in the diameter direction coaxially;

[0027] The fourth step, rolling sprocket: the regenerated sprocket 3 is formed by hobbing with a gear hobbing machine, and the number of teeth of the regenera...

Embodiment 2

[0031] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 , a motorcycle sprocket regeneration method for waste sprockets with an injection-molded protective layer, comprising the following steps:

[0032] The first step, waste sprocket recycling: selectively recycle waste motorcycle sprockets with no cracks in the sprocket body. Weight reduction holes and 4 one-way clutch screw connection holes 2;

[0033] The second step, recycling of injection molding materials: heat the waste sprockets to melt the injection molding materials and separate them from the body of the waste sprockets and recycle the injection molding materials;

[0034] The third step, annealing treatment: tempering the waste sprocket;

[0035] The fourth step, cutting process: use a lathe to cut off the sprockets of the waste sprocket by cutting to form the addendum circle of the regenerated sprocket 3 and the chamfers on both sides of the regenerated sprocket 3;

[0036] Step 5, rolling sprocket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com